Gas turbine engine with a gearbox-mounted starter

A gas turbine and engine technology, applied in gas turbine installations, machines/engines, engine components, etc., can solve problems such as oil leakage, and achieve the effect of reducing the risk of emptying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

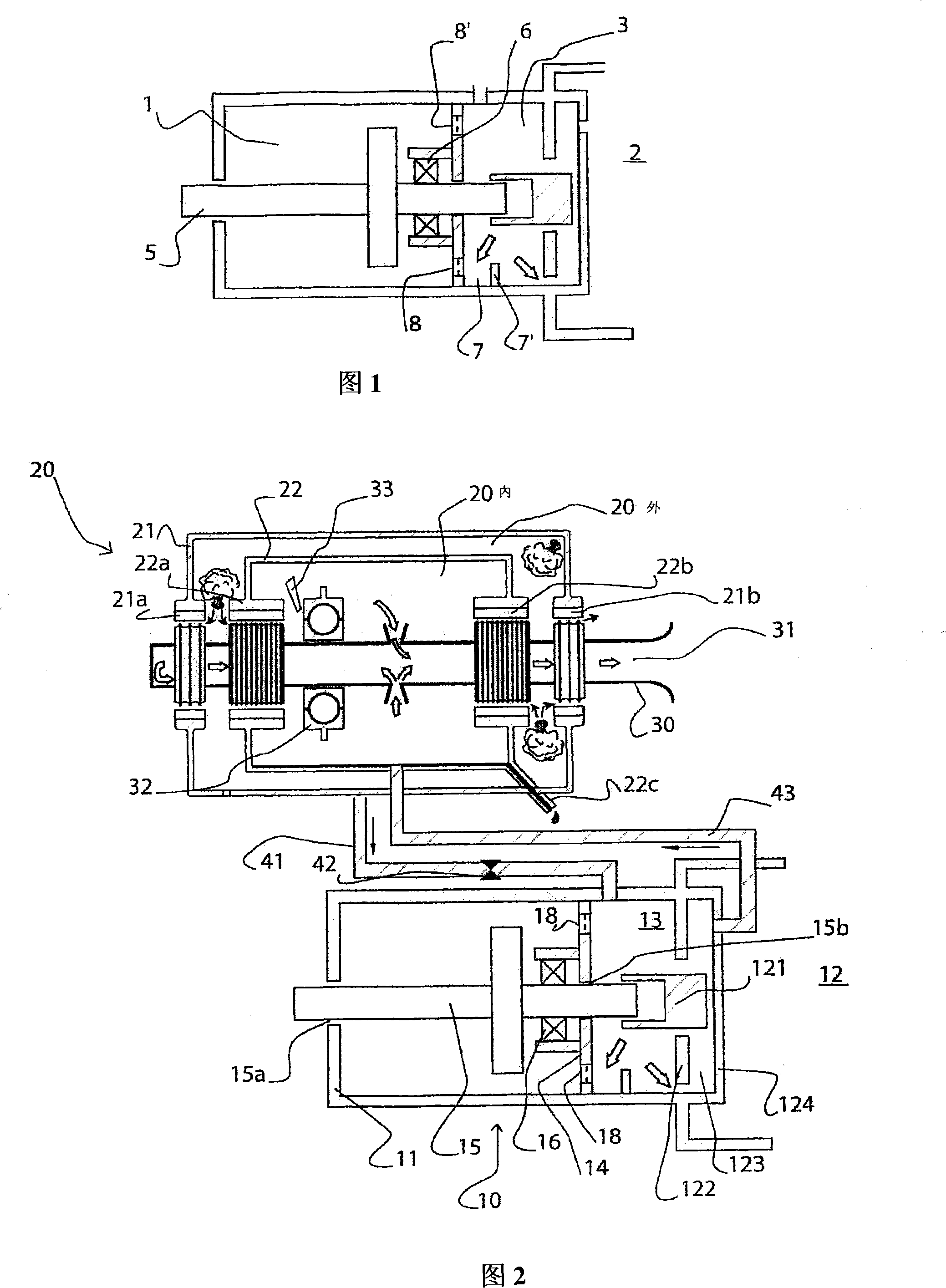

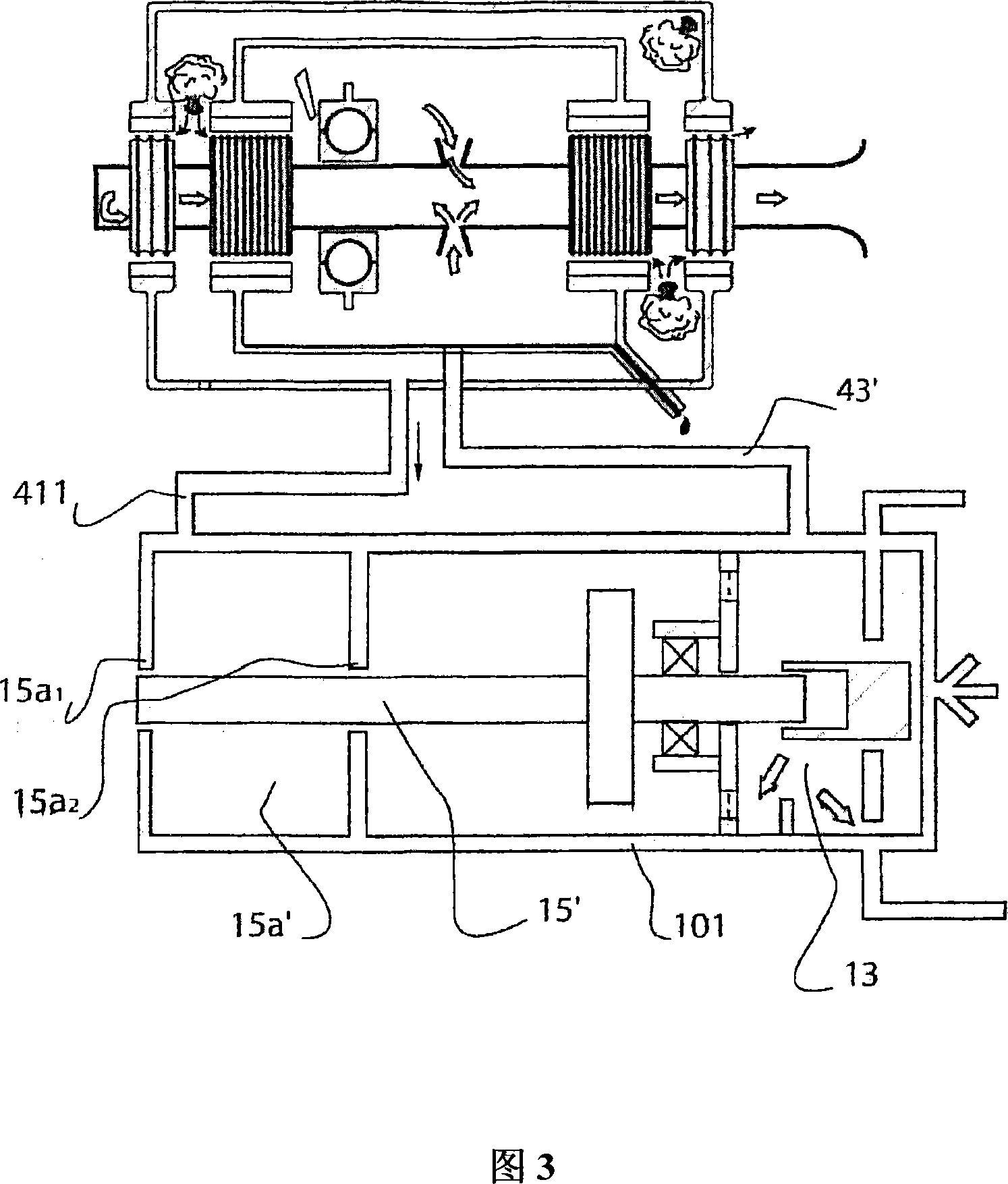

[0018] Referring now to FIG. 2, FIG. 2 is a schematic diagram of a typical arrangement according to a first embodiment of the present invention.

[0019] Starter 10 includes a closed housing 11 for supplying lubricant to the rotating components of starter 10 , representatively a rotating assembly or shaft 15 rotatably mounted within housing 11 via bearings 16 . It should be understood that associated with this rotating assembly are associated pinions, reduction gears, fuses and other components that make up the starter. Since the present invention does not aim at the structure of the starter, the situation of the structure of the starter will not be further described in detail. This rotating assembly 15 is connected to one side of an air turbine, not shown. When the turbojet is started, the turbine turns the rotating assembly 15 in rotation. Turbine seal 15 a provides a seal between rotating assembly 15 and casing 11 . On the other hand, the rotating assembly passing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com