Turbulent tube grid tower capable of improving desulfurization efficiency

A desulfurization efficiency and turbulent tube technology, applied in the field of turbulent tube grid towers and wet flue gas desulfurization equipment, can solve the problems of increasing the liquid flux of non-blocking parts, shutting down for maintenance, and high operating costs, achieving high promotion and application value, maintenance Easy management and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

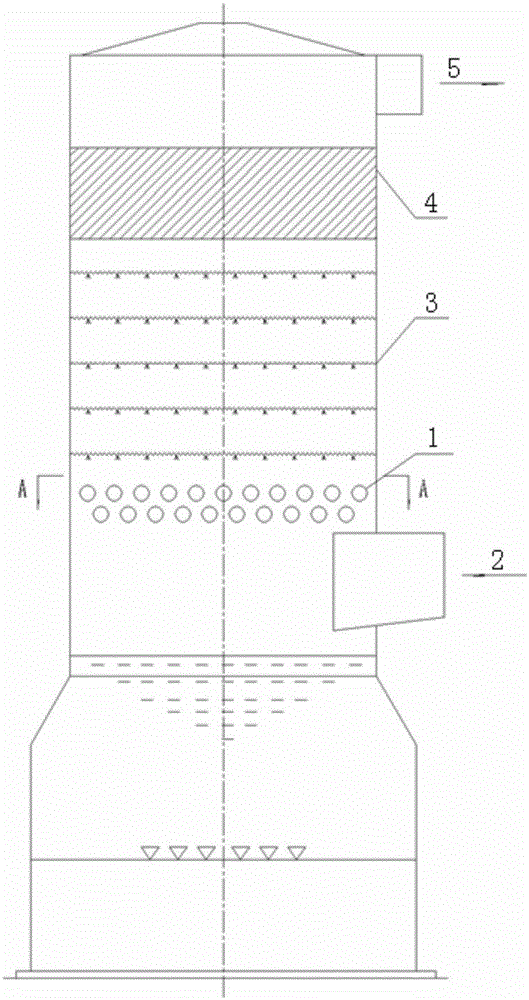

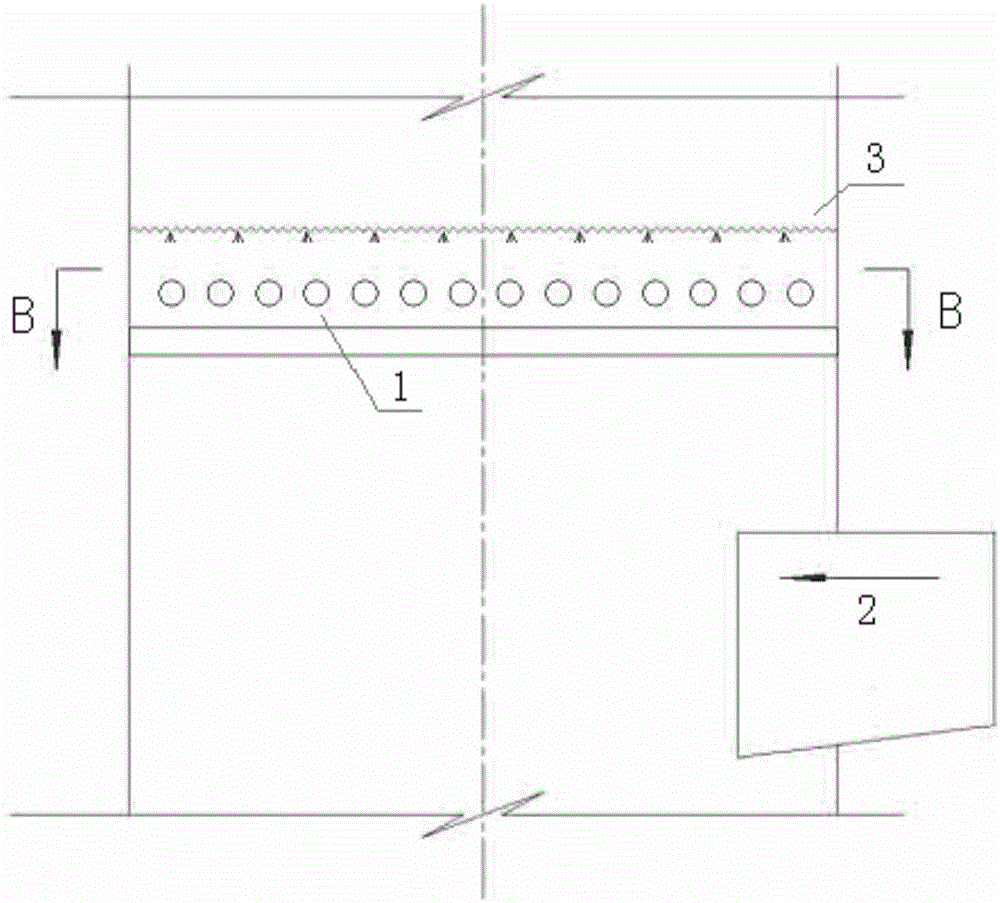

[0048] Such as figure 1As shown, the turbulent pipe grid tower for improving desulfurization efficiency of the present invention includes a flue gas inlet 2, a spray layer 3, a demister 4 and a flue gas outlet 5; between the flue gas inlet 2 and the spray layer 3, a Tube grid structure 1, including at least two layers of tube rows arranged in parallel layers; the tube row includes several parallel tubes; The projections of are non-coincident or partially co-incident. The pipe grid structure 1 is installed at 1.5-2.5 meters above the flue gas inlet 2 . The vertical distance between the flue gas inlet and the spray layer is 3-5 meters. However, the height of the swirl device in the swirl coupling tower is about 2 meters, so the distance between the flue gas inlet and the first layer of spraying is relatively large, at least 4 meters is required to ensure a sufficient installation position. Therefore, compared with the swirl-sink coupling tower, the tower height of the turbule...

Embodiment 2

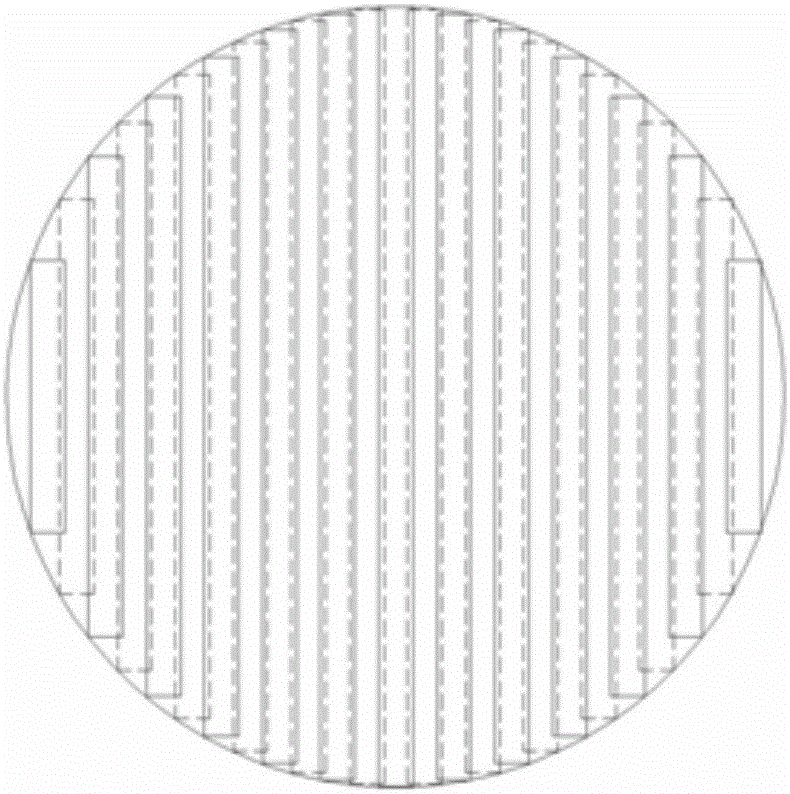

[0055] Such as image 3 and Figure 4 As shown, some adjustments are made on the basis of Embodiment 1, wherein the projections in the vertical direction of the tubes in one tube row and the tubes in the other tube row are perpendicular to each other. The simulated flow field calculation shows that the vertical arrangement of the tube spaces in adjacent tube columns can also obtain better desulfurization effect. The specific calculation process of the simulated flow field is as follows:

[0056] Fluent flow field simulation software is used to simulate the flue gas flow field under different porosity arrangements. It can be seen that the vertical arrangement between the tube rows can also obtain better turbulent flow effects, and the flue gas flow field is very uniform after passing through the device. , can better avoid the problem of sticking flow.

[0057] A) Layout parameters: the pipe diameter is 65mm, the horizontal spacing is fixed at 115mm, and the horizontal spacin...

Embodiment 3

[0059] Such as Figure 5 and Figure 6 As shown, the tubes in the tube row can also be elliptical tubes with a minor axis of the outer wall of 30-70mm and an ellipticity of 0.4-0.7, and the tubes in one tube row are staggered and parallel to the tubes in the other tube row. The specific calculation process of the simulated flow field is as follows:

[0060] Fluent flow field simulation software is used to simulate the flue gas flow field under different porosity arrangements. It can be seen that when using elliptical tubes, the width of the flow channel between the tubes can be increased, the range of turbulent flow between the tubes can be increased, and it can be appropriately reduced. The flow velocity between the pipes reduces the impact of the airflow on the pipe fittings.

[0061] A) Layout parameters: the size of the elliptical tube is 84*65mm, the horizontal spacing is 114mm, and the vertical spacing is 100mm; the velocity cloud diagram and velocity vector diagram ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com