Protective structure and protective method of coated counterweight sea pipe

A technology for protective structures and sea pipes, applied in pipeline anticorrosion/rust protection, damage protection, pipeline protection, etc., can solve problems such as waste of resources, damage at the end of the counterweight layer, aging of the end anticorrosion layer, etc., to prevent steel pipes Corrosion, avoid wall thickness reduction, and prolong the effect of storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the drawings:

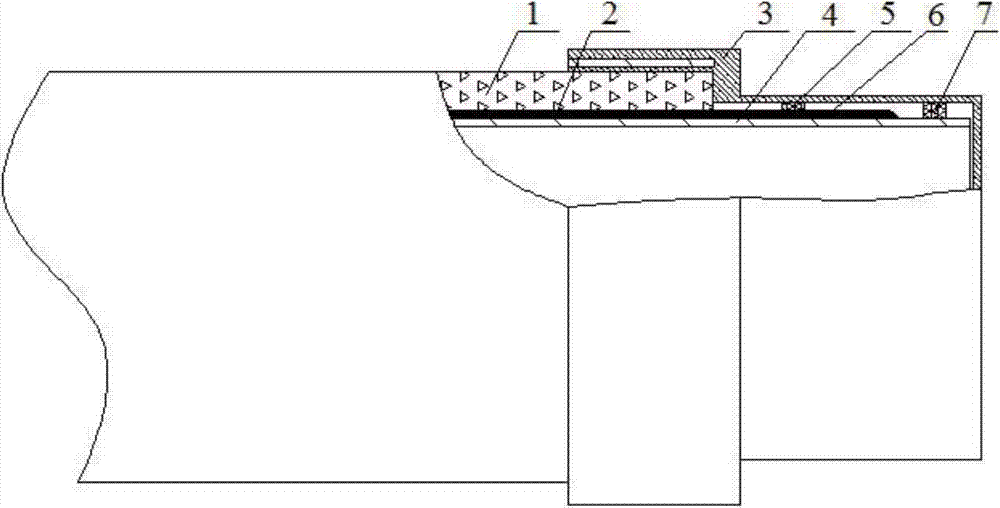

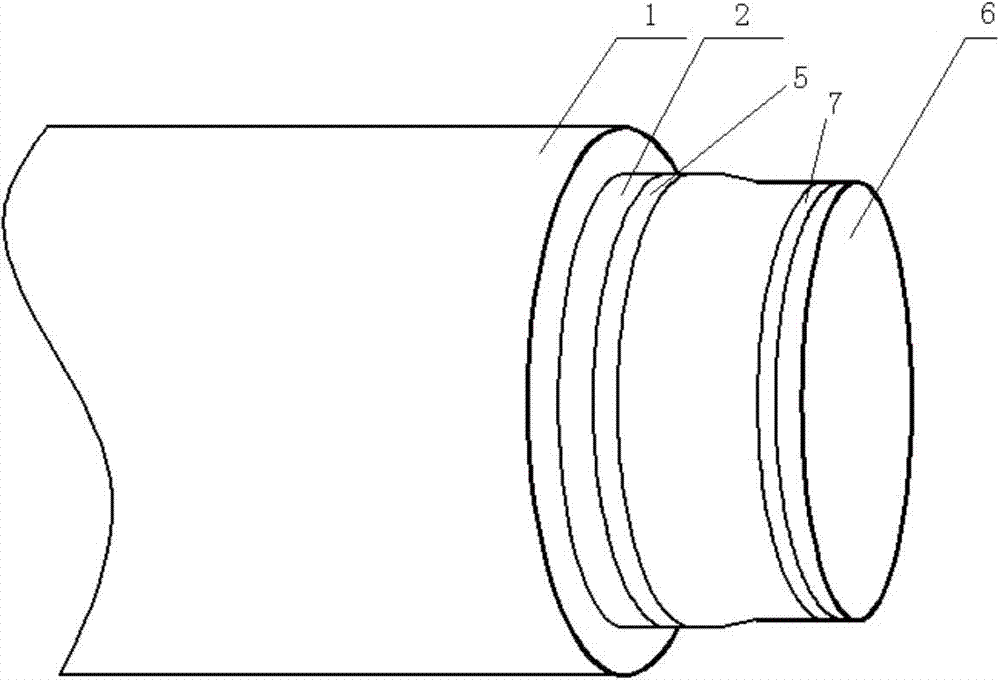

[0033] The present invention provides a protective structure for coating a counterweight submarine pipe, including: a left end seal, a right end seal 6, a left end protector, and a right end protector 3; figure 1 Only a cross-sectional view of one end of the protective structure coated with the counterweight submarine pipe is shown. figure 2 It also only shows the structural schematic diagram of one end of the counterweight submarine pipe with the seal added.

[0034] The counterweight submarine pipeline includes a submarine pipe substrate 4, an anticorrosion layer 2 and a counterweight layer 1. The outer surface of the submarine pipe substrate is coated with an anticorrosion layer to protect the submarine pipe substrate from corrosion; Thereby increasing the weight of the submarine pipe itself, thereby increasing the stability of the submarine pipe underwater. Wherein, the length of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com