Burn-in detection system

A detection system and an aging technology, applied in the direction of power supply testing, etc., can solve problems such as low efficiency, achieve the effects of improving efficiency, reducing testing costs, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

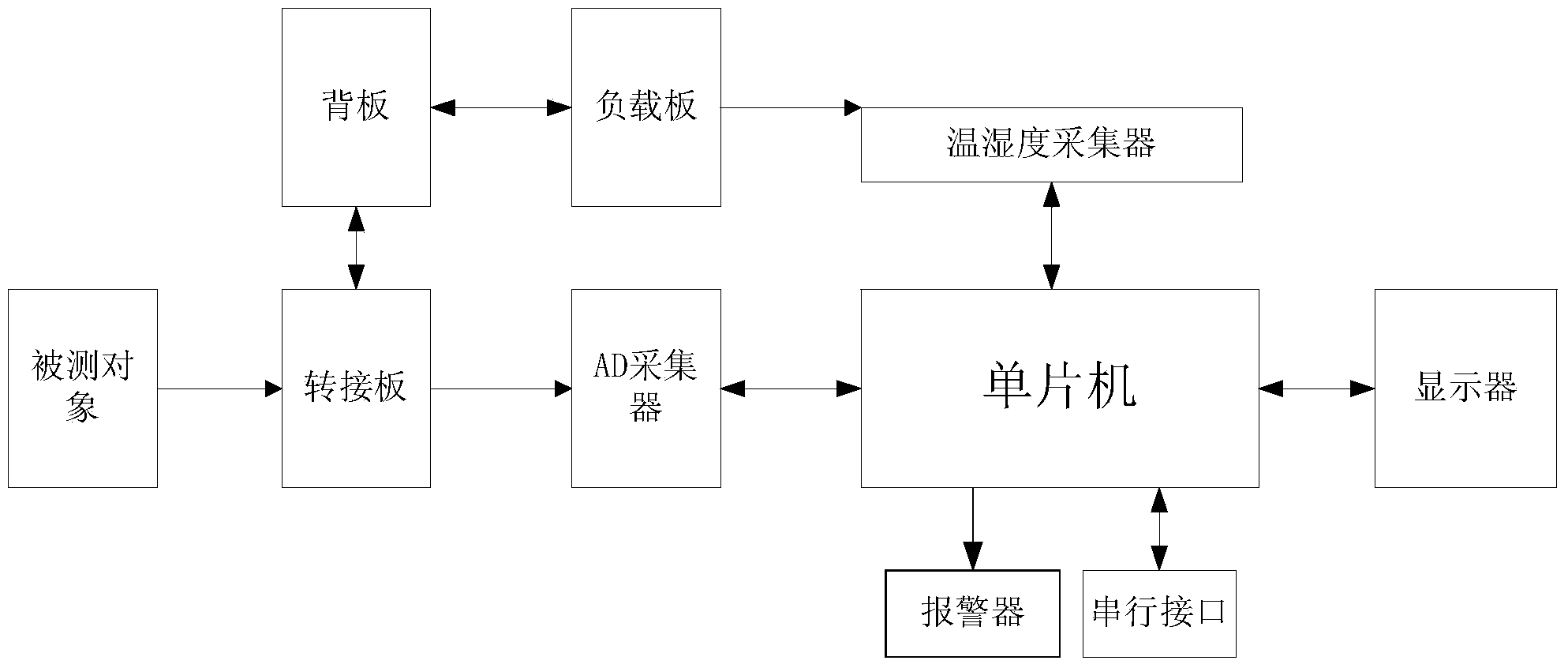

[0023] figure 1 It is a working principle diagram of the burn-in detection system of the present invention. In the figure, MSP430F149 single-chip microcomputer is used as the microcontroller. This single-chip microcomputer is at the core of the system and is used to receive the temperature and humidity data collected by the temperature and humidity collector and the voltage data collected by the AD collector. After signal processing, it will monitor The result is transferred to the display. And the monitoring data alarm range can be set through programming. If the monitored data exceeds the set range, the single chip computer will trigger an alarm command to the alarm. The single-chip microcomputer is equipped with a serial communication interface. After the level conversion of the single-chip microcomputer data, it communicates with the computer through the RS232 interface, and the computer can be used as a terminal device for related operations.

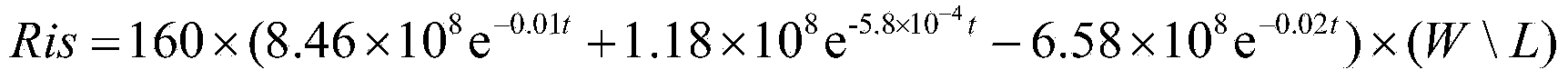

[0024] The AD collector m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com