Front shaft sleeve assembly of lower shaft

A front axle sleeve and lower axle technology, which is applied to sewing machine components, textiles, papermaking, sewing equipment, etc., can solve problems such as oil leakage and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

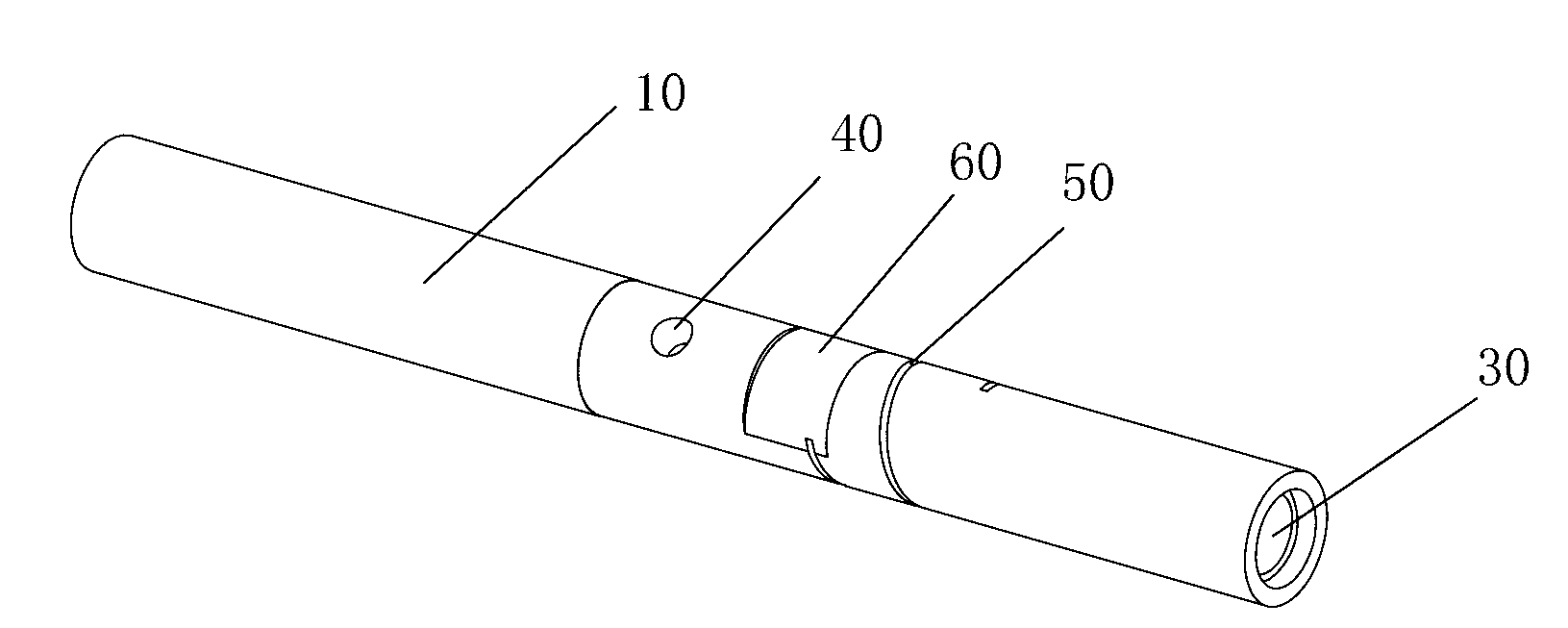

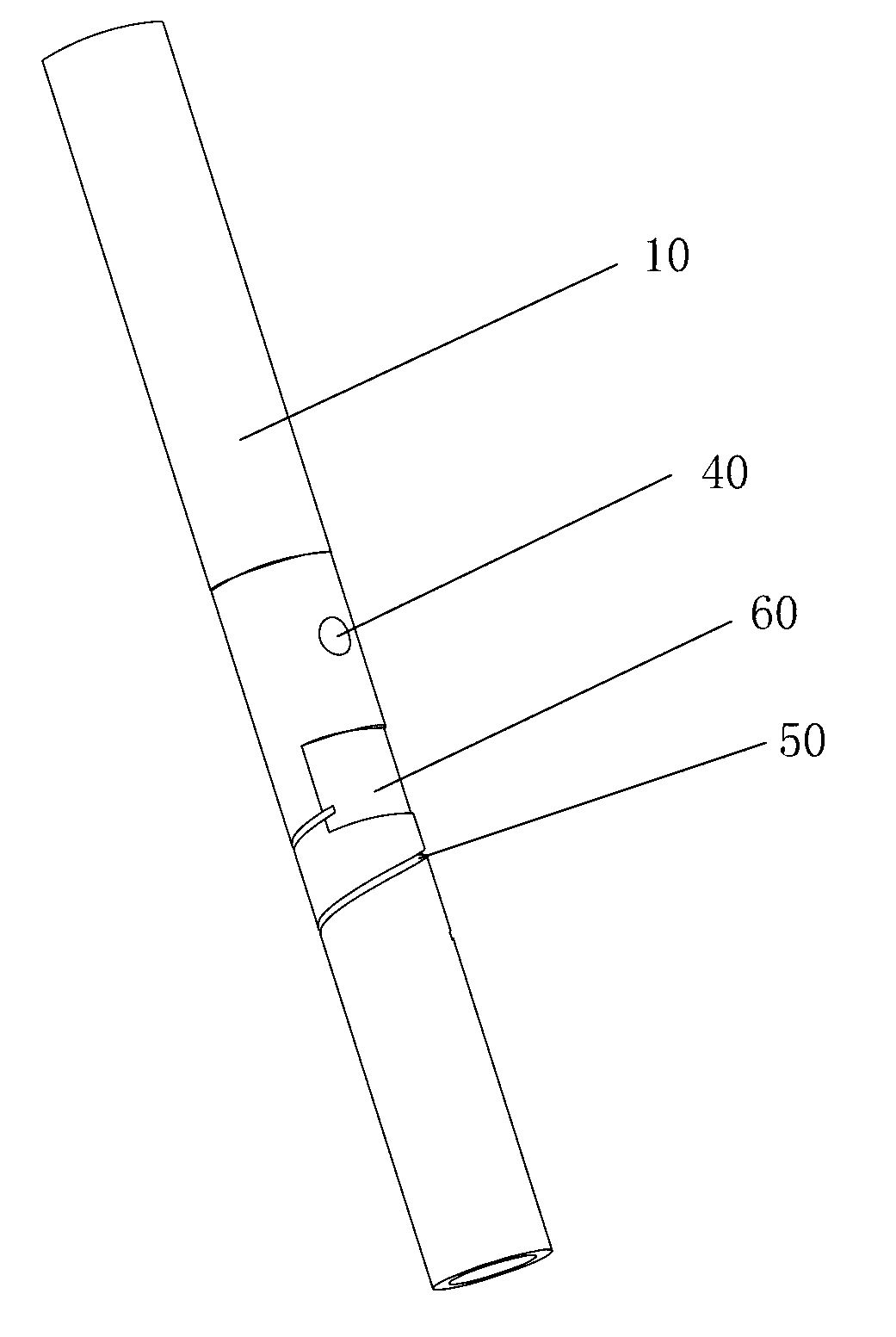

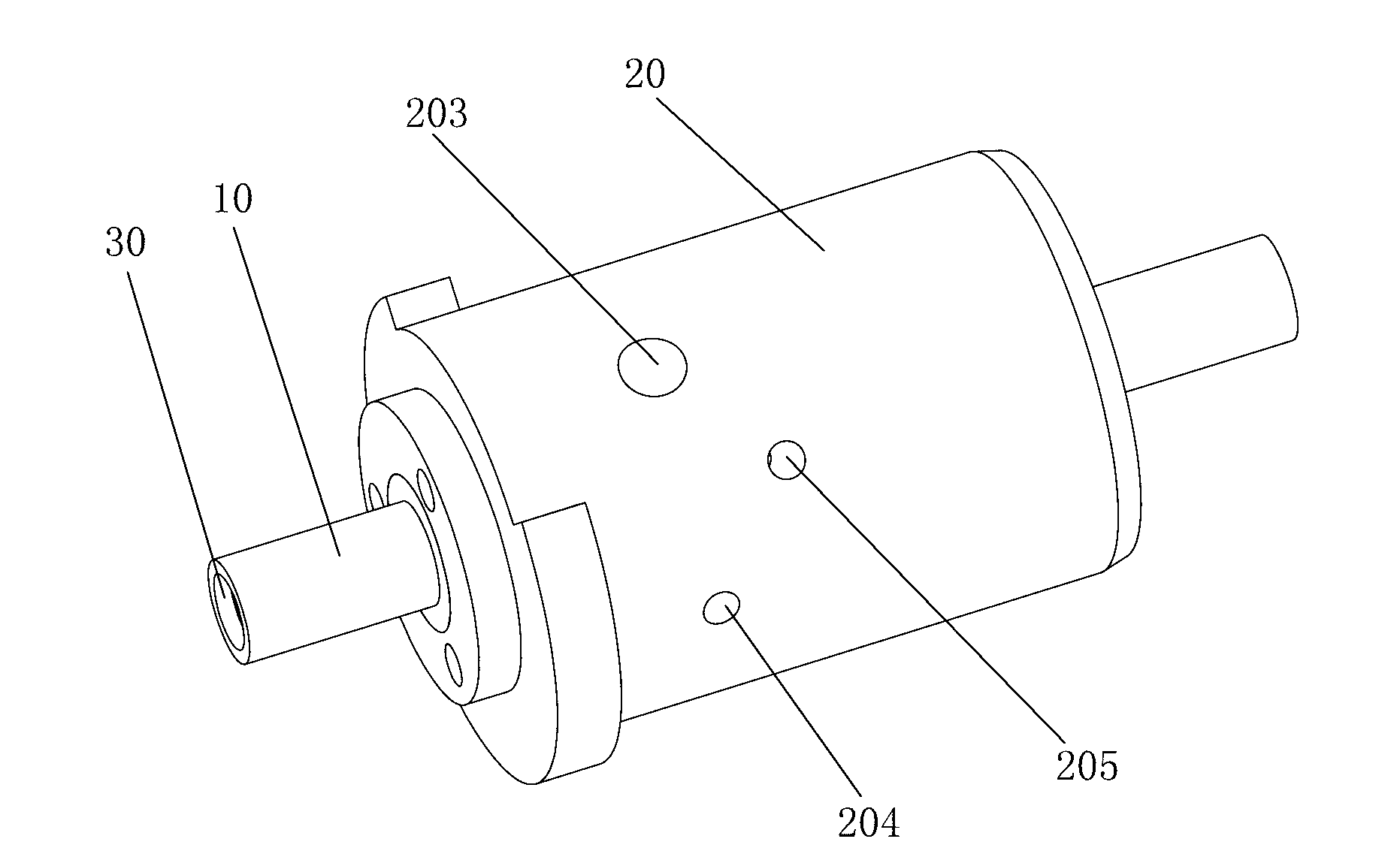

[0022] The present invention will be further described below with specific embodiment, see figure 1 -5:

[0023] A lower shaft front bushing assembly, comprising a lower shaft 10 and a bushing 20 set outside the lower shaft 10, the lower shaft 10 rotates in the bushing 20, the lower shaft body is axially provided with a blind hole, blind The hole is the rotary hook oil supply pipeline 30, and the outer surface of the lower shaft body located in the axle sleeve 20 is radially provided with a through hole 40 communicating with the rotary hook oil supply pipeline 30. On one side of the through hole 10, the rotary hook The outer surface of the lower shaft body at the end where the oil supply pipe 30 is located is provided with a groove 60 and a return groove 50 in sequence, and the return groove 50 guides the oil to the groove 60 when the lower shaft 10 rotates to form an inner circulation of the casing. The return groove 50 may be arranged in a spiral direction opposite to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com