Automatic ton bucket blow molding self-inspection production line

An automatic production line and self-inspection technology, applied in the direction of conveyor objects, object stacking, object destacking, etc., can solve the problems of inconsistent product quality and low production efficiency, reduce investment, save manpower, and improve labor productivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

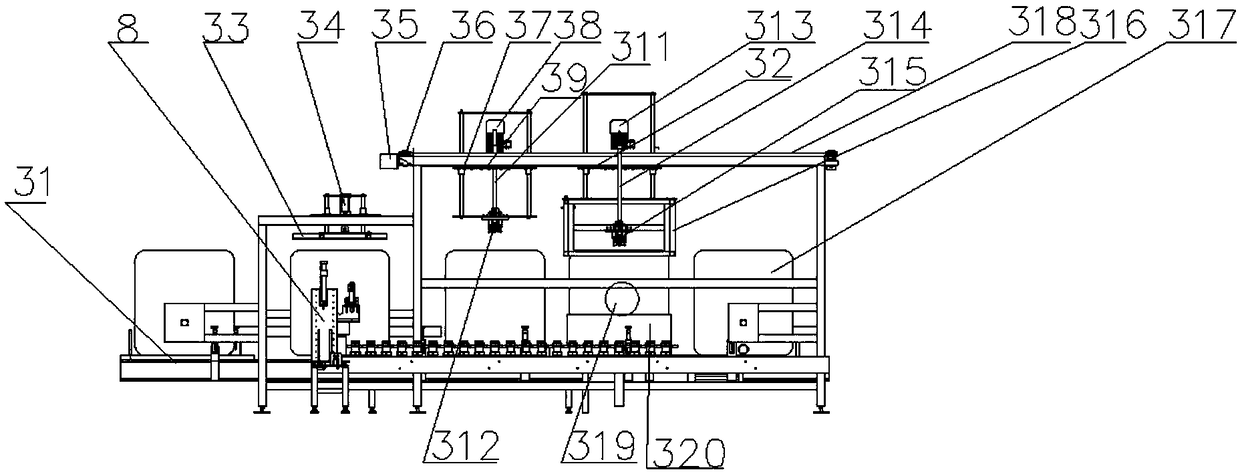

[0019] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

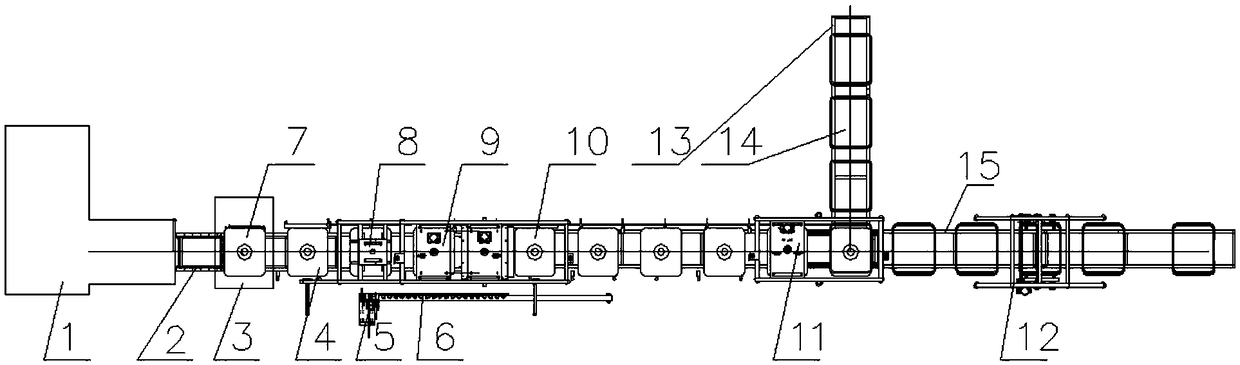

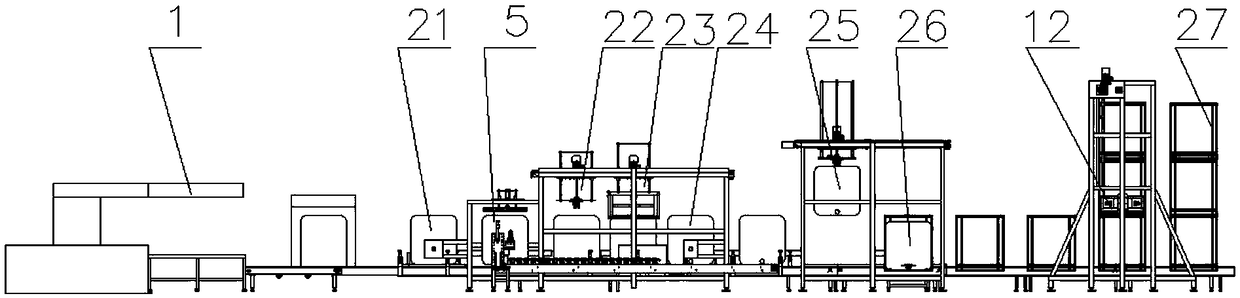

[0020] Such as figure 1 As shown, the automatic production line of the present invention includes an injection molding machine 1, a plastic liner conveying mechanism 2, a deburring mechanism 3, a conveying line, a weighing and rejecting mechanism 4, a screwing valve mechanism 8, and a screwing valve mechanism arranged sequentially from left to right. Manipulator 5, valve conveying line 6, leak detection mechanism 9, waste product rejecting mechanism 10, cage loading mechanism 11 and palletizing mechanism 12, also includes a controller, which is connected with injection molding machine 1, plastic liner conveying mechanism 2, de-flying mechanism respectively Side mechanism 3, conveying line, weighing and rejecting mechanism 4, valve twisting mechanism 8, valve twis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com