Robot laser overlapping weld clamp for white car body trunk lid

A technology for trunk lids and welding fixtures, which is applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of great influence on welding quality, and achieve the effect of firm and stable structure, convenient operation, and guaranteed flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

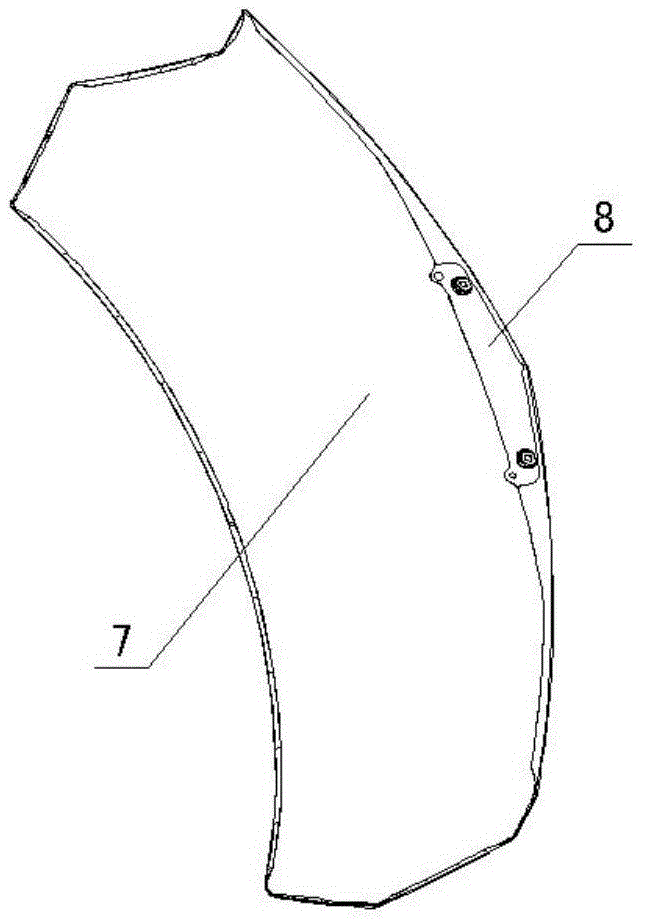

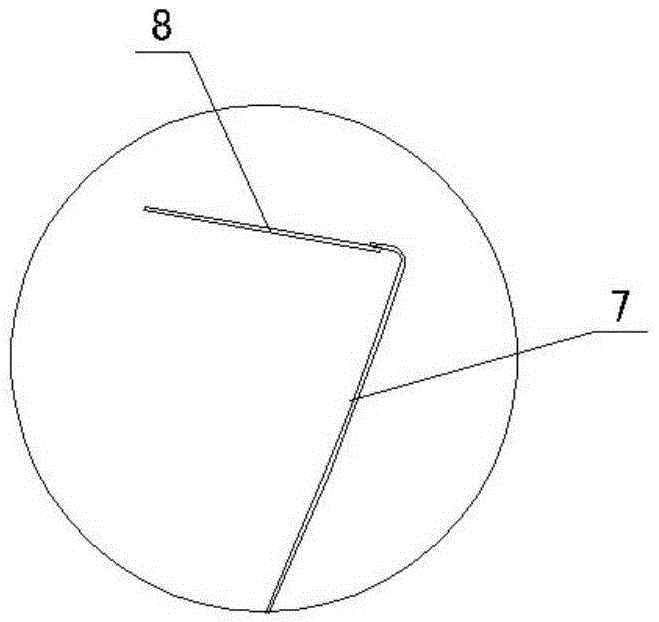

[0035] Such as Figure 1a with Figure 1b As shown, the trunk lid in the present embodiment is formed by the upper cover plate 8 and the side cover plate 7, the upper cover plate 8 is a horizontal plate, the side cover plate 7 is a vertical plate, and the top edge of the side cover plate 7 The bends are horizontally lapped and lapped on the edge of the upper cover plate 8 to form a lapped welding zone.

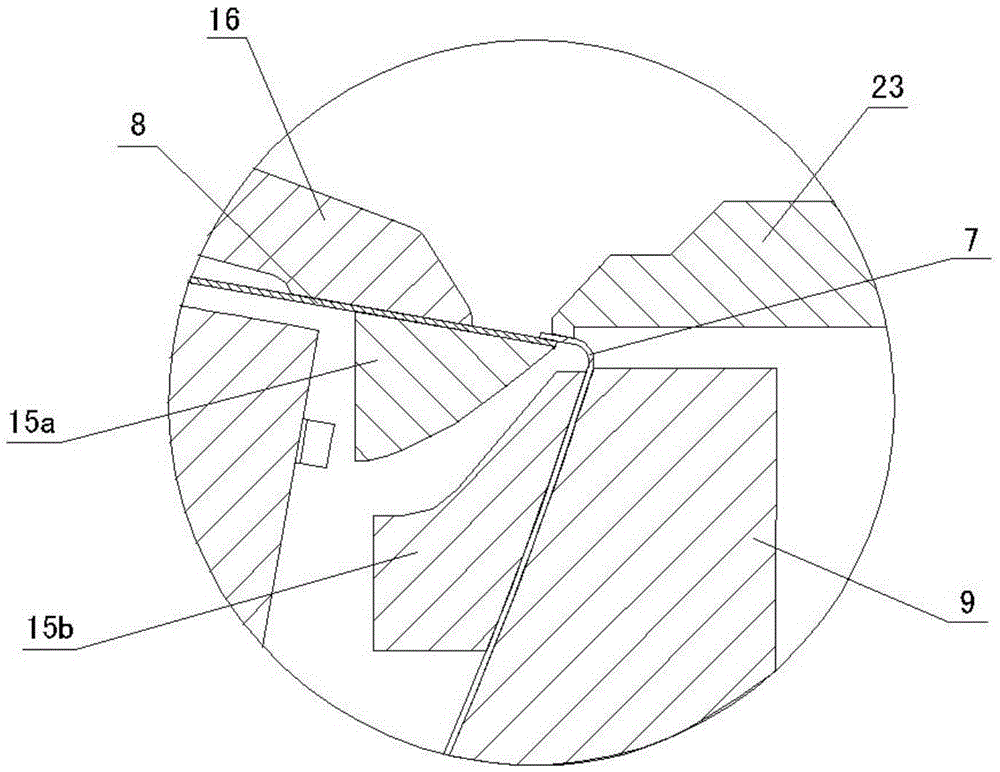

[0036] Such as figure 2 shown and image 3 As shown, the structural form of the laser lap welding fixture of the body-in-white trunk lid robot on the welding position P in this embodiment is:

[0037] The top member 15a in the lower support 15 is supported on the bottom of the upper cover 8, and the side members 15b in the lower support 15 are supported on the inner side of the side cover 7; the first upper pressing head 16 is pressed against the upper cover 8 On the top, it forms a clamping for the upper cover plate 8 in the form of opening and closing relative to the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com