Aluminum borate whisker reinforced zinc-based alloy composite material and preparation method thereof

A technology of aluminum borate whiskers and composite materials, which is applied in the field of aluminum borate whiskers reinforced zinc-based alloy composite materials and its preparation, can solve the problems of high whisker density, low strength, cracks, etc., and achieve the elimination of shrinkage porosity and holes , improve the strength, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

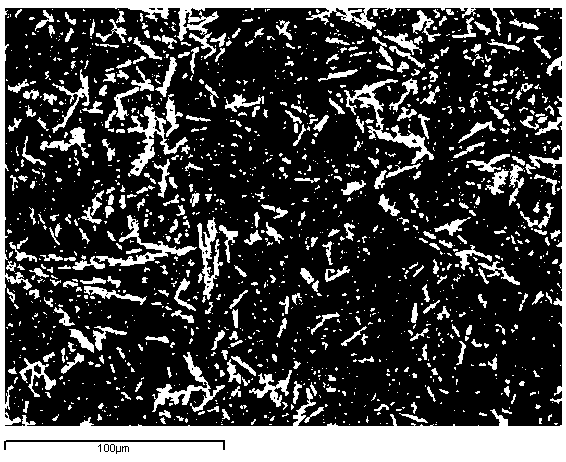

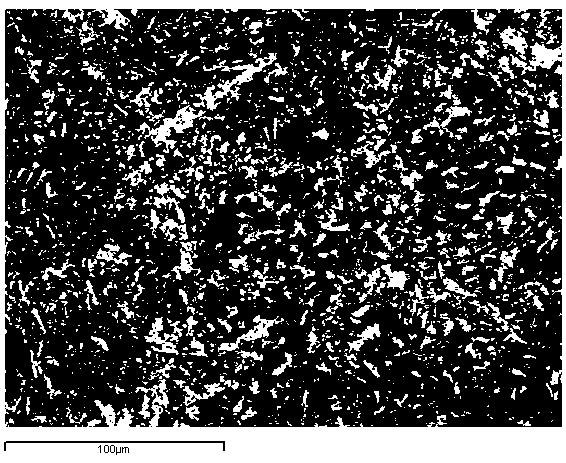

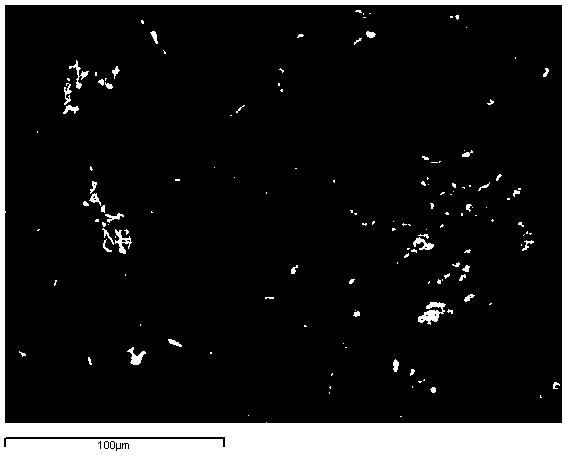

Image

Examples

Embodiment 1

[0025] A preparation method of aluminum borate whisker reinforced zinc-based alloy composite material, comprising the following steps:

[0026] (1) Take 7.5Kg of aluminum borate whiskers and 5Kg of SiO 2 -Na 2 O-B 2 o 3 Mix the glass particles, mix them evenly and put them into the high-speed stirring container, then add 9.5Kg of distilled water into the high-speed stirring container, start the stirrer to stir, the stirring speed is 4000r / min, after stirring for 2 minutes, add 1Kg of PVA, 0.5 Kg of sodium cetyl sulfonate, then reduce the stirring speed to 600r / min, stir for 5 minutes, then insert an ultrasonic vibrator into the solution, open the vibrator to vibrate for 5 minutes, and make a mixed slurry; wherein, SiO 2 -Na 2 O-B 2 o 3 The particle diameter of the glass particles is 2 μm;

[0027] (2) Put the mixed slurry into the spray dryer, and use the spray dryer to pelletize the mixed slurry to make 70 μm spherical whisker coarse particles; wherein, the diameter of...

Embodiment 2

[0032] Embodiment 2: The difference from Embodiment 1 is that in step (4), the zinc-based alloy is heated and melted at a temperature of 520°C to form a zinc-based alloy liquid for later use; 80 parts by volume of aluminum borate whiskers are prefabricated The body is preheated to 450°C in a box-type holding furnace, and the preheated aluminum borate whisker prefabricated body is put into a metal mold, poured into a zinc-based alloy liquid with a volume of 320 parts, and the mold sealing system is closed. Open the high-pressure air valve at the riser of the mold to feed nitrogen, the nitrogen pressure is 20 MPa, keep the pressure until it cools and solidifies, and obtain aluminum borate whisker-reinforced zinc-based alloy composite material. Among them, the zinc-based alloy is made of the following raw materials in mass fractions: Al28%, Cu2.5%, Mg0.02%, and the rest is Zn.

[0033] The volume fraction of the aluminum borate whisker preform of the aluminum borate whisker-reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com