Technological method for co-production of ammonium bicarbonate through melamine tail gas

A technology for co-production of melamine and exhaust gas, which is applied in the direction of ammonium carbonate/acid carbonate, etc., can solve the problems such as the difficulty of gas outlet purification indicators, the difficulty of gas purification to meet the standards, and the acceleration of the formation of fine crystals. Difficulty of sewage treatment and environmental protection pressure, the effect of alleviating the impact of carbonization process and reducing ammonia loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

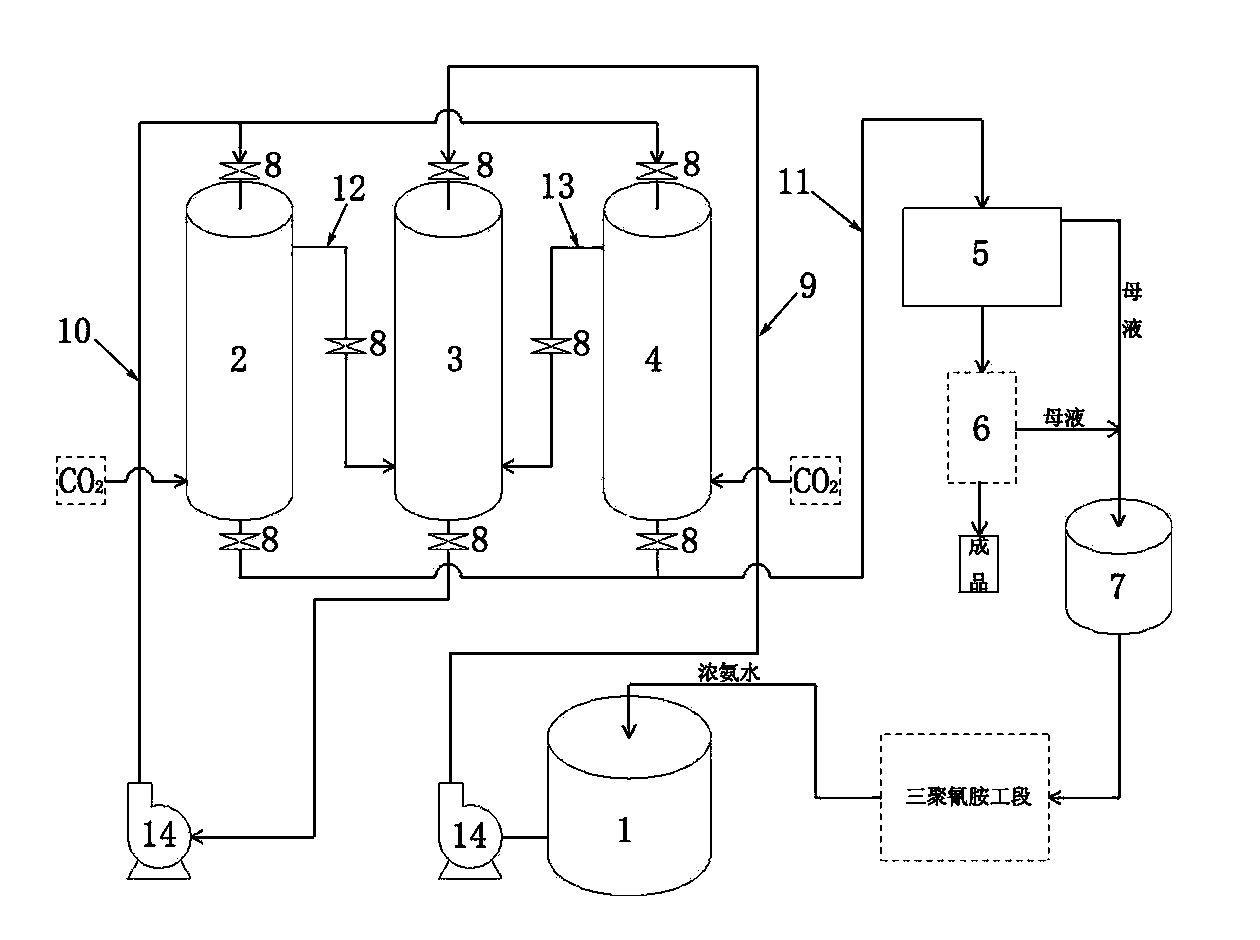

[0022] Such as figure 1 Shown, a kind of processing method of melamine tail gas coproduction ammonium bicarbonate comprises the steps:

[0023] 1) Design and manufacture of co-production process system: the production system includes ammonia water tank 1, carbonization main tower 2, carbonization auxiliary tower 3, bubble tower 4, thickener 5, centrifuge 6 and mother liquor tank 7; ammonia water tank 1, carbonization The top and bottom of the main tower 2, the carbonization auxiliary tower 3, the bubble tower 4, and the mother liquid tank 7 are respectively provided with a water inlet and a water outlet, wherein the water inlet and the outlet of the carbonization main tower 2, the carbonization auxiliary tower 3, and the bubble tower 4 All be provided with valve 8 on the water inlet; The water outlet of ammonia water tank 1 is connected with the water inlet of carbonization sub-tower 3 by the first pipeline 9, and the water outlet of carbonization sub-tower 3 is connected with...

Embodiment 2

[0027] Such as figure 1 Shown, a kind of processing method of melamine tail gas coproduction ammonium bicarbonate comprises the steps:

[0028] 1) Design and manufacture of co-production process system: the production system includes ammonia water tank 1, carbonization main tower 2, carbonization auxiliary tower 3, bubble tower 4, thickener 5, centrifuge 6 and mother liquor tank 7; ammonia water tank 1, carbonization The top and bottom of the main tower 2, the carbonization auxiliary tower 3, the bubble tower 4, and the mother liquid tank 7 are respectively provided with a water inlet and a water outlet, wherein the water inlet and the outlet of the carbonization main tower 2, the carbonization auxiliary tower 3, and the bubble tower 4 All be provided with valve 8 on the water inlet; The water outlet of ammonia water tank 1 is connected with the water inlet of carbonization sub-tower 3 by the first pipeline 9, and the water outlet of carbonization sub-tower 3 is connected with...

Embodiment 3

[0032] like figure 1 Shown, a kind of processing method of melamine tail gas coproduction ammonium bicarbonate comprises the steps:

[0033] 1) Design and manufacture of co-production process system: the production system includes ammonia water tank 1, carbonization main tower 2, carbonization auxiliary tower 3, bubble tower 4, thickener 5, centrifuge 6 and mother liquor tank 7; ammonia water tank 1, carbonization The top and bottom of the main tower 2, the carbonization auxiliary tower 3, the bubble tower 4, and the mother liquid tank 7 are respectively provided with a water inlet and a water outlet, wherein the water inlet and the outlet of the carbonization main tower 2, the carbonization auxiliary tower 3, and the bubble tower 4 All be provided with valve 8 on the water inlet; The water outlet of ammonia water tank 1 is connected with the water inlet of carbonization sub-tower 3 by the first pipeline 9, and the water outlet of carbonization sub-tower 3 is connected with ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com