Engine oil filter assembly and assemble method and disassembly method thereof

An oil filter and assembly method technology, applied in the installation/connection of lubricant purification device, controlling the pressure of lubricant, lubricating parts and other directions, can solve the problem of short life of oil filter and oil return control mechanism, oil return control The mechanism is aging quickly, and it is too late to flow away from the oil return port, etc., to achieve the effect of improving work safety, simplifying work and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

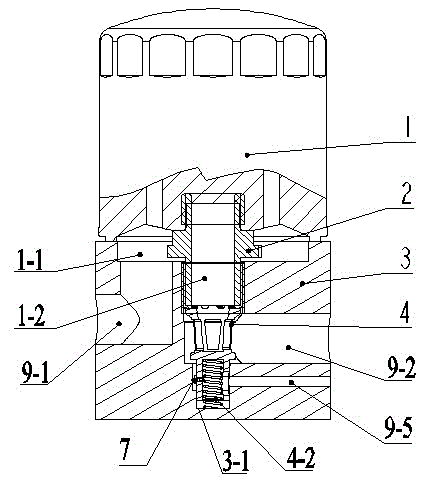

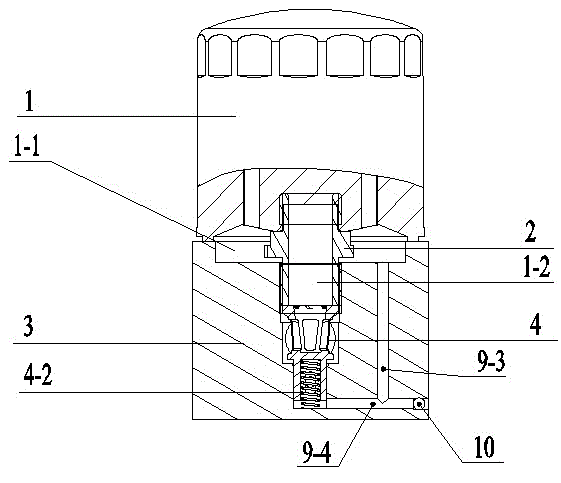

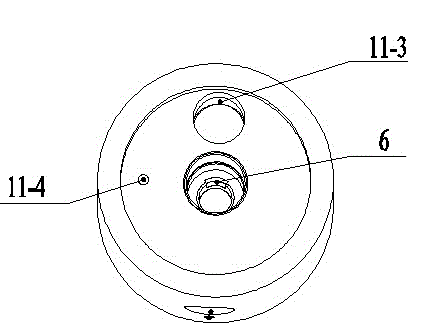

[0037] Embodiment An oil filter assembly and its assembly method and disassembly method

[0038] An oil filter assembly of this embodiment has a structure such as figure 1 , figure 2 As shown, it includes an oil filter 1, and the oil filter 1 is connected with the oil return control mechanism provided in the mounting seat cavity 3-1 of the mounting seat 3 through the connecting pipe 2 and used to support the oil filter 1 4-phase connection,

[0039] The oil inlet chamber 1-1 of the oil filter is connected with the oil outlet of the oil pump through the oil inlet pipe 9-1 before filtering, and the oil outlet chamber 1-2 of the oil filter passes through the oil outlet 9 after filtering. -2 is connected with the main oil passage of the engine, and the oil filter inlet cavity 1-1 is also connected to the horizontal oil return pipeline 9-4 of the pre-filtered machine oil through the vertical oil return pipeline 9-3 of the pre-filtered machine oil. The oil outlet of the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com