Reflection ring lifting device for improving thermal field of zone-melting single-crystal furnace

A technology of reflective ring and furnace thermal field, which is applied in the direction of single crystal growth, self-regional melting method, crystal growth, etc., can solve the problems of low quality of grown single crystal and unadjustable thermal field, and achieve optimized thermal field distribution, convenient Front and rear position adjustment, effect of crack prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

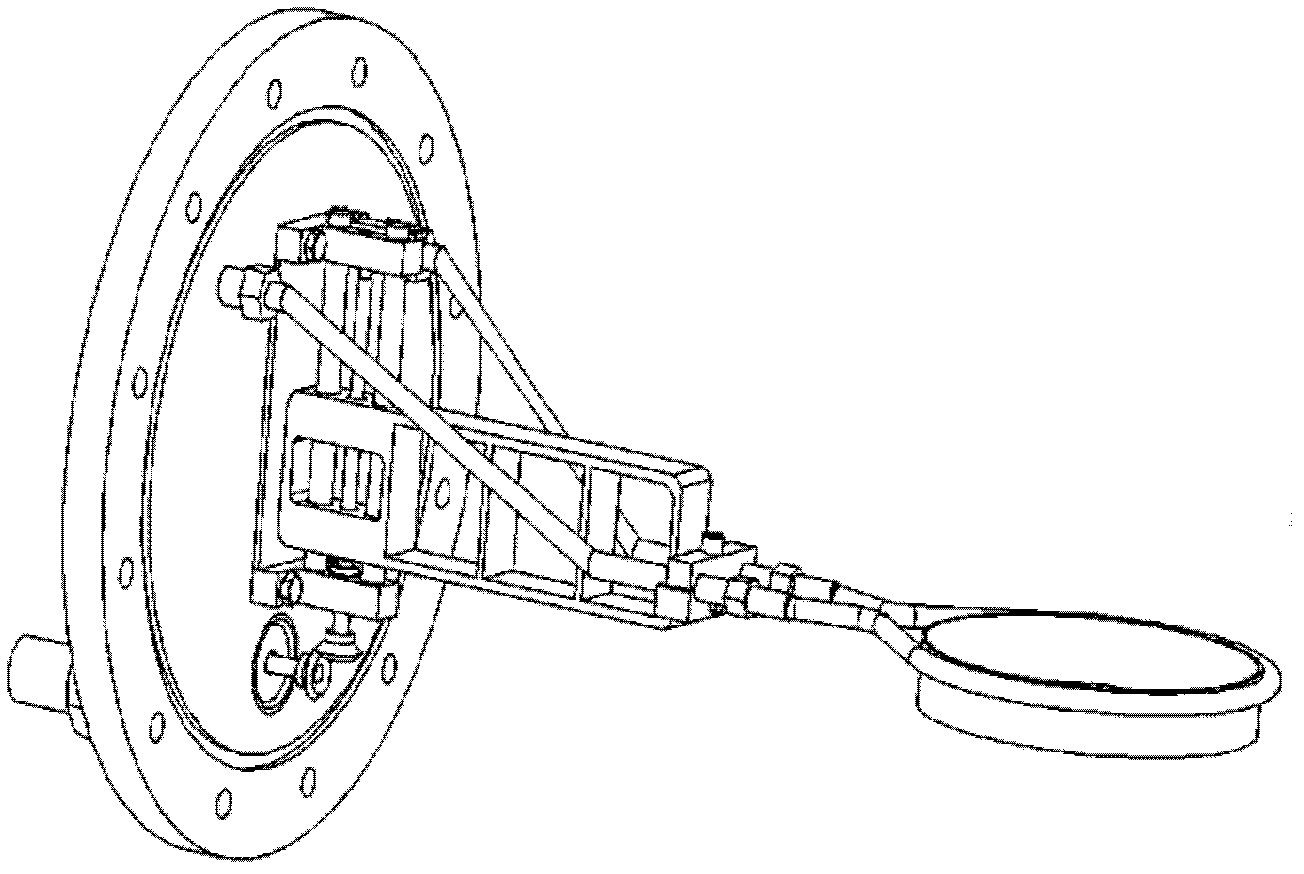

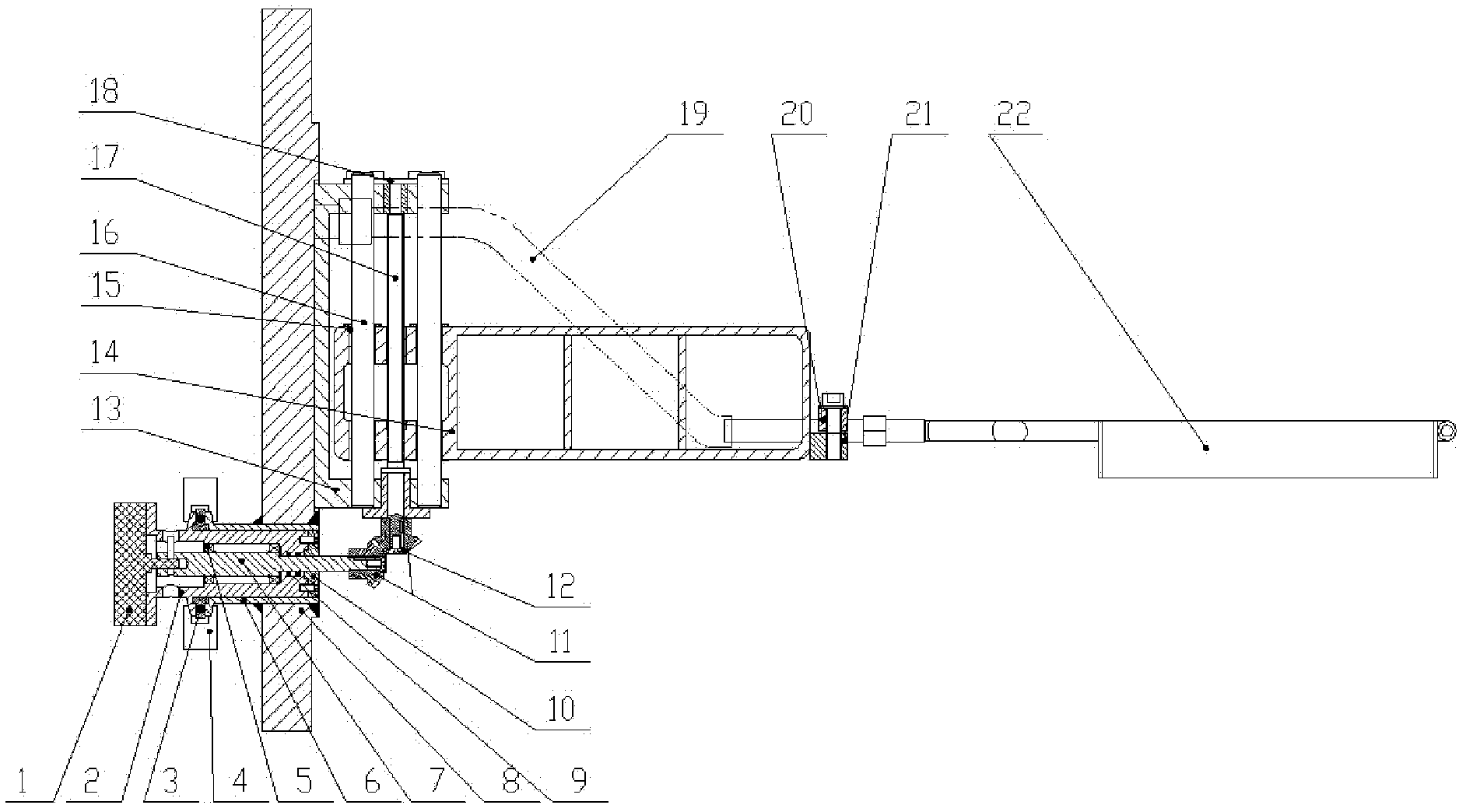

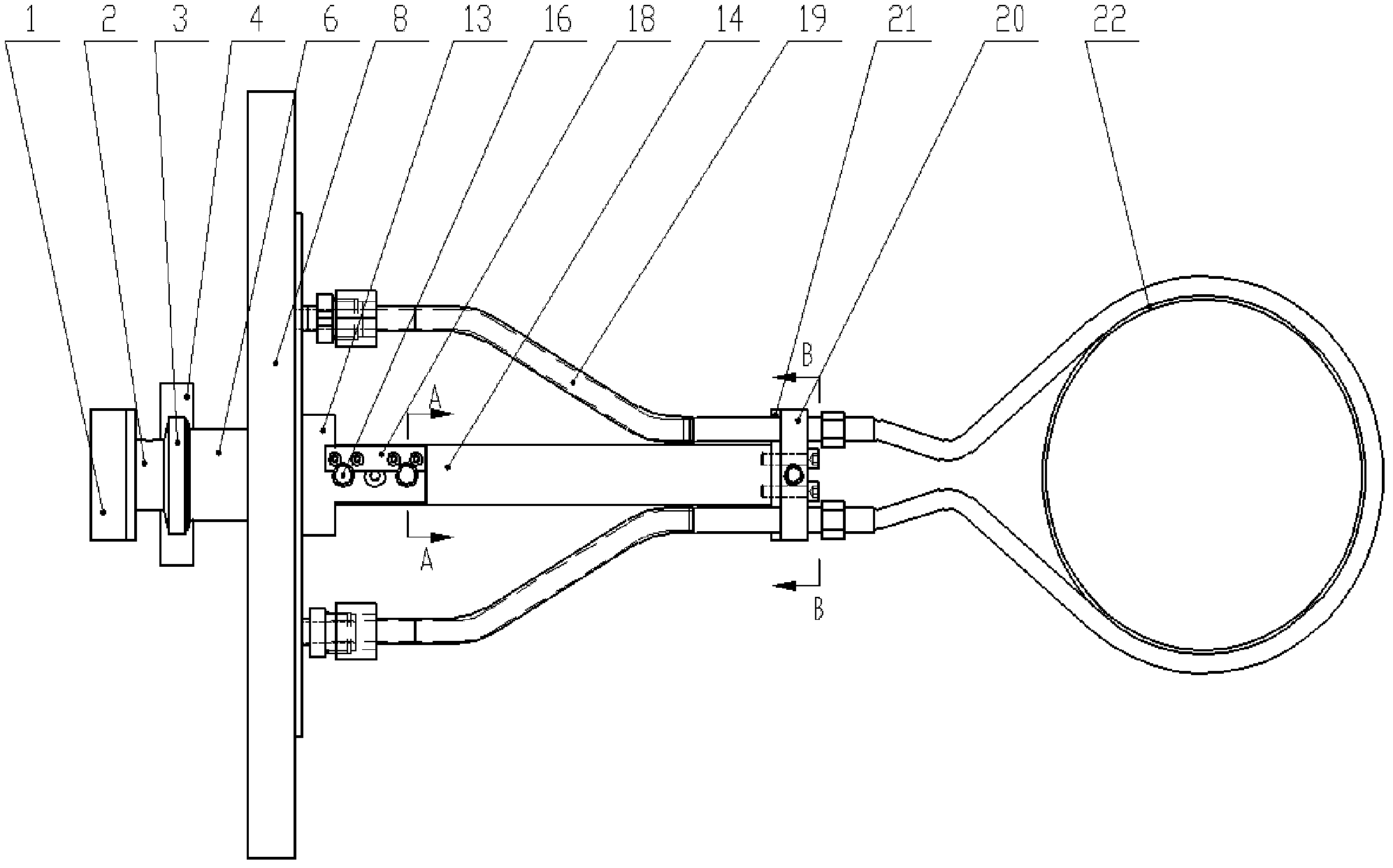

[0027] Such as figure 2 , 3 shown. The hoisting device for the reflective ring of the zone melting single crystal furnace includes a reflective ring 22 and a window flange 8 fixed on the flange of the main furnace chamber. The reflective ring 22 is an annular red copper sheet with a diameter of 200-350 mm and a thickness of 3-10 mm. A hollow cooling pipe is set on the outer side of the reflection ring 22, and the two ends of the cooling pipe are respectively connected to the metal sealing joint provided on the inner wall of the window flange 8 through the bellows 19; the metal sealing joint is arranged through the window flange 8, And stretch out the outer wall of the window flange 8 as the inlet and outlet of cooling water; the part where the bellows 19 is connected with the cooling pipe is fixed on one end of the bracket 14; the other end of the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com