Backup wall reinforcement with t-type siderail

a technology of reinforcement and siderail, which is applied in the direction of walls, building components, shock-proofing, etc., can solve the problems that the current state of the art does not meet the need for a hybrid anchor and reinforcement assembly that provides a 3-axis restraint system, and none of these devices offers a backup wall reinforcement and anchor. , to achieve the effect of limiting veneer displacement, low unit cost and economical manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

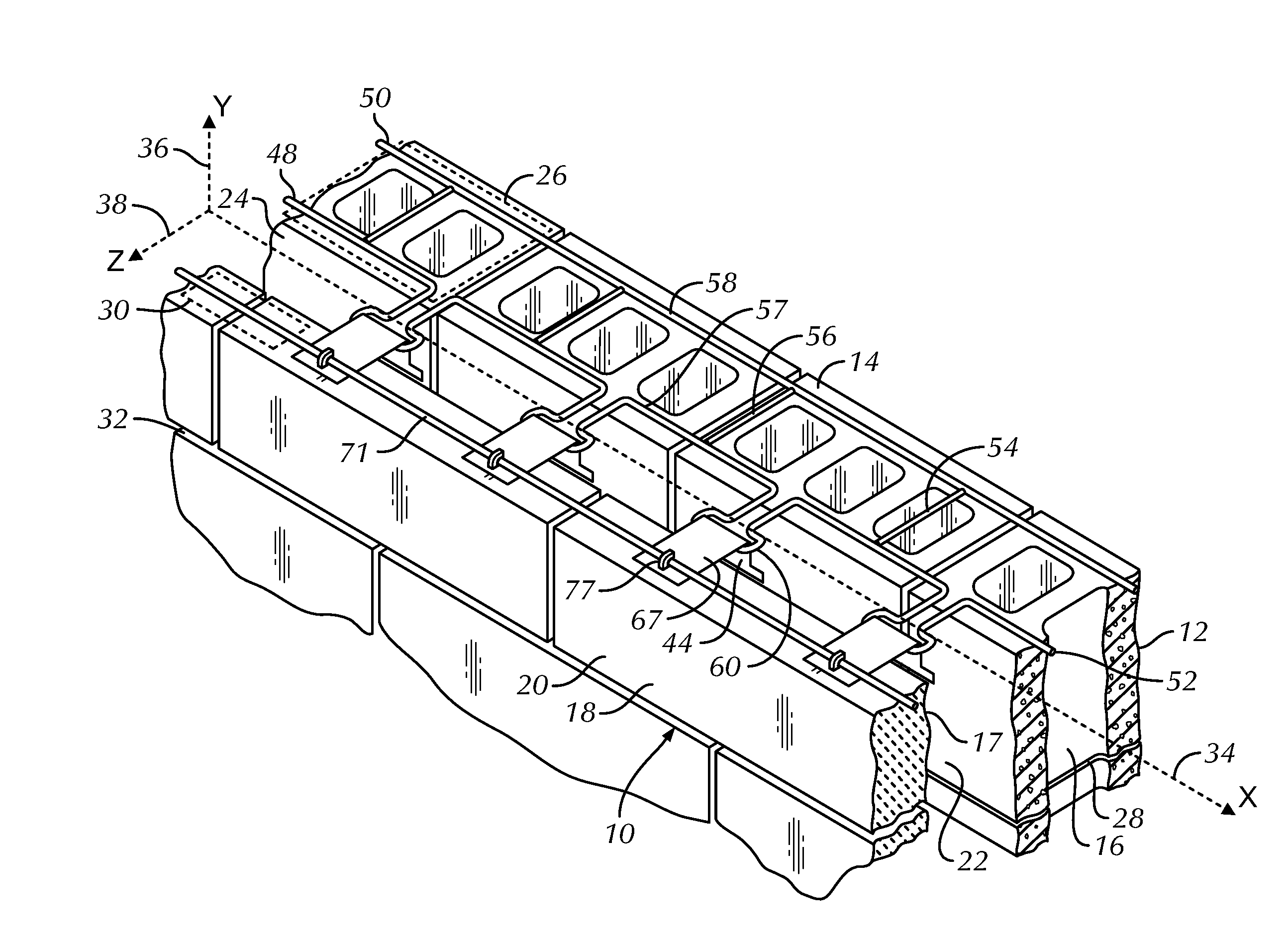

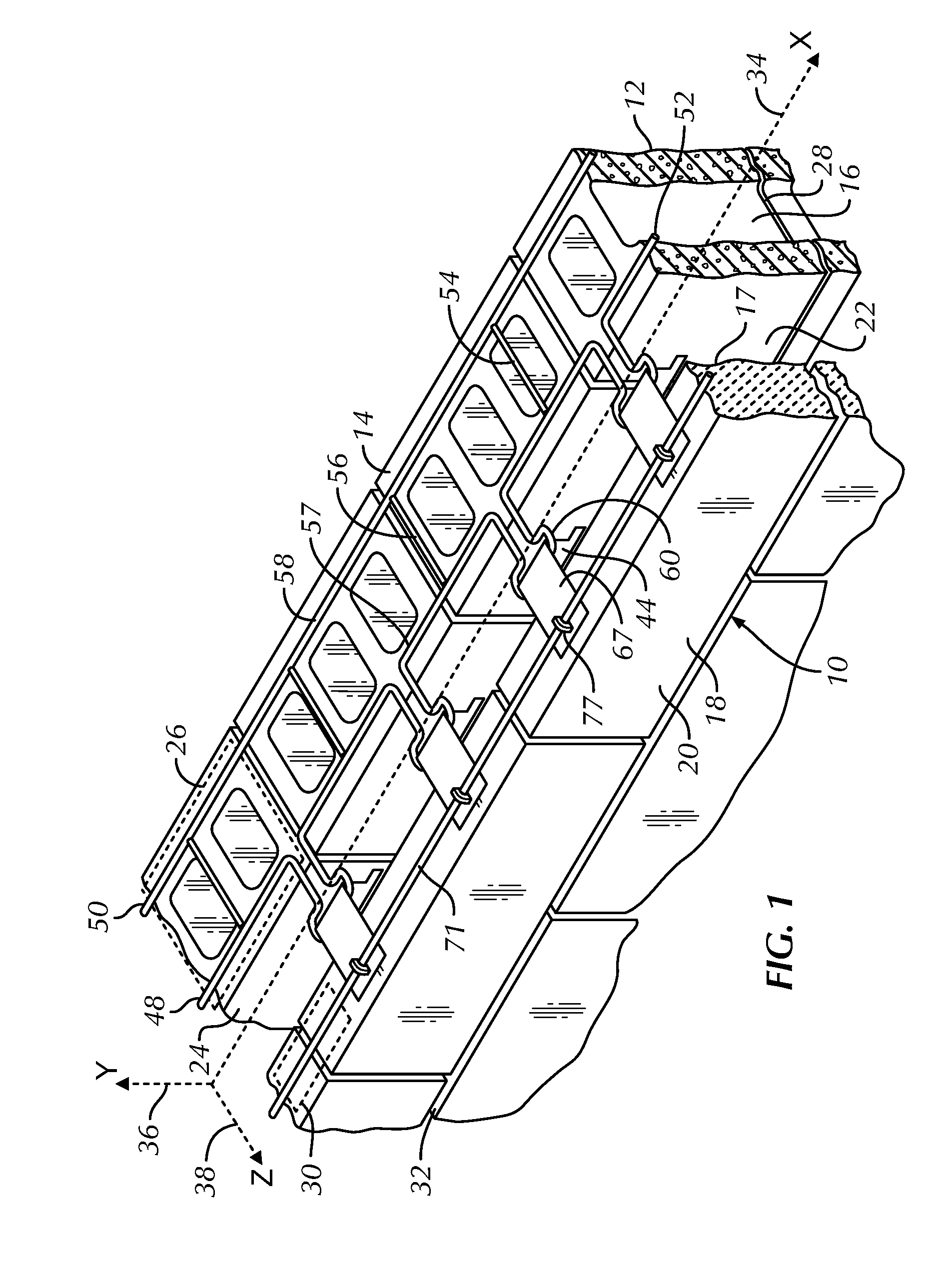

[0050]Referring now to FIG. 1 through 5, an anchoring system utilizing a backup wall reinforcement with T-type siderails is shown and is referred to generally by the numeral 10. In this embodiment, a masonry wall structure 12 is shown having a backup wall or exterior wythe 14 of masonry blocks 16 and a facing wall, exterior wall or veneer 18 of facing brick or stone 20. Between the backup wall 14 and the facing wall 18, a cavity 22 is formed, which cavity 22 extends outwardly from the interior surface 24 of backup wall 14. The backup wall 14 and the facing wall 18 have interior surfaces or sides 24 and 17, respectively that face the cavity 22.

[0051]In this embodiment, successive bed joints 26 and 28 are formed between courses of blocks 16 and the joints are substantially planar and horizontally disposed. Also, successive bed joints 30 and 32 are formed between courses of facing brick 20 and the bed joints are substantially planar and horizontally disposed. For each structure, the be...

second embodiment

[0055]The veneer tie 44 contains a free end portion 47. The free end 47 includes a cavity portion 67 and an insertion portion or bed joint portion 77. The cavity portion 67 spans the cavity 22 and the insertion portion is dimensioned for disposition within the bed joint 30 of the facing wall 18. When inserted in the facing wall 18, the free end 47 is in a substantially horizontal plane with the bed joint 30. The bed joint portion 77 contains one or more reinforcement notches 69 to secure a reinforcement wire 71 within the bed joint portion 77 for embedment in the bed joint 30 of the facing wall 18. The inclusion of the reinforcement wire 71 completes the seismic construct. The veneer tie 44 optionally contains an offset (not shown) similar to that shown in the second embodiment below. The free end 47 optionally contains apertures 73 to limit thermal transfer. Optionally, insulation (not shown) may be added to the interior 24 of the backup wall 14. If insulation is installed, the str...

third embodiment

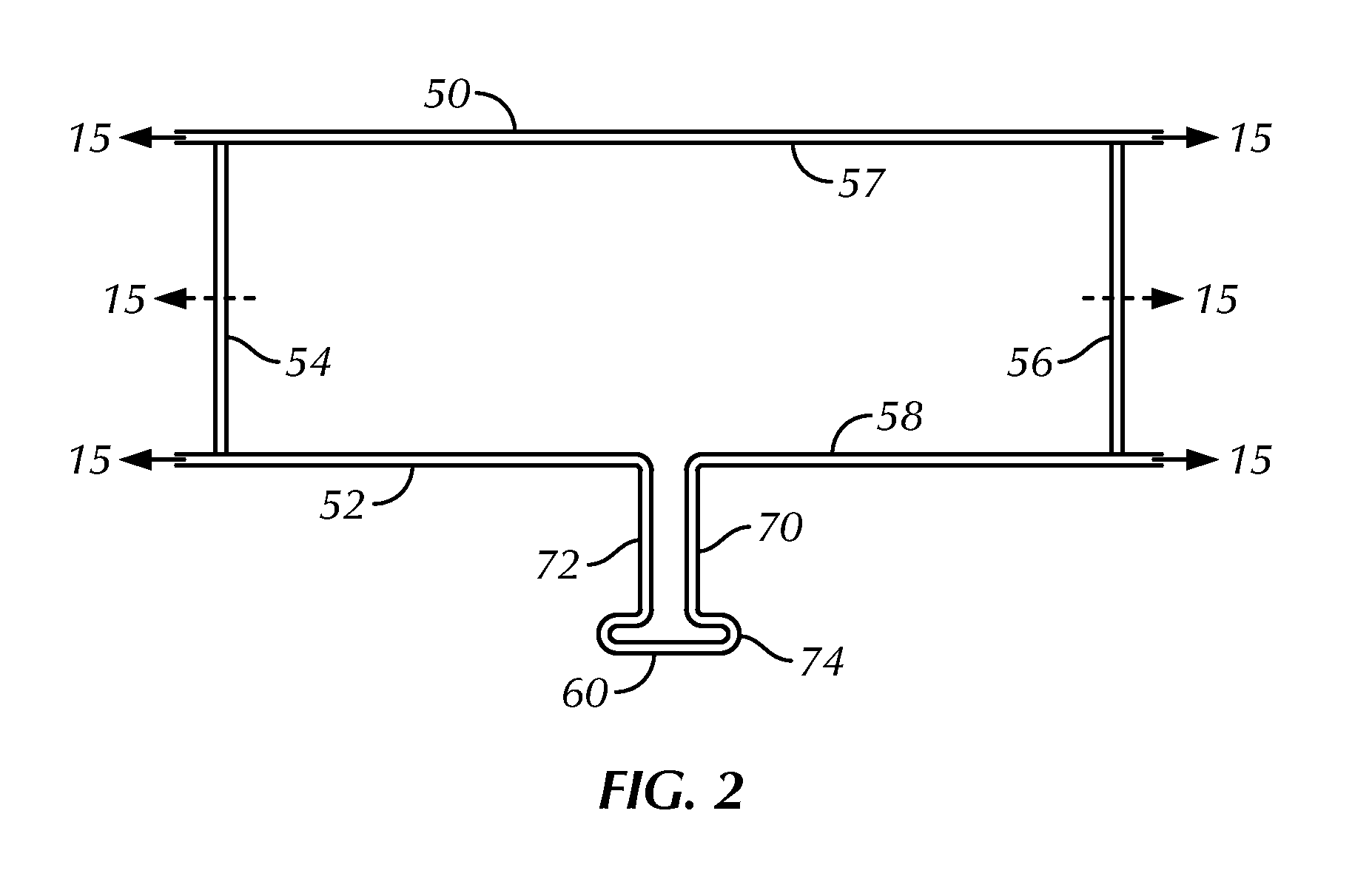

[0067]Referring now to FIGS. 11 through 13, a backup wall reinforcement with T-type siderails of this invention is shown and is referred to generally by the numeral 210. In this embodiment, a cavity wall structure is not shown but is substantially similar to the cavity wall structure shown in FIGS. 1 and 6. The anchoring system 210 includes a reinforcement device or wall reinforcement portion 248 with an integral anchor or wall anchor portion 260. The reinforcement device 248 is embedded in the bed joints and includes two side rails or wires 250, 252 which are parallel to each other. One or more intermediate wires 254, 256 are attached to the interior sides or surfaces of 257, 258 of the side rails 250, 252 and maintain the parallelism of the side rails 250, 252. The intermediate wires form a ladder 254, 256 configuration or optionally, a truss configuration (not shown). The longitudinal axis of the intermediate wires 254, 256 and the side rails 250, 252 is substantially similar to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com