Bulging draw forming method for variable-camber half flat tube part

A technology of variable curvature and parts, applied in the field of aircraft manufacturing, to avoid cracking, improve mold clamping accuracy and reliability, and solve the effects of springback and wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

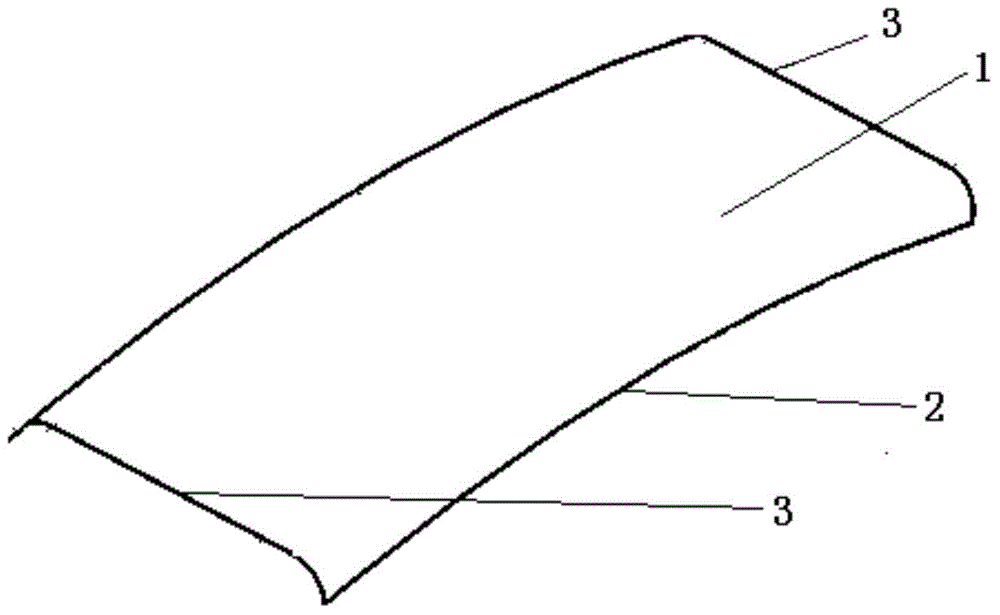

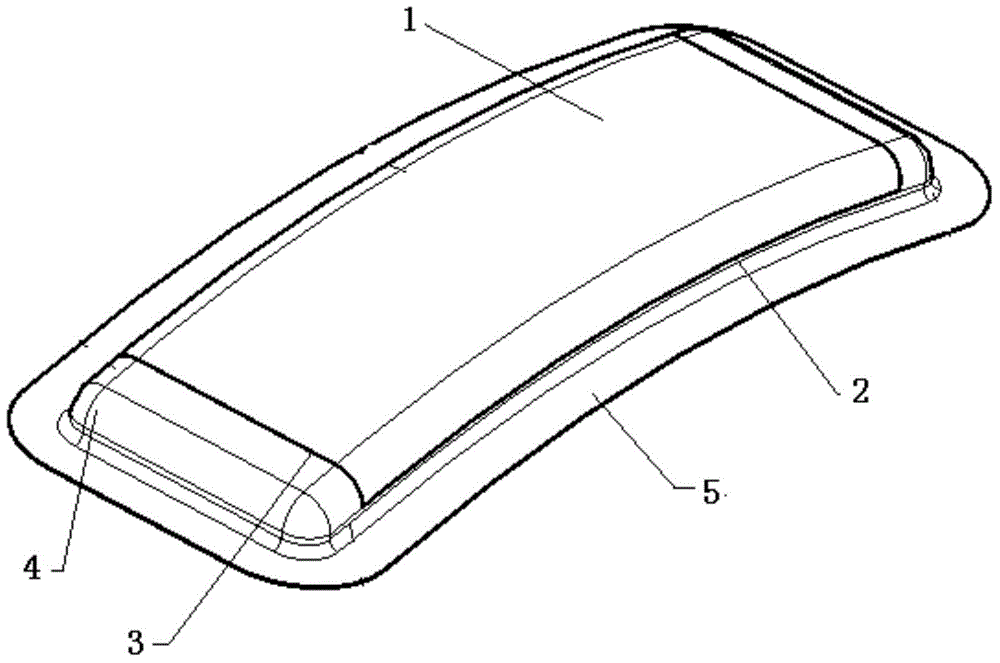

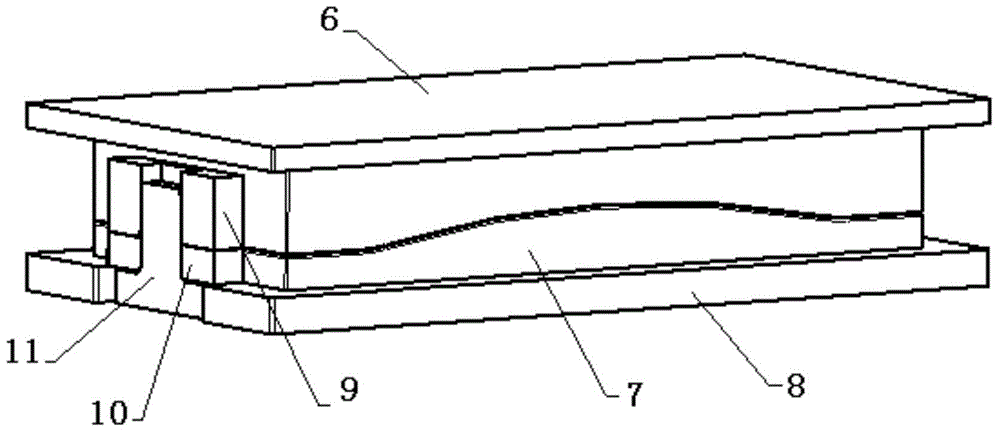

[0017] See attached picture, figure 1 Shown is the known theoretical model 1 of variable curvature semi-flat tube parts. Firstly, according to the theoretical model of the part, the process model of the bulging and deep drawing forming of the part is established, such as figure 2 As shown, the process model extends the bending line 2 on both sides of the theoretical model 1 of the part and the end line 3 at both ends and performs process compensation to make it a cavity with a rounded process compensation end 4. The bottom surface of the cavity is Annular flange edge 5, the flange edge 5 is kept parallel to the flange line 2 of theoretical model 1; then the unfolded wool material for part processing is made according to the process model; the expanded wool material is estimated based on the principle that the wool material before and after forming is equal to the surface area of the part, and the expanded wool material and the part surface area are equal The outer contour ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com