Patents

Literature

32results about How to "Avoid duplication of tests" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Testing method and device of application programs

InactiveCN104461873AAvoid duplication of testsShorten test timeSoftware testing/debuggingOperational systemApplication software

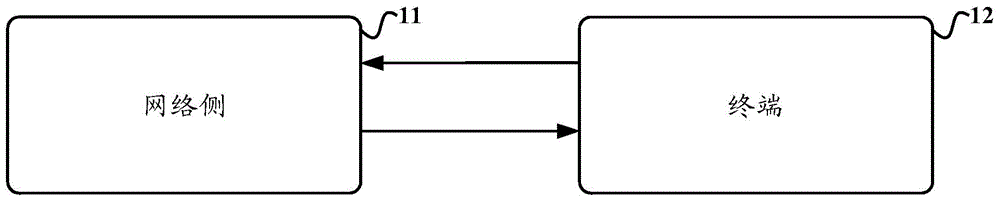

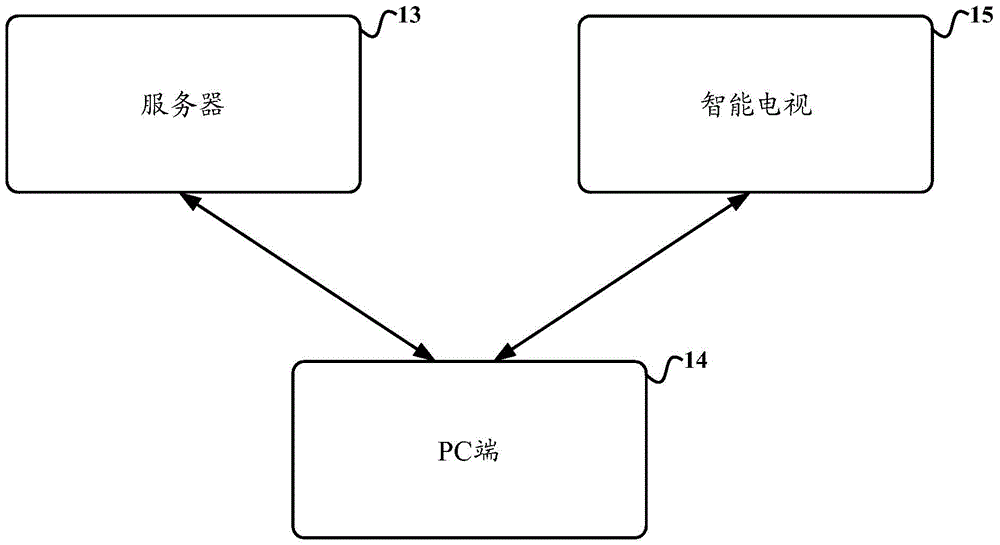

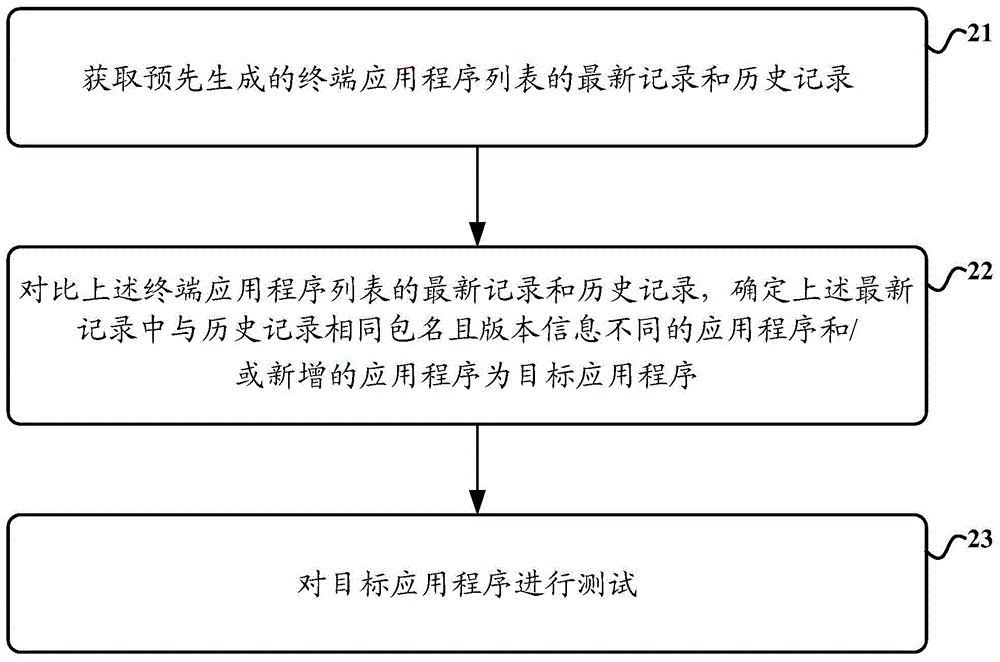

The embodiment of the invention discloses a testing method and device of application programs, and relates to the field of communication. The testing method and device are used for solving the problem that after an operating system of a terminal is upgraded, non-upgraded application programs are repeatedly tested. The method comprises the steps that a latest record and a historical records of a terminal application program list generated in advance are acquired, wherein the latest record records the package name and version information of each application program running in an operating system in a current version, and the historical record records the package name and version information of each application program running in an operating system in a historical version; the latest record and the historical record of the terminal application program list are compared, and application programs, the same as those in the historical record in package name but different in version information, in the latest record and / or new application programs are determined as target application programs. Thus, the problem is solved.

Owner:HISENSE VISUAL TECH CO LTD

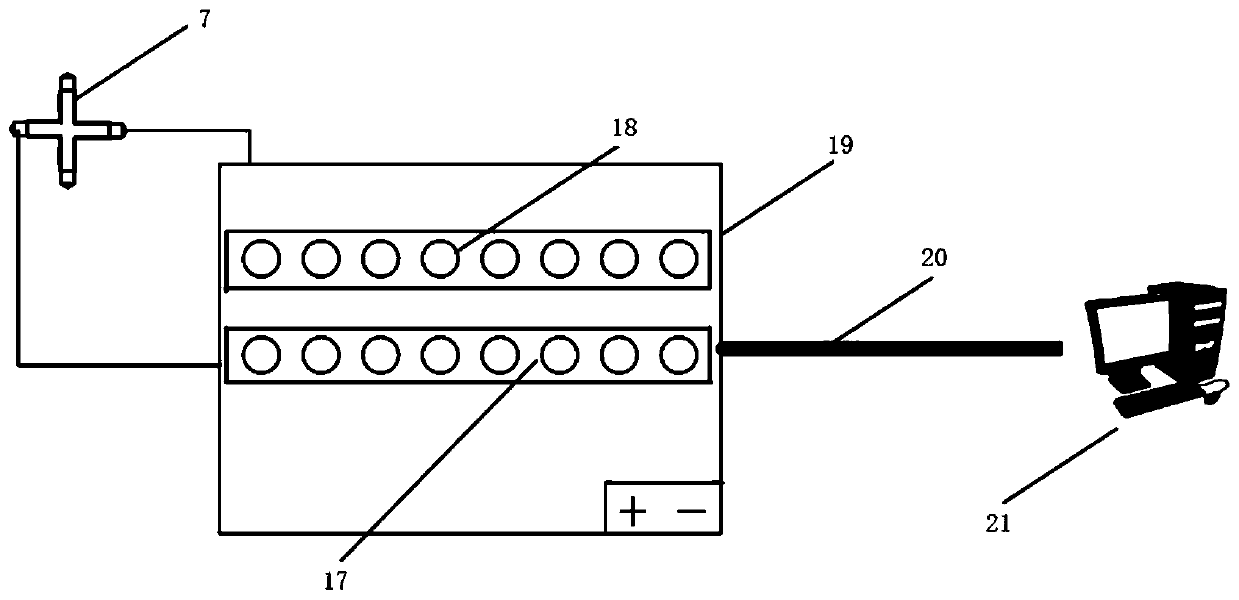

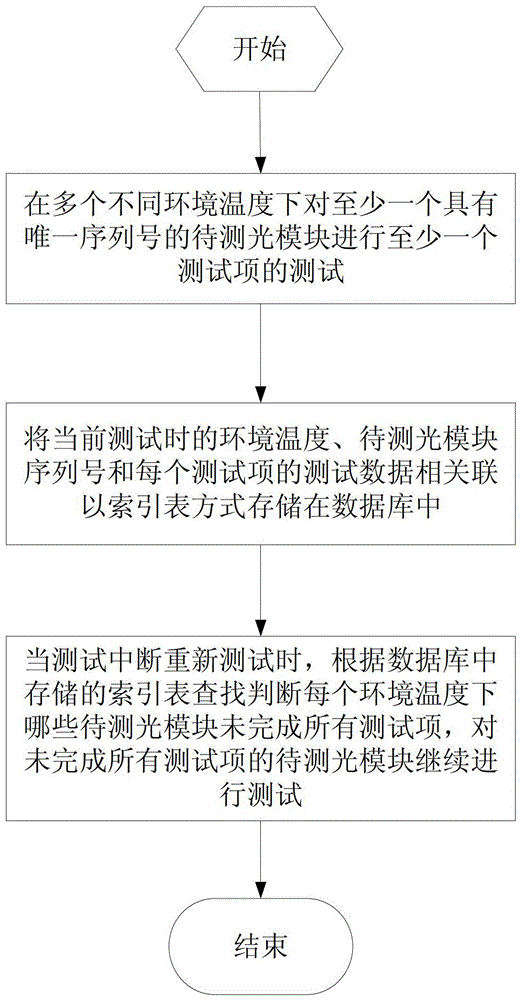

Light module test method

ActiveCN103001693AAvoid duplication of testsImprove test efficiencyTransmission monitoring/testing/fault-measurement systemsSimulationIndustrial engineering

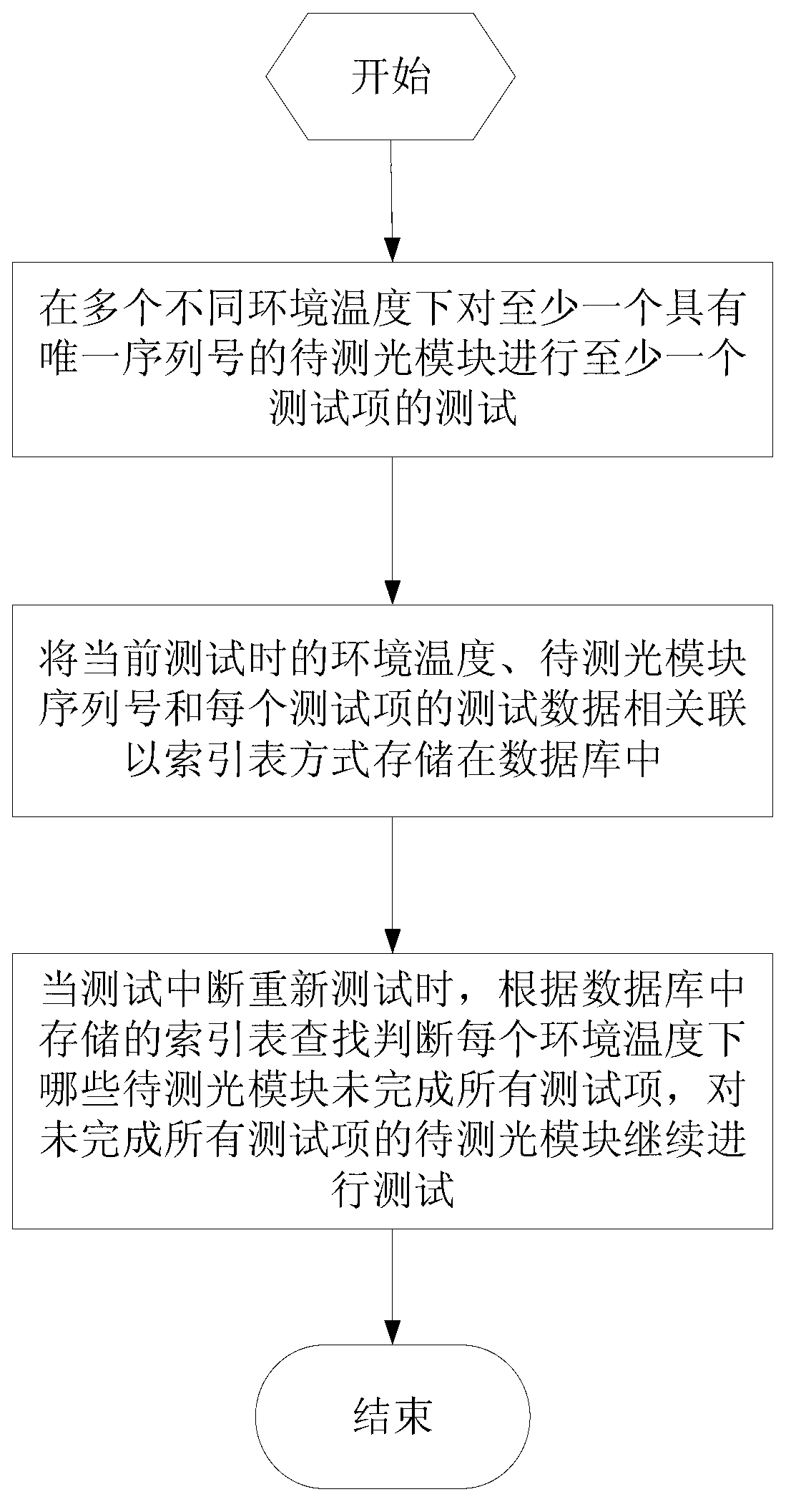

The invention discloses a light module test method which includes the following steps: conducting test of at least one test item on at least one light module to be tested and with unique serial number under multiple different environment temperatures, correlating environment temperature, serial number of the light module to be detected and test data of each test item in current test, storing the data in a local database in index table mode, enabling the test data of each test item to utilize the serial number of the light module to be tested as index and the serial number of the light module to be tested to utilize the environment temperature as index, searching and judging which light modules to be tested under each environment do not finish all test items according to an index table stored in the local database and continue testing on the light modules to be tested and not finishing all the test items when the test is suspended and restarted. The light module test method does not require testing the light modules finishing all tests, avoids repeated test and improves test efficiency.

Owner:SOURCE PHOTONICS CHENGDU

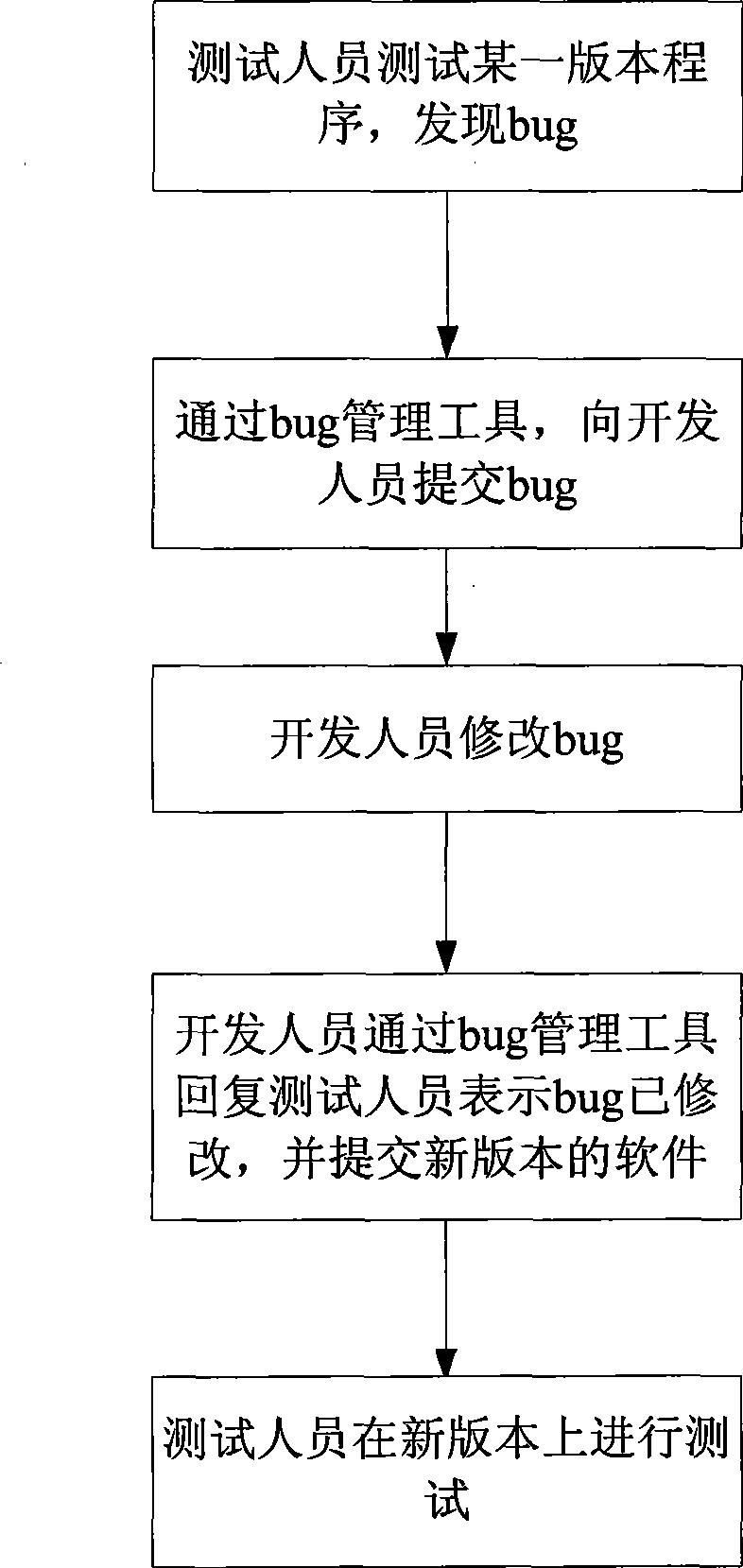

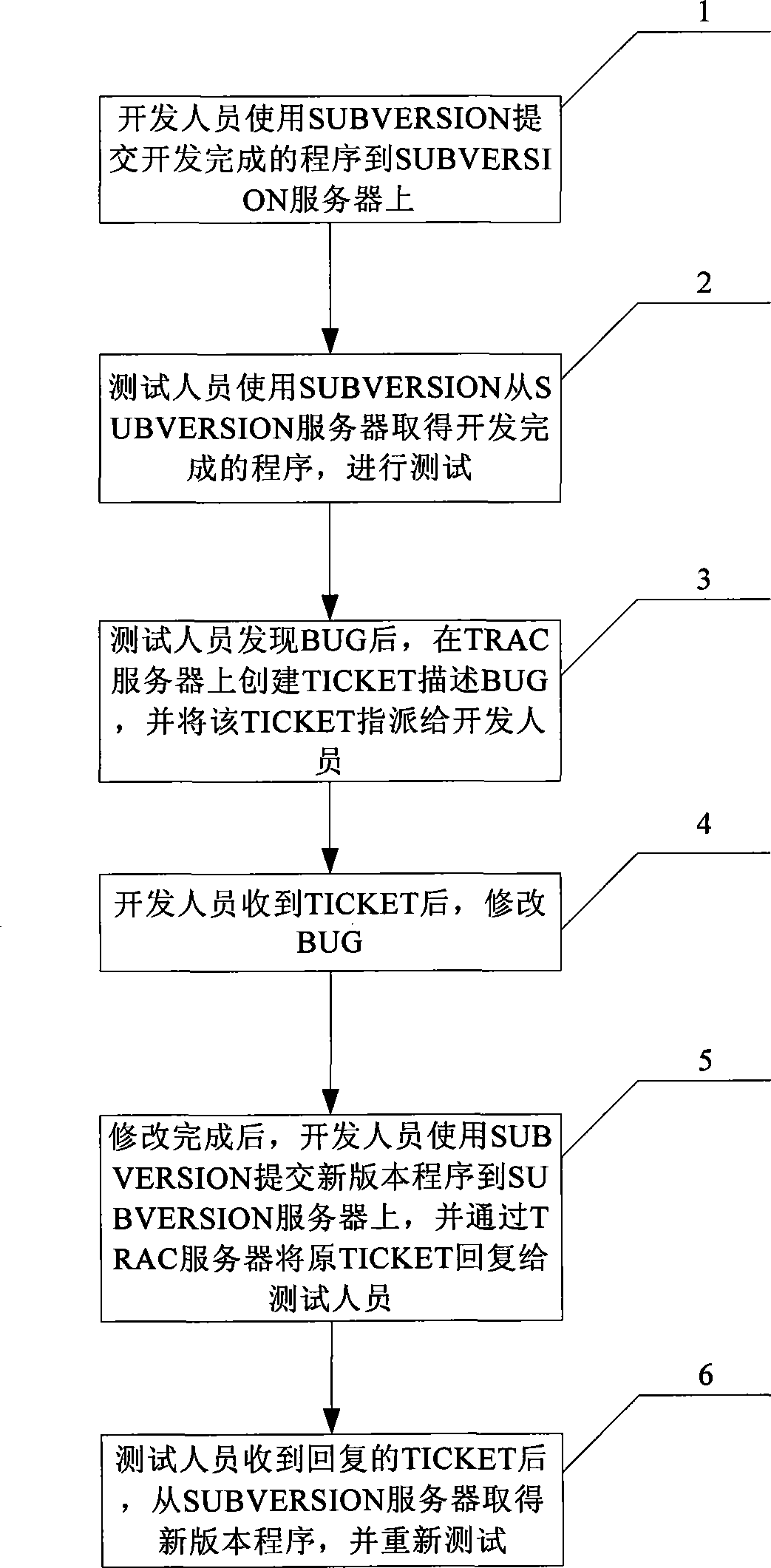

Method for processing program BUG in program test process flow

InactiveCN101436157ARealize the bindingAvoid duplication of testsSoftware testing/debuggingRelevant informationProgram testing

The invention relates to a method for processing a program BUG in the program testing flow. The method comprises the following steps: a developer uses a SUBVERSION client terminal to submit a completed program to a SUBVERSION server; a tester uses the SUBVERSION client terminal to obtain the developed program from the SUBVERSION server and carries out testing; after the tester finds BUG, a TICKET with a serial number is established in a TRAC server; the relevant information of the BUG is described in the TICKET; the TICKET is assigned to the developer; after the developer receives the TICKET, the BUG is modified; after modification is completed, the developer uses the SUBVERSION client terminal to submit a new-version program bond with a serial number of an original TICKET to the SUBVERSION server; the original TICKET is replied to the tester through the TRAC server; and after the tester receives the replied the TICKET, the new-version program is obtained from the SUBVERSION server and is retested. Compared with the prior art, the method avoids that the developer does not submit the new-version program so as to cause repeated testing on an old-version program by the tester.

Owner:SHANGHAI BROADBAND TECH

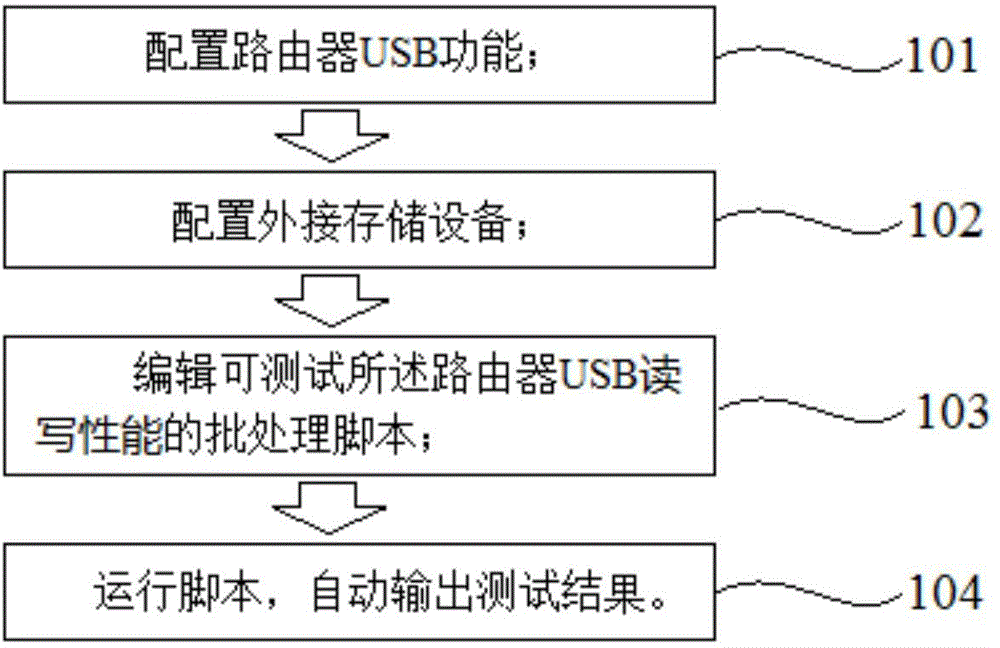

Automatic testing system and method of router USB performance

InactiveCN104598355AEfficient use ofDealing with high volumeSoftware testing/debuggingTest efficiencyExtensibility

The invention discloses an automatic testing system and method of router USB performance. The testing method includes the following steps that (101), functions of a router USB are configured; (102), external storage equipment is configured; (103), batch scripts capable of testing the read-write performance of the router USB are edited; (104), the scripts are run, and a testing result is automatically output. The automatic testing system and method have the advantages that by the adoption of the BAT, portability is good, all platforms can be run, meanwhile, efficiency is high, a lot of manual testing work can be replaced, repeated testing is avoided, and a lot of labor is saved; precision is high, expandability is good, the cost is lowered, the testing efficiency is improved, existing resources can be better utilized, and time needed for putting the product into the market is shortened.

Owner:PHICOMM (SHANGHAI) CO LTD

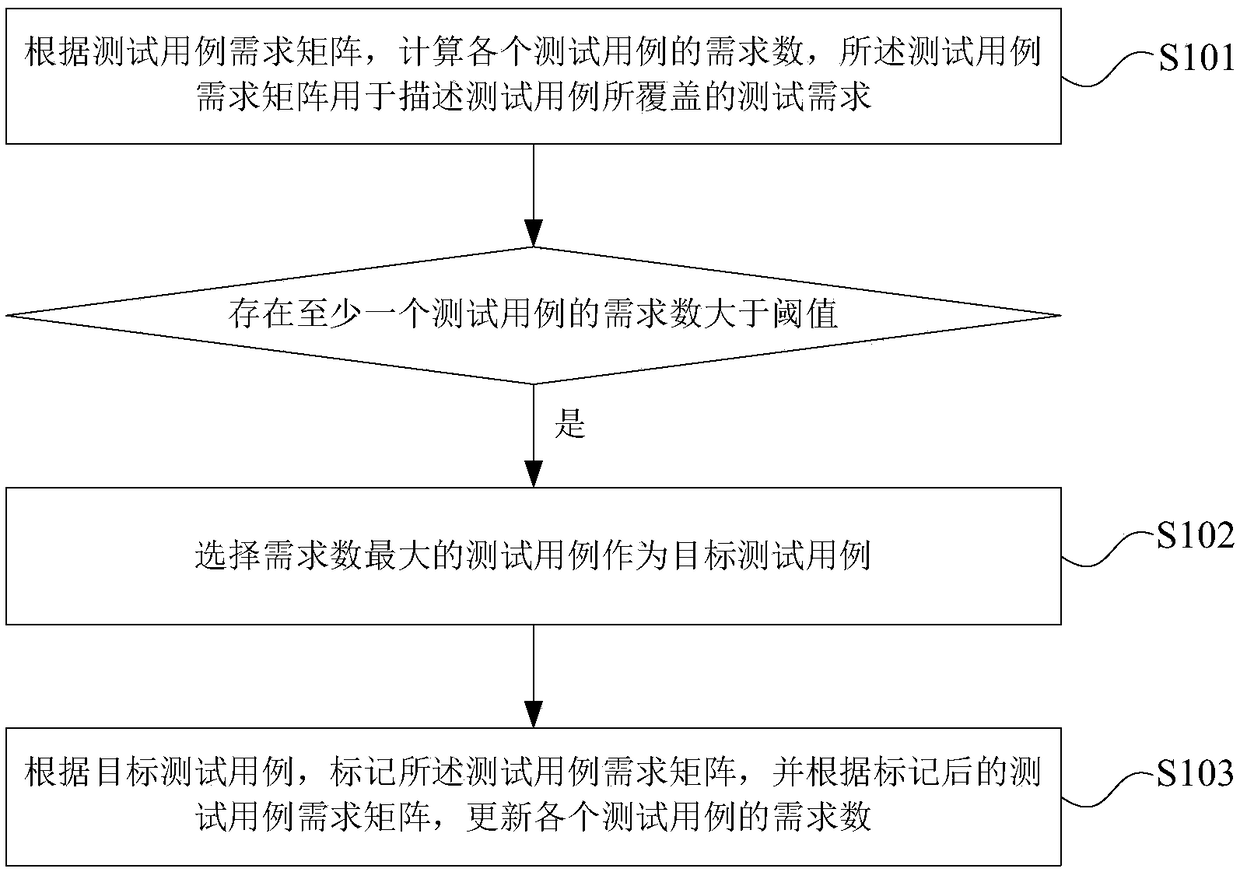

Testing method, testing device and electronic equipment

InactiveCN108920353AAvoid duplication of testsAvoid missing testSoftware testing/debuggingTest efficiencyRepeat testing

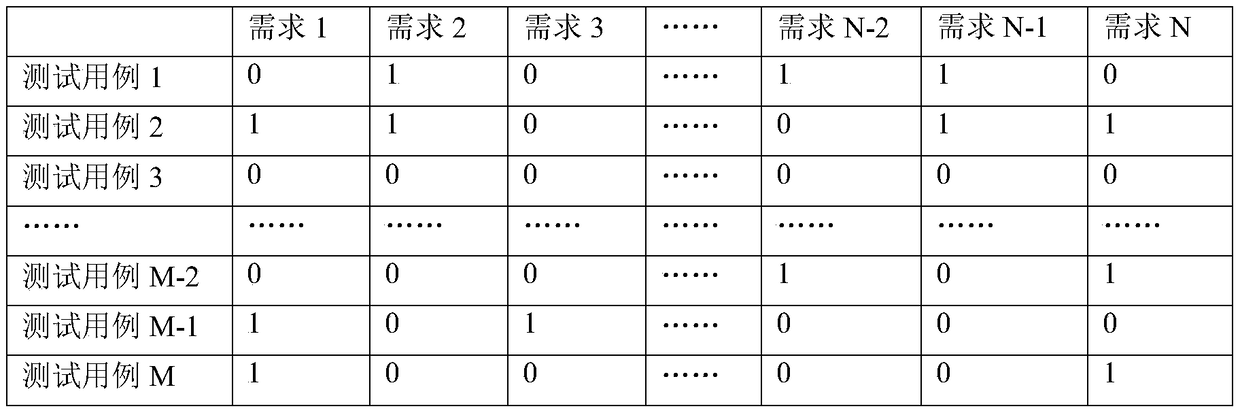

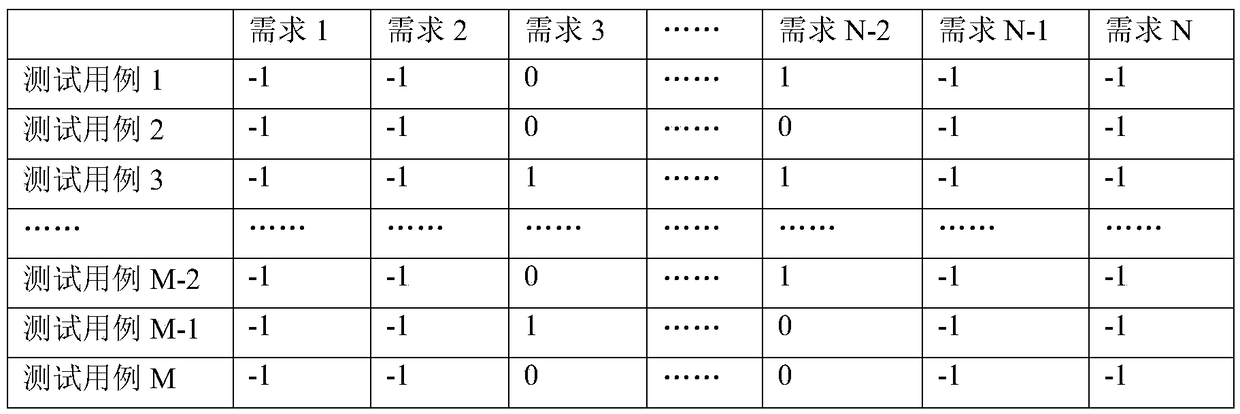

An embodiment of the invention provides a testing method, a testing device and electronic equipment. The testing method includes steps: calculating demanded quantity of each test case according to a test case demand matrix, wherein the test case demand matrix is used for describing test demands covered by test cases; when the demanded quantity of at least one test case is larger than a threshold,selecting the test case largest in demanded quantity as a target test case; according to the target test case, marking the test case demand matrix, and updating the demanded quantity of each test caseaccording to the marked test case demand matrix, wherein all selected target test cases are used for testing. By testing of the demand matrix, the test case covering most test demands is screened out, so that adopting few test cases for covering most test demands in testing can be guaranteed, repeated testing and missing measurement are prevented, and test efficiency and precision are effectivelyimproved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

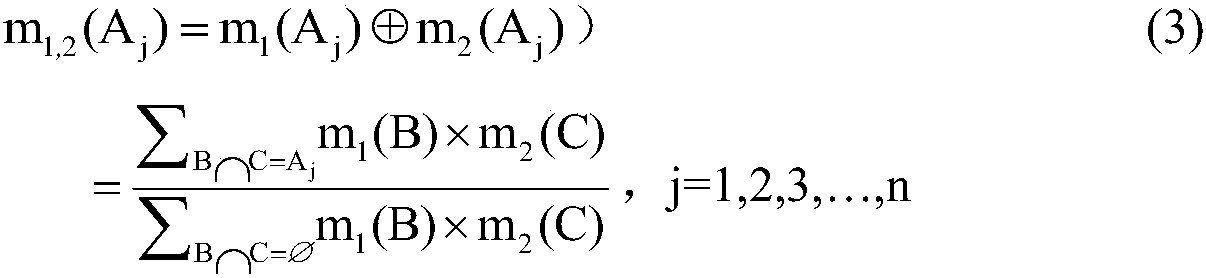

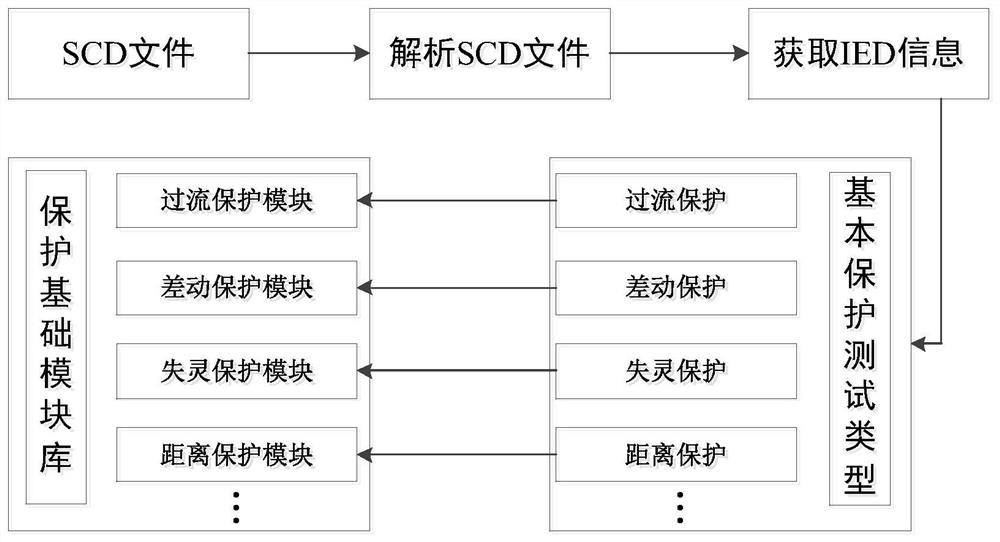

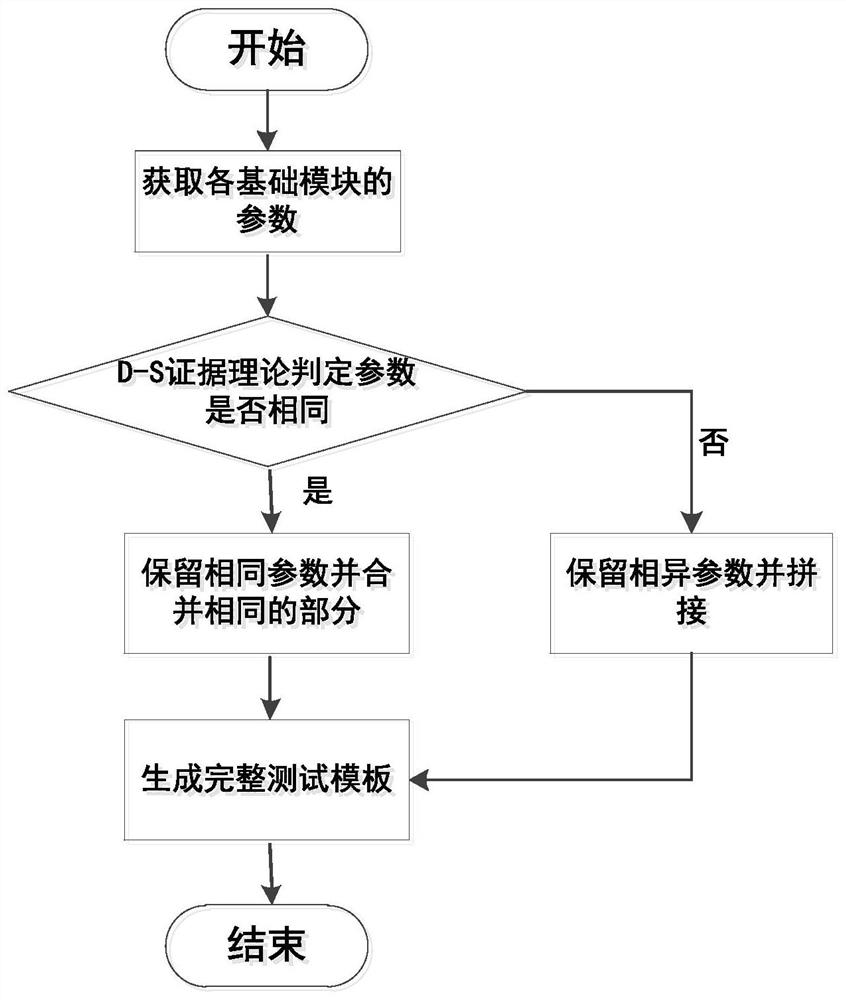

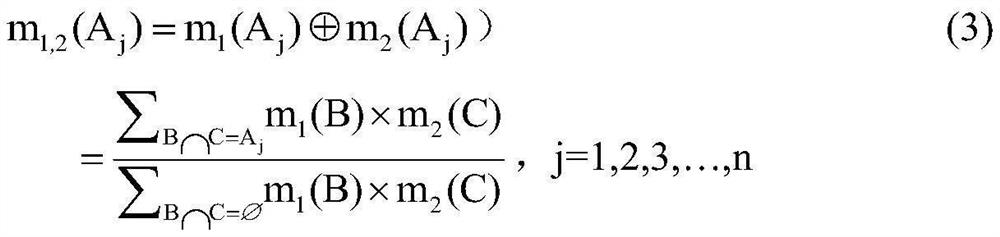

Relay protection device automatic testing template based on D-S evidence theory

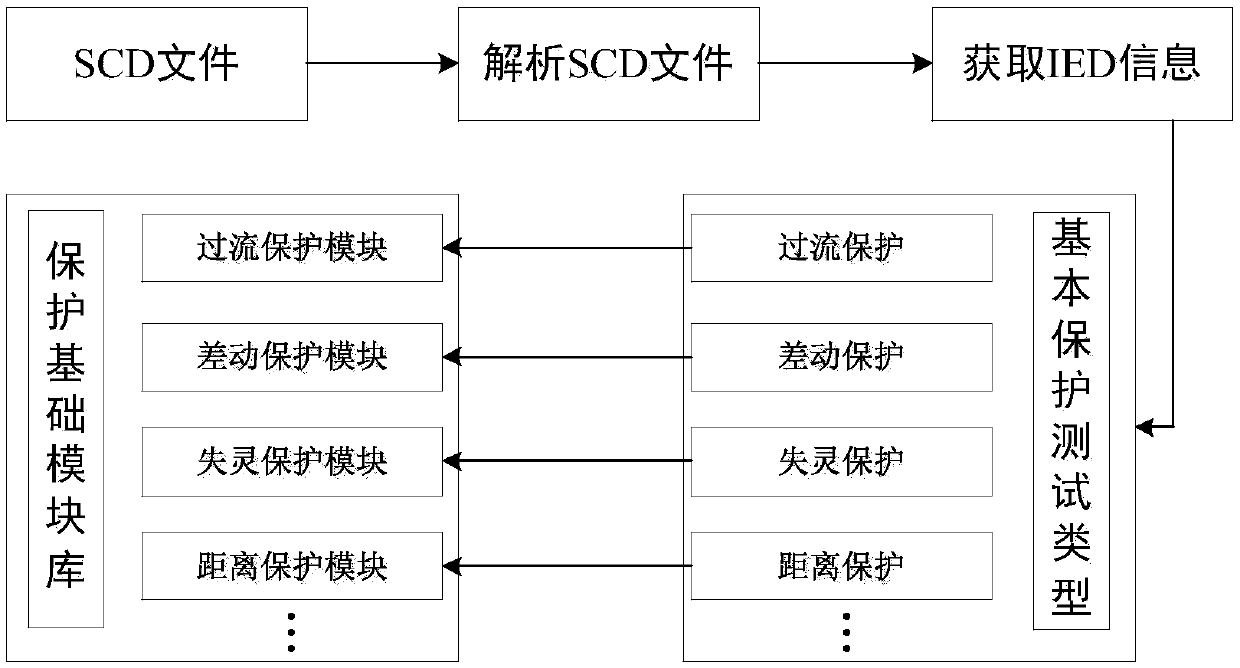

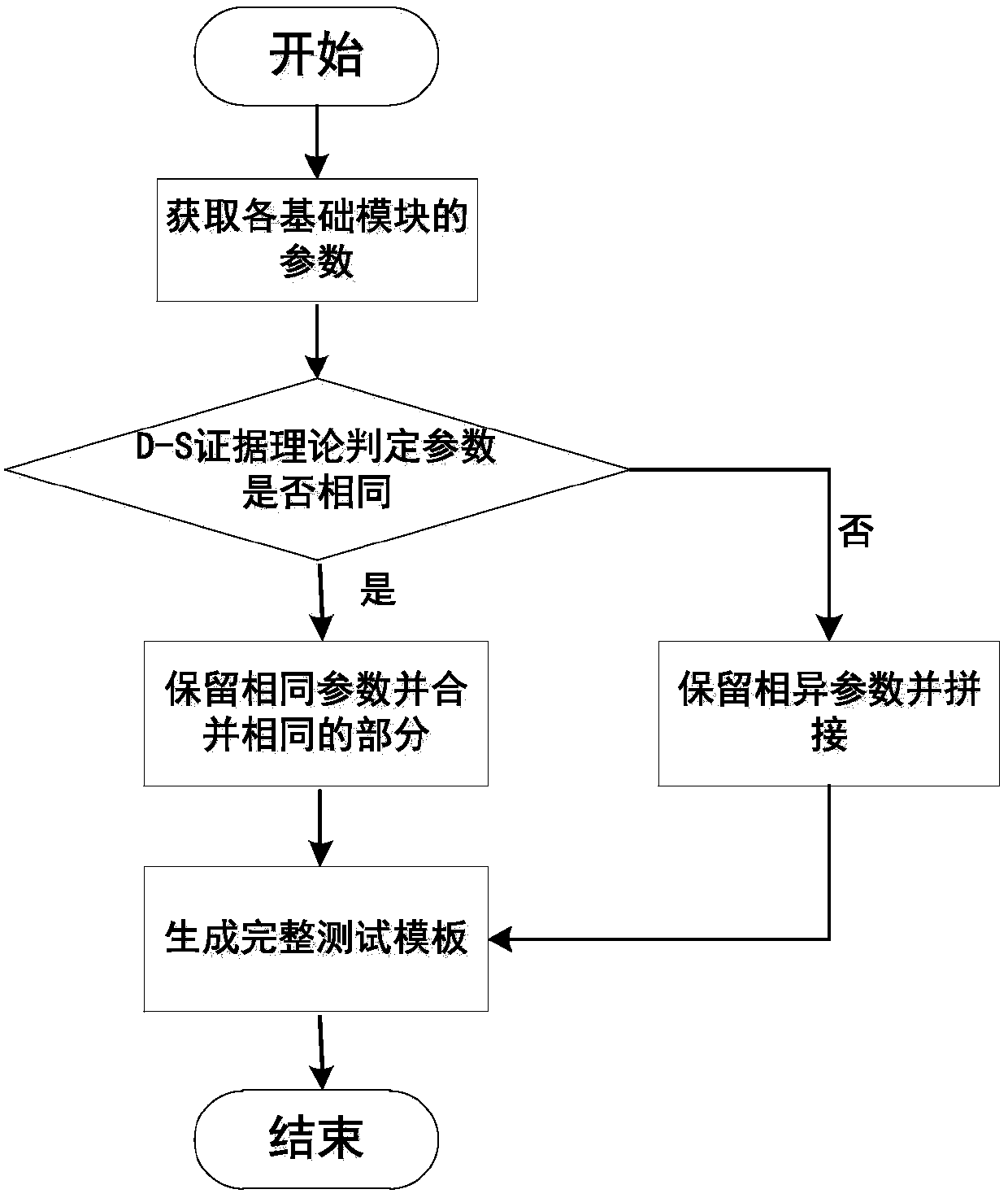

ActiveCN108548970AImprove intelligenceAvoid duplication of testsElectrical testingTest efficiencyTemplate based

The invention discloses a relay protection device automatic testing template based on a D-S evidence theory. The method comprises the following steps of (1), in a protection base module database, acquiring the parameter of each protection base module; (2), determining whether the same parameter exists among the base modules according to the D-S evidence theory, if yes, keeping one same parameter and combining the parts with the same parameter; after combination, if no same parameter exists, keeping the respective parameters for performing splicing combination; (3), after splicing, successivelyexpanding the testing items for testing; and (4), after testing, automatically generating a protection testing report. The relay protection device automatic testing template according to the invention is based on module splicing of the D-S evidence theory has advantages of preventing repetitive testing, improving testing efficiency, and laying a basis for intelligentization and automation improvement of the whole set of automatic testing system.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +6

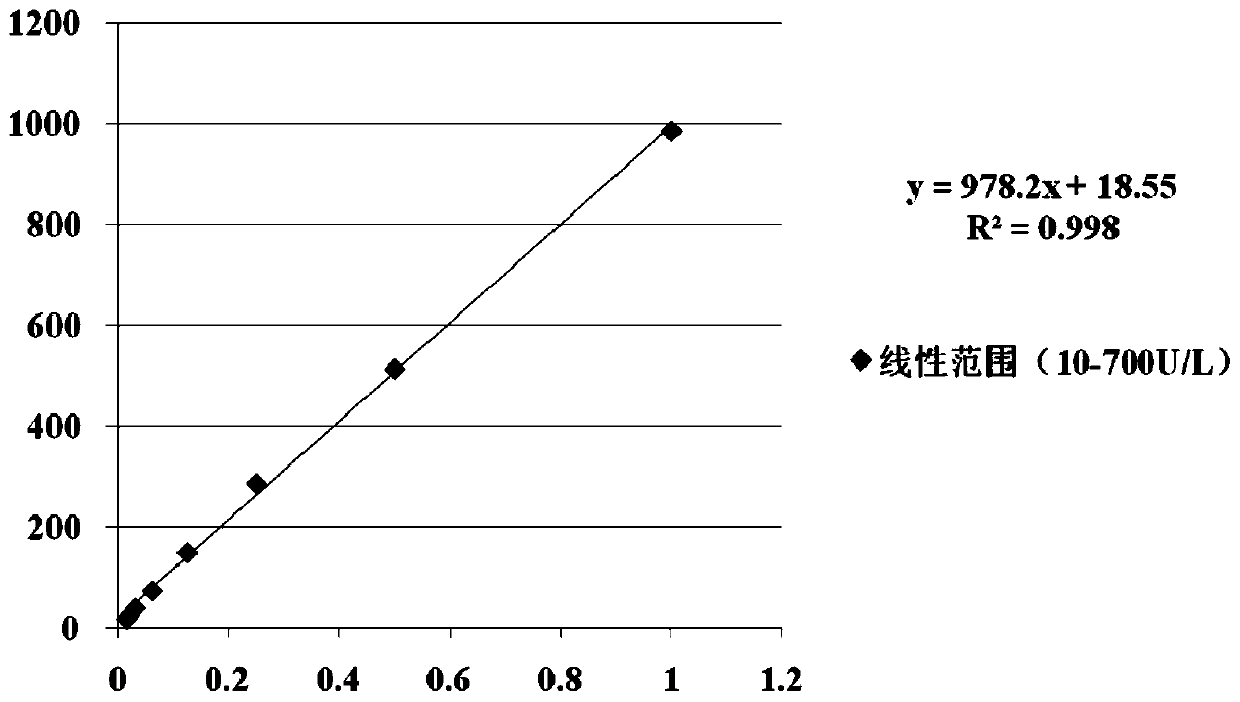

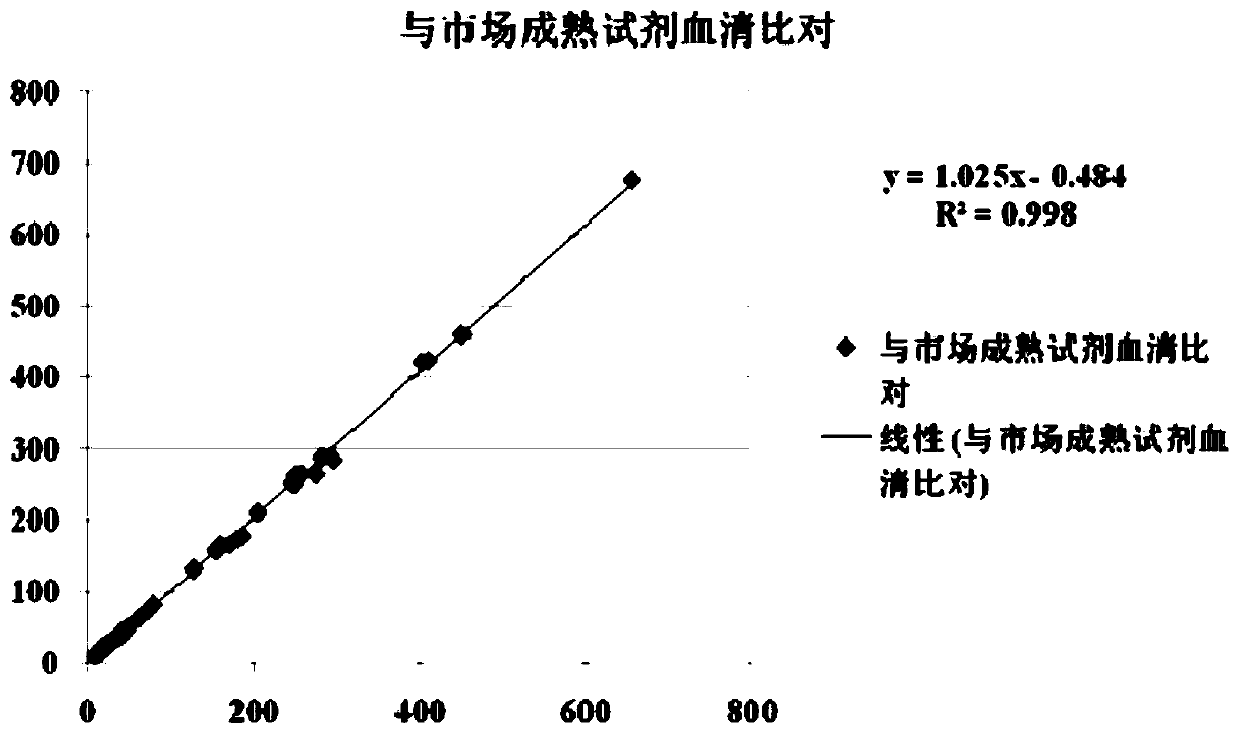

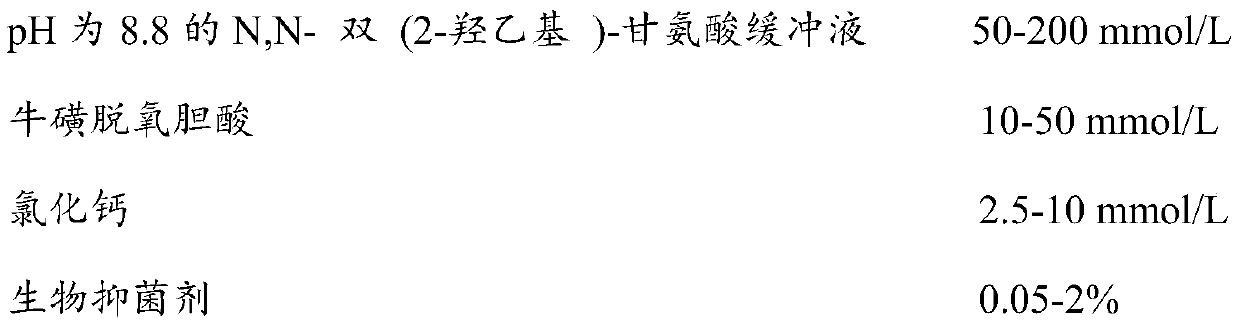

Serum lipase detection kit as well as preparation method and application thereof

PendingCN110923292AReduce consumptionWide linear rangeMicrobiological testing/measurementBiological material analysisGlutaric acidGlycerol

The invention discloses a serum lipase detection kit as well as a preparation method and application thereof. The kit comprises a reagent R1 and a reagent R2, wherein the reagent R2 comprises the following components: a tartaric acid buffer solution of which the pH value is 5.5, 1,2-dilauryl glycerinum-3-glutaric acid-(6'-methyl resorufin)-ester, mannitol, triton-100, DMSO (dimethyl sulfoxide), normal propyl alcohol, lecithin and BSA (bull serum albumin). The kit is wide in linear range (100-700U / L), low in cost, good in stability and high in sensitivity, and has good market popularization application prospects.

Owner:ZHONGSHAN CHUANGYI BIOCHEM ENG

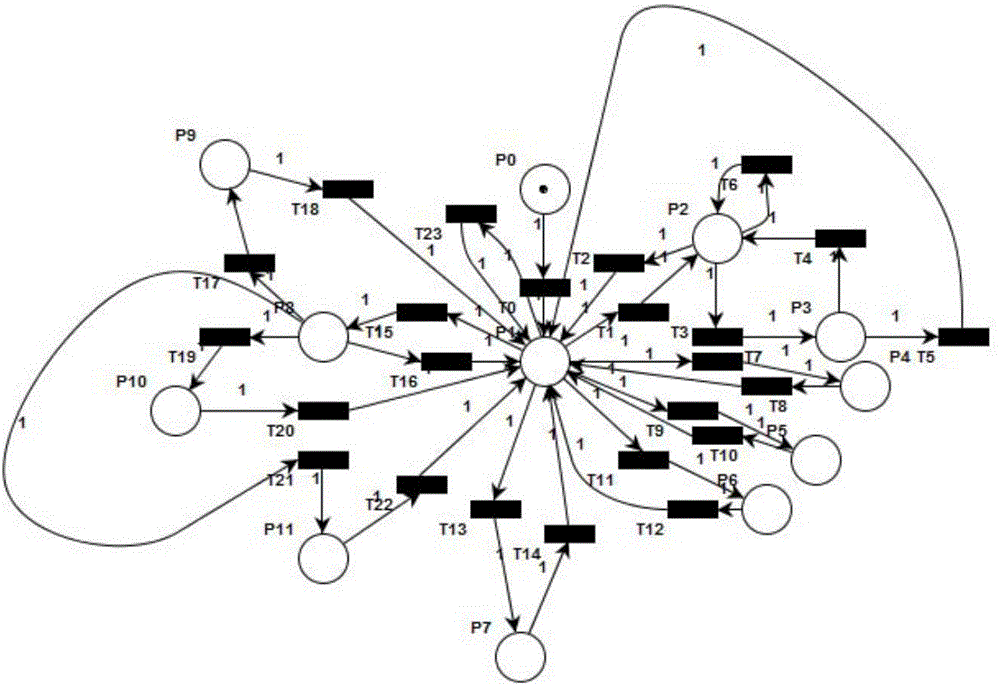

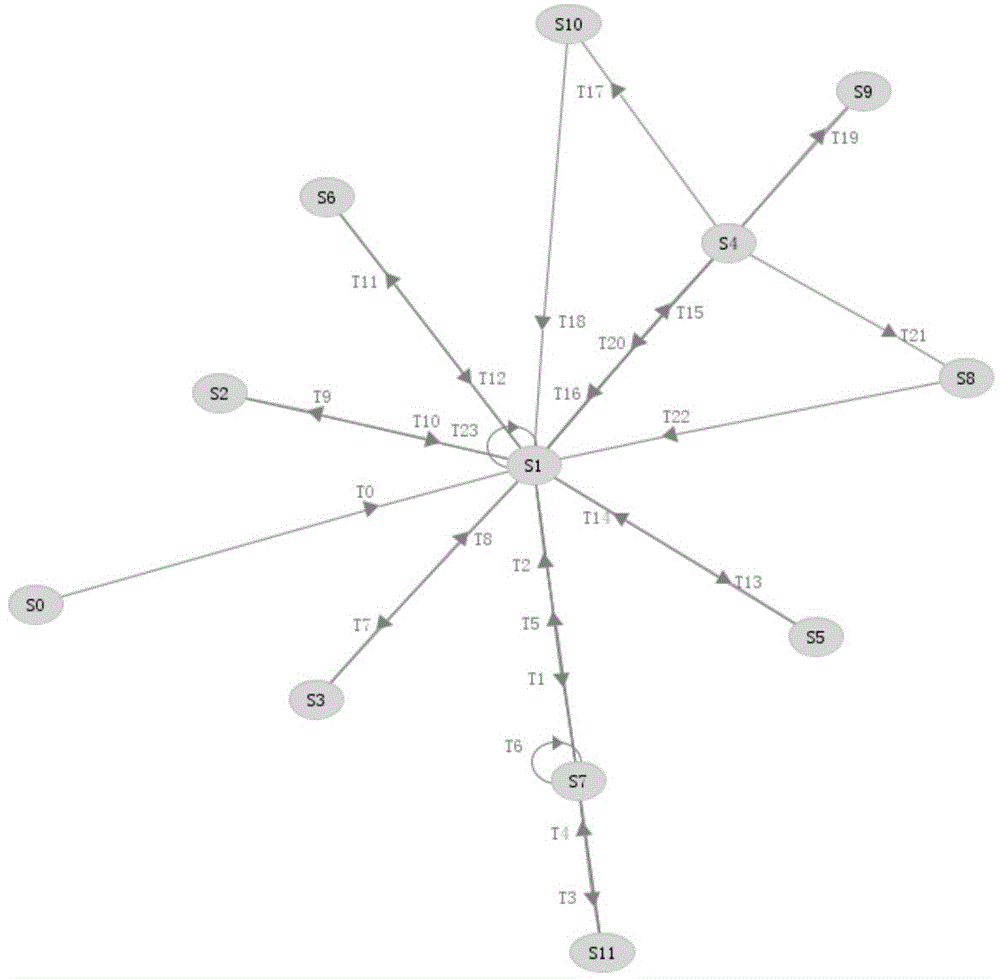

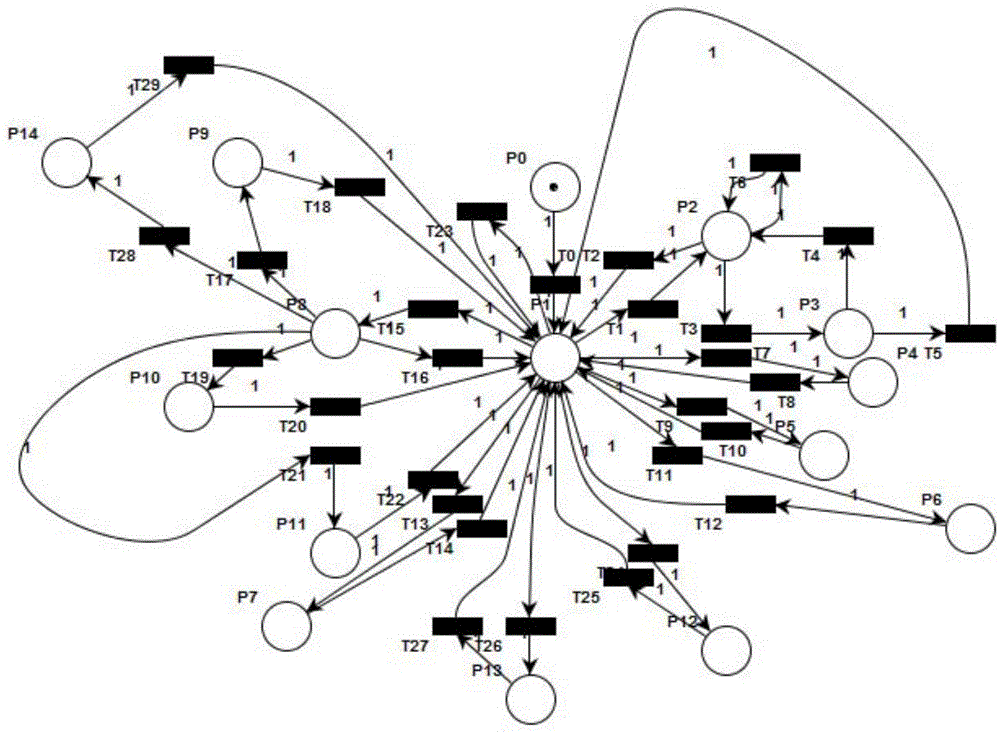

Method of generating WIA-PA (Wireless networks for Industrial Automation-Process Automation) protocol test set based on equipment life cycle Petri net

InactiveCN105591827AComprehensive judgmentQuick judgmentData switching networksFull life cycleWireless mesh network

The invention discloses a method of generating a WIA-PA (Wireless networks for Industrial Automation-Process Automation) protocol test set based on an equipment life cycle Petri net, which particularly relates to the industrial wireless sensor network technology. In view of characteristics such as the equipment type, the topological structure and the protocol stack structure of a WIA-PA network, according to the equipment life cycle, a Petri net model is built, information such as the place, the change and the initialization condition of the model structure are analyzed and checked, a change happening sequence is generated, and a full life cycle test set with the adding process, the operation process and the leaving process as the main body is generated for the equipment finally. An effective testing method is provided for testing the coincidence degree between the developed WIA-PA equipment and a WIA-PA standard, and thus, interconnection and interoperation between WIA-PA equipment developed by different factories can be ensured.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

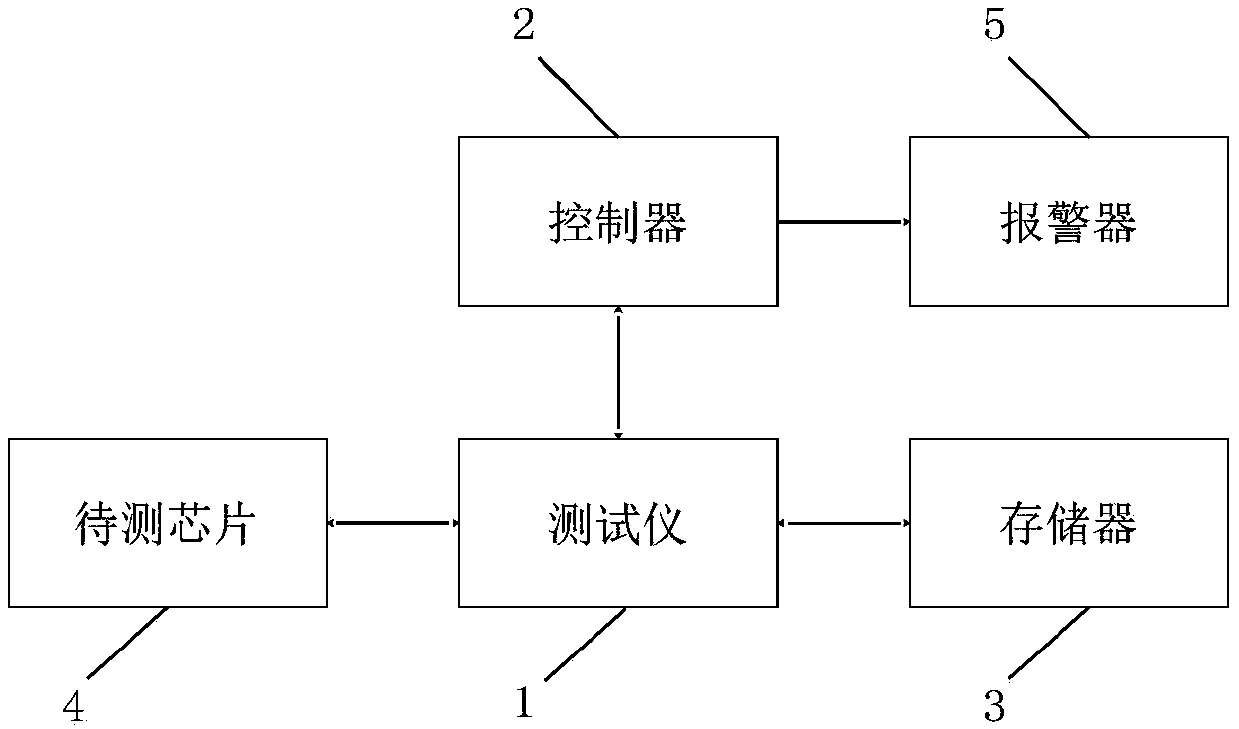

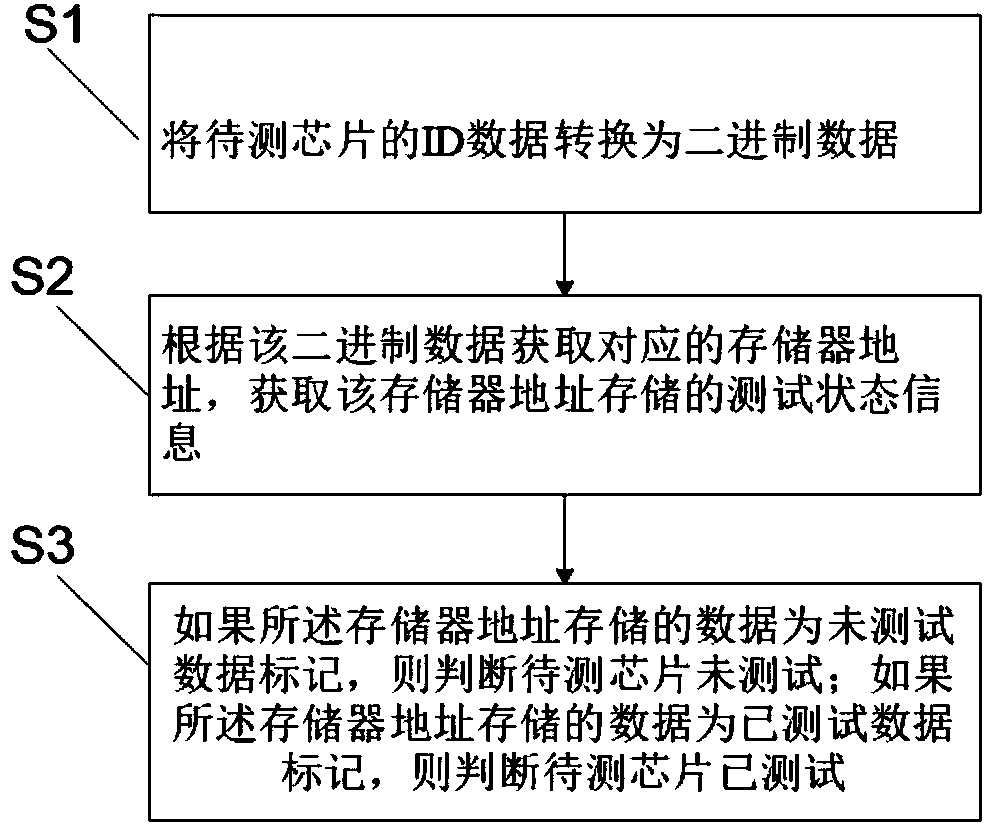

Chip test system and method

PendingCN107656188AAvoid duplication of testsSave spaceElectronic circuit testingMemory addressControl signal

The invention discloses a chip test system which includes a tester, a controller and a memory. The tester transmits the ID data of a chip under test to the controller. The controller sends an ID reading control signal to the tester, and receives the ID data of the chip under test transmitted by the tester and converts the ID data into binary data. The controller acquires a corresponding memory address according to the binary data, and acquires test state information stored in the memory address. If the test state information stored in the memory address is an untested data marker, the controller determines that the chip under test has not been tested. If the test state information stored in the memory address is a tested data marker, the controller determines that the chip under test has been tested. The memory stores the test state information of the chip under test. Whether the ID of the chip under test repeats can be determined. A function of anti-repeated-code test is achieved. Repeated test of chips can be prevented. The invention further discloses a chip test method.

Owner:SHENZHEN AIXIESHENG TECH CO LTD

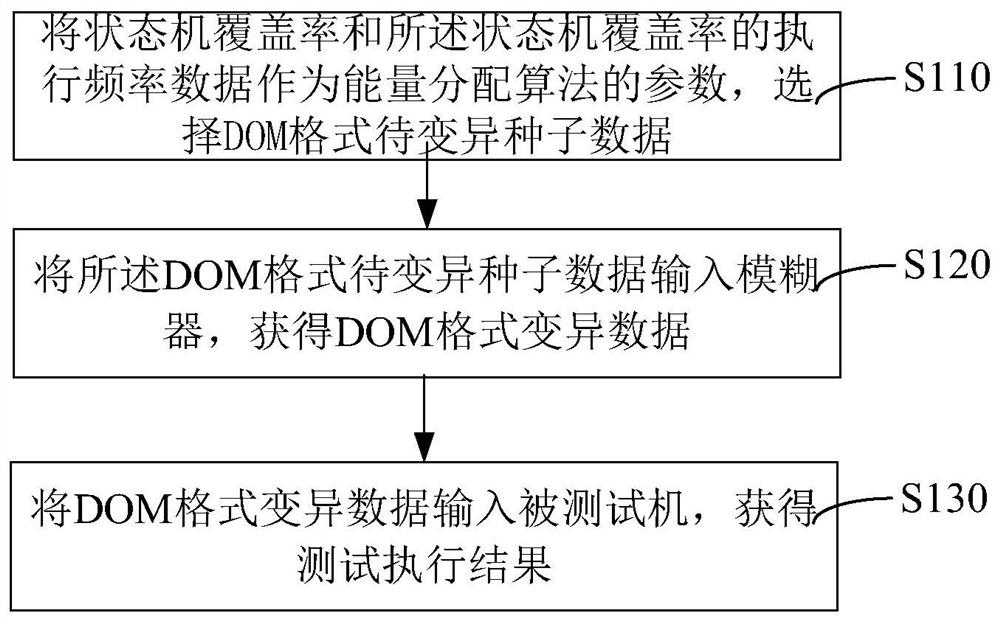

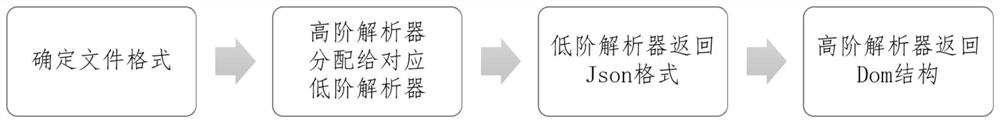

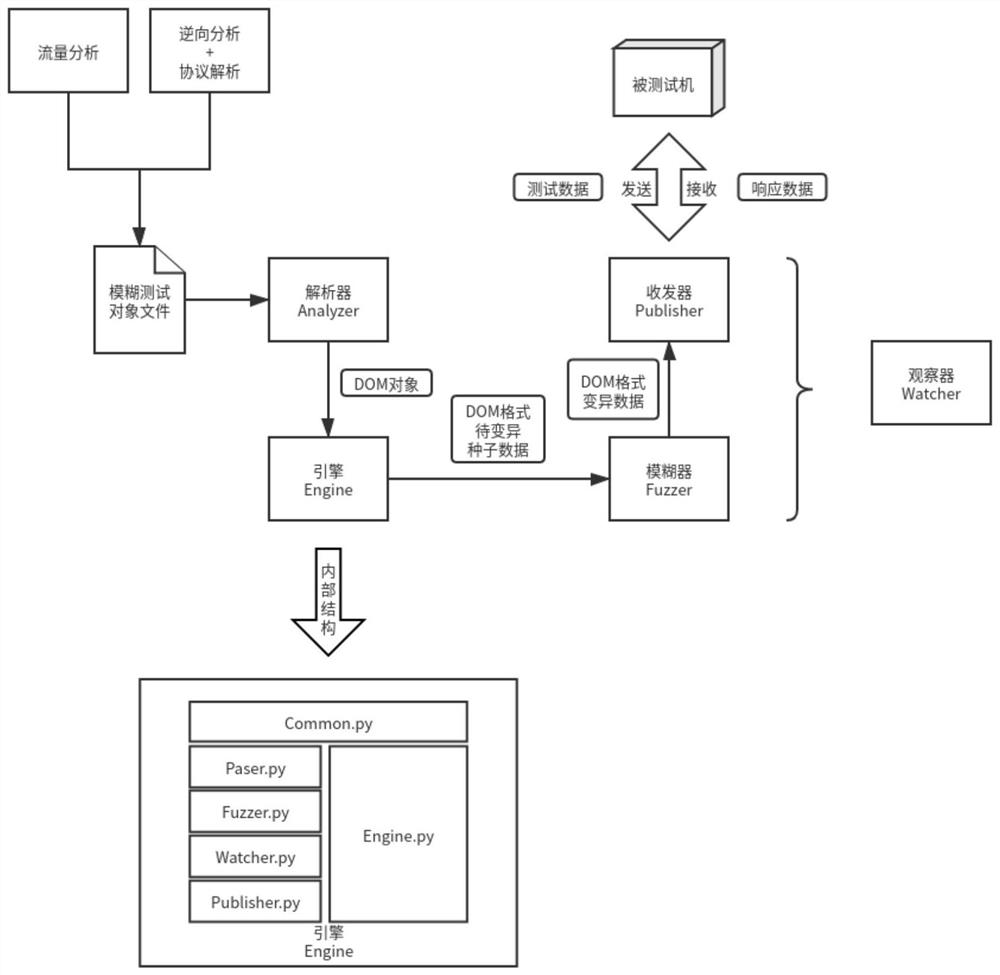

Fuzzy test method, device and system

ActiveCN112052156AAvoid duplication of testsImprove test efficiencySoftware testing/debuggingFuzzy logic based systemsTest efficiencyAlgorithm

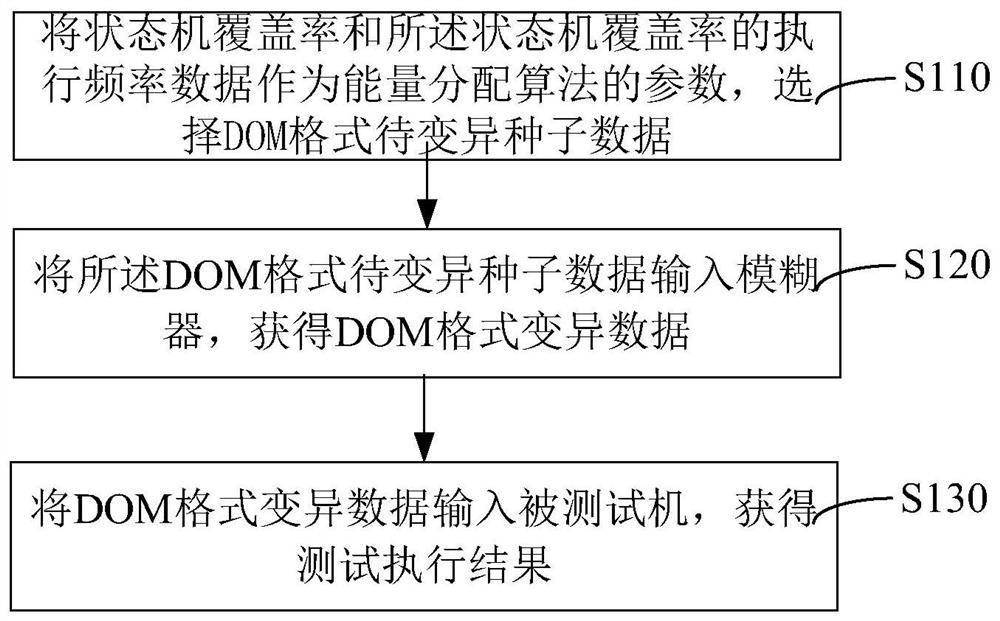

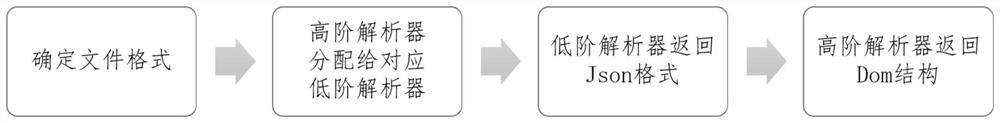

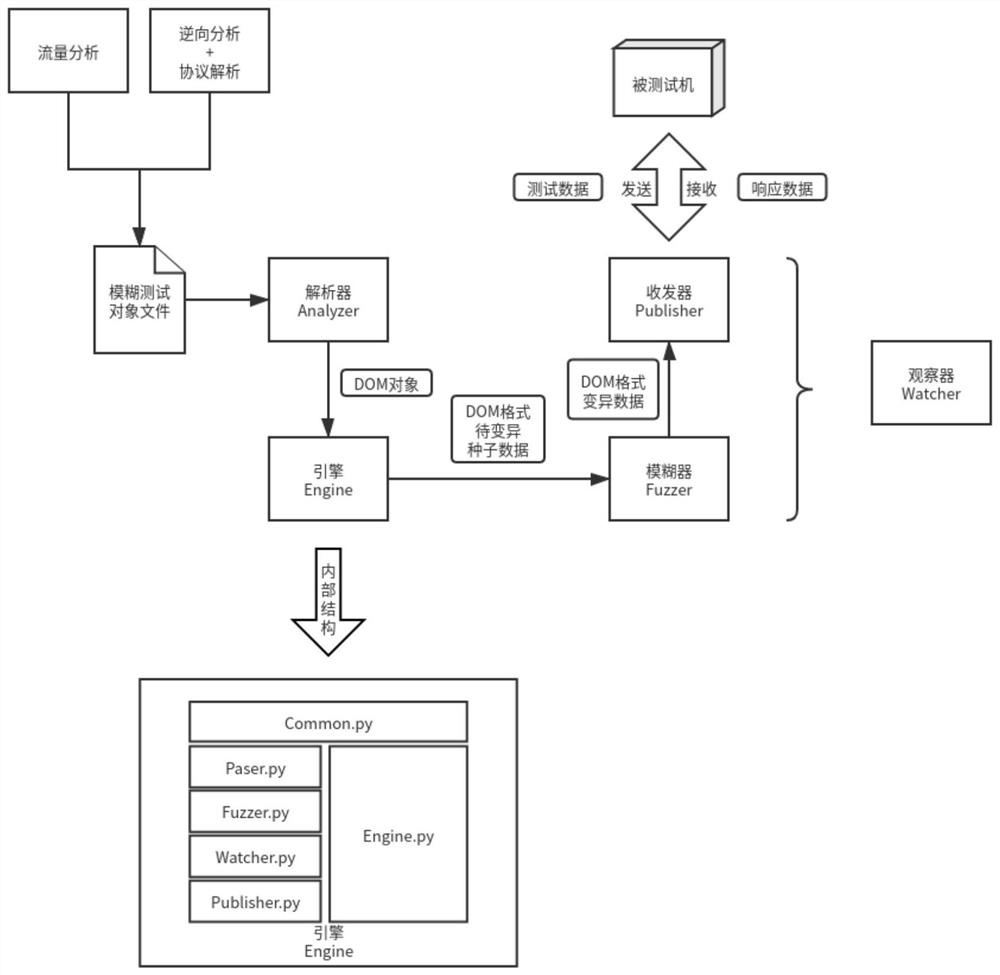

The invention relates to a fuzzy test method, device and system. The method comprises the following steps: taking a state machine coverage rate and execution frequency data of the state machine coverage rate as parameters of an energy distribution algorithm, and selecting DOM-format to-be-mutated seed data; inputting the DOM-format to-be-mutated seed data into a fuzzifier to obtain DOM-format mutation data; inputting the DOM format variation data into a tested machine to obtain a test execution result; wherein the test execution result comprises an execution log of the tested machine. By adopting the method, the test efficiency can be improved.

Owner:浙江木链物联网科技有限公司

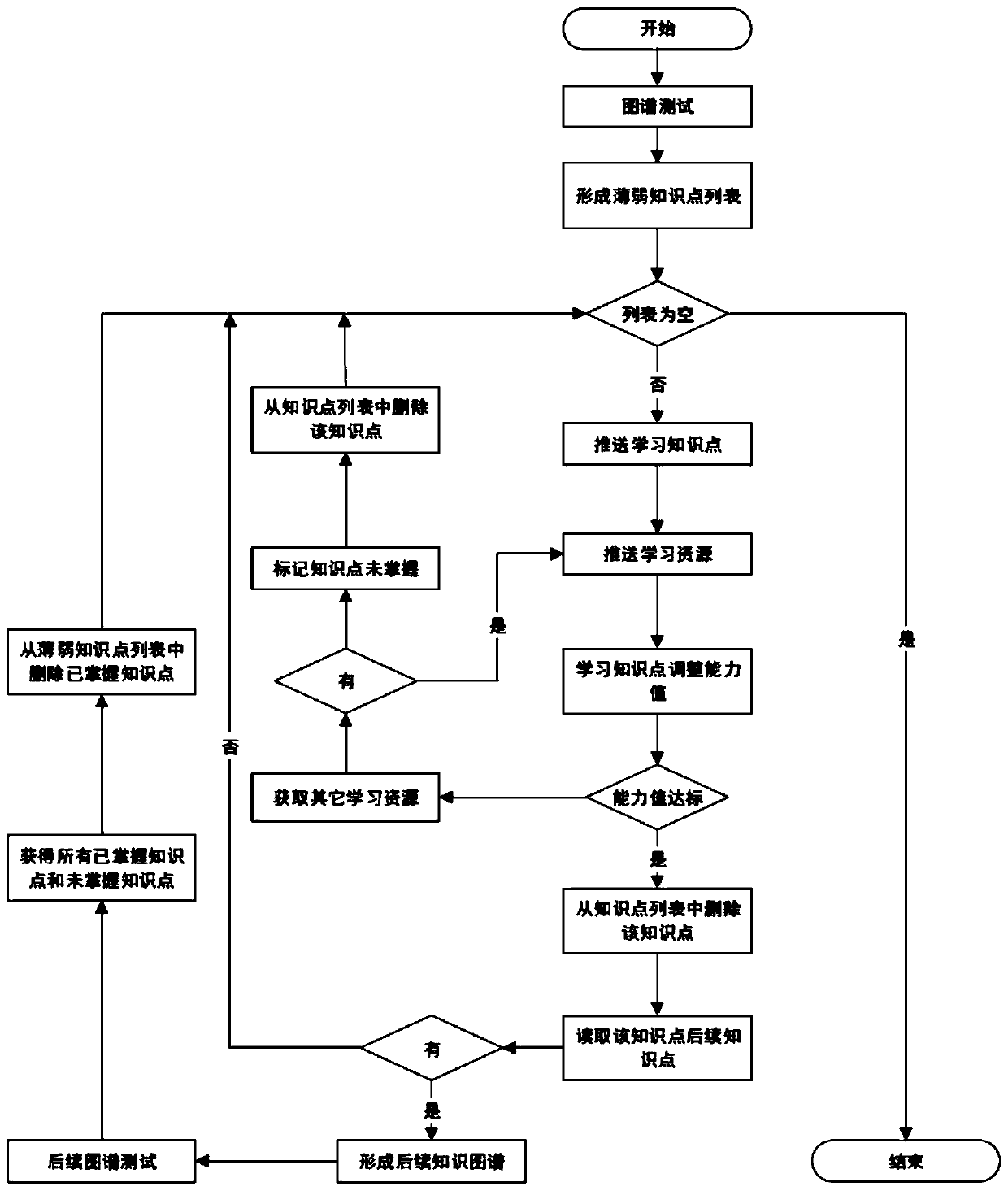

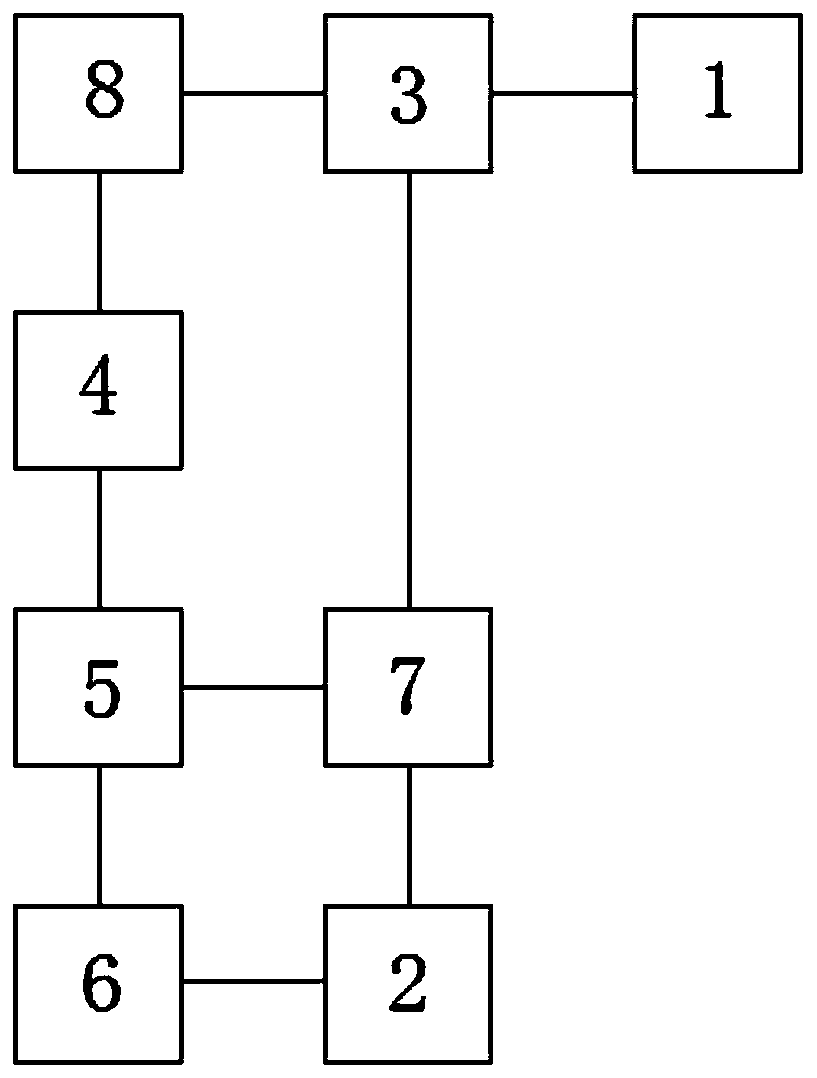

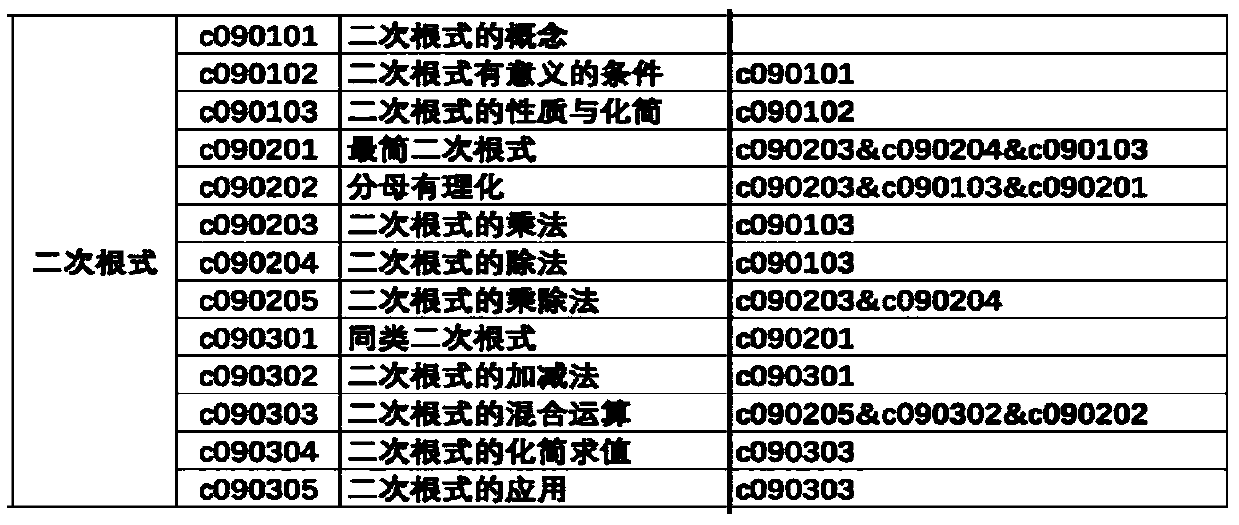

Mathematical edge measurement and edge learning system and method in adaptive learning

InactiveCN109993673AAdjust learning paths in real timeBe personalizedData processing applicationsElectrical appliancesTest efficiencyAdaptive learning

The invention discloses a mathematical side edge learning system and method in adaptive learning. The method comprises the following steps: S1, making all knowledge points into a knowledge point listthrough a front / rear relation; S2, selecting to-be-tested knowledge points from the knowledge point list; S3, pushing test questions of the to-be-tested knowledge points to students, judging whether the students master the to-be-tested knowledge points or not, if so, skipping to S4, and if not, skipping to S6; S4, according to the knowledge point map, searching whether the to-be-tested knowledge point has a front knowledge point or not, if yes, skipping to S5, and if not, skipping to S7; S5, deleting the knowledge points to be tested and the front knowledge points thereof from the knowledge point list, and skipping to S7; S6, pushing the learning material of the test knowledge point to the students, and skipping to S3; and S7, re-selecting the knowledge points to be tested, and skipping tothe step S3 until the knowledge point list is empty. Repeated testing of the preposed knowledge points can be avoided, and the testing efficiency is improved.

Owner:SHANGHAI SQUIRREL CLASSROOM ARTIFICIAL INTELLIGENCE TECH CO LTD

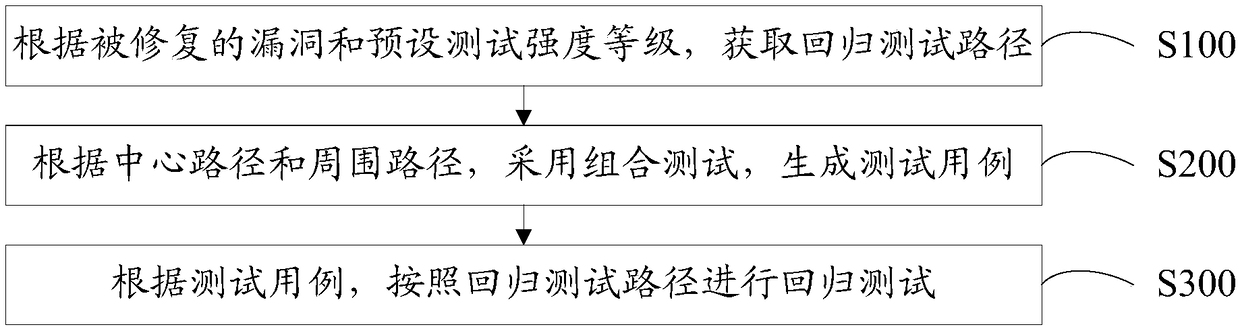

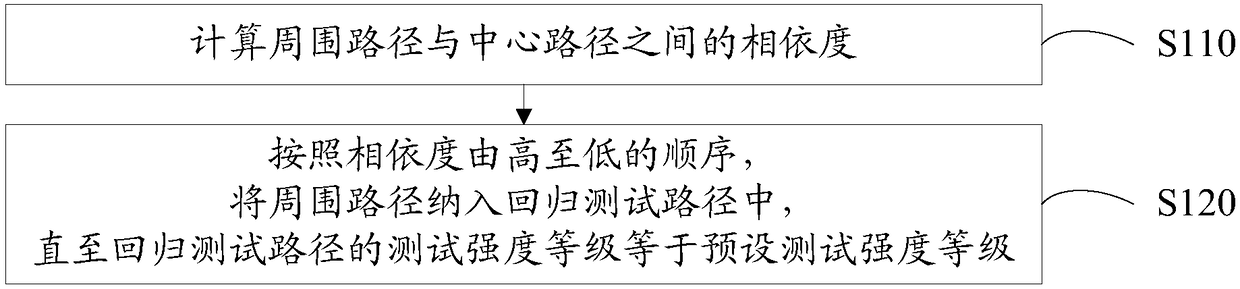

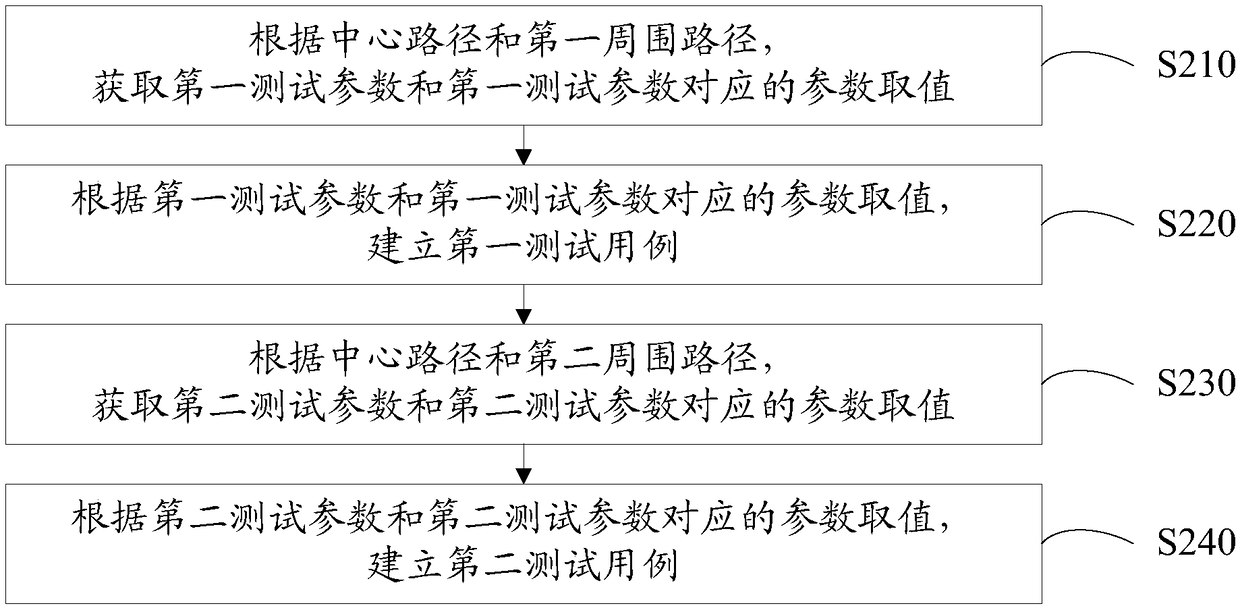

Regression testing method, equipment and device and computer readable storage medium

PendingCN108536600AReduce the numberGuarantee test reliabilitySoftware testing/debuggingRegression testingTest efficiency

The invention discloses a regression testing method. The regression testing method includes the following steps that according to repaired loopholes and the preset testing strength grade, regression testing paths are obtained, wherein the regression testing paths include the center path in which the repaired loopholes are located and the peripheral path of the repaired loopholes, and the peripheral path is determined according to the preset testing strength grade; according to the center path and the peripheral path, combination testing is adopted, and a testing use case is generated; according to the testing use case, regression testing is carried out according to the regression testing paths. The invention also discloses regression testing equipment, a regression testing device and a computer readable storage medium. According to the egression testing method, equipment and device and the computer readable storage medium, the testing reliability is guaranteed; meanwhile, testing efficiency is improved, and the testing cost is reduced.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

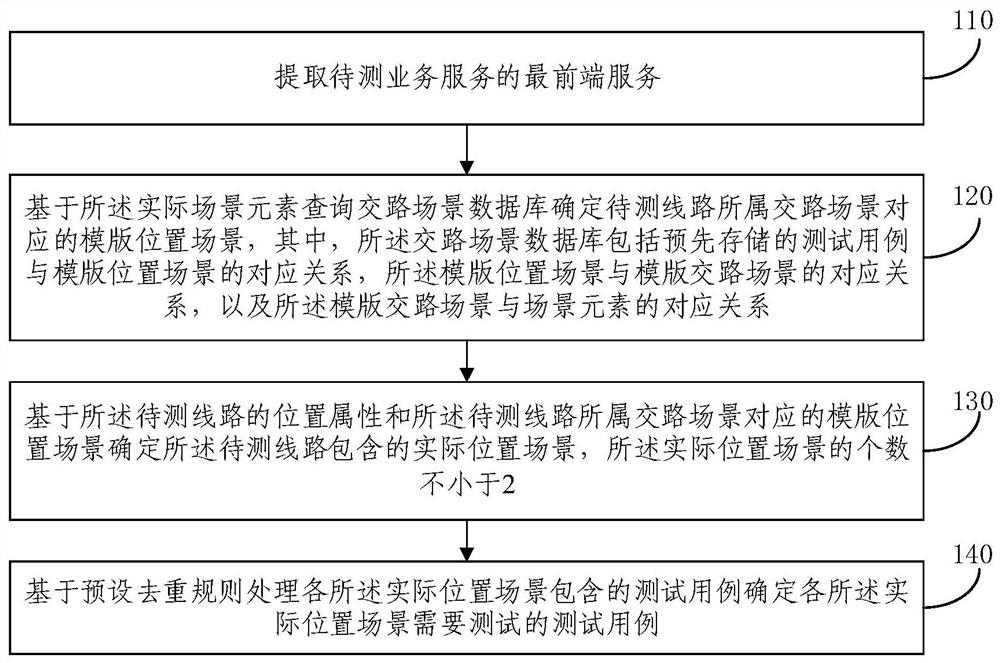

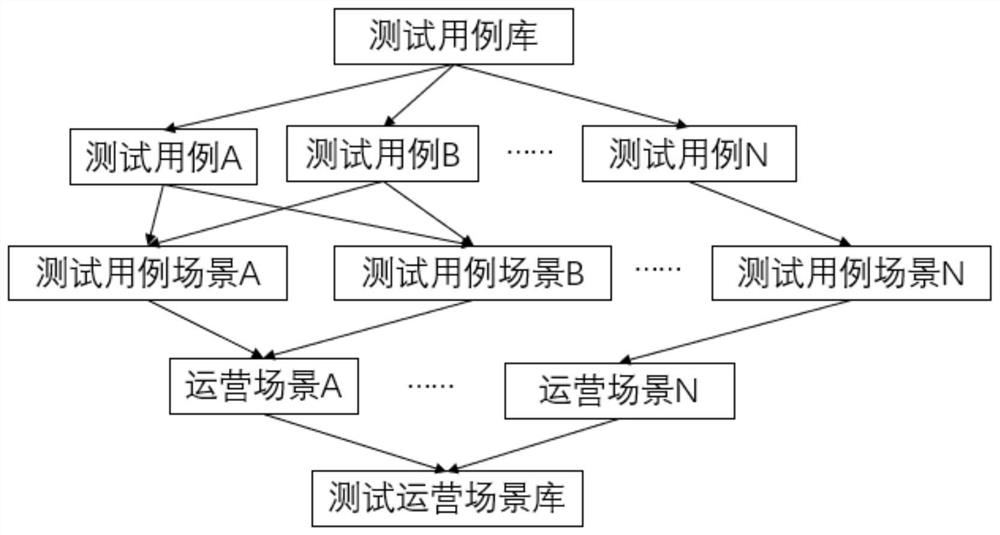

Test case layout method and device based on to-be-tested line intersection information

PendingCN112540928AAvoid duplication of testsImprove completion efficiencySoftware testing/debuggingAlgorithmEngineering

The invention provides a test case layout method and device based on to-be-tested line intersection information. The method comprises the following steps: extracting actual scene elements and positionattributes in the to-be-tested line intersection information; querying an intersection scene database based on the actual scene elements to determine a template position scene corresponding to the intersection scene to which the to-be-tested line belongs; determining an actual position scene contained in the to-be-tested line based on the position attribute of the to-be-tested line and a templateposition scene corresponding to the intersection scene to which the to-be-tested line belongs; and processing the test cases contained in each actual position scene based on a preset deduplication rule, and determining the test cases needing to be tested in each actual position scene, the intersection scene database comprising pre-stored template intersection scenes, template position scenes andcorresponding relationships among the test cases. According to the method and the device provided by the invention, the test task completion efficiency is improved, the task time consumption is reduced, and the waste of manpower and material resources caused by repeated test of the same test case in the same road crossing scene can be avoided.

Owner:TRAFFIC CONTROL TECH CO LTD

Air conditioning system filling parameter acquiring method and device

ActiveCN110816209ASave correction timeReliable data supportAir-treating devicesVehicle heating/cooling devicesEngineeringAir conditioning

The invention relates to the technical field of air conditioner filling, in particular to an air conditioning system filling parameter acquiring method and device. The method comprises the following steps that vacuum sensors and pressure sensors are arranged at joints and filling valves of air conditioning system pipelines; filling is carried out on multiple air conditioning systems separately through a quantitative filling method, and maximum pressure values and minimum pressure values of filling of the air conditioning systems are acquired; and normal distribution is performed on the acquired plurality of maximum pressure values and minimum pressure values separately, the filling pressure range is acquired, and the corresponding filling time range is acquired. According to the method anddevice, the reliable data support is provided for the early-stage filling process verification, repeated testing is avoided, and the parameter correcting time is saved.

Owner:DONGFENG MOTOR CORP HUBEI

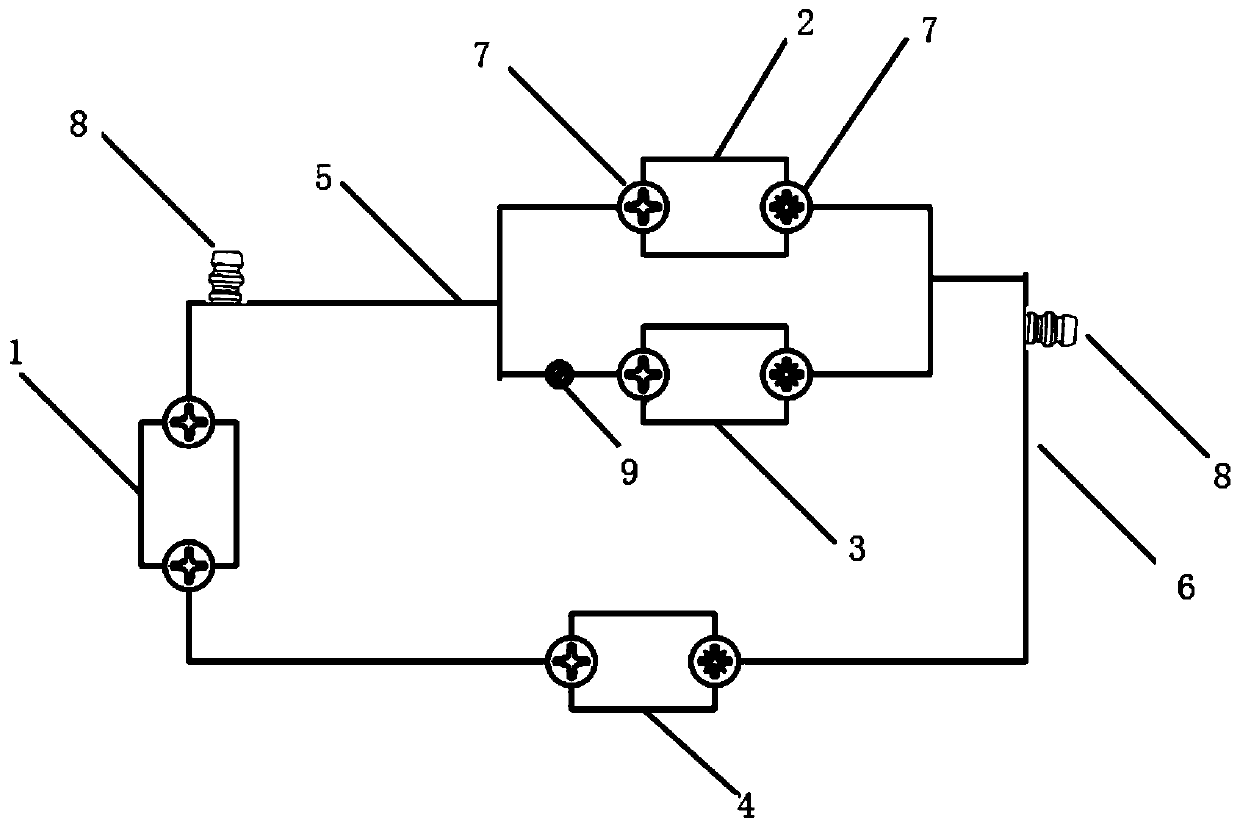

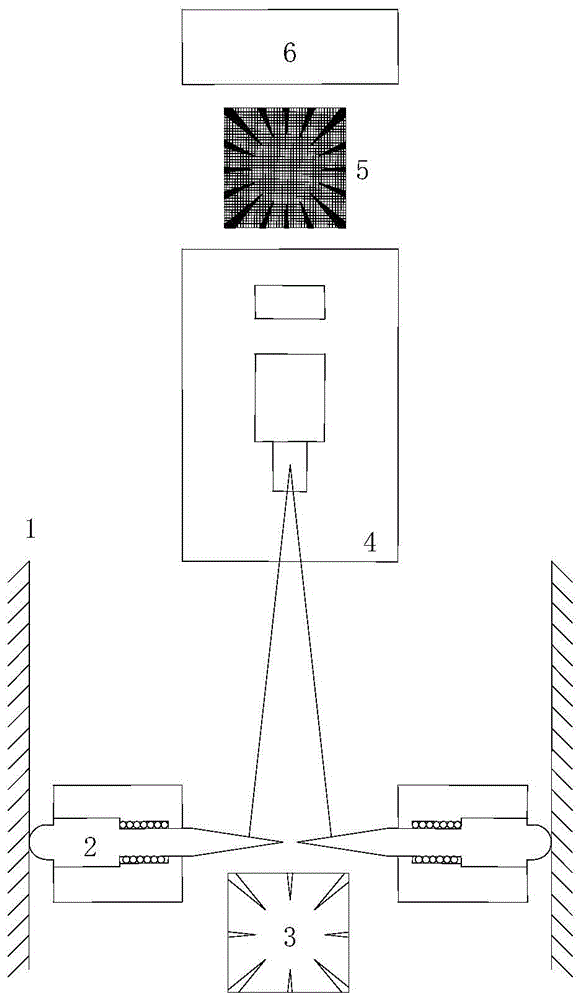

Auxiliary reading device for photoelectric sampler

InactiveCN106291444AImprove stabilityAvoid duplication of testsElectrical measurementsElectric energyMetallic materials

The invention discloses an auxiliary reading device for a photoelectric sampler. The auxiliary reading device comprises a support frame and a connector arranged on the support frame, wherein the connector is made from a metal material; a through hole is formed in the connector; a pulse signal can pass through the through hole. The auxiliary reading device provided by the invention can be used for assisting the photoelectric sampler in reading the real-time test data of an electric energy meter onsite calibrator; the connector is arranged for adsorbing the photoelectric sampler (generally containing magnetic material) to the connector when in use; the connector is arranged on the support frame, so that the photoelectric sampler adsorbed to the connector can be effectively supported by the support frame and cannot shake, the stability of reading work can be greatly improved and the repeated test can be avoided; a worker can grasp the working condition of the onsite equipment by analyzing data; the calibration time can be shortened; the safety risk of the worker by originally holding the photoelectric sampler by hand can be lowered.

Owner:ANQING POWER SUPPLY COMPANY OF STATE GRID ANHUI ELECTRIC POWER +1

An in-situ stress test method for optical microscopic measurement of aperture deformation

ActiveCN104279975BIntuitive and accurate aperture deformation measurementComprehensive dataForce measurement by measuring optical property variationUsing optical meansStress measurementTheory analysis

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

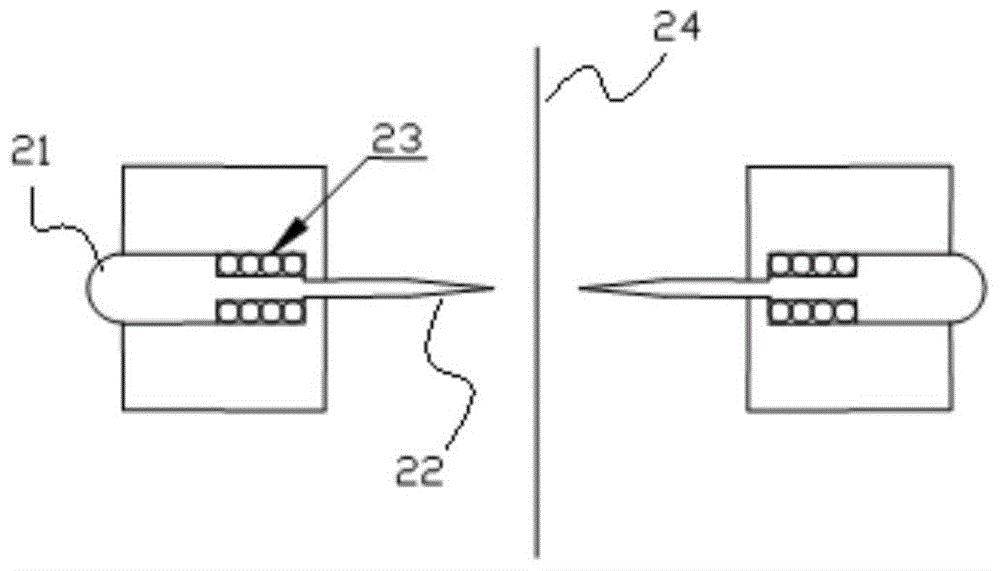

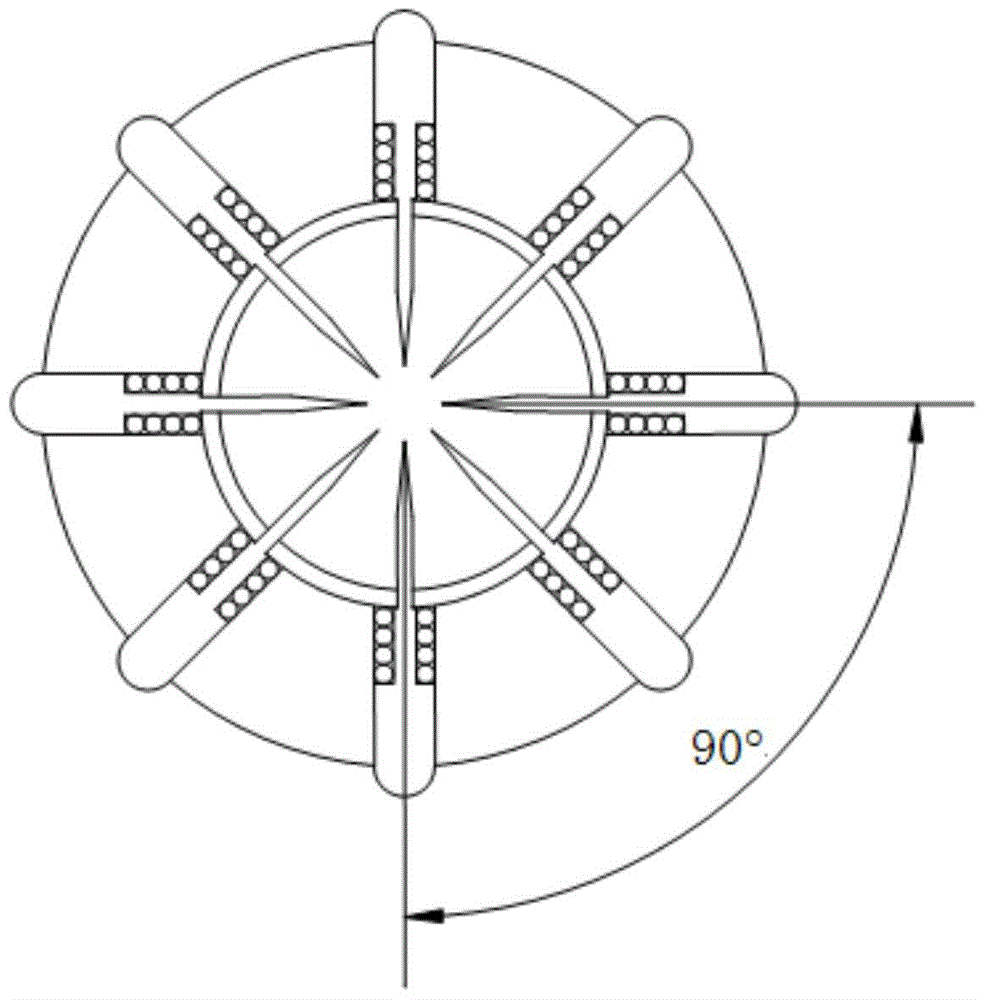

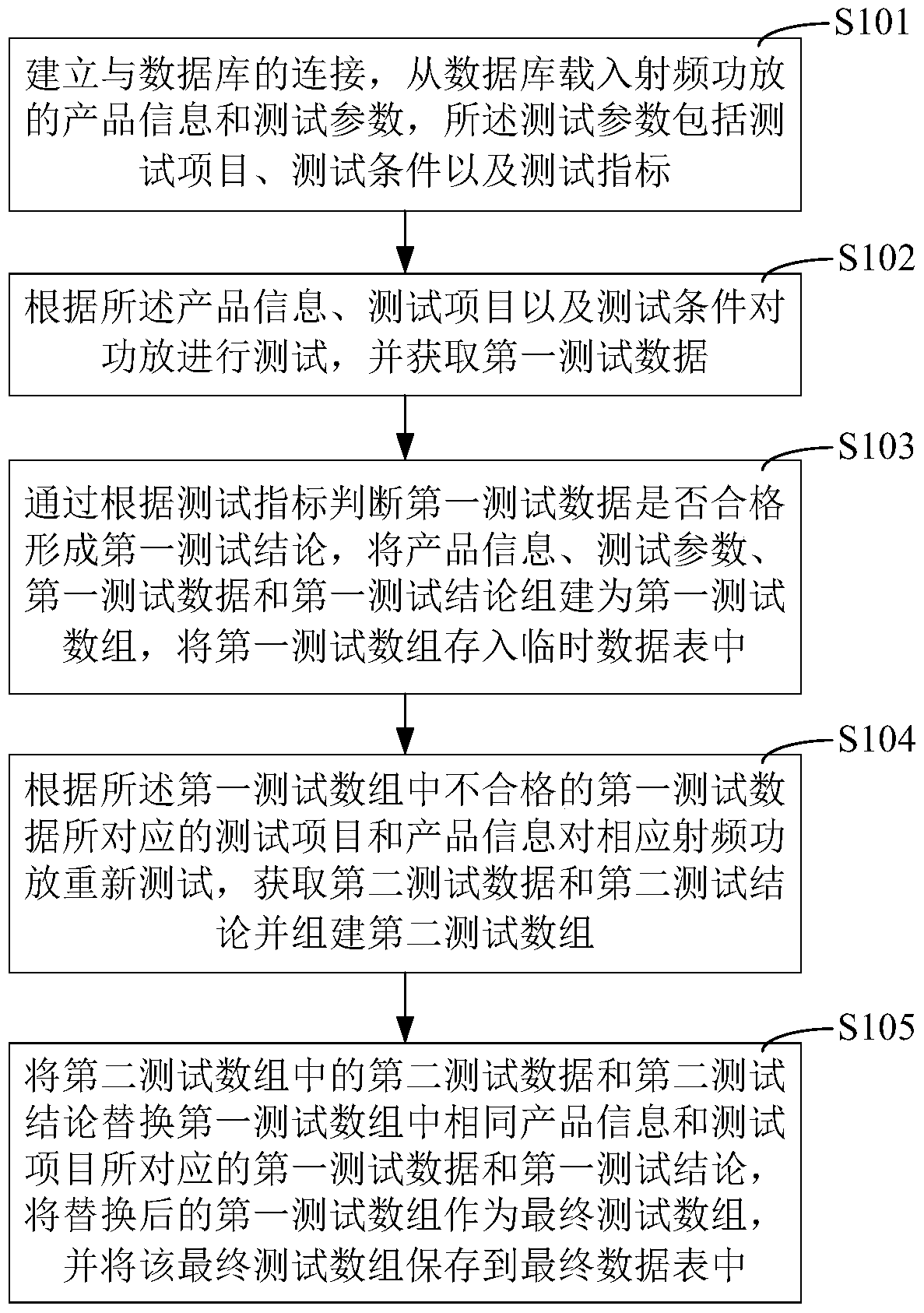

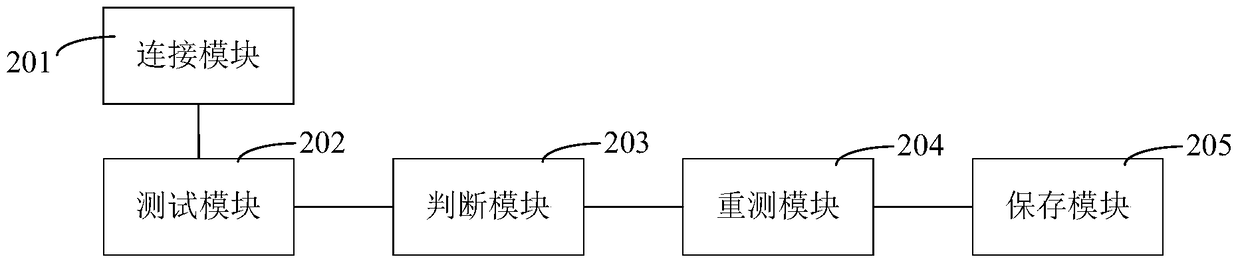

A test data management method and system for a radio frequency power amplifier

ActiveCN105306151BImprove test efficiencyReduce redundancyTransmission monitoringSpecial data processing applicationsTest efficiencyArray data structure

The invention discloses a method and a system for managing test data of a radio-frequency power amplifier. The method comprises the following steps of establishing a connection with a database and loading product information and test parameters of the radio-frequency power amplifier; testing the power amplifier and obtaining first test data; judging whether the test data is qualified according to a test index, forming a text conclusion and screening unqualified test items in the test conclusion; retesting the test items and obtaining second test results; combining the second test results into a first test result; and lastly, taking a first replaced test array as a final test array and storing the final test array. When the radio-frequency power amplifier is retested, the unqualified test items are tested only, so that the repeated test of the qualified test items is avoided, and thus the test time is saved and the test efficiency of the radio-frequency power amplifier is improved. In addition, a second test array is combined into the first test array rather than be independently stored, so that the repeated storage of the test array of one product is avoided, and thus redundancy of a data table is reduced.

Owner:COMBA TELECOM SYST CHINA LTD

A fuzz testing method, device and system

ActiveCN112052156BAvoid duplication of testsImprove test efficiencySoftware testing/debuggingFuzzy logic based systemsTest efficiencyAlgorithm

The present application relates to a fuzz testing method, device and system. The method includes: using the state machine coverage rate and the execution frequency data of the state machine coverage rate as parameters of the energy distribution algorithm, and selecting the DOM format to be mutated seed data; DOM format mutation data; input the DOM format mutation data into the machine under test to obtain a test execution result; wherein the test execution result includes the execution log of the machine under test. Using this method can improve the test efficiency.

Owner:浙江木链物联网科技有限公司

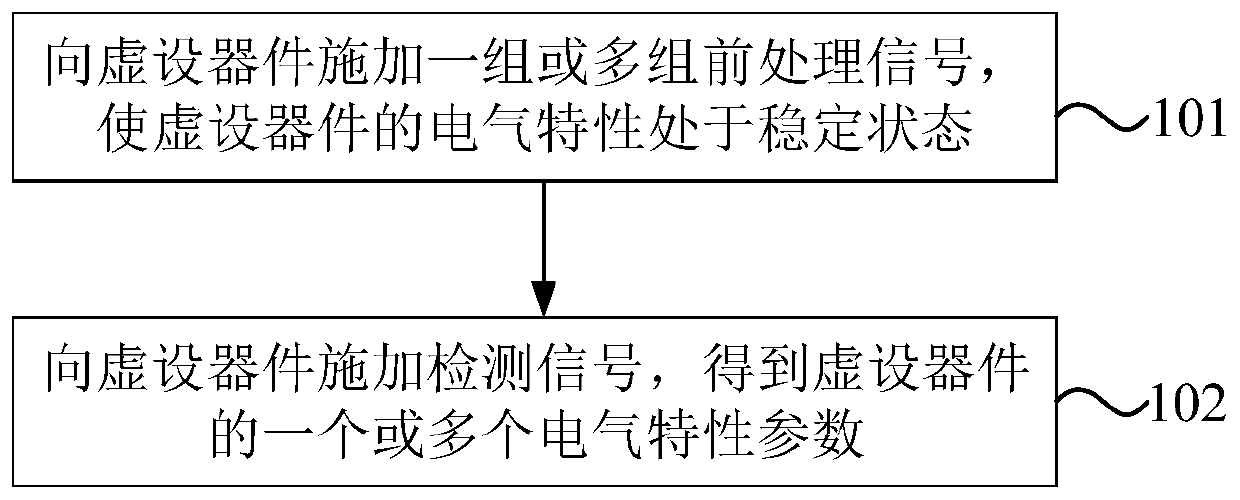

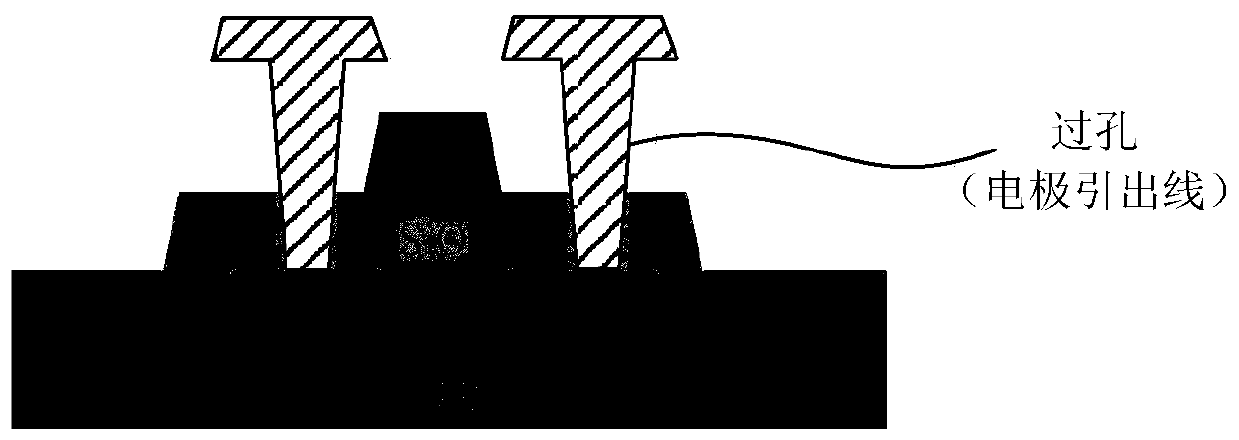

Screen body dummy device detection method and device

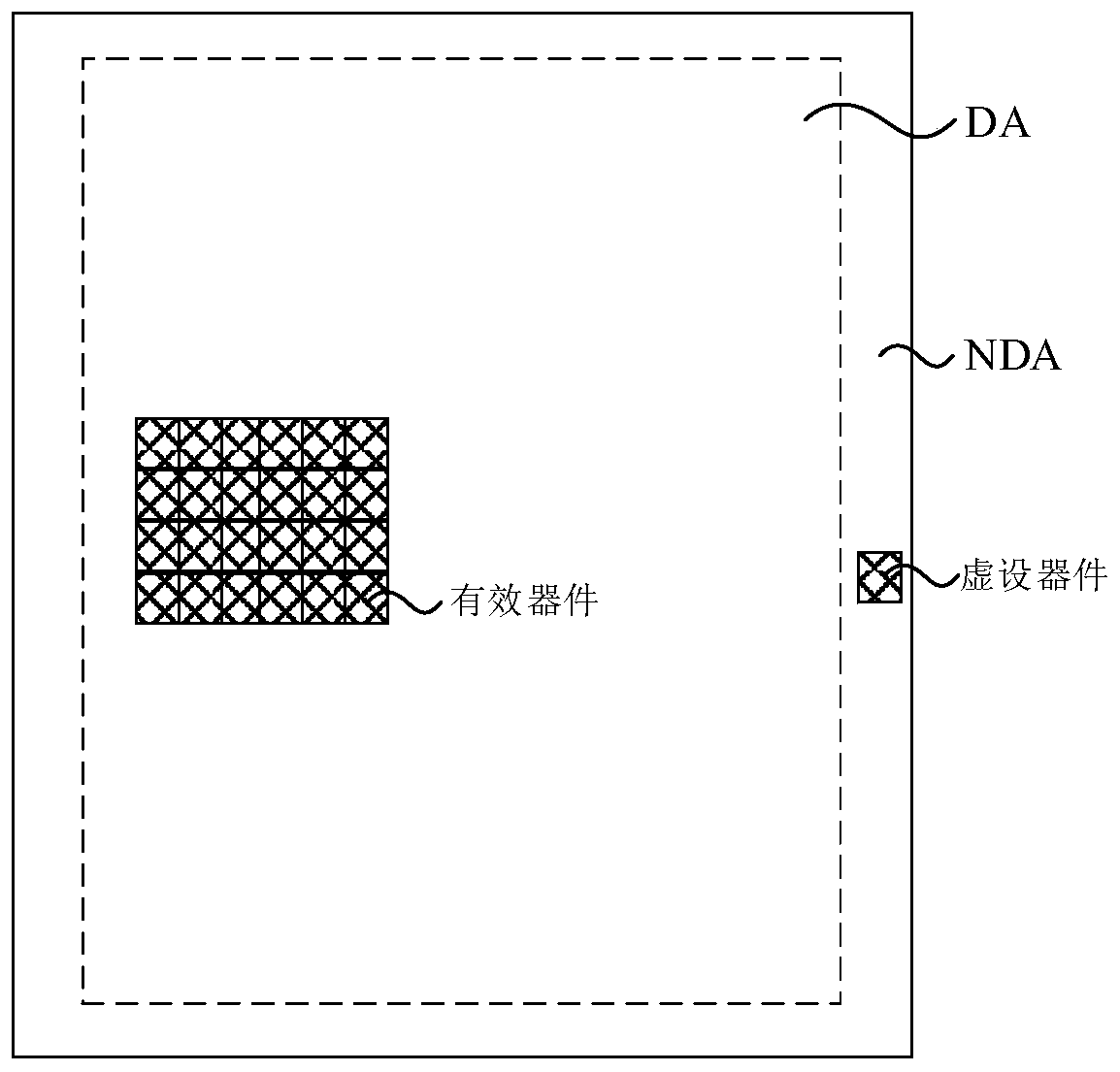

ActiveCN110379347AImprove accuracy and precisionAvoid duplication of testsStatic indicating devicesRepeat testingStable state

The invention discloses a screen body dummy device detection method and device. The method comprises the following steps: applying one or more groups of preprocessing signals to a dummy device to enable the electrical characteristics of the dummy device to be in a stable state; and applying a detection signal to the dummy device to obtain one or more electrical characteristic parameters of the dummy device. By adopting the technical scheme of the embodiment of the invention, the electrical characteristics of the dummy device can be stabilized, the precision and accuracy of detection data are improved, and repeated testing is avoided.

Owner:YUNGU GUAN TECH CO LTD

An optical microscopic stress measurement device based on the principle of aperture deformation

ActiveCN104279976BIntuitive and accurate aperture deformation measurementComprehensive dataForce measurement by measuring optical property variationUsing optical meansMicro imagingStress measures

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Method of recovering tsk series probe station map by using test data

ActiveCN105067984BBack to work made easyAvoid duplication of testsIndividual semiconductor device testingReference mapTest requirements

The present invention relates to a method for recovering TSK series probe station MAP by using test data, which comprises the following steps: step 1, generating a recovery reference map corresponding to the test data according to the test data; step 2, according to the Complete the MAP diagram of the complete test to adjust the restoration reference diagram generated above, and restore the reference diagram to form an adjustment restoration diagram after adjustment; Step 3, utilize the adjustment restoration diagram after setting the die test attribute to generate a restoration MAP diagram; Step 4, when When the XY coordinates of the die in the restored MAP map are consistent with the XY coordinates of the die in the restored reference map, it is determined that the restoration of the MAP map according to the test data is successful; otherwise, adjust the XY coordinates of the die in the test data and repeat the above steps until it is determined The MAP is successfully restored based on the test data. The invention avoids the repeated testing of wafers, greatly reduces the possible quality risk caused by repeated testing, can meet the strict testing requirements of some special industries, and is safe and reliable.

Owner:WUXI ZHONGWEI TENGXIN ELECTRONICS

An automatic test template of relay protection device based on d-s evidence theory

ActiveCN108548970BImprove intelligenceAvoid duplication of testsElectrical testingTest efficiencyAlgorithm

The invention discloses a relay protection device automatic testing template based on a D-S evidence theory. The method comprises the following steps of (1), in a protection base module database, acquiring the parameter of each protection base module; (2), determining whether the same parameter exists among the base modules according to the D-S evidence theory, if yes, keeping one same parameter and combining the parts with the same parameter; after combination, if no same parameter exists, keeping the respective parameters for performing splicing combination; (3), after splicing, successivelyexpanding the testing items for testing; and (4), after testing, automatically generating a protection testing report. The relay protection device automatic testing template according to the invention is based on module splicing of the D-S evidence theory has advantages of preventing repetitive testing, improving testing efficiency, and laying a basis for intelligentization and automation improvement of the whole set of automatic testing system.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +6

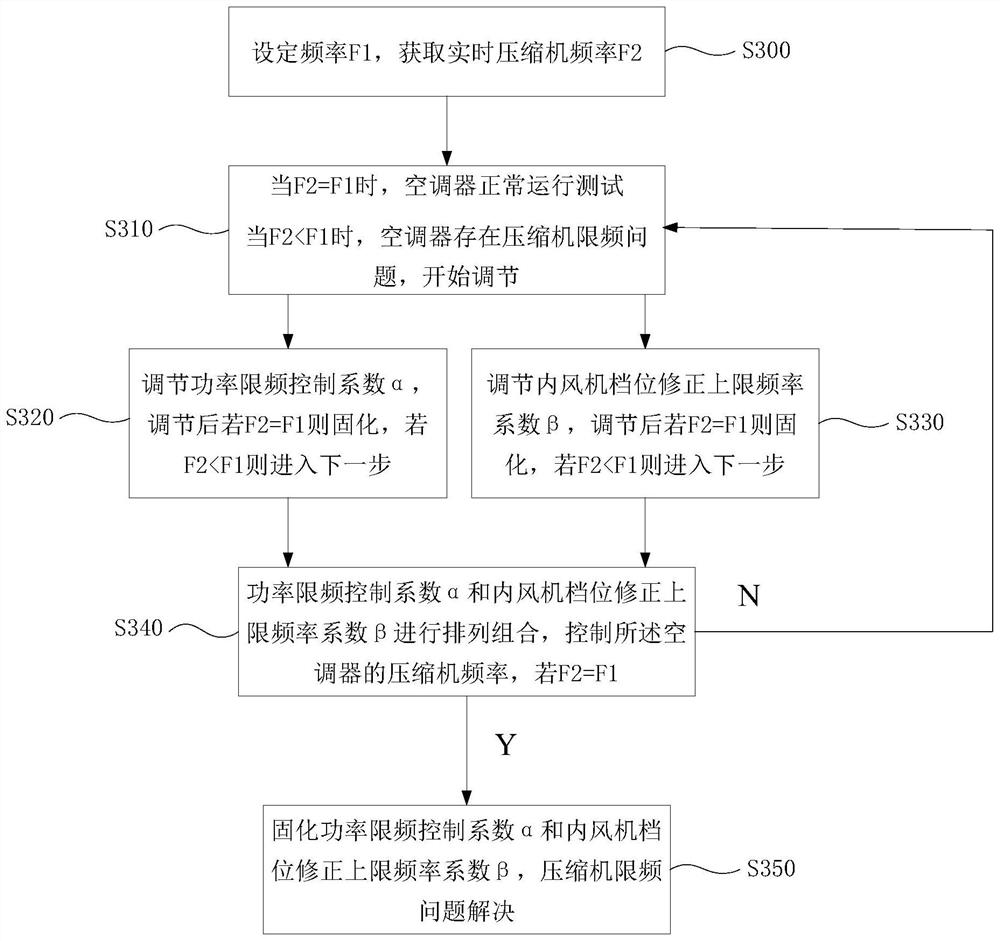

Air conditioner, control method and device of air conditioner and readable storage medium

PendingCN114264031AReduce operational misjudgments and time costsImprove regulation efficiencyMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringMechanical engineering

The invention provides an air conditioner, a control method and device of the air conditioner and a readable storage medium. The method comprises the steps that in the system testing process of the air conditioner, under the condition that the compressor frequency limiting problem exists in the air conditioner, the compressor frequency of the air conditioner is controlled by adjusting frequency related parameters of the air conditioner; wherein the frequency related parameters comprise a power frequency limiting control coefficient alpha and / or an inner fan gear correction upper limit frequency coefficient beta. The problem that the frequency limiting problem of the compressor of the air conditioner cannot be effectively adjusted according to the technical scheme in the related technology is solved.

Owner:NINGBO AUX ELECTRIC +1

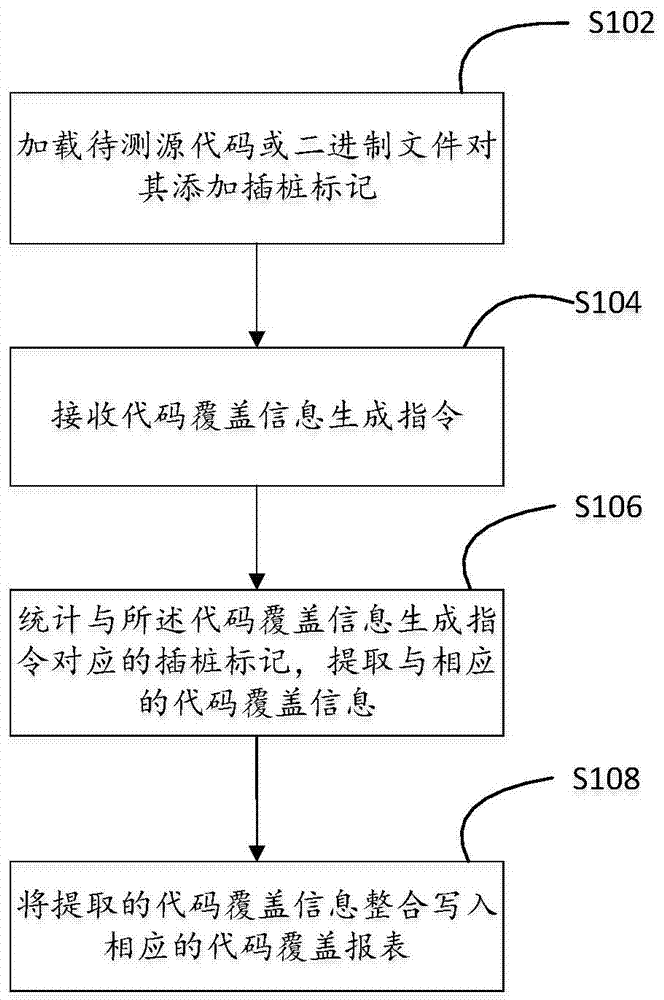

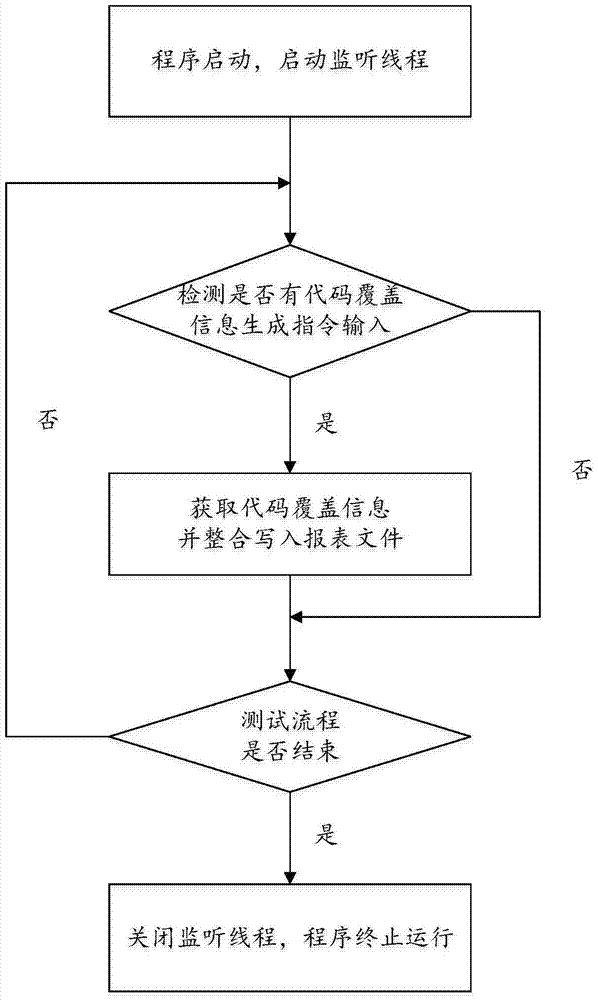

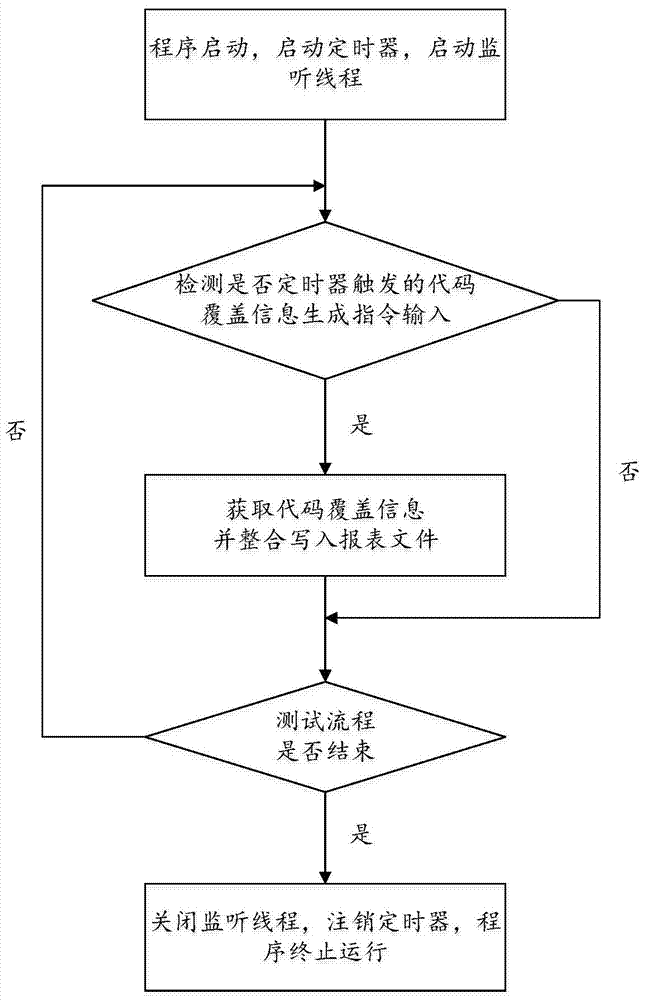

Method and device for obtaining code coverage information

ActiveCN104199773BAvoid duplication of testsImprove test efficiencySoftware testing/debuggingTest efficiencyCode coverage

A method for obtaining code coverage information comprises the steps that source codes or binary files to be tested are loaded, and instrumentation marks are added to the source codes or binary files to be tested; code coverage information generating instructions are received; the instrumentation marks corresponding to the code coverage information generating instructions are counted, and corresponding code coverage information is extracted; the extracted code coverage information is integrated and written into a corresponding code coverage report. In addition, the invention provides a device for obtaining the code coverage information. The method and device for obtaining the code coverage information can avoid a repeated testing process, and thus testing efficiency is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

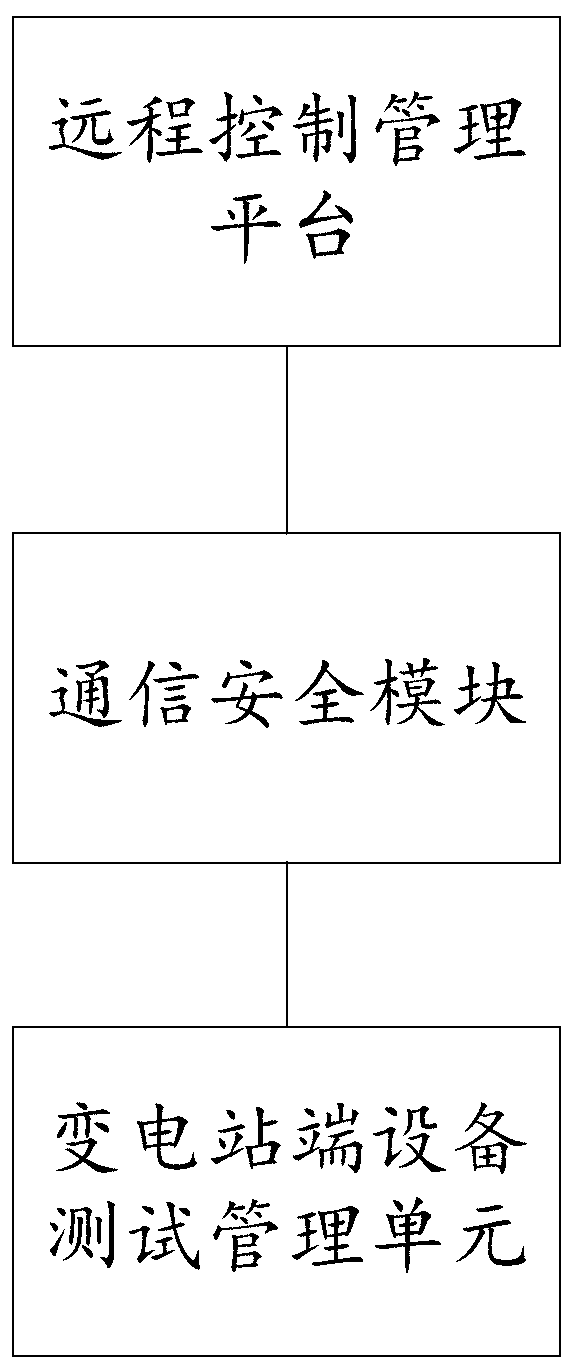

Remote test system substation automation equipment capable of being controlled and intervened freely

InactiveCN110058583ATest GuaranteeImprove test qualityCircuit arrangementsElectrical testingCommunications securityRemote control

The invention discloses remote test system substation automation equipment capable of being controlled and intervened freely, which comprises a substation end equipment test management unit, a remotecontrol management platform and a communication safety module, and provides a function of intervention control in a remote test process through a safety communication channel. The test case parameterscan be remotely edited, and the test cases and the test tasks can be remotely issued to the station side. The process and intermediate results are tested at a remote monitoring station. The start, stop and recovery of the test in a remote substation can be remotely controlled. The test flow can be observed at a remote end, the test process can be monitored, and remote guidance can be provided. The test result is automatically uploaded to a remote control management platform for unified management, and scientific analysis and statistics are carried out on the test result. By the system, the problems that test cases are not unified, the test process is uncontrollable and the test result cannot be traced and analyzed are solved, and the investment of a considerable amount of testers is saved.

Owner:GUANGDONG POWER GRID CO LTD +1

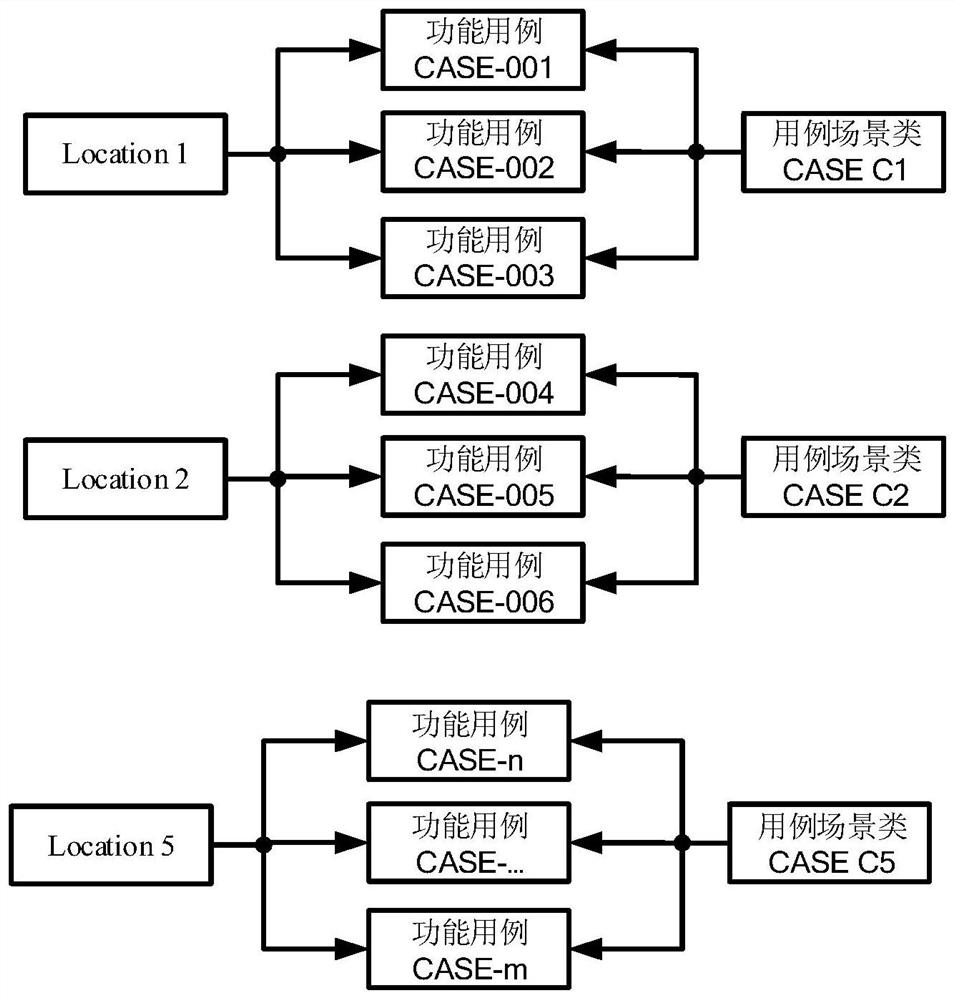

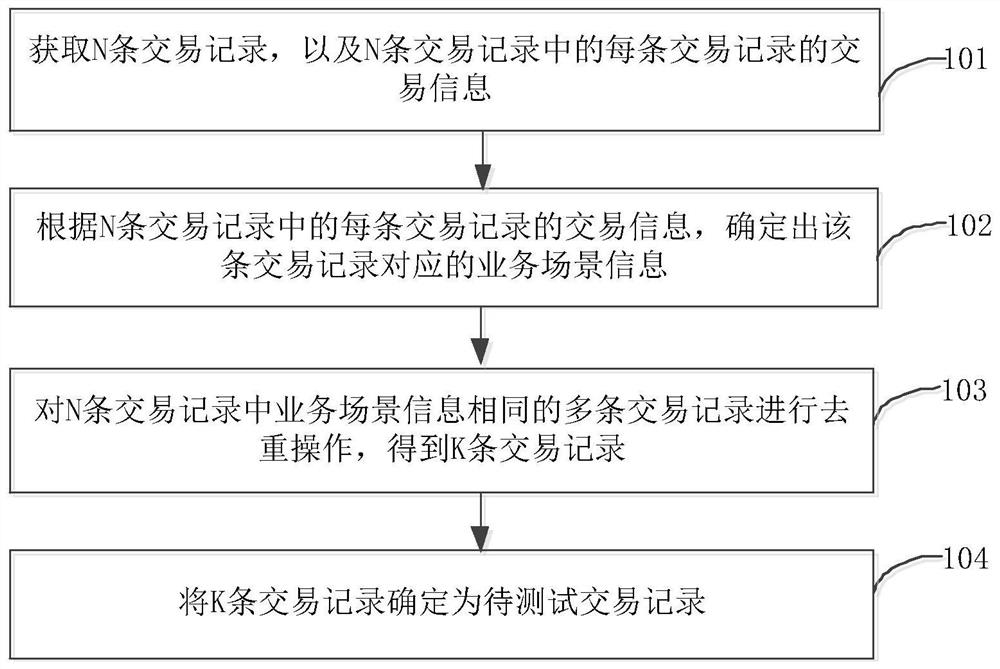

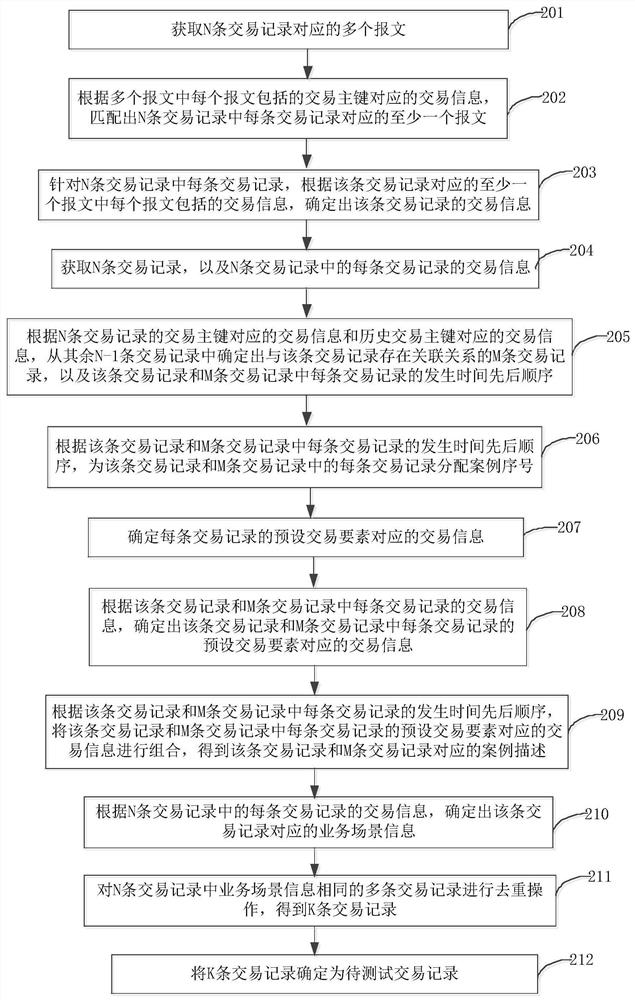

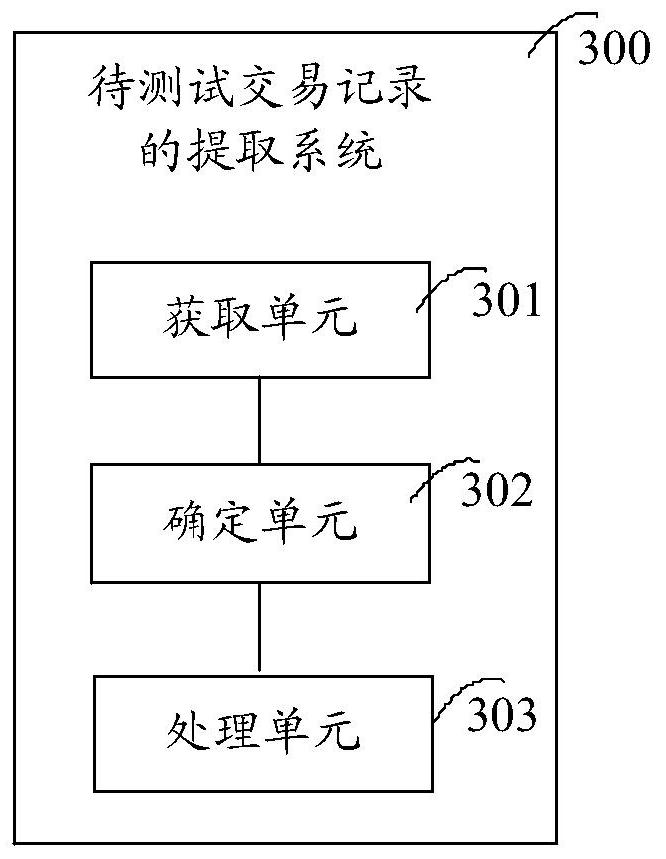

A method and device for extracting transaction records to be tested

ActiveCN106803202BAvoid duplication of testsImprove test efficiencyFinanceSoftware testing/debuggingTest efficiencyEngineering

The embodiments of the present invention relate to the communication field, and in particular to a method and device for extracting transaction records to be tested, so as to improve test efficiency. In the embodiment of the present invention, N transaction records and the transaction information in the N transaction records are obtained; N is an integer greater than 1; according to the transaction information of each transaction record in the N transaction records, it is determined that the transaction record corresponds to business scenario information; deduplicate multiple transaction records with the same business scenario information among the N transaction records, and obtain K transaction records; K is an integer greater than or equal to 1 and less than or equal to N; determine the K transaction records It is the transaction record to be tested. Due to the deduplication operation on the transaction records with the same business scenario in the obtained N transaction records, the transaction records to be tested do not include the transaction records of the same business scenario, and then the test transaction records to be tested can avoid duplication of the same business scenario Test questions and improve test efficiency.

Owner:CHINA UNIONPAY

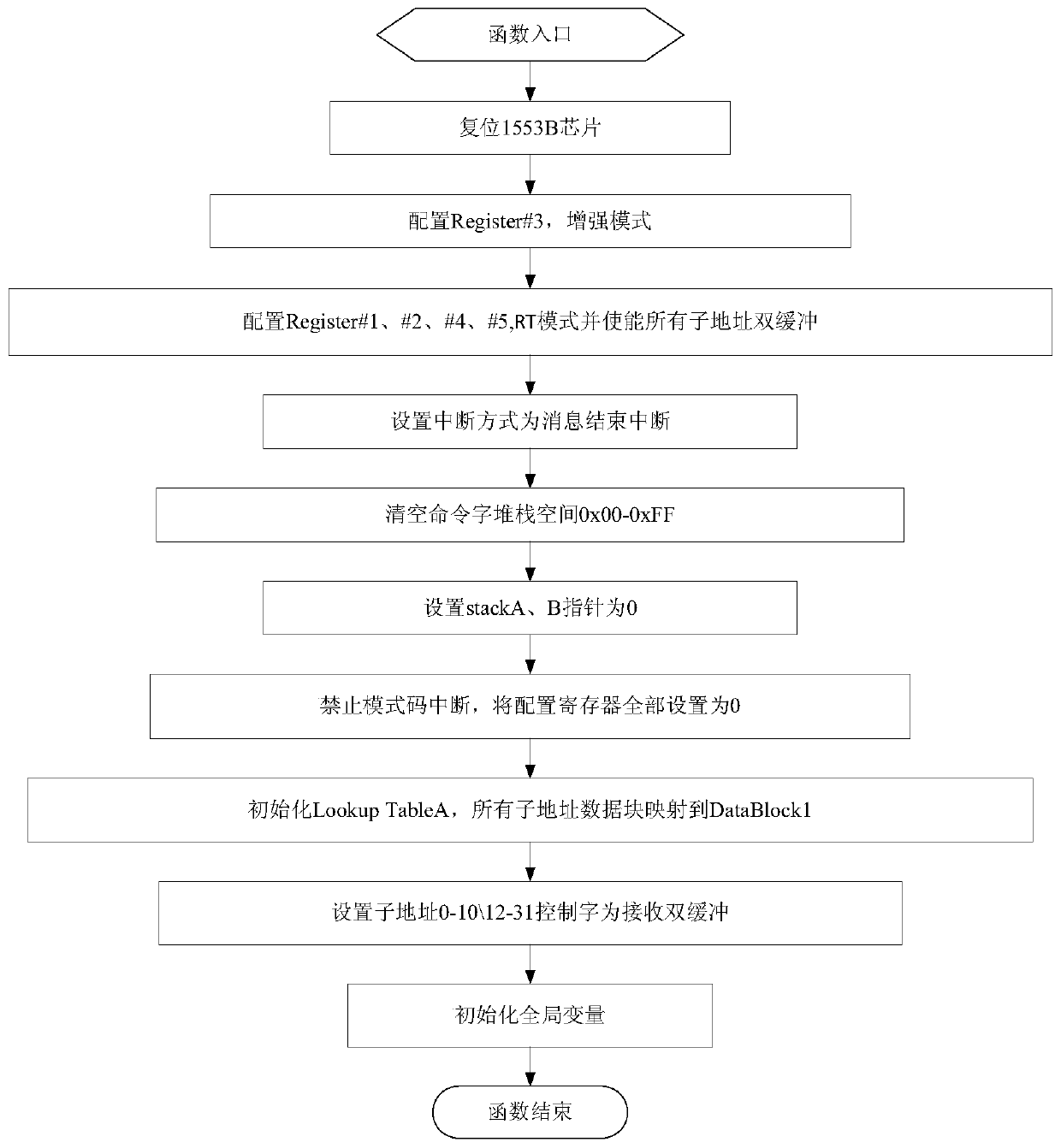

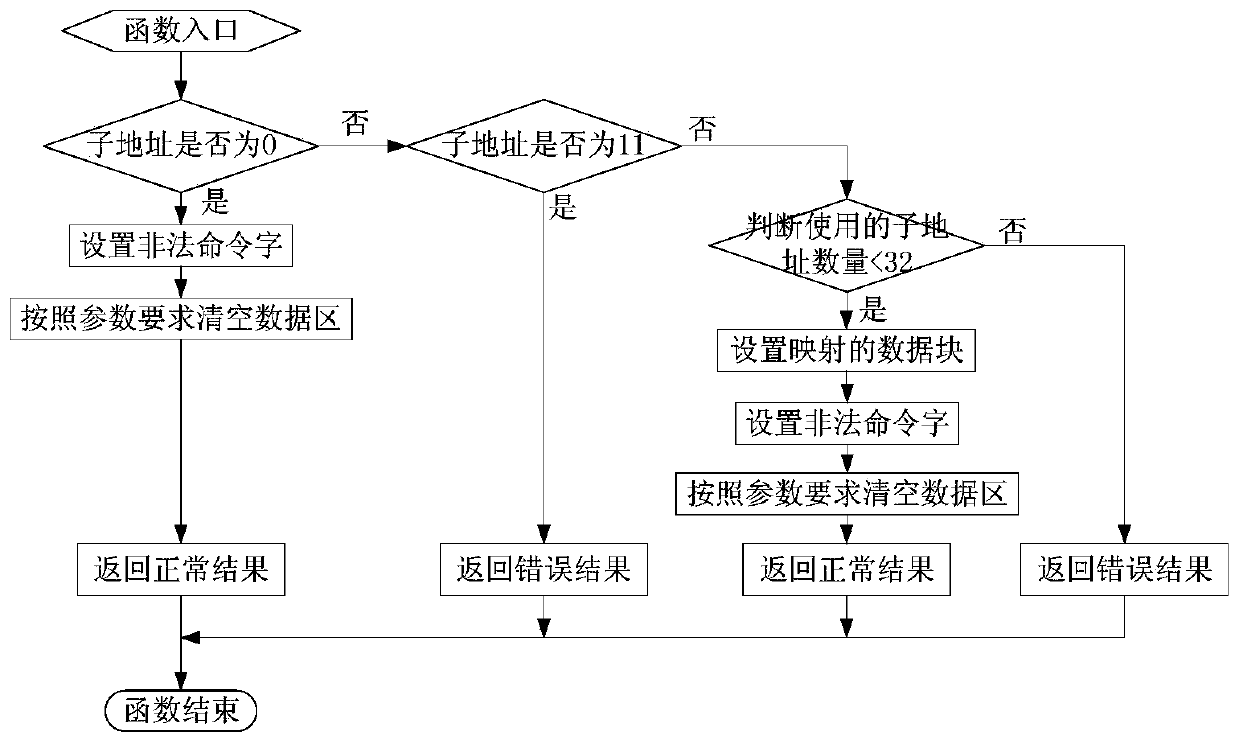

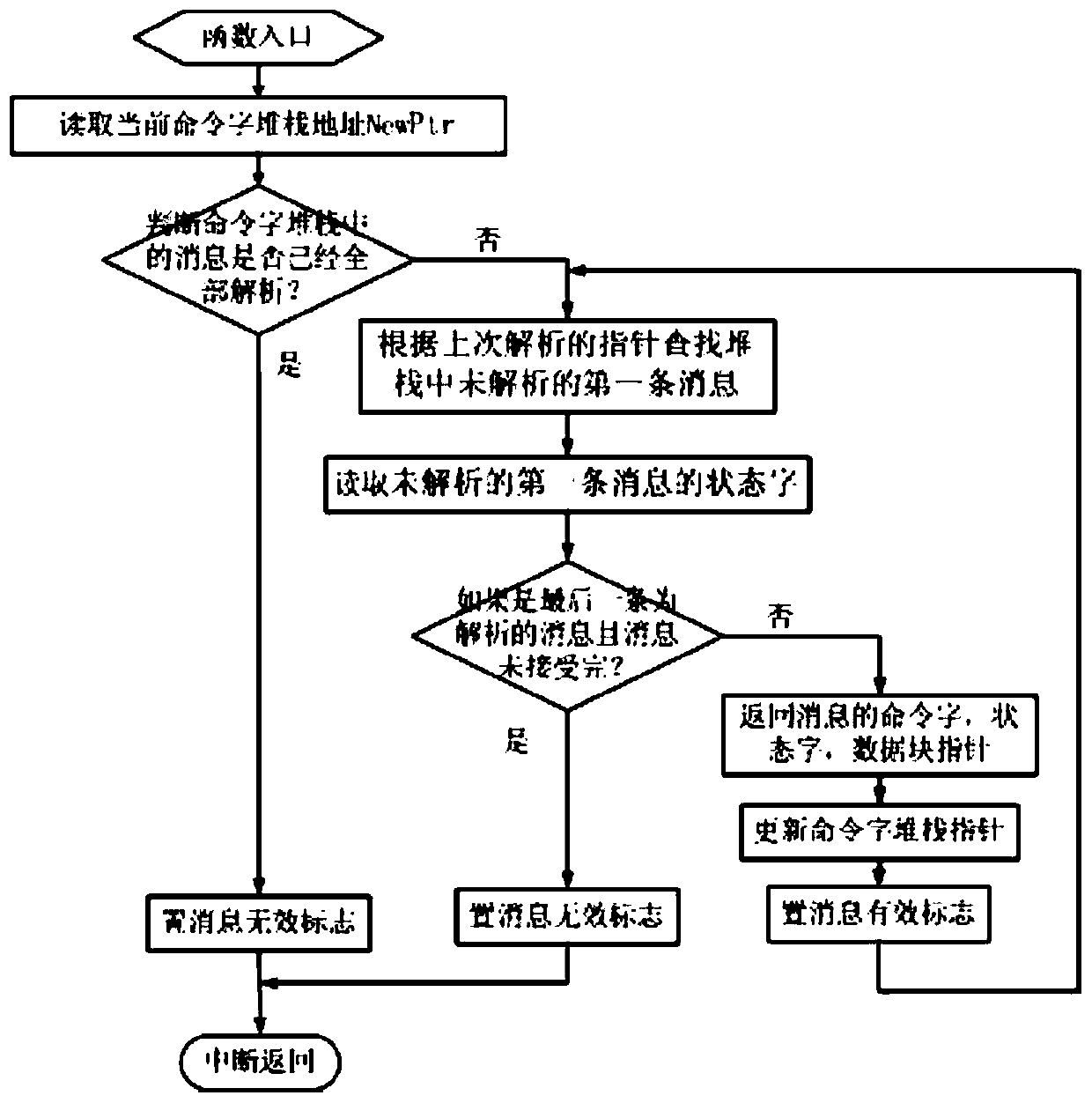

A 1553B bus productization assembly

InactiveCN109815179AEnsure development qualityImprove reliabilityElectric digital data processingEmbedded systemComputer architecture

The invention discloses a 1553B bus productization assembly. According to the 1553B bus communication module, the general part in the 1553B communication process is packaged by the component, and a differential configuration interface is reserved, so that developers only need to call the component and carry out differential configuration with different requirements through the configuration interface, and the configuration of the 1553B bus communication module can be realized. The 1553B communication development cycle can be greatly shortened, and the working stability and reliability of the 1553B communication development cycle can be improved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Optical module test method

ActiveCN103001693BAvoid duplication of testsImprove test efficiencyTransmission monitoring/testing/fault-measurement systemsOptical ModuleSerial code

Owner:SOURCE PHOTONICS CHENGDU

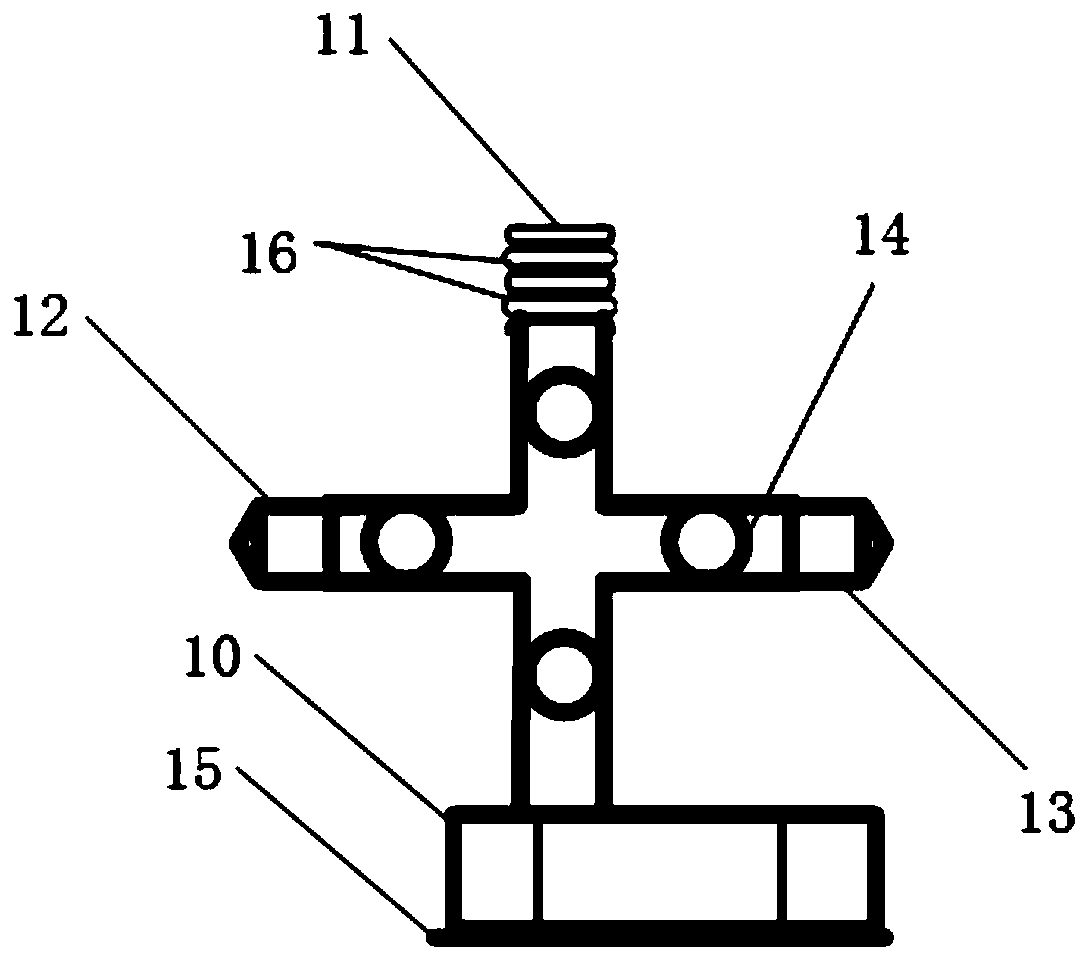

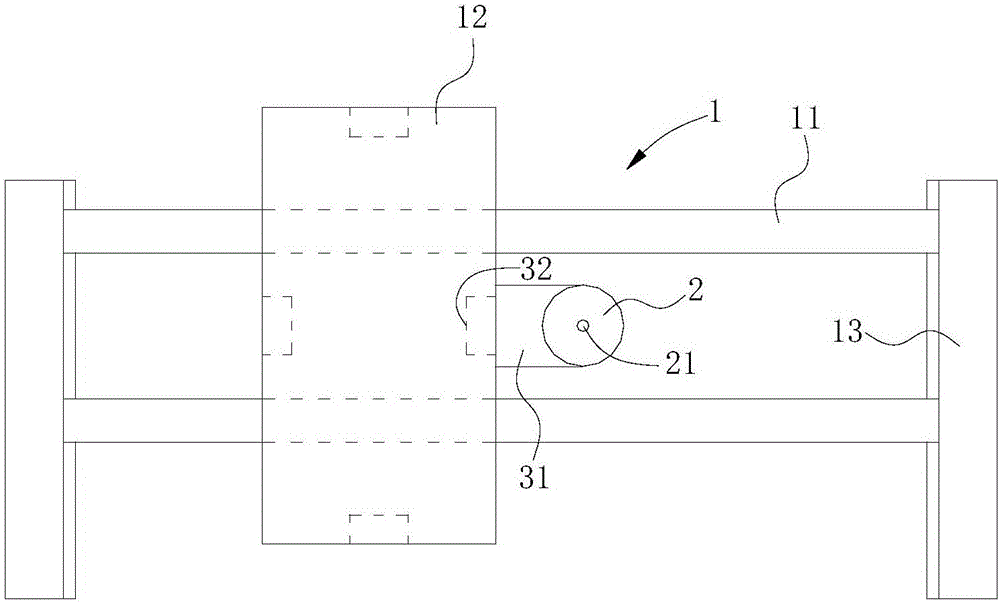

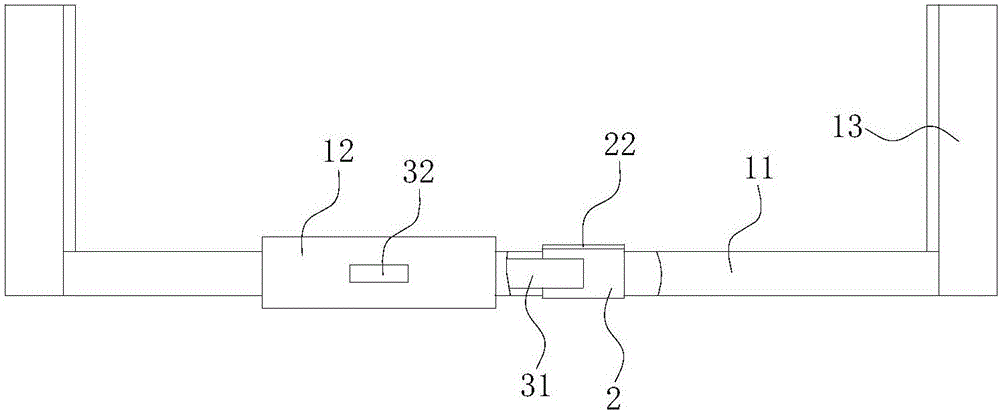

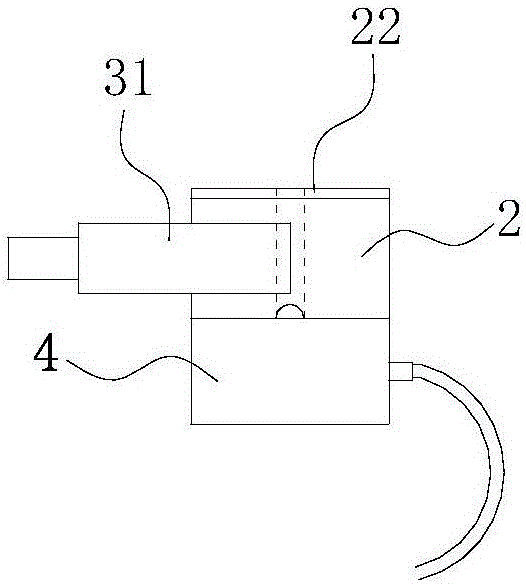

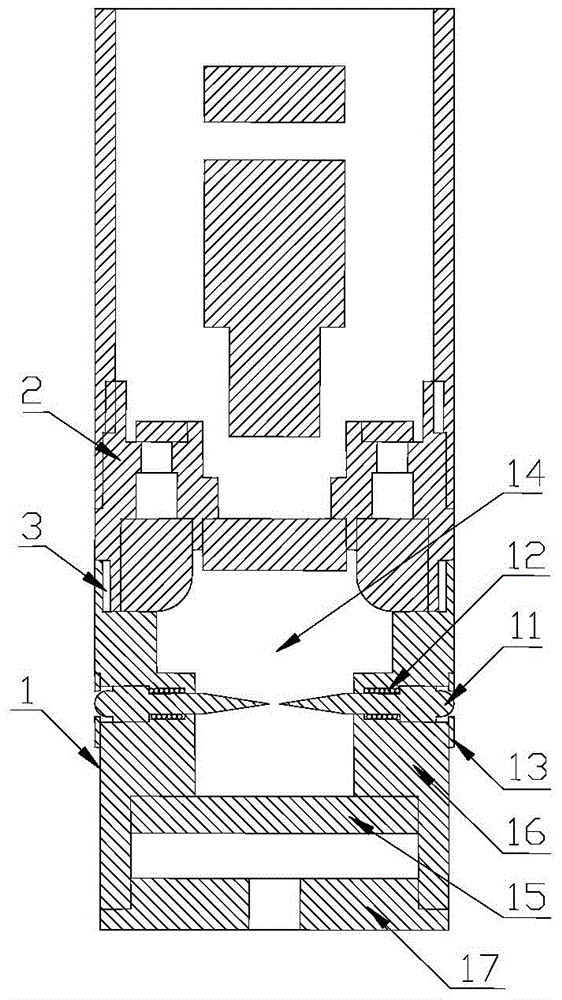

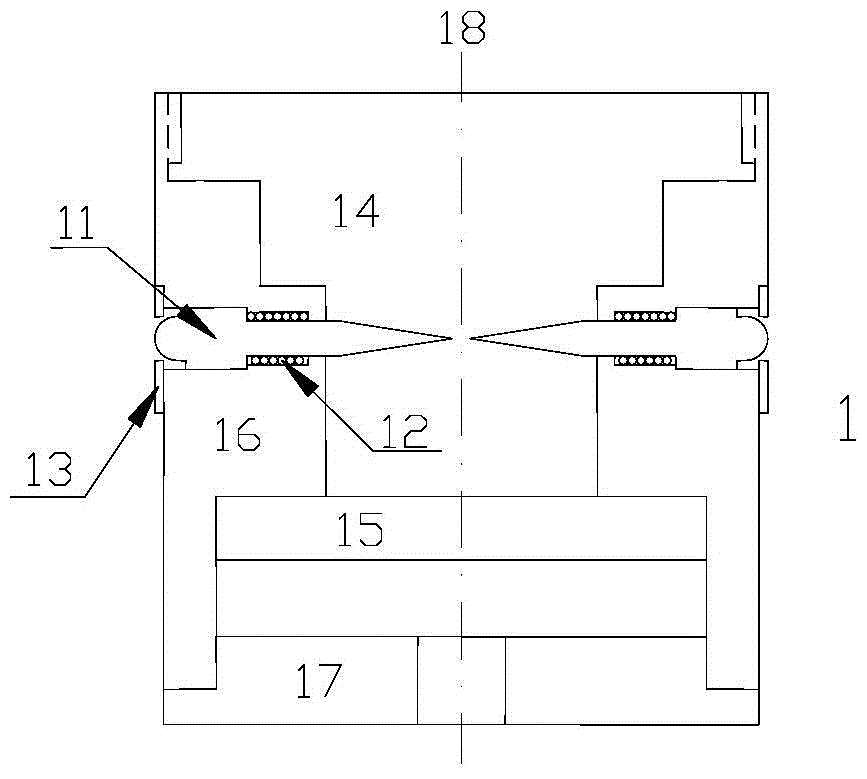

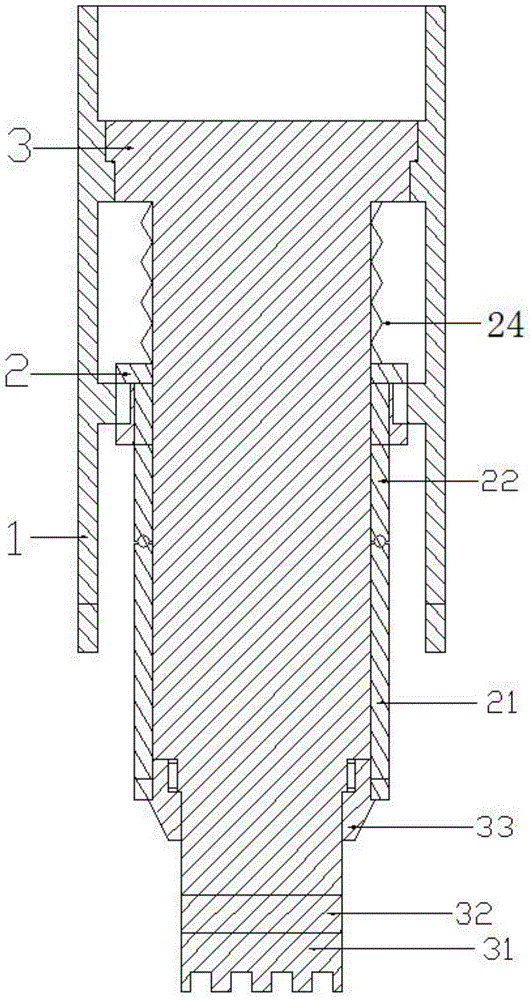

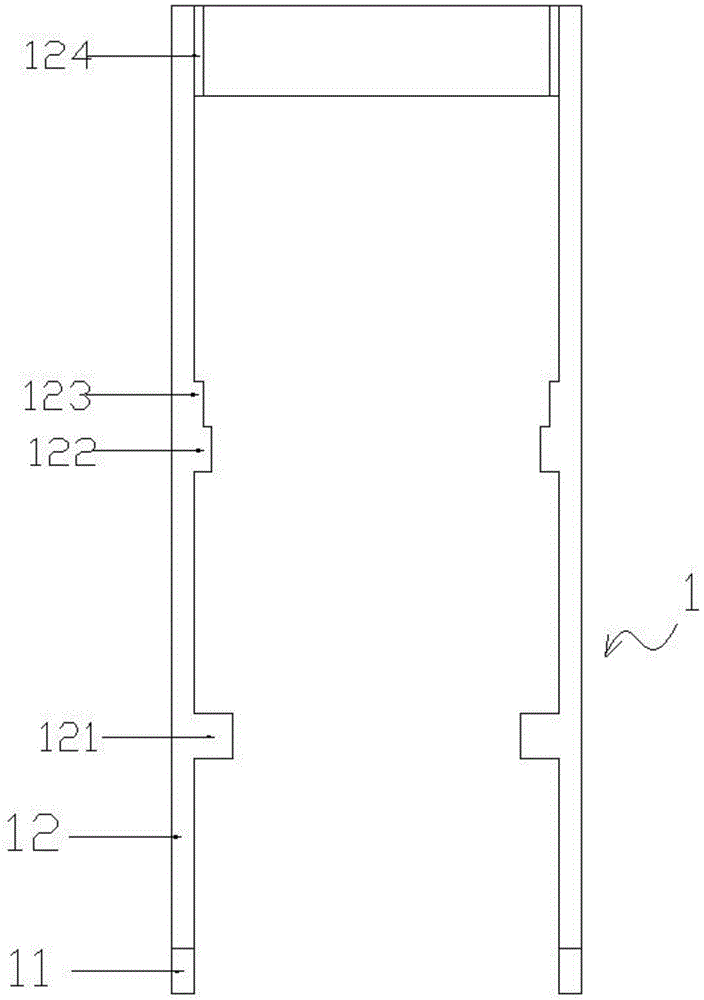

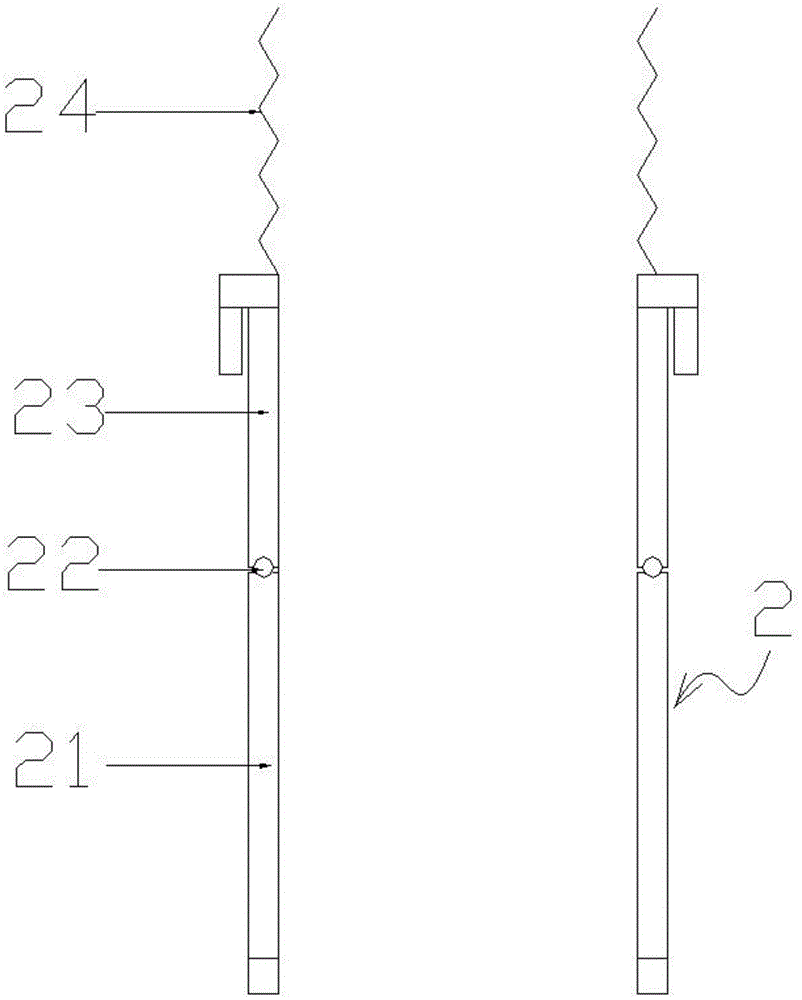

A Drilling and Measuring Integrated Device Based on Stress Relief Method

ActiveCN105507876BRealize integrationSimple mechanical structureSurveyDrilling machines and methodsStress reliefIntegrated devices

The invention discloses a drilling and measuring integrated device based on a stress relief method. The drilling and measuring integrated device comprises a tubular relief hole drill bit part, a breakaway control part and a measuring hole drill bit part. The relief hole drill bit part comprises a tubular drill rod, transmission teeth are arranged on the inner side of the drill rod, a relief hole drill bit is arranged at the bottom of the drill rod, the measuring hole drill bit part comprises a columnar shell, an upper sleeve of the shell is provided with an annular positioning portion while the bottom of the same is provided with a measuring hole drill bit, a wedge-shaped drill bit sleeves the upper portion of the measuring hole drill bit and comprises a tubular connecting column and a conical head below the connecting column, the breakaway control part comprises a limiting ring, an upper limiting plug-pin and a short limiting plug-pin, and the upper limiting plug-pin and the short limiting plug-pin are arranged on the limiting ring. By the drilling and measuring integrated device, drilling and measuring integration can be realized, the problem that the stress relief method is complex in operation process and low in measuring depth is solved, testing capability is improved remarkably, and requirements on testing environment are lowered remarkably.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

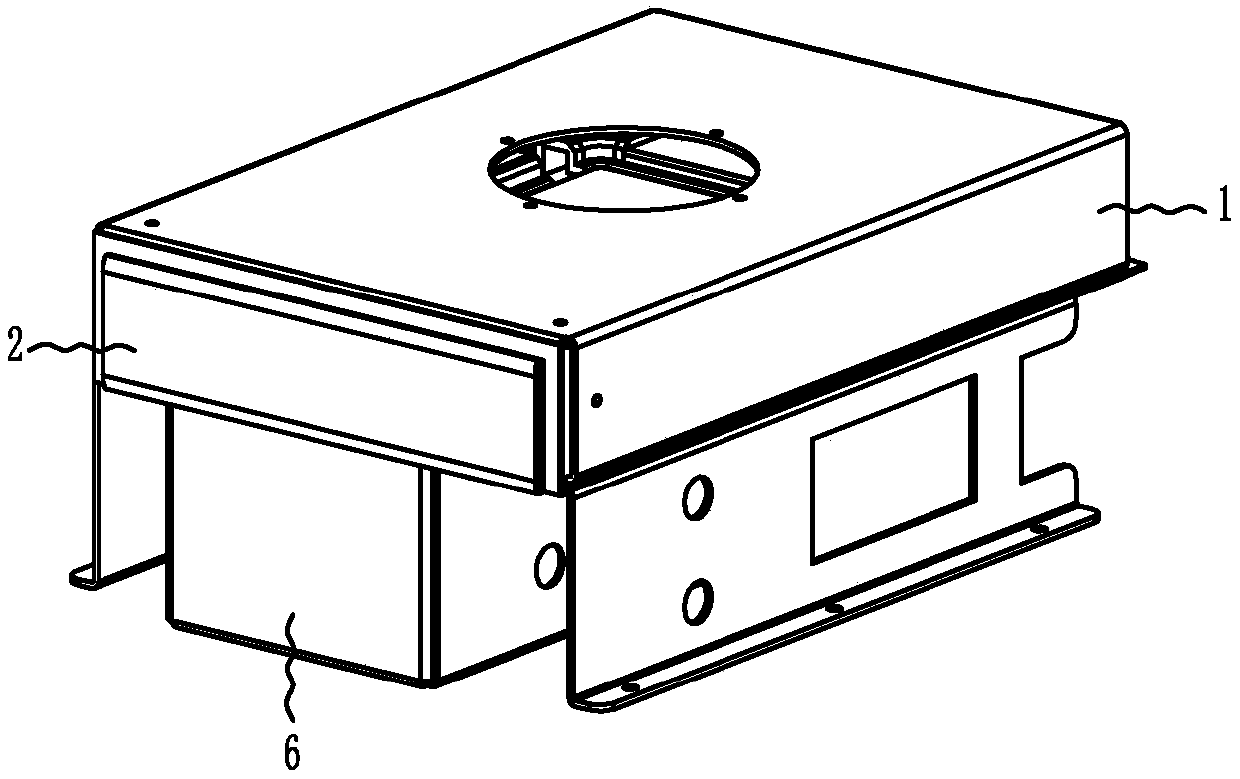

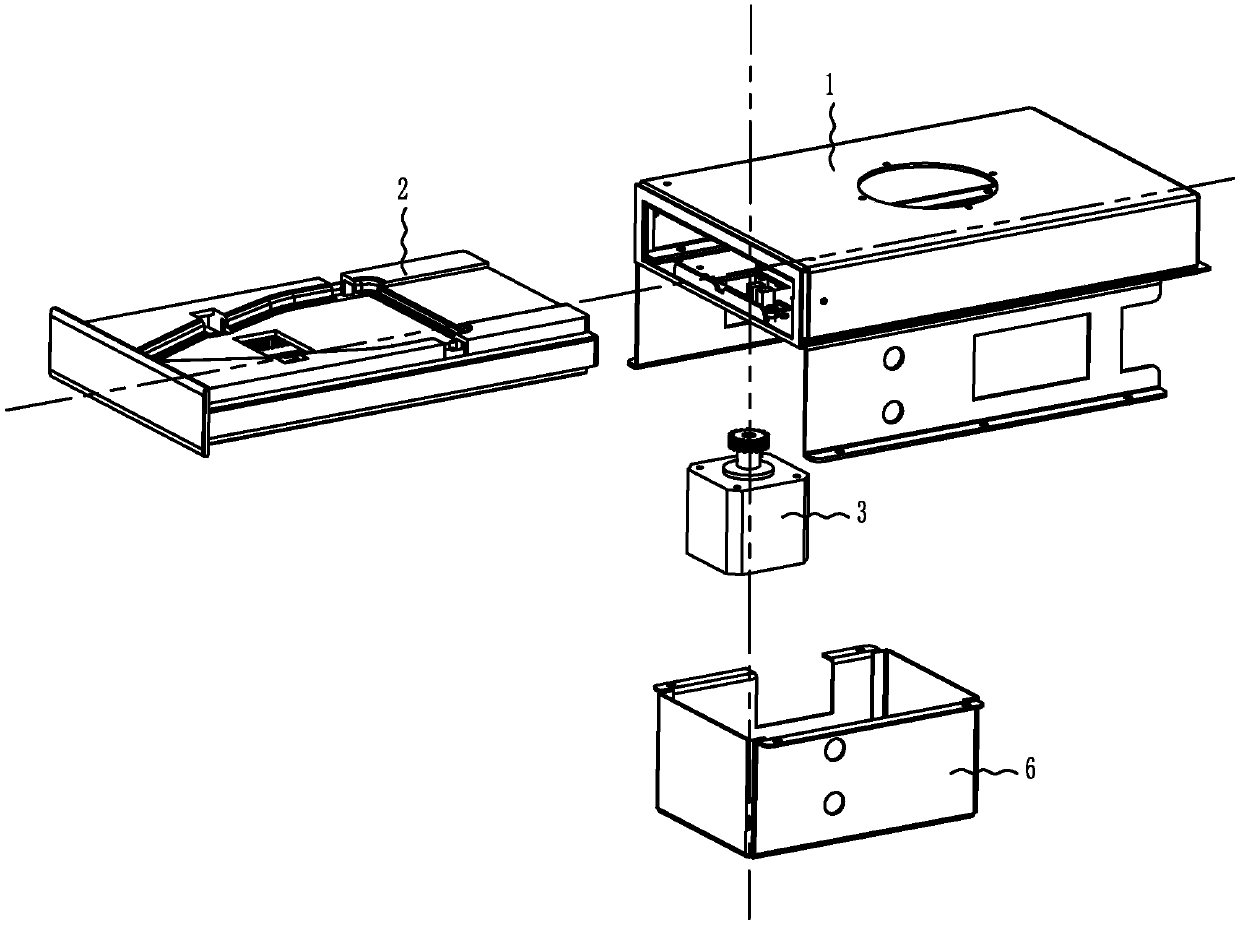

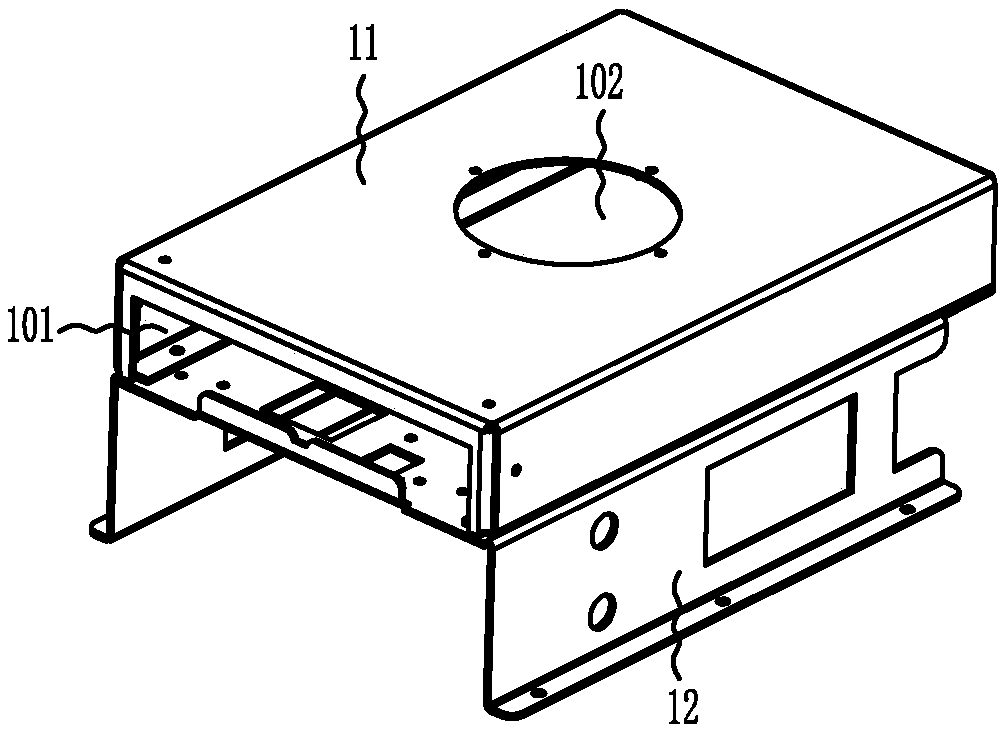

Darkroom assembly and detection equipment

PendingCN109540956AEasy to operateAvoid duplication of testsMaterial analysis using wave/particle radiationEngineeringScintillator

The invention relates to the field of medical detection equipment, and discloses a darkroom assembly and detection equipment. The darkroom assembly comprises a darkroom, a stage, and a power module. The darkroom is provided with a sample opening communicating with an inner cavity of the darkroom. The stage can enter or leave the inner cavity through the sample opening under the drive of the powermodule. The inner cavity forms a dark space after the sample opening is closed. The darkroom assembly and the detection equipment are provided with the darkroom, the stage, and the power module. The darkroom is provided with the sample opening communicating with the inner cavity of the darkroom. The stage is used for loading the sample to be tested and a scintillator, and can enter the inner cavity of the darkroom to assist the darkroom to form the dark space, so that the sample to be tested and the scintillator are detected in the same dark space. Therefore, the darkroom assembly and the detection equipment are convenient to operate and can be adapted to the detection of low-energy rays, and the detection efficiency and the detection accuracy are improved.

Owner:深圳市福瑞康科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com