Method for depriving sulfureted hydrogen in biogas and device

A biogas and hydrogen sulfide technology, applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of low desulfurization efficiency and high operating costs of biogas, and achieve simple methods, good desulfurization efficiency, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

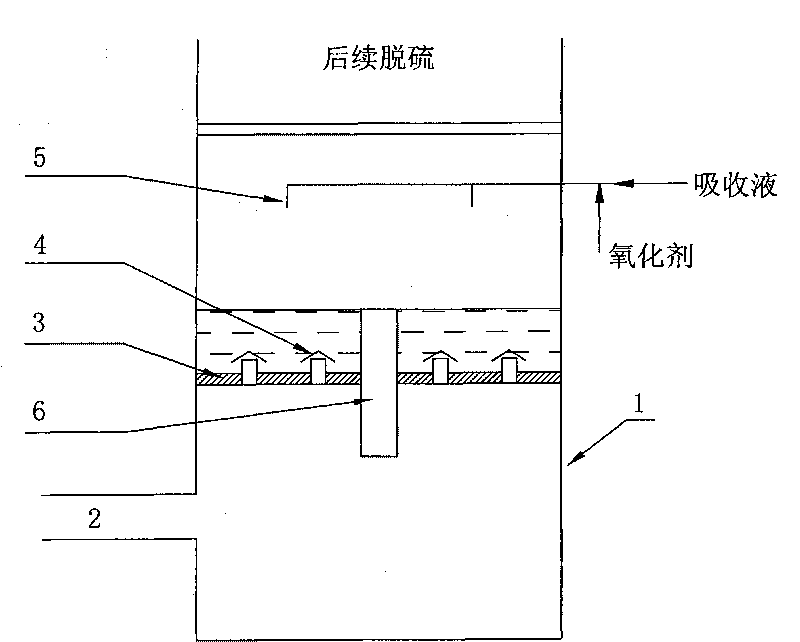

[0026] Such as figure 1 shown.

[0027] A method for removing hydrogen sulfide in biogas, it comprises the following steps:

[0028] First, the biogas enters the bubble tray absorption and oxidation device, and the hydrogen sulfide in the biogas is absorbed by the sprayed absorption liquid containing oxidant, and the absorption liquid is Na 2 CO 3 / NaHCO 3 or Na 2 CO 3 / NaHCO 3 The compound solution with high-valent iron salt complexes, the compound ratio is 1:0.5-5% by mass, where Na 2 CO 3 / NaHCO 3 or Na 2 CO 3 / NaHCO 3 The mass ratio of the high-valent iron salt complex is 1, and the mass ratio of the high-valent iron salt complex is 0.5 to 5. The high-valent iron (ferric iron) salt complex can be EDTA complex iron, sulfosalicylic acid complex iron, triethanolamine Complexed iron, etc.: the oxidizing agent is one or a combination of ozone, hydrogen peroxide or potassium permanganate, wherein the concentration range of ozone is: 0.2 ~ 10g / m 3 , the concentration...

Embodiment 2

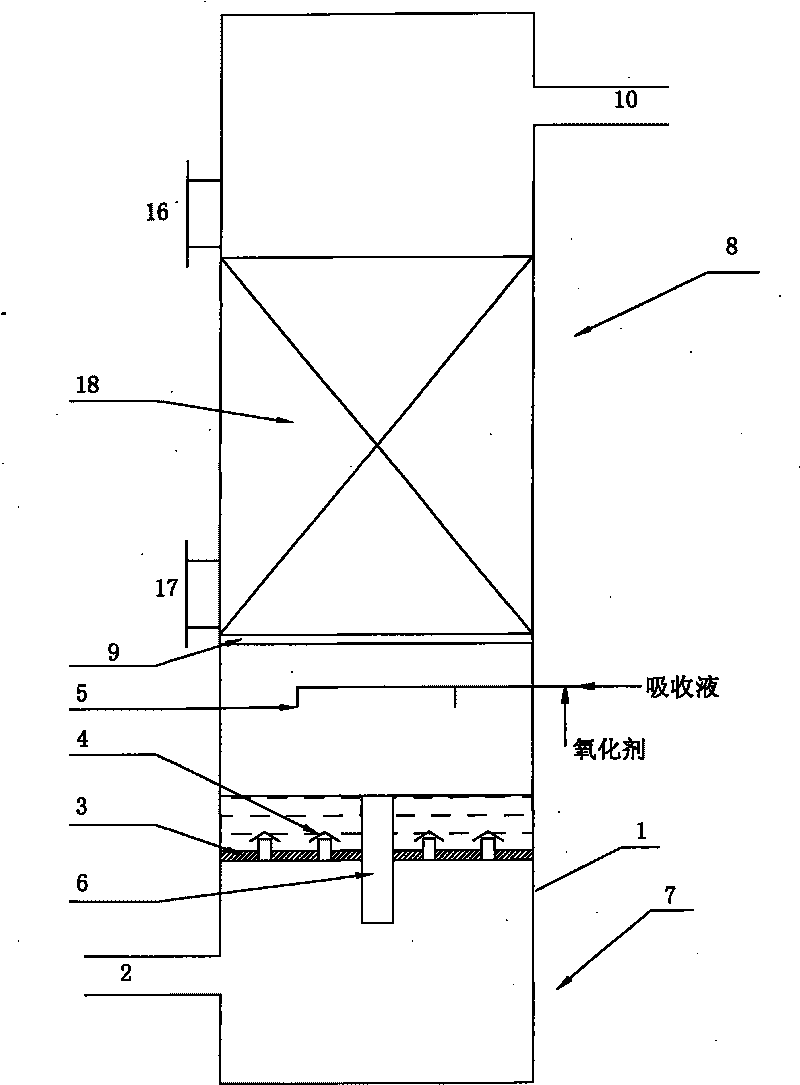

[0033] Such as figure 2 shown.

[0034] A device for removing hydrogen sulfide in biogas, which is mainly composed of a bubbling tray absorption and oxidation device 7 and a dry desulfurization tower 8, and the dry desulfurization tower 8 is located on the upper part of the bubbling tray absorption and oxidation device 7, two The upper grid plate 9 is used as the air inlet of the dry desulfurization tower 8, and the upper part of the dry desulfurization tower 8 is provided with an air outlet 10, and the lower part of the air outlet 10 is provided with a feeding port 16 , the lower part of the feeding port 16 is the desulfurizing agent layer 18 of the main desulfurization unit of the dry-type desulfurization tower. The bottom of the grid plate 9 is installed with the absorption liquid spray pipe 5 in the bubble tray absorption and oxidation device 7; Gas inlet 2, the upper part of the housing 1 is provided with a biogas outlet, in the housing 1, above the inlet 2, a grid pla...

Embodiment 3

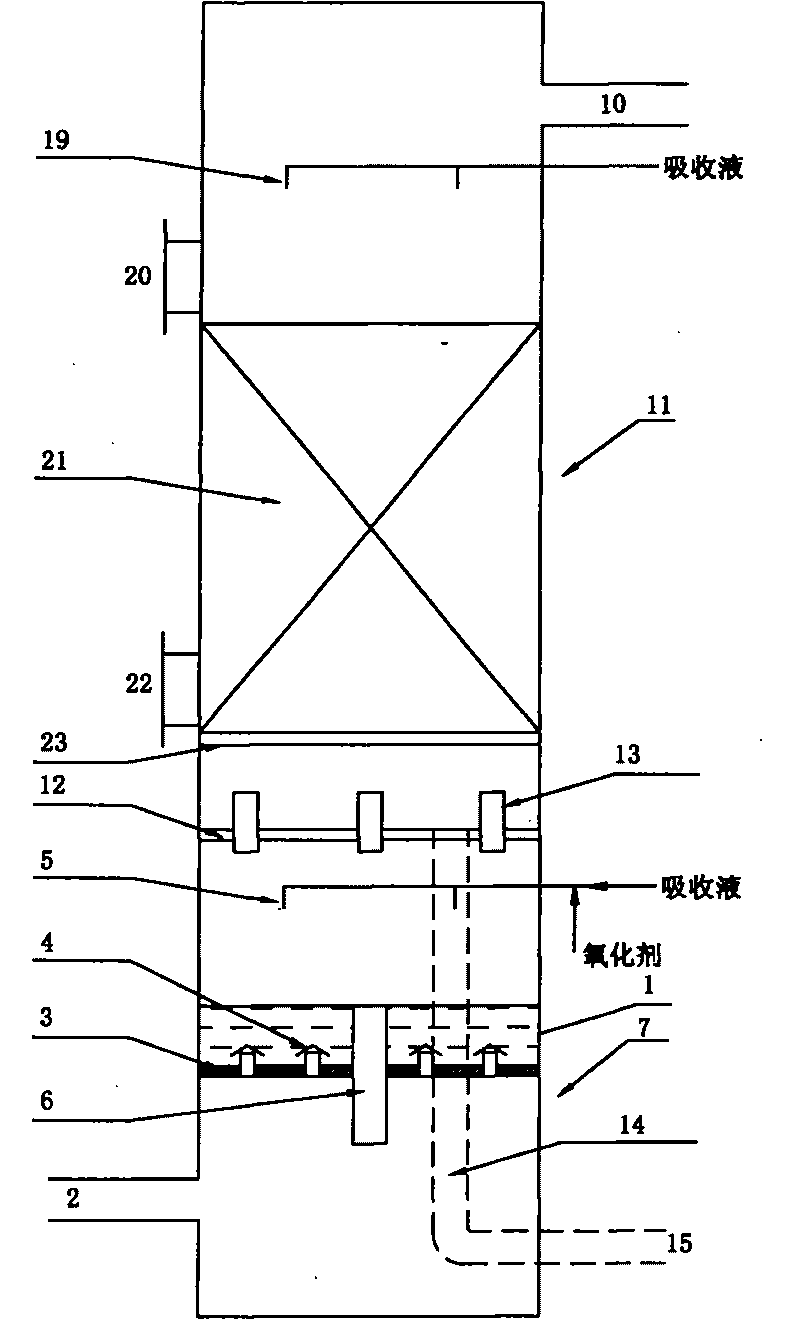

[0036] Such as image 3 shown.

[0037] A device for removing hydrogen sulfide in biogas, which is mainly composed of a bubbling tray absorption and oxidation device 7 and a wet desulfurization tower 11, and the wet desulfurization tower 11 is located at the upper part of the bubbling tray absorption and oxidation device 7, between the two The space is separated by a partition 12, and the partition 12 is equipped with a gas lift tube 13 and a downcomer 14, and the lower end of the downcomer 14 extends from the lower part of the bubble tray absorption oxidation device 7 and the absorption liquid regeneration circulation device 15 The gas outlet 10 and the absorption liquid spray pipe 19 are arranged on the upper part of the wet desulfurization tower 11. The middle of the wet desulfurization tower 11 is a packing layer 21, and the packing layer 21 is supported on the upper grid plate 23. The upper part of the packing layer 21 is provided with There is a feed port 20, the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com