Supercritical extraction and suspension bed hydrogenation combined system for heavy oil raw material and method

A combined system and suspended bed technology, which is applied in the field of combined systems of supercritical extraction and suspended bed hydrogenation, can solve the problems of increasing the tendency of coking and deactivation of catalyst coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

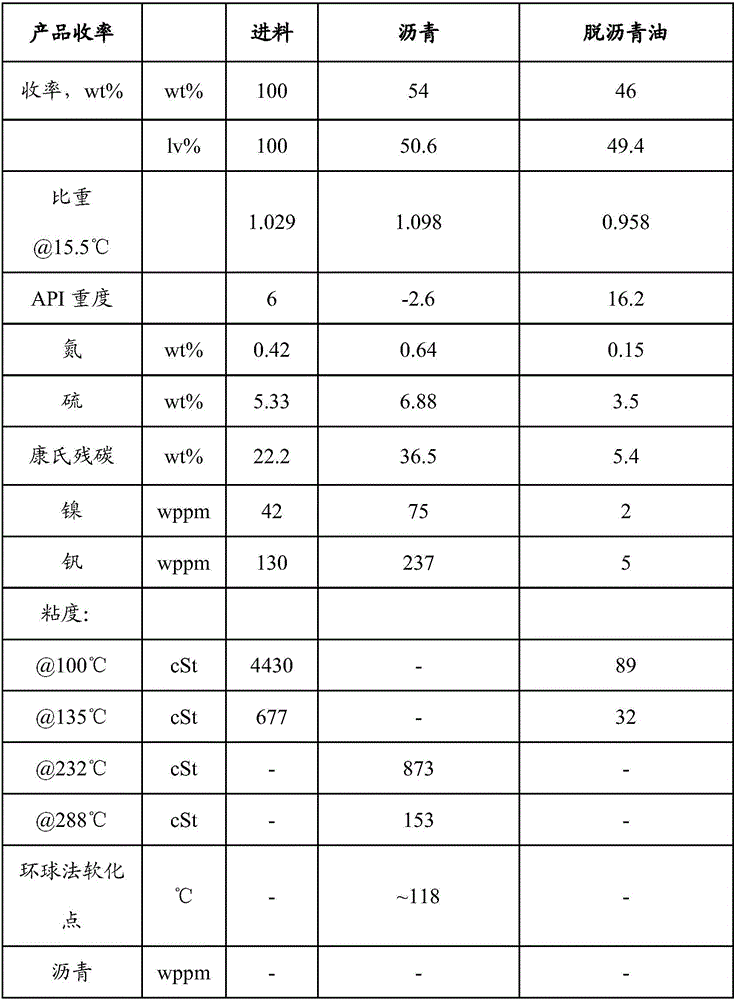

[0110] The properties of feed residue oil are shown in Table 1;

[0111] The extraction solvent was mixed butanes (50% iC4, 50% nC4).

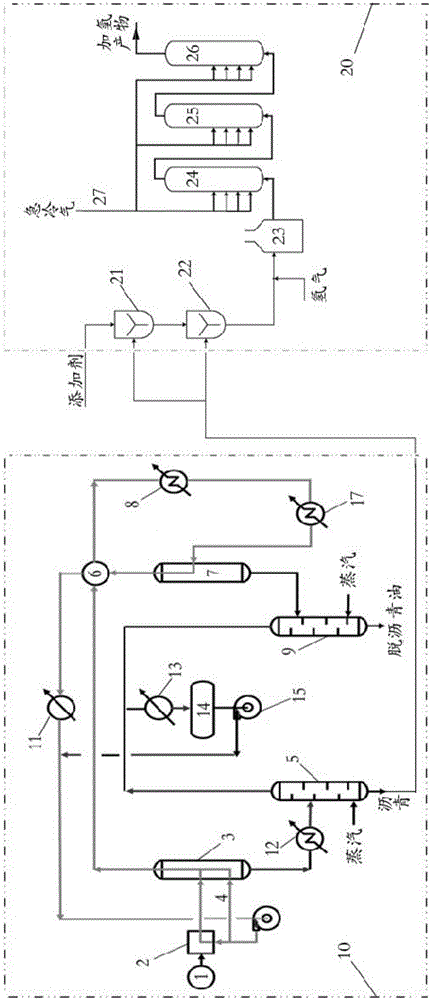

[0112] The supercritical residual oil treatment of the present invention is in such as figure 1 in the system shown. Wherein, the volume ratio of the extraction solvent and the residue in the diluted residue is 1.5:1; the volume ratio of the total extraction solvent entering the asphalt separation tower and the residue is 6:1;

[0113] Among them, the operating conditions of the asphalt separation tower are 4-5Mpag, 80-110°C; the operating conditions of the deasphalted oil separation tower are 4-5Mpag, 120-160°C.

[0114] After the above-mentioned system treatment, the obtained asphalt products and deasphalted oil products are shown in Table 1.

[0115] Table 1

[0116]

[0117] The deasphalted oil in this embodiment is used as feed to the downstream lubricating oil unit to produce high-viscosity lubricating oil. The asphalt is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com