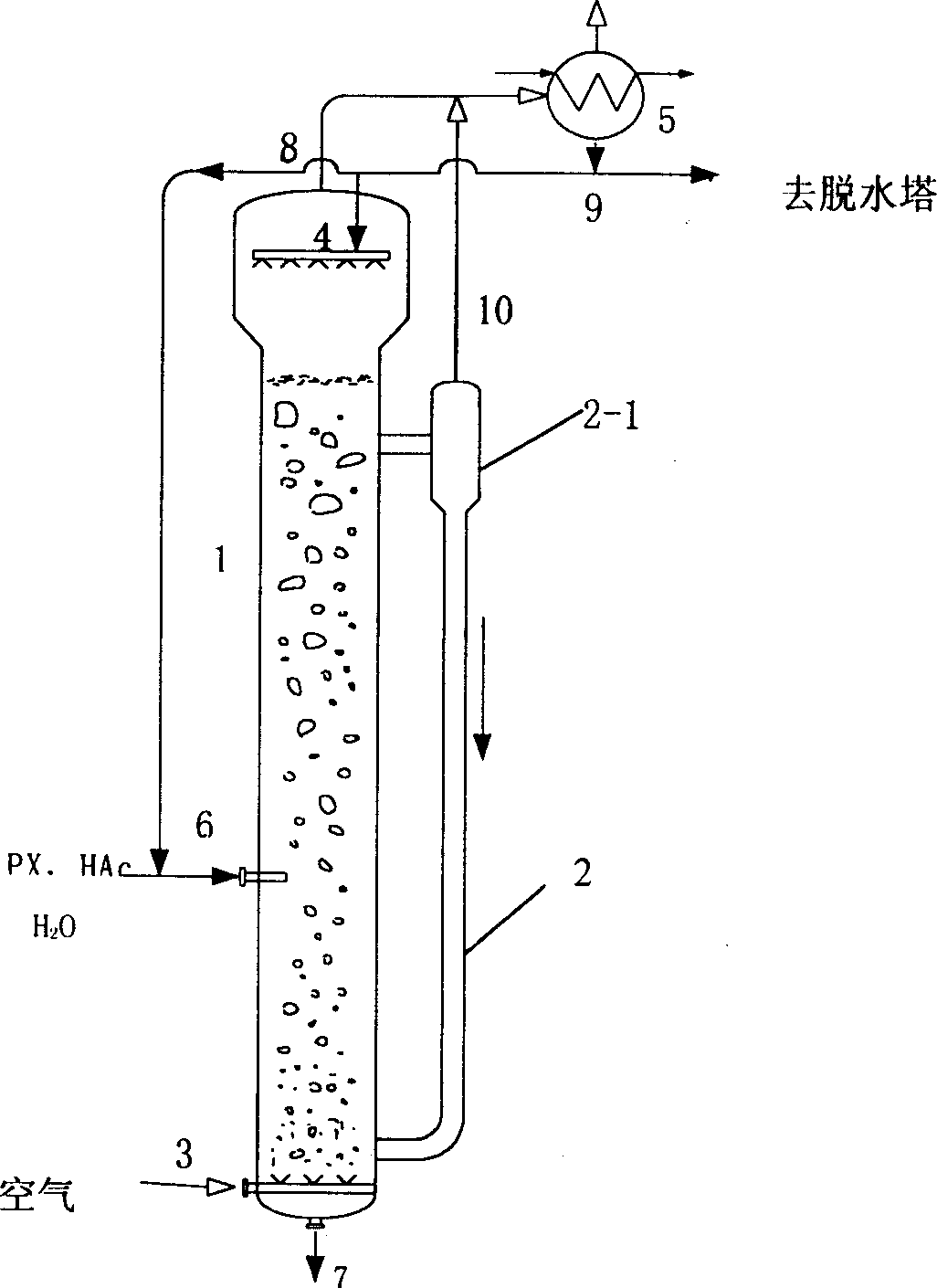

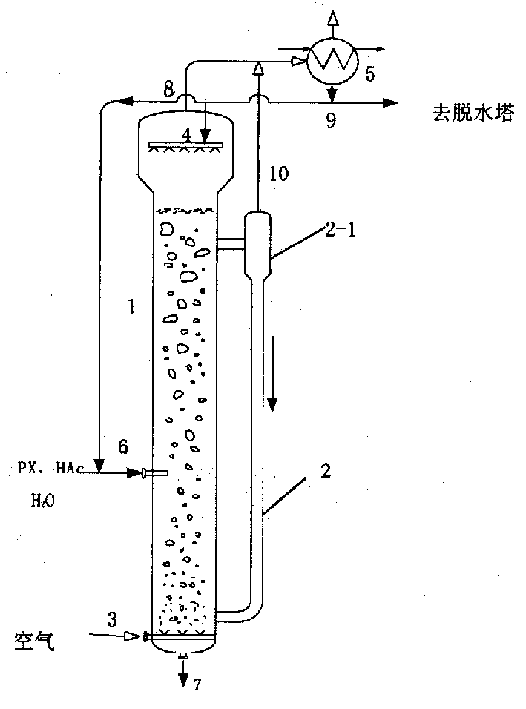

Air lift externally circulating bubble fower oxidation unit for producing terephthalic acid

A technology of terephthalic acid and oxidation device, which is applied in the fields of organic chemistry, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of intensified combustion consumption of solvents, reduced volume utilization rate of reactors, poor mixing, etc. The effect of simplicity, low construction and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The low-temperature oxidation process is used to produce terephthalic acid. The annual production capacity of a single reactor is 200,000 tons of TA, and the annual production time is 7600 hours. The reaction conditions are given in Table 1.1.

[0026] Central temperature

[0027] The corresponding reactor structure and size are given in Table 1.2.

[0028] diameter (m)

[0029] In the table, D is the diameter of the tower, which is determined according to the production capacity, and H is the height of the reaction section. For a single air-lift external circulation bubble column reactor (ALECBCR) with an annual output of 200,000 tons of terephthalic acid, when the aspect ratio is selected to be 8, D = 3.68m, and the reaction results and related indicators are given in Table 1.3 In the table, the reaction indicators of the bubble column reactor (BCR) without external circulation pipe under the same conditions are also given for comparison.

[0030]...

Embodiment 2

[0033] The medium temperature oxidation process is used to produce terephthalic acid. The annual production capacity of a single reactor is still 200,000 tons of TA, and the annual production time is 7600 hours. The reaction conditions are given in Table 2.1.

[0034] Central temperature

degree(℃)

PX processing capacity

(10 3 kg / h)

Top pressure

(Mpa, absolutely

pressure)

Spend

(v O2 , %)

catalyst concentration

(to the mass fraction of HAc

number, 10 -6 )

h 2 O / HAc

(mass percentage)

Feed HAc / PX

co

mn

Br

185.0

17.72

1.168

3.50

691

406

892

7.52

4.66∶1

[0035] For the medium temperature oxidation process, when the aspect ratio is selected as 8, D=3.19m, and the structure and size of the reactor are given in Table 2.2

[0036] diameter (m...

Embodiment 3

[0040] The high-temperature oxidation process is used to produce terephthalic acid. The annual production capacity of a single reactor is still 200,000 tons of TA, and the annual production time is 7600 hours. The reaction conditions are given in Table 3.1. The structure and size of the reactor are shown in Table 3.2, and the output results of the reactor are listed in Table 3.3. Under the same reaction conditions and output results, the external circulation bubble reactor is 3.2% larger than the conventional bubble column reactor. The effect of the external circulation pipe in the above three cases is slightly different, which is mainly due to the difference in the size of the reactor and the external circulation pipe, resulting in different circulation flow rates.

[0041]

[0042] diameter (m)

[0043] PX conversion

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com