Automated self-cleaning litter box for cats

a litter box and automatic technology, applied in the field of automatic self-cleaning litter boxes for cats, can solve the problems of personal obnoxious task of emptying cat litter, inappropriate periodic cleaning, etc., and achieve the effect of simple and economical construction and extended operating li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

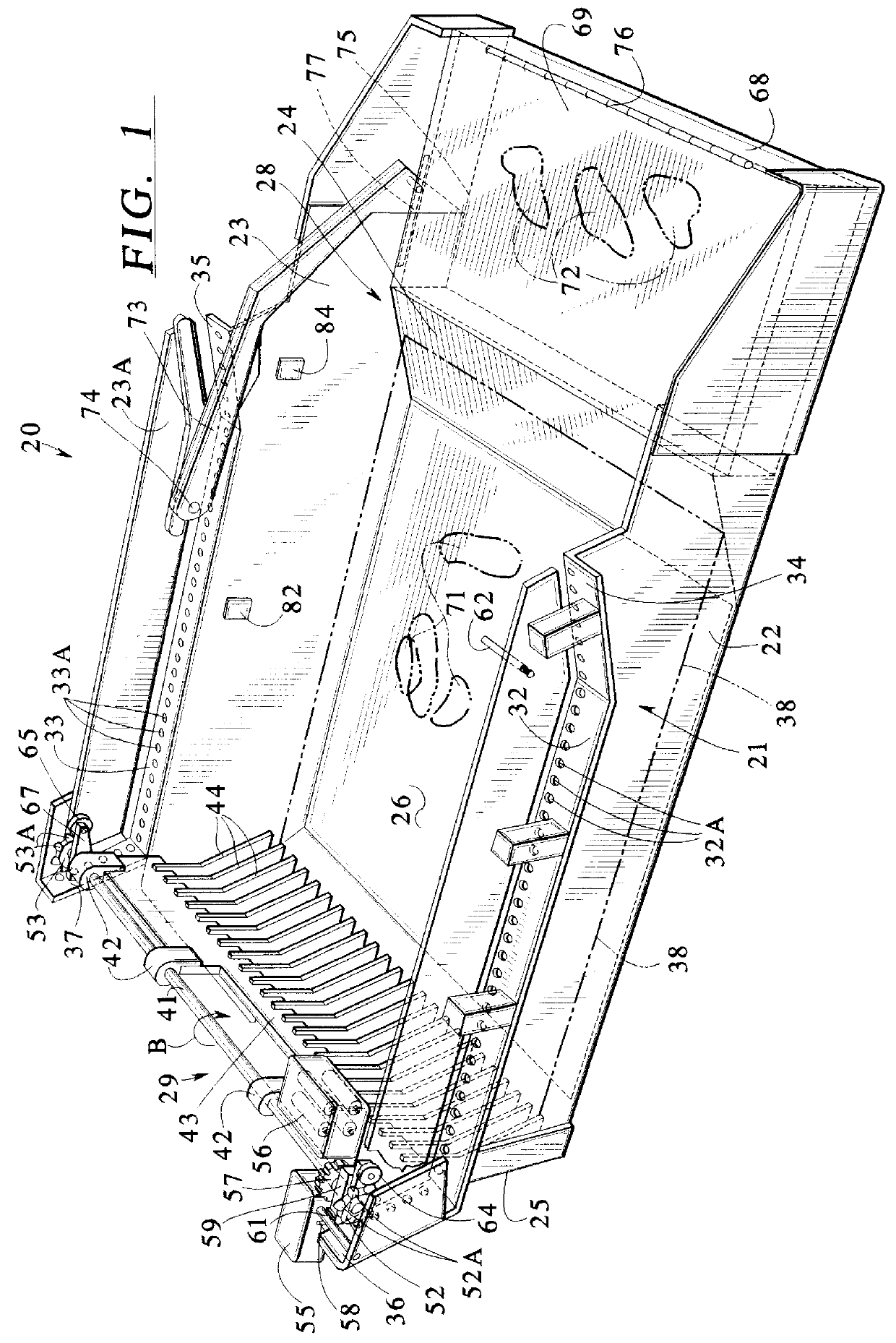

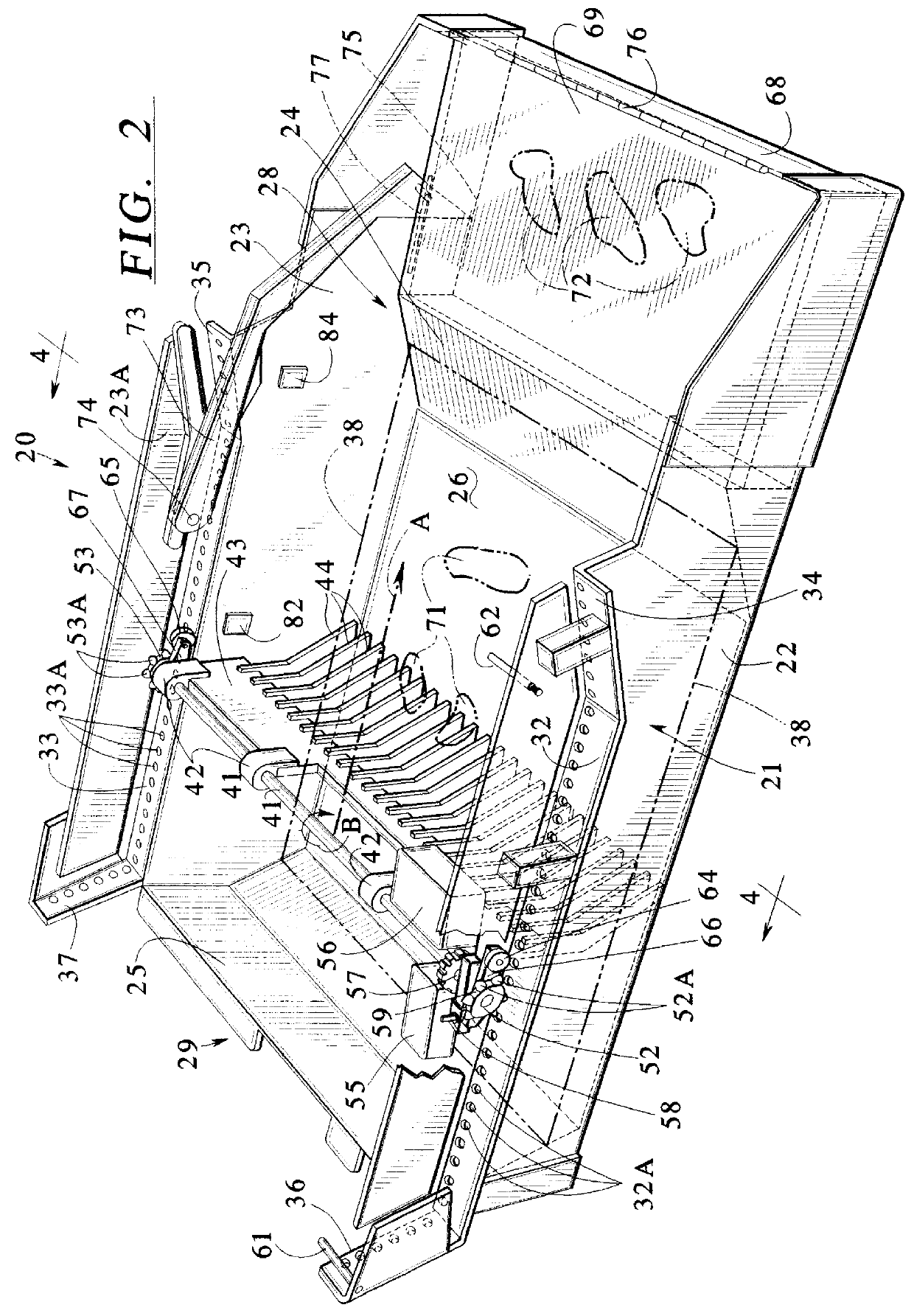

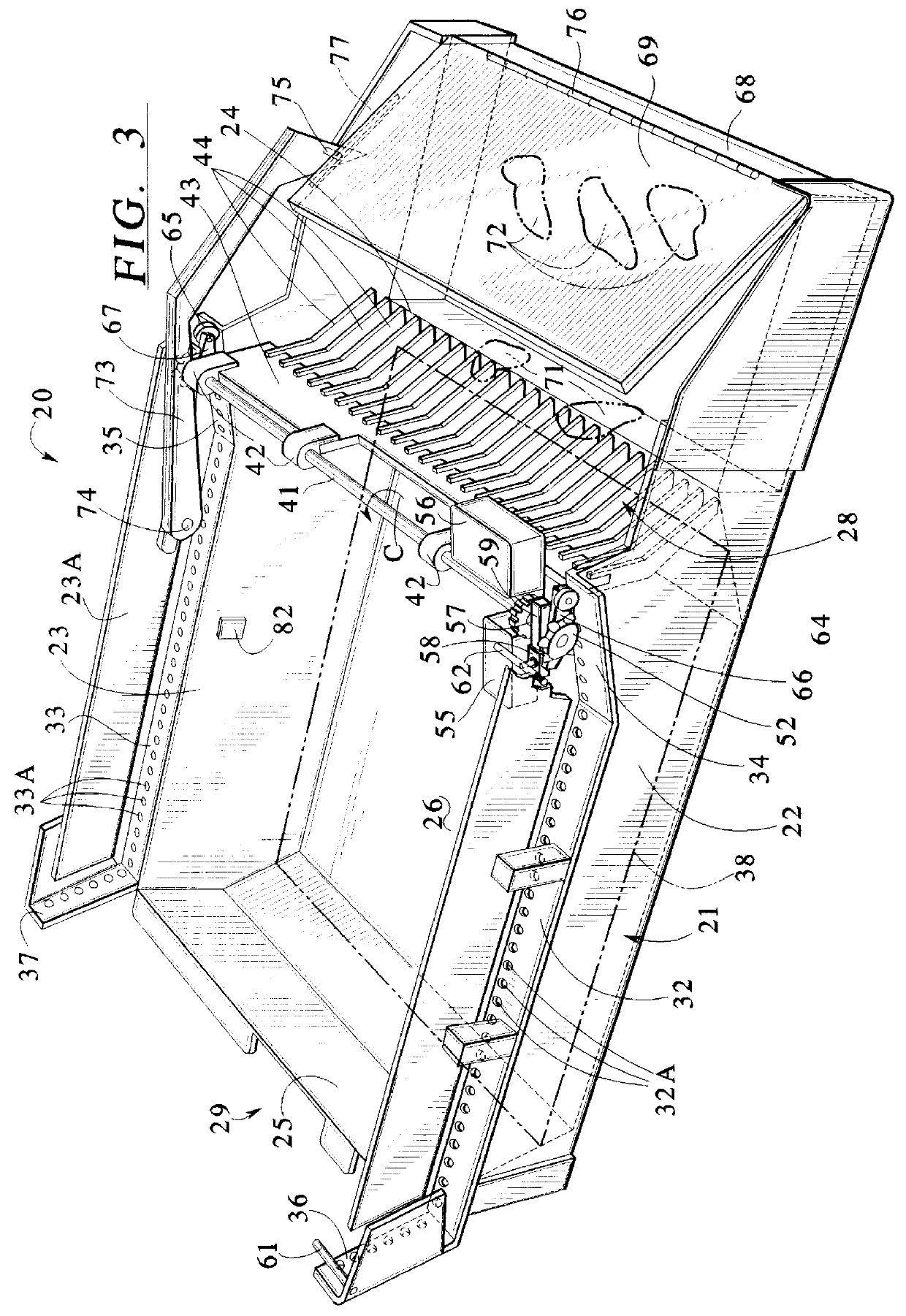

FIGS. 1-3 illustrate successive positions for the operating mechanism of la cat litter box 20 that affords automated self-cleaning operation. Litter box 20 comprises a pan-shaped housing 21 having a near side wall 22, a far side wall 23, a discharge end wall 24 joining walls 22 and 23 at one end of the litter box and a comb storage end wall 25 connecting walls 22 and 23 at the other end of litter box 20. The bottom of litter box 20 is identified by reference numeral 26 and the fill level to which box 20 is usually filled with cat litter is shown by phantom line 38. Thus, in litter box 20 there is a discharge end 28 at one end of the litter box and a comb storage end 29 at the opposite end of the litter box. Litter level line 38 may be afforded by a continuous or interrupted ridge in the interior of housing 21, as discussed in regard to FIG. 8. All of the members 22-26 are preferably formed in a molding operation that produces the complete housing 21.

An elongated near Side track or p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com