Method for dewatering microalgae with bubble column

A technology of bubbles and microalgae, which can be used in sterilization methods, methods of supporting/immobilizing microorganisms, methods of sampling biological materials, etc., and can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

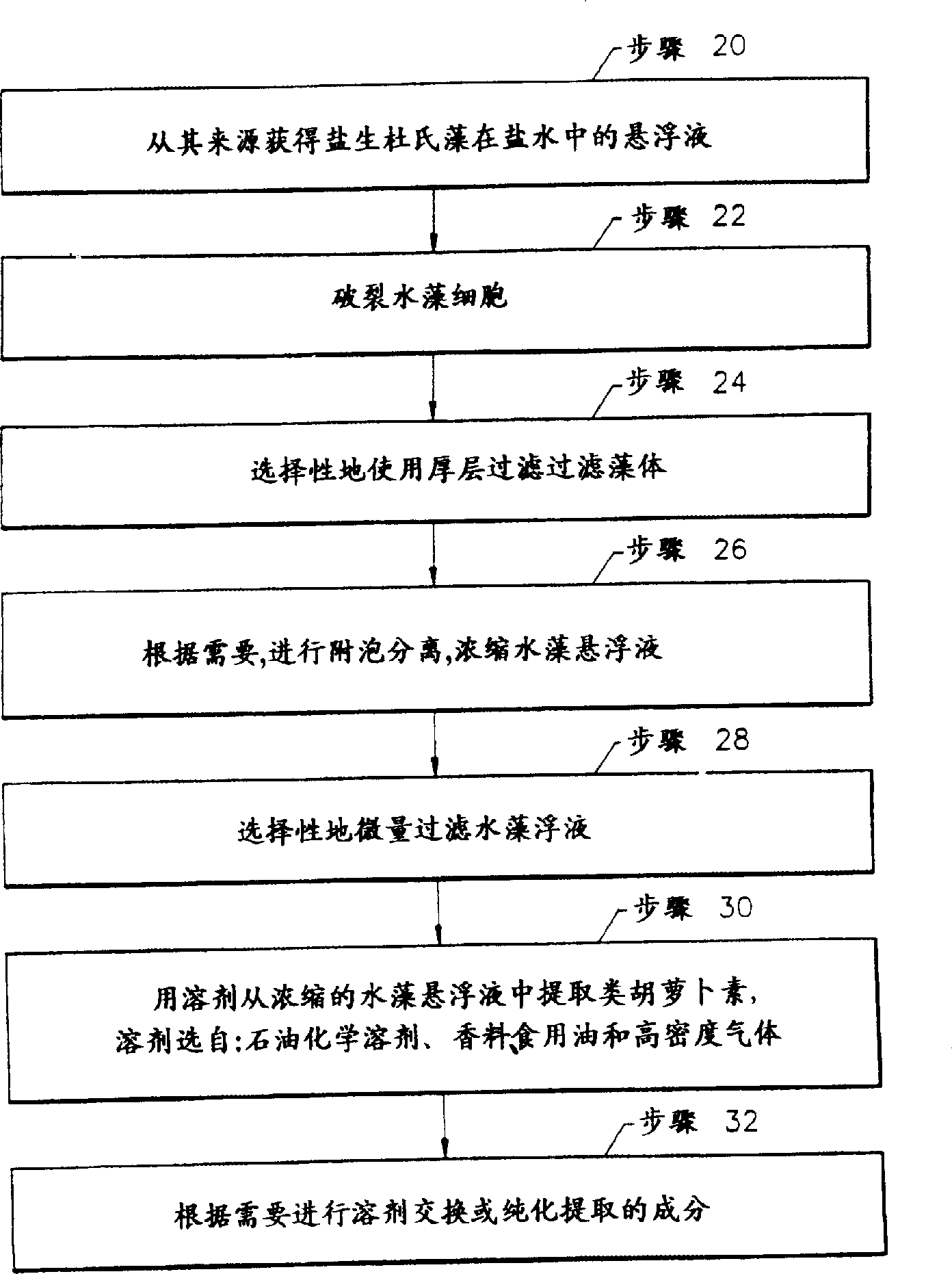

Method used

Image

Examples

Embodiment 8-10

40CFH

1500

84

[0295] 2000 milliliters of brines containing low, medium and high concentrations of Dunaliella salina were respectively charged into the flotation cell and mixed for 10 minutes. The effect of cell concentration on carotenoid recovery is summarized in Table 7.

[0296] Example number

Carotenoid concentration

Carotenoids

Recovery rate(%)

26

0.00032 mg / ml saline (~1800 cells

/ ml)

90%

27

0.002 mg / ml saline

70%

28

0.125 mg / ml saline (~1.3M cells /

ml)

66%

[0297] 2000 milliliters of suspended brine containing Dunaliella salina is loaded into the flotation cell. Triton X-100 was added to the brine and the solution was mixed for 1 minute at 1500 rpm without air. Then the air valve was opened and the suspension was mixed with air for 20 minutes. Carotenoid recovery was measured after 10 minutes and the results are summarize...

Embodiment 34

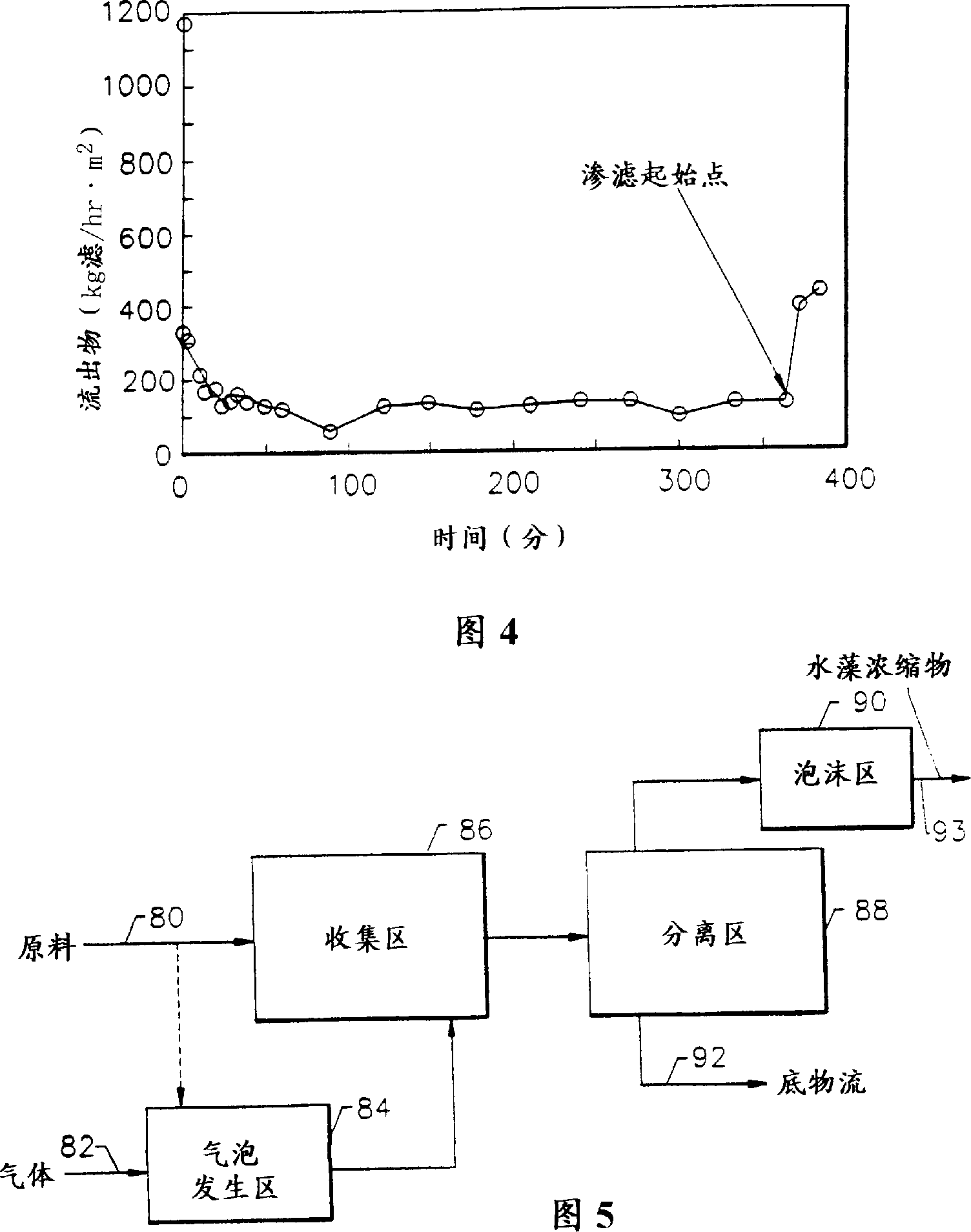

[0302] The foam generated in the test described in Example 34 was collected and treated with a Jameson tank having the geometry described in Example 34 to further concentrate the carotenoids. Groove J g The value is 0.27 cm / s. The jet velocity was 10.6 m / s. The surface velocity of the downcomer is 0.13 m / s. The downcomer liquid residence time was 23.2 seconds. The ratio of air to feedstock was 0.49. The recovery of carotenoids from this process averaged 89.7%. The percentage of solids in the foam was 0.5% (excluding gases). Example 36

[0303] The brine containing the Dunaliella salina suspension was treated with a Jameson tank having the geometry described in Example 34 without any mechanical or chemical pretreatment. Groove J g The value is 0.65 cm / s. The jet velocity was 46.1 m / s. The surface velocity of the downcomer is 0.175 m / s. The downcomer liquid residence time was 17.5 seconds. The ratio of air to feedstock was 0.88. The recovery of carotenoids from this...

Embodiment 37

[0304] The foam generated in the test described in Example 34 was collected and treated with a Jameson tank having the geometry described in Example 34 to further concentrate the carotenoids. The Jg value of the groove is 0.29 cm / sec. The jet velocity was 11.9 m / s. The surface velocity of the downcomer is 0.14 m / s. The downcomer liquid residence time was 21.7 seconds. Feed pressure was 22 psi. The ratio of air to feedstock was 0.49. Carotenoid recovery from this process averaged 68%. The percent solids in the foam was 8.3% (excluding gas). Example 38

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com