Configurable Cooling Assembly and Cooling Method

a cooling assembly and configurable technology, applied in the field of configurable cooling blocks, can solve the problems of limiting the effectiveness of cooling fans and making the challenge of preventing overheating of hsms more difficult, and achieve the effect of being easily configurabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

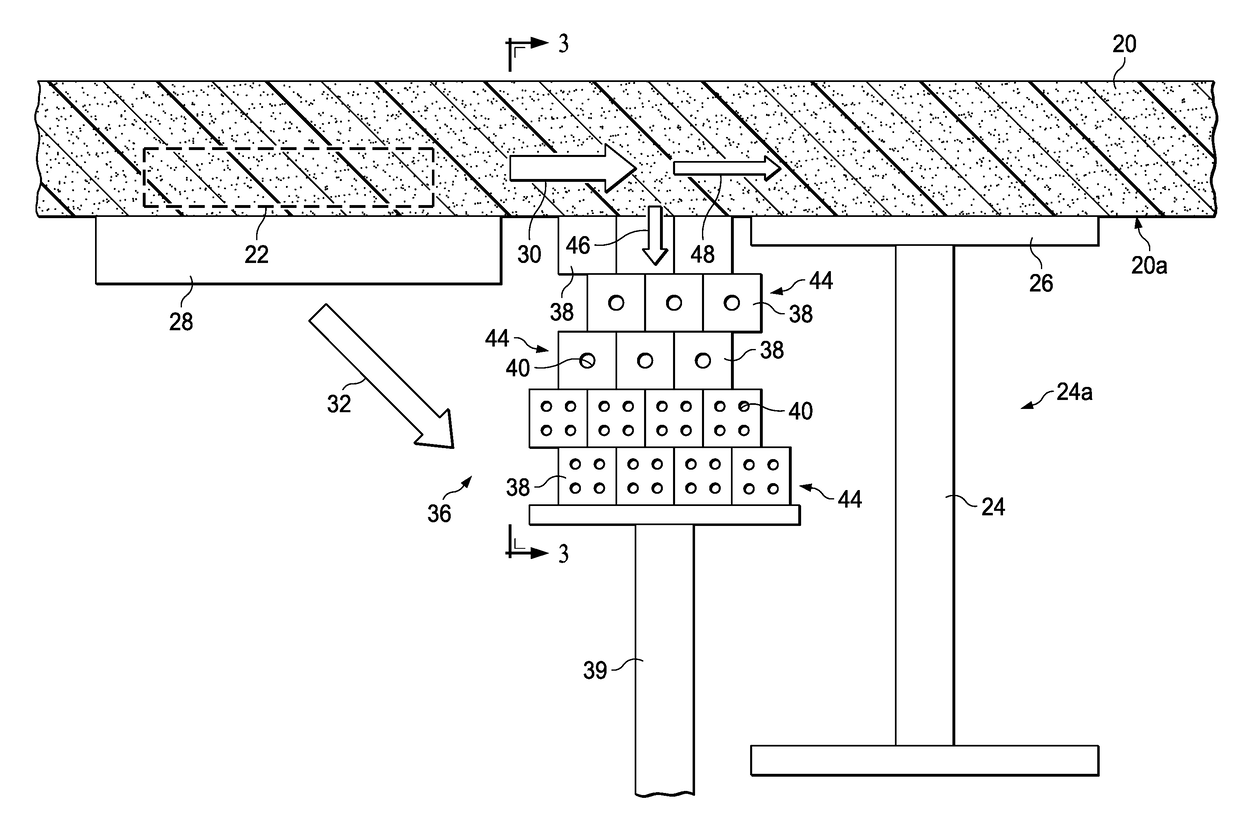

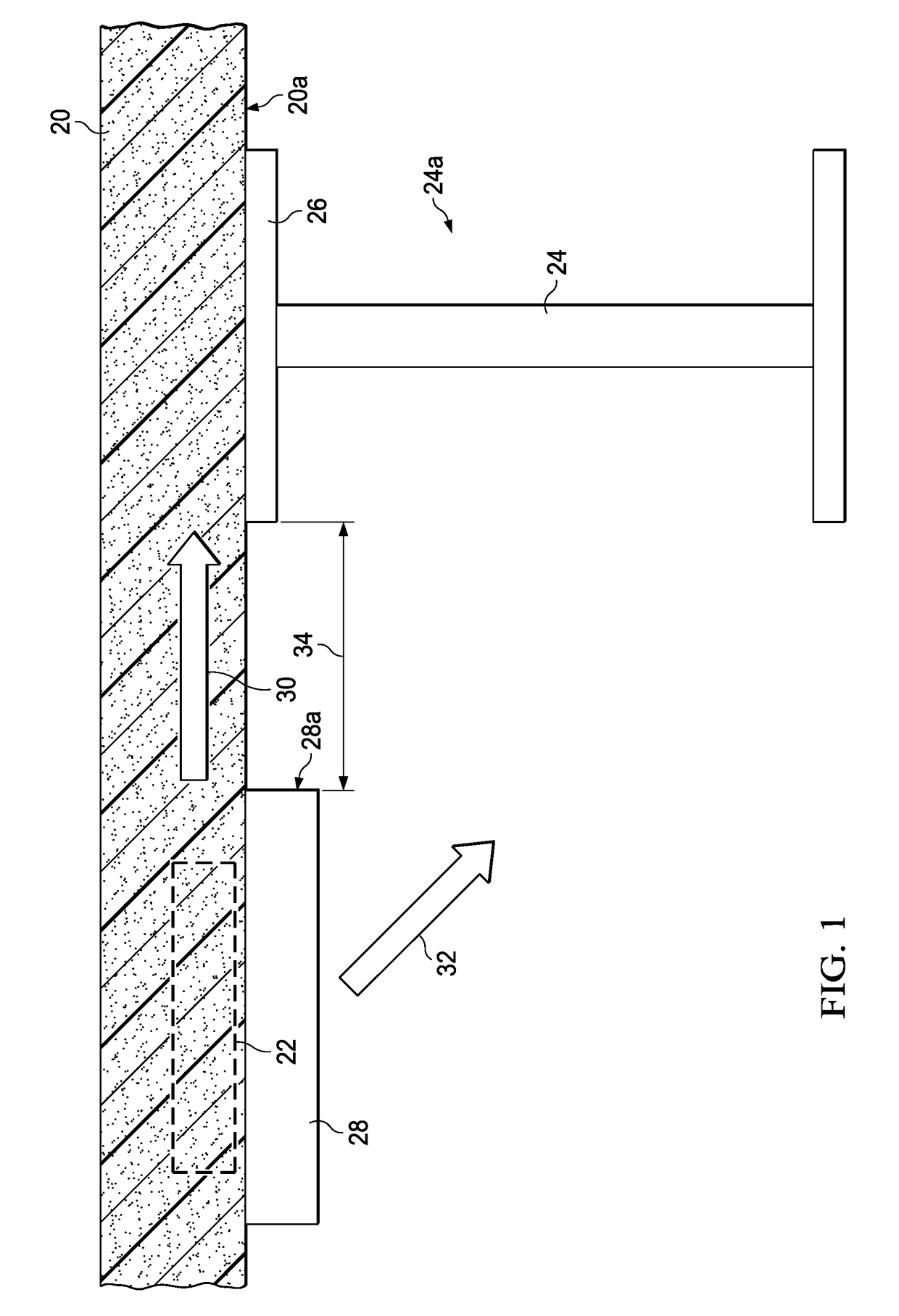

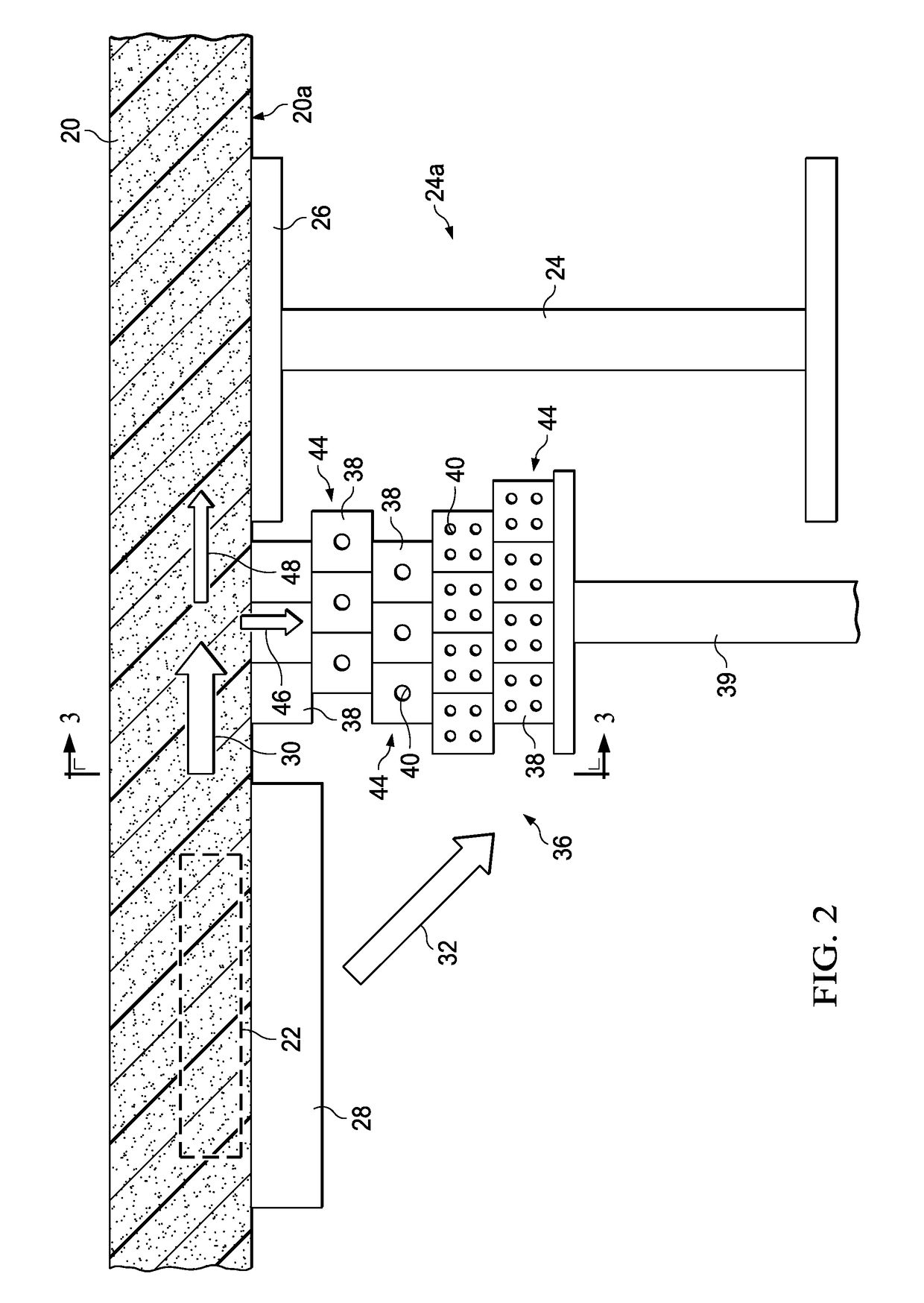

[0027]FIG. 1 illustrates a composite laminate structure such as a composite aircraft skin 20 having an area 22 (hereinafter “repair area”) requiring in-situ repair or rework in order to correct an out-of-specification condition such as impact damage. Although not shown in the Figures, the repair is carried out using a cured or uncured composite laminate patch that is bonded to the skin 20 using a bonding adhesive. A curing assembly (not shown) that includes a heating blanket 28, is used to thermally cure the bonding adhesive and / or the repair patch, which is typically comprised of a fiber reinforced, thermoset or a thermoplastic laminate. The curing assembly may also include a vacuum bag (not shown) that is used to compact the repair patch during the cure process.

[0028]The repair area 22 is located near a heat sensitive material (HSM) 24 which, in the illustrated example, comprises a structural stiffener 24a having a cap 26 which is bonded or otherwise fixed to the surface 20a of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

| thermally conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com