A kind of preparation method of low-density macroporous ceramic grinding wheel

A technology of ceramic grinding wheels and large pores is applied in the field of grinding wheels, which can solve the problems of low green strength of grinding wheels, cracks of ceramic grinding wheels, affecting product quality, etc., and achieve the effects of reducing the rate of morphology defects, reducing dosage, and shortening drying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

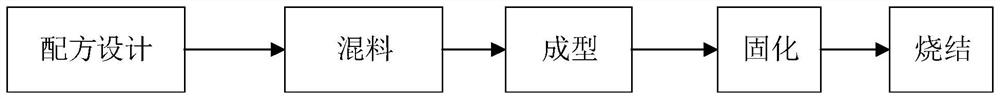

[0040] In addition, the present invention also provides a method for preparing a low-density large-porosity ceramic grinding wheel, which is used to manufacture the low-density large-porosity ceramic grinding wheel as in the first embodiment, including:

[0041] S1, formula design, formulate according to the following components,

[0042] Abrasive 100 parts;

[0043] 10-30 copies of ceramic bond;

[0044] 5-15 parts of pore-forming agent;

[0045] Resin binder 2-5 parts;

[0046] Wherein, the resin binder is a mixture of resin liquid and diluent, and the ratio of resin liquid and diluent is 1:1 to 1:4;

[0047] S2. Mixing, mix the resin binder and the abrasive evenly, the mixing time is 5-8min, then add the pore-forming agent and mix for about 3-5min, then add the ceramic bond and mix for 10-15min; after mixing evenly, according to the particle size of the abrasive sieving;

[0048] S3, forming, the speed of the press turntable is controlled at 30-50r / min when spreading; ...

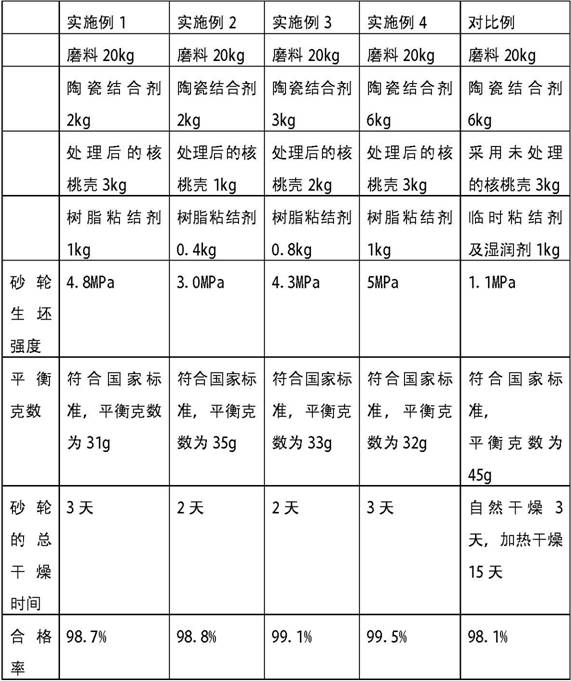

Embodiment 1

[0055] Abrasive 20kg, ceramic bond 1kg, pore-forming agent 3kg, resin bond 1kg; specifically, the abrasive is white corundum, and the ceramic bond includes 45wt% SiO 2 , 5wt% B 2 O 3 , 10wt% Al 2 O 3 , 10wt% alkali metal oxide, the pore-forming agent is the treated walnut shell, the resin solution is furfural, and the diluent is alcohol.

[0056] First, mix the resin binder and the abrasive particles evenly for about 5 minutes, then add the pore-forming agent and mix for about 3 minutes, and finally add the ceramic bond and mix for 10 minutes; after mixing evenly, sieve according to the particle size of the abrasive and pore-forming agent; There is no need for stuffing after feeding. In order to prevent the blank from solidifying and hardening, it can be directly pressed and formed; when spreading the material, the speed of the press turntable is controlled at 30r / min to improve the uniformity of the spreading; Directly heat and cure at 80 °C for 4 hours; in a sufficient o...

Embodiment 2

[0058] Abrasive 20kg, ceramic bond 2kg, pore-forming agent 1kg, resin bond 0.4kg. Among them, the abrasive is white corundum, and the ceramic bond includes 50wt% SiO 2 , 10wt% B 2 O 3 , 15wt% Al 2 O 3 , 15wt% alkali metal oxide, the pore-forming agent is the treated walnut shell, the resin liquid is phenolic, and the diluent is alcohol.

[0059] First, mix the resin binder and the abrasive particles uniformly for about 6 minutes, then add the pore-forming agent and mix for about 4 minutes, and finally add the ceramic bond and mix for 12 minutes; after mixing evenly, sieve according to the particle size of the abrasive and pore-forming agent; There is no need to stuff the material after the material, in order to prevent the material from solidifying and hardening, it can be directly pressed and formed; when the material is spread, the speed of the rotary table of the press is controlled at 40r / min to improve the uniformity of the material; Directly heat and cure at 100 °C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com