Bubbling type system for gathering carbon dioxide (CO2) by hydrate process

A technology of carbon dioxide and hydrate, which is applied in the direction of carbon compounds, educts, inorganic chemistry, etc., can solve the problems of easy degradation of chemical adsorption solvents, high investment and high energy consumption in the cryogenic separation process, and improve resource utilization efficiency, Effect of improving capture economy and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

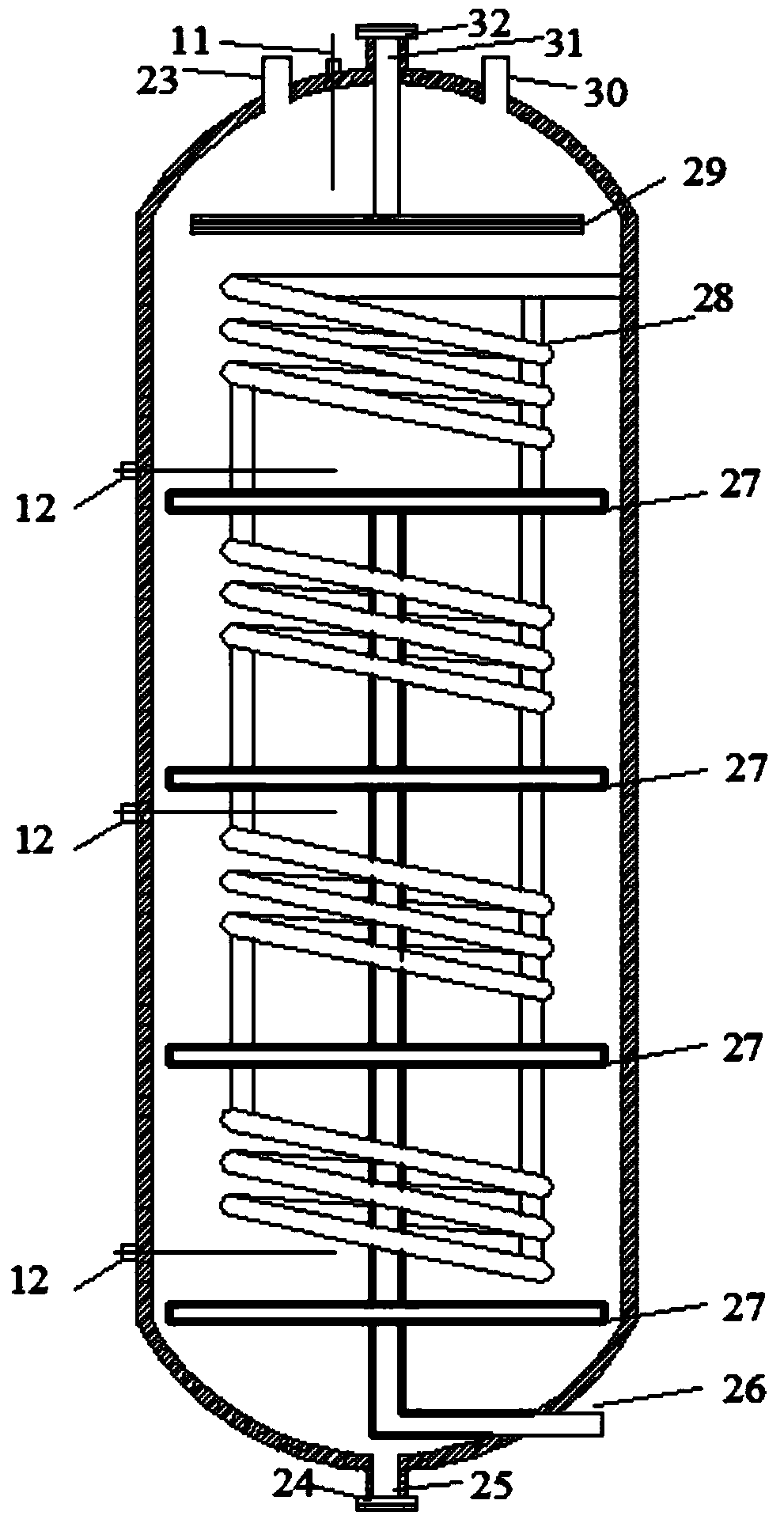

[0035] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions in the description.

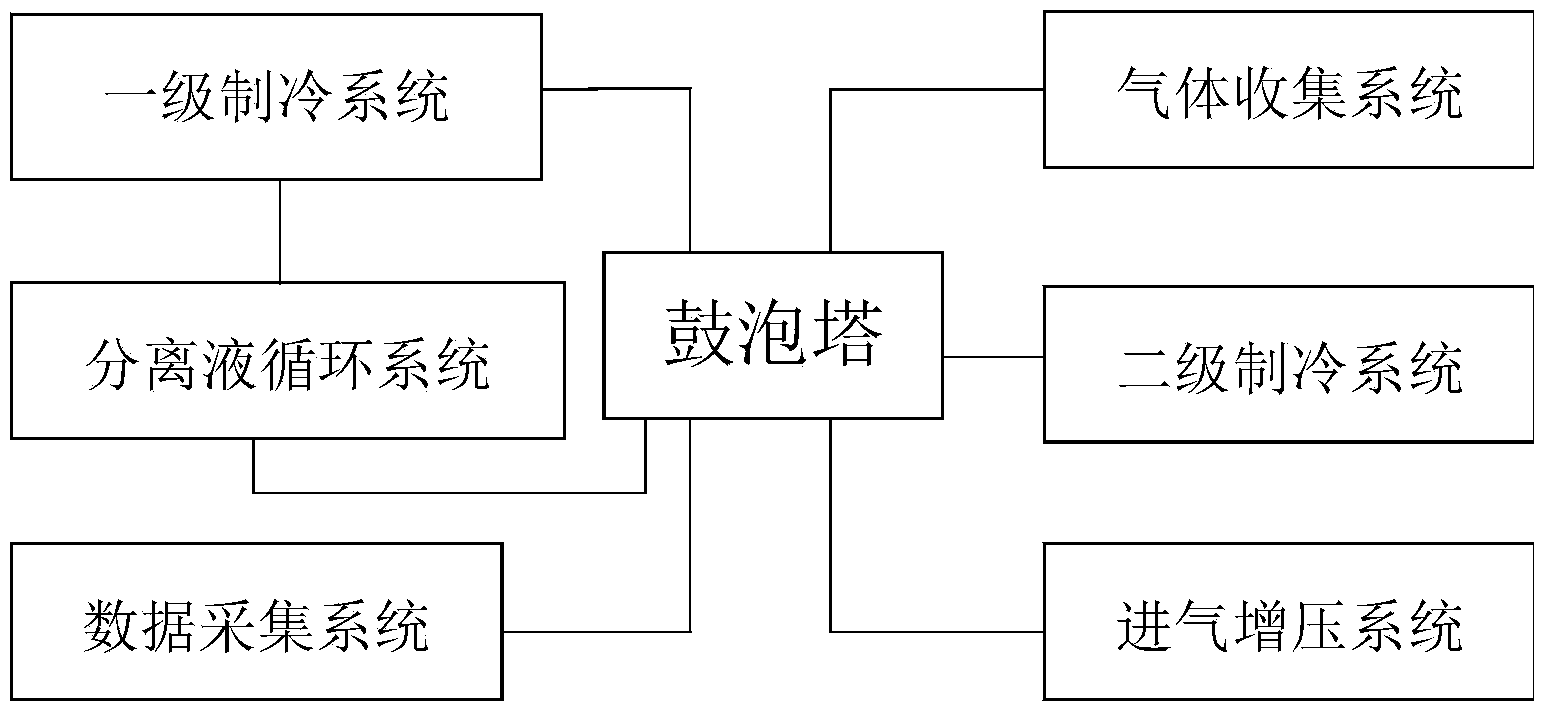

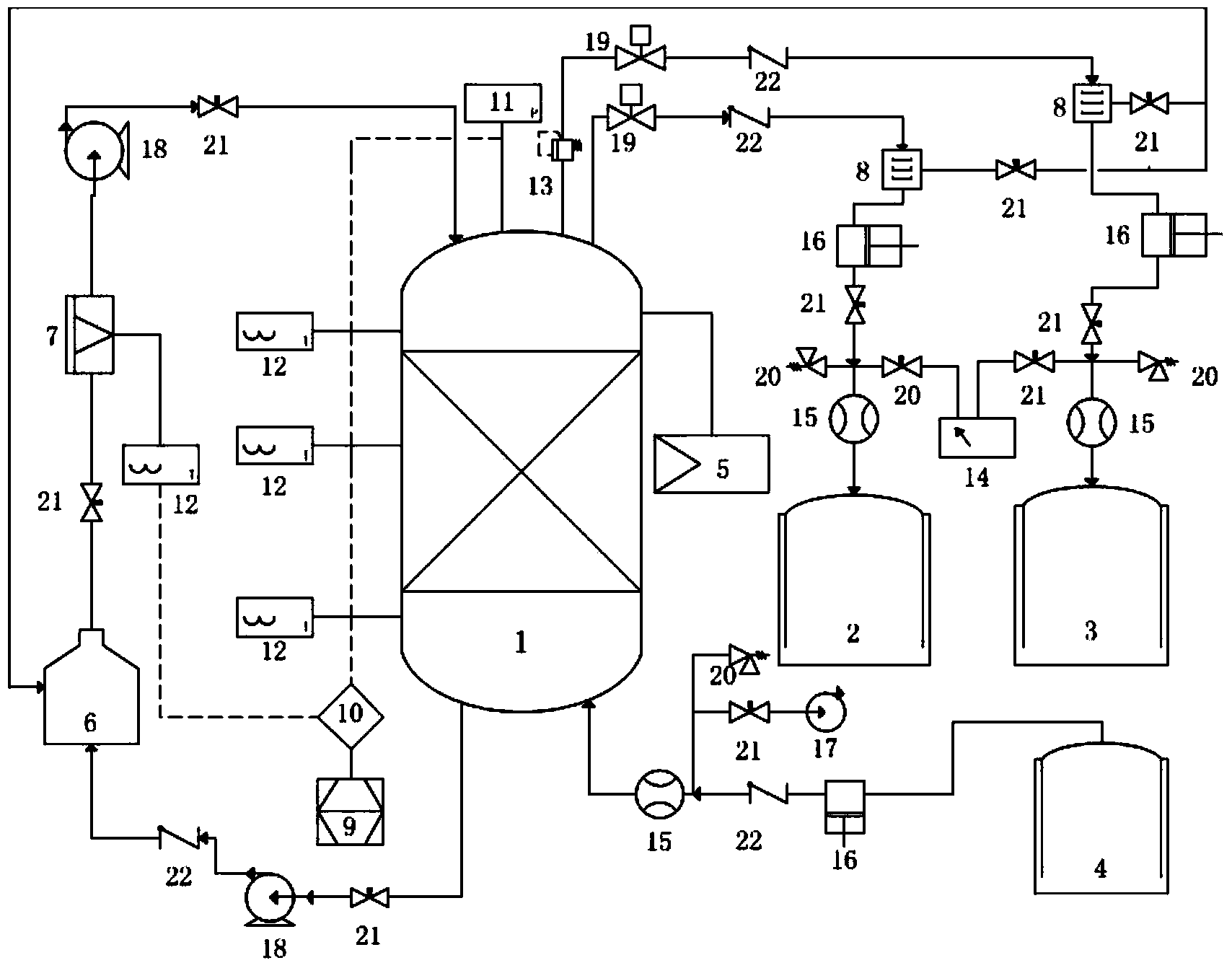

[0036] figure 1 Shown is a block diagram of the working principle of the trapping device, and its working process is as follows: the separated liquid is cooled by the primary refrigeration system and passed into the bubble column. The mixed gas in the inlet pressurization system passes into the bubble column 1 after being pressurized by the gas booster pump 16 . The secondary refrigeration system performs refrigeration to maintain a constant low temperature in the bubble column so that CO 2 A large number of hydrates are formed. Separated high-purity CO 2 Both the gas and residual gas are collected by the gas collection system. Wherein, the residual gas is recycled to the residual gas storage tank 2 through the residual gas collection pipeline, and the CO 2 After hydrate formation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com