Deburring machine tool

A deburring and machine tool technology, which is applied to grinding machines, machine tools suitable for grinding the edge of workpieces, metal processing equipment, etc., can solve the problems of hidden dangers to life and property, scattered processes, low production efficiency, etc., and achieve thorough deburring and simple operation , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

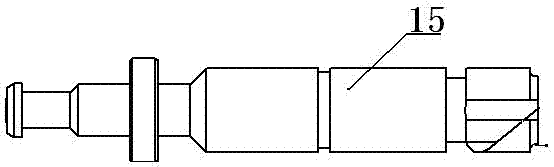

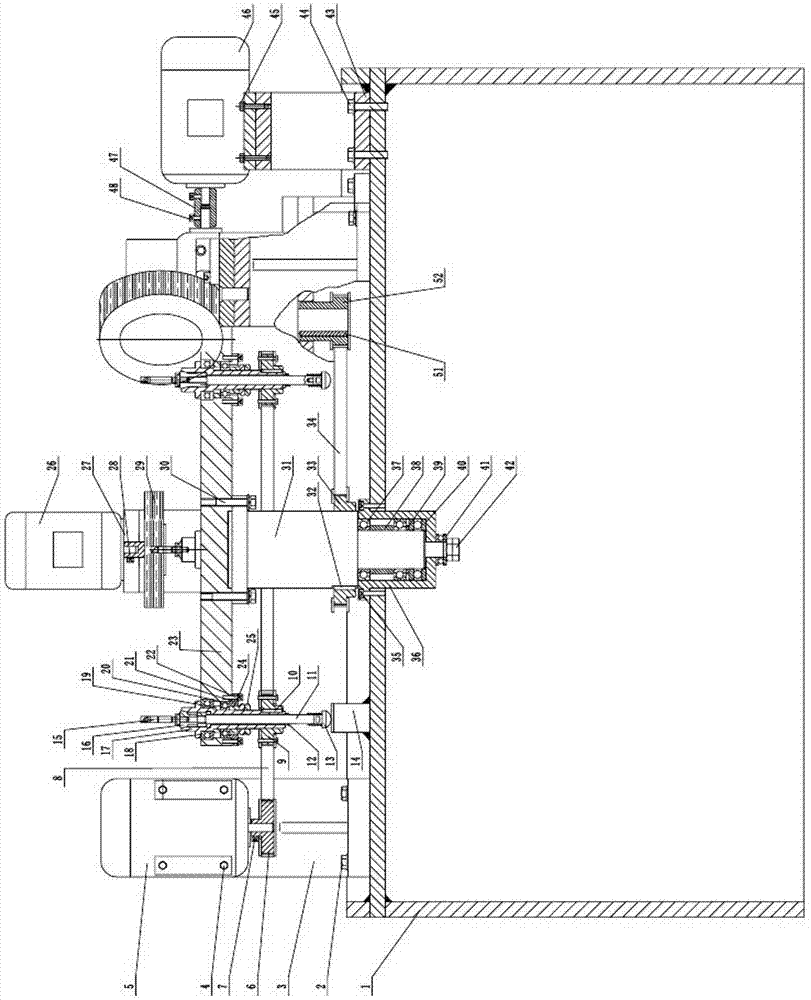

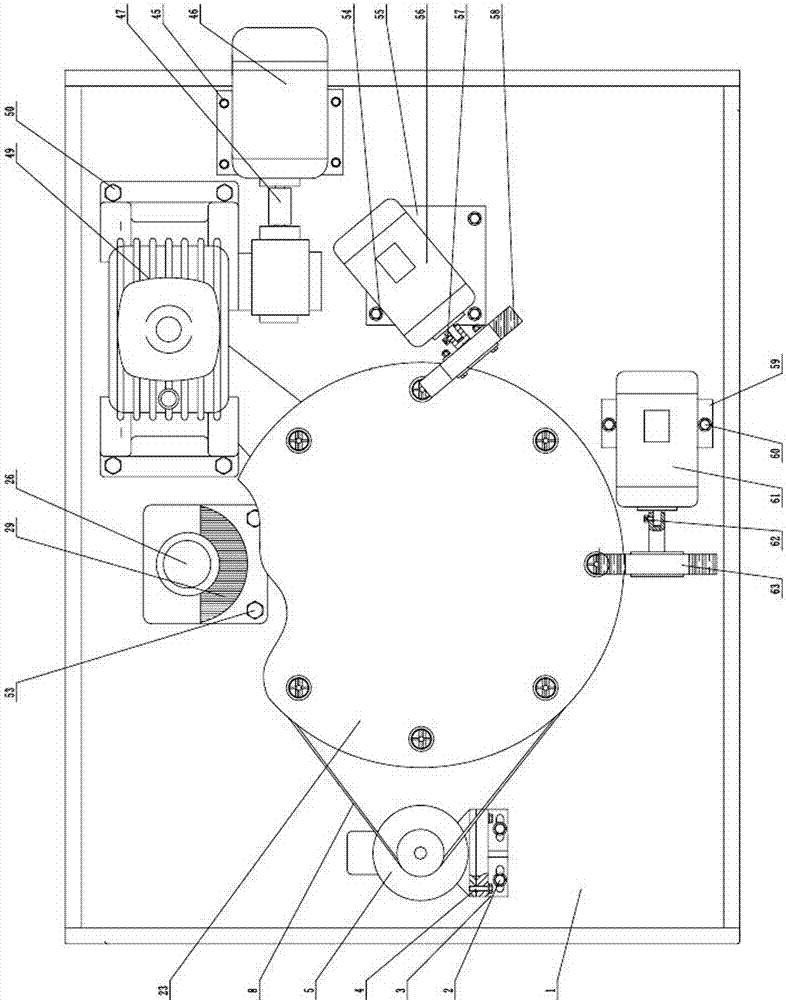

[0015] Refer to attached Figure 1~3 , The deburring machine tool includes bed 1, outer hexagon bolt 1 2, fixture transmission motor seat 3, outer hexagon bolt 2 4, micro motor 1 5, fixture driving pulley 6, hexagon socket head screw 1 7, timing belt 8 , Fixture driven pulley 9, flat key one 10, pull rod 11, compression spring one 12, very block 13, chuck top block 14, elastic chuck 16, elastic chuck seat 17, plane bearing one 18, spacer ring 19, Deep groove ball bearing 120, lower end cover 21, hexagon socket head screw 222, rotary disc 23, bushing 24, joint cap 25, micro motor 26, horizontal motor bracket 27, hexagon socket head screw 3 28, disc Type steel brush 1 29, outer hexagon bolt 3 30, main shaft 31, flat key 2 32, main shaft pulley 33, timing belt 2 34, hexagon socket head screw 4 35, bearing seat 36, deep groove ball bearing 2 37, bushing 38. Spacer ring 39, plane bearing 2 40, plane bearing 3 41, nut 42, main motor bracket 43, outer hexagon bolt 4 44, outer hexago...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com