A kind of production technology that utilizes microchannel reactor to prepare tetrabromoethane

A technology of microchannel reactor and production process, applied in the direction of halogen addition preparation, organic chemistry, etc., can solve the problems of waste water, waste gas, energy consumption and other by-products that are easy to form explosive mixtures, shorten the production process, reduce labor intensity, Reduce the effect of manual controls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of production technology that utilizes microchannel reactor to prepare tetrabromoethane:

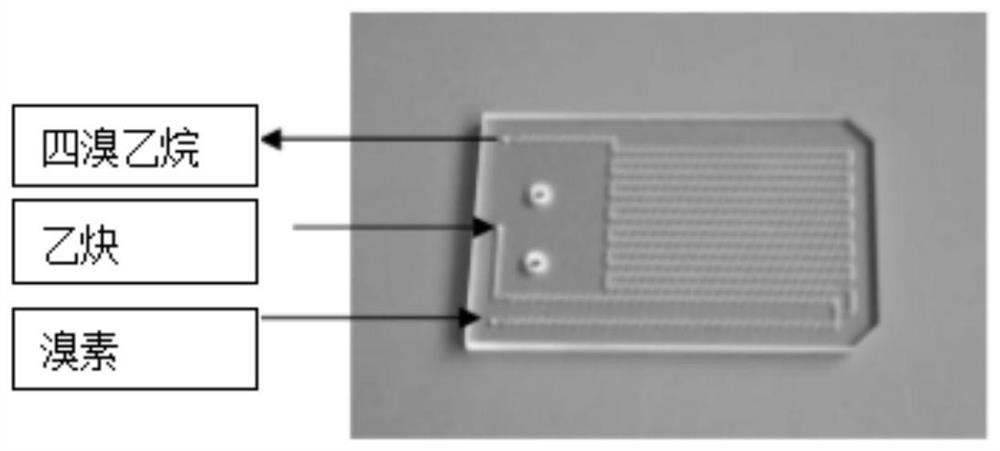

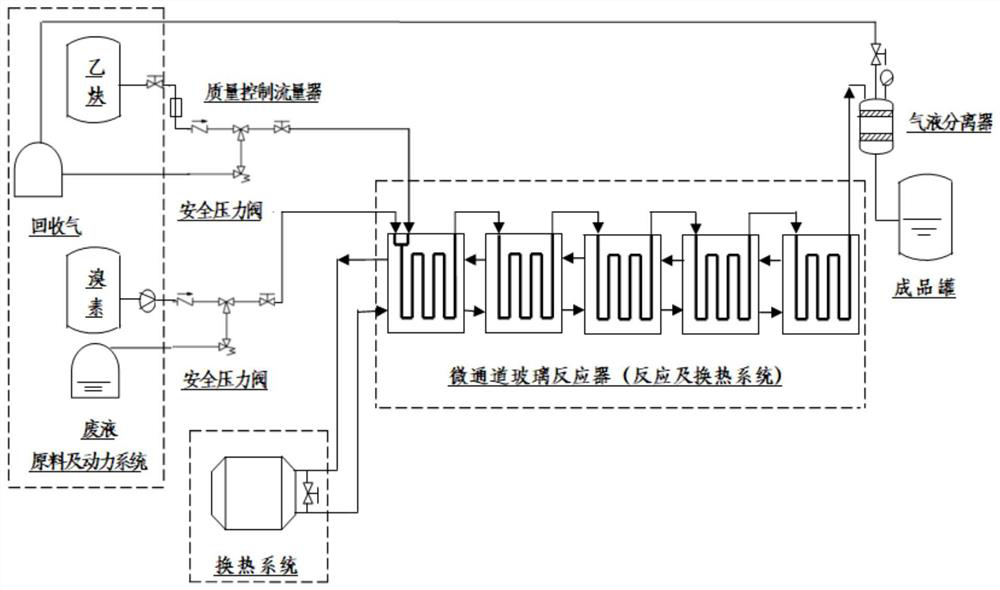

[0040] (1) Microchannel reactor: the inner diameter of the reaction channel is 500 μm; the total volume of the reaction zone of the microchannel reactor is 27ml;

[0041] (2) Under the drive of the plunger pump of the power system, the raw material bromine is continuously introduced into the microchannel reactor at a flow rate of 0.7kg / min; the acetylene is continuously introduced into the microchannel reaction at a flow rate of 0.057kg / min through the gas mass flow controller device; before the acetylene and bromine are passed into the microchannel reactor, they respectively flow through the valve group, and the valve group includes a one-way valve, a safety valve and a switch.

[0042](3) The acetylene and bromine that pass into are fully mixed and reacted in the microchannel reactor; the system pressure is 0.2MPa in the microchannel reactor; Reaction temperature≤70°C); ...

Embodiment 2

[0045] A kind of production technology that utilizes microchannel reactor to prepare tetrabromoethane:

[0046] (1) Microchannel reactor: the inner diameter of the reaction channel is 1000um; the total volume of the reaction zone of the microchannel reactor is 45ml;

[0047] (2) Under the drive of the plunger pump of the power system, the raw material bromine is continuously introduced into the microchannel reactor at a flow rate of 0.8kg / min; the acetylene is continuously introduced into the microchannel reaction at a flow rate of 0.065kg / min through the gas mass flow controller device; before the acetylene and bromine are passed into the microchannel reactor, they respectively flow through the valve group, and the valve group includes a one-way valve, a safety valve and a switch.

[0048] (3) The acetylene and bromine that pass into are fully mixed and reacted in the microchannel reactor; the system pressure in the microchannel reactor is 0.3MPa; by the heat exchange system,...

Embodiment 3

[0051] A kind of production technology that utilizes microchannel reactor to prepare tetrabromoethane:

[0052] (1) Microchannel reactor: the inner diameter of the reaction channel is 1500um; the total volume of the reaction zone of the microchannel reactor is 54ml;

[0053] (2) Under the drive of the plunger pump of the power system, the raw material bromine is continuously introduced into the microchannel reactor at a flow rate of 0.9kg / min; the acetylene is continuously introduced into the microchannel reaction at a flow rate of 0.073kg / min through the gas mass flow controller device; before the acetylene and bromine are passed into the microchannel reactor, they respectively flow through the valve group, and the valve group includes a one-way valve, a safety valve and a switch.

[0054] (3) The acetylene and bromine that pass into are fully mixed and reacted in the microchannel reactor; the system pressure in the microchannel reactor is 0.4MPa; by heat exchange system, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com