Bidirectional, out-of-plane, comb drive accelerometer

a comb drive and accelerometer technology, applied in the direction of acceleration measurement using interia forces, instruments, dynamo-electric components, etc., can solve the problem that the electrostatic comb drive type does not have the ability to pull the rotor comb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

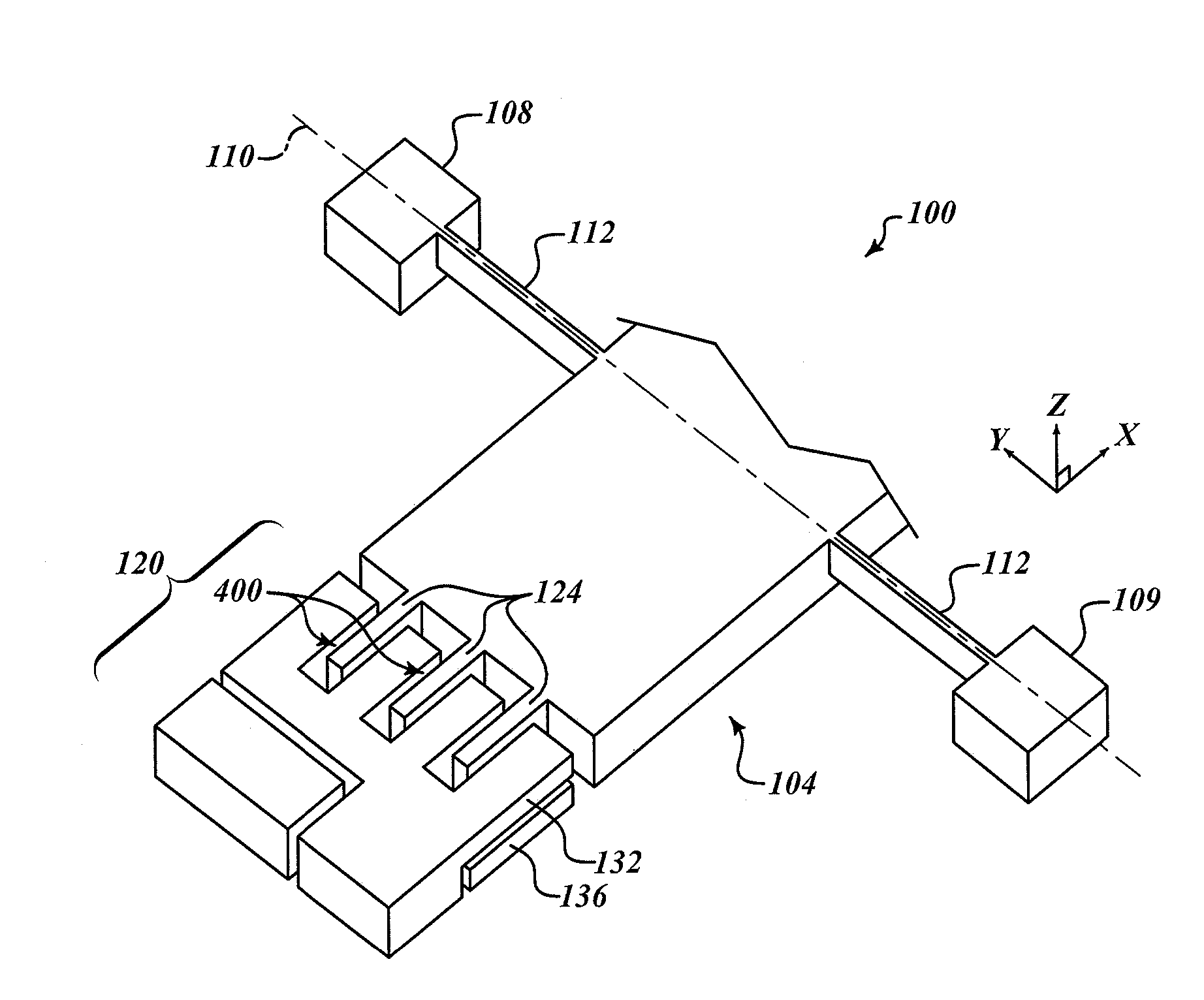

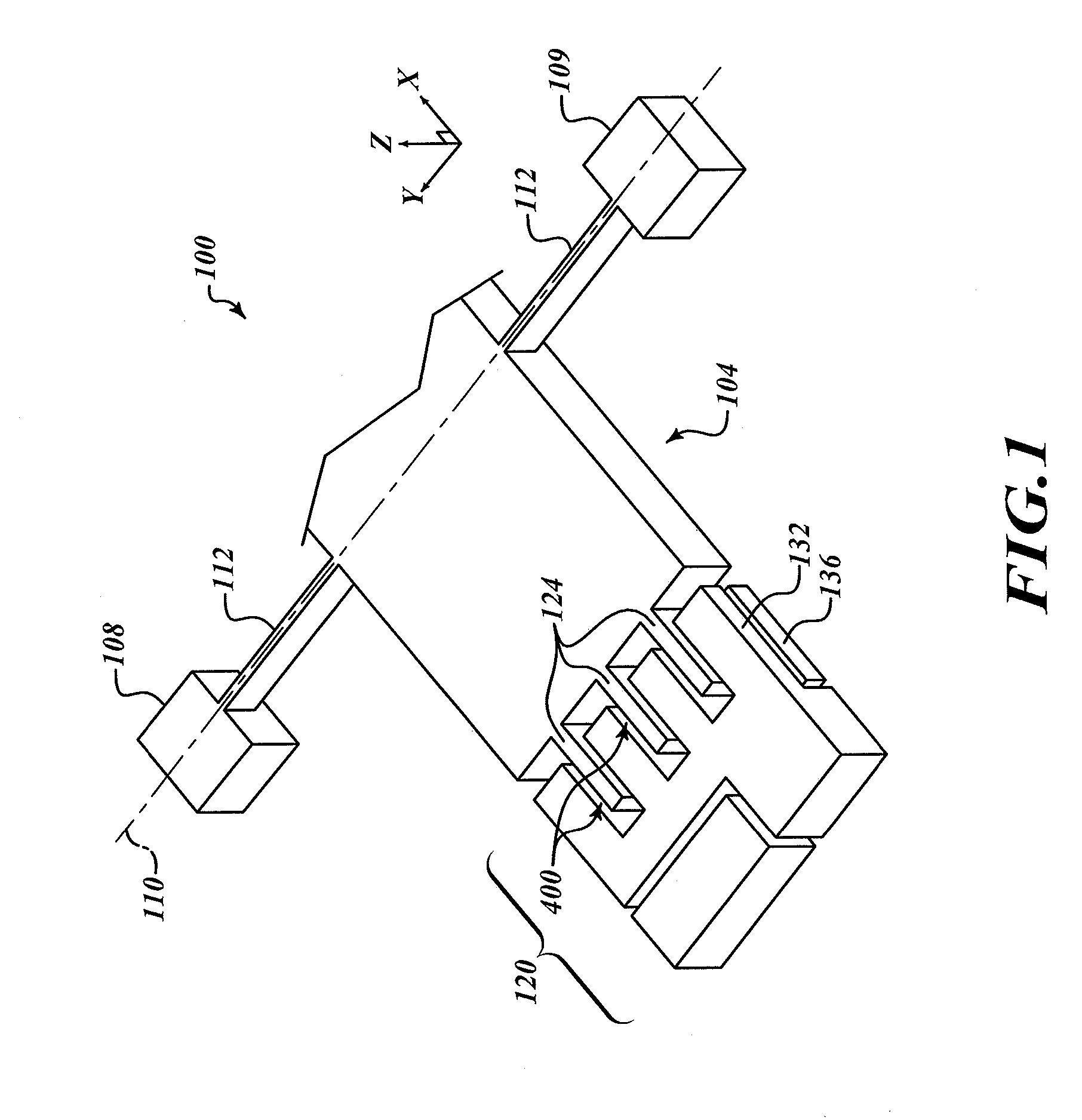

[0015]FIG. 1 shows a top-side perspective view of a portion of an example bi-directional out-of-plane electrostatic comb drive accelerometer 100. The bi-directional out-of-plane electrostatic comb drive 100 includes a proof mass 104, first and second anchors 108 and 109, flexures 112, a stator 120, rotor tines 124, an upper row of stator tines 132 and a lower row of stator tines 136. The bi-directional out-of-plane electrostatic comb drive 100 is fabricated using micro-electromechanical systems (MEMS) technologies.

[0016]The proof mass 104 is suspended above a substrate (not shown) so that the proof mass 104 is free to rotate about an illustrated axis of rotation 110. The proof mass 104 is suspended from the first anchor 108 and the second anchor 109 by the flexures 112. The first anchor 108 and the second anchor 109 are bonded to the substrate (not shown). The flexures 112 substantially limit movement of the proof mass 104 in the X and Y axes, yet permit rotation in the Z direction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com