Patents

Literature

88results about How to "Simplify the mixing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibiotic-free beef cattle growing and fattening premix and feed

InactiveCN104970257AStrong appetizing and flavoringPromote animal growthAnimal feeding stuffMicro environmentDigestion

The present invention relates to an antibiotic-free beef cattle growing and fattening premix and feed. The beneficial effects of the premix and feed are as follows: the probiotics, enzyme preparations, origanum oil and allicin work together to constitute a healthy and complete digestion micro-environment in the gastrointestinal environment, the scientifically added several substances with appropriate proportions are matched with other raw materials to make feed digestibility reach the best and the cattle gastrointestinal health be further improved, and to increase the growth rate of the beef cattle. The technique method is simple, safe and reliable, and can completely replace antibiotics.

Owner:何贵明

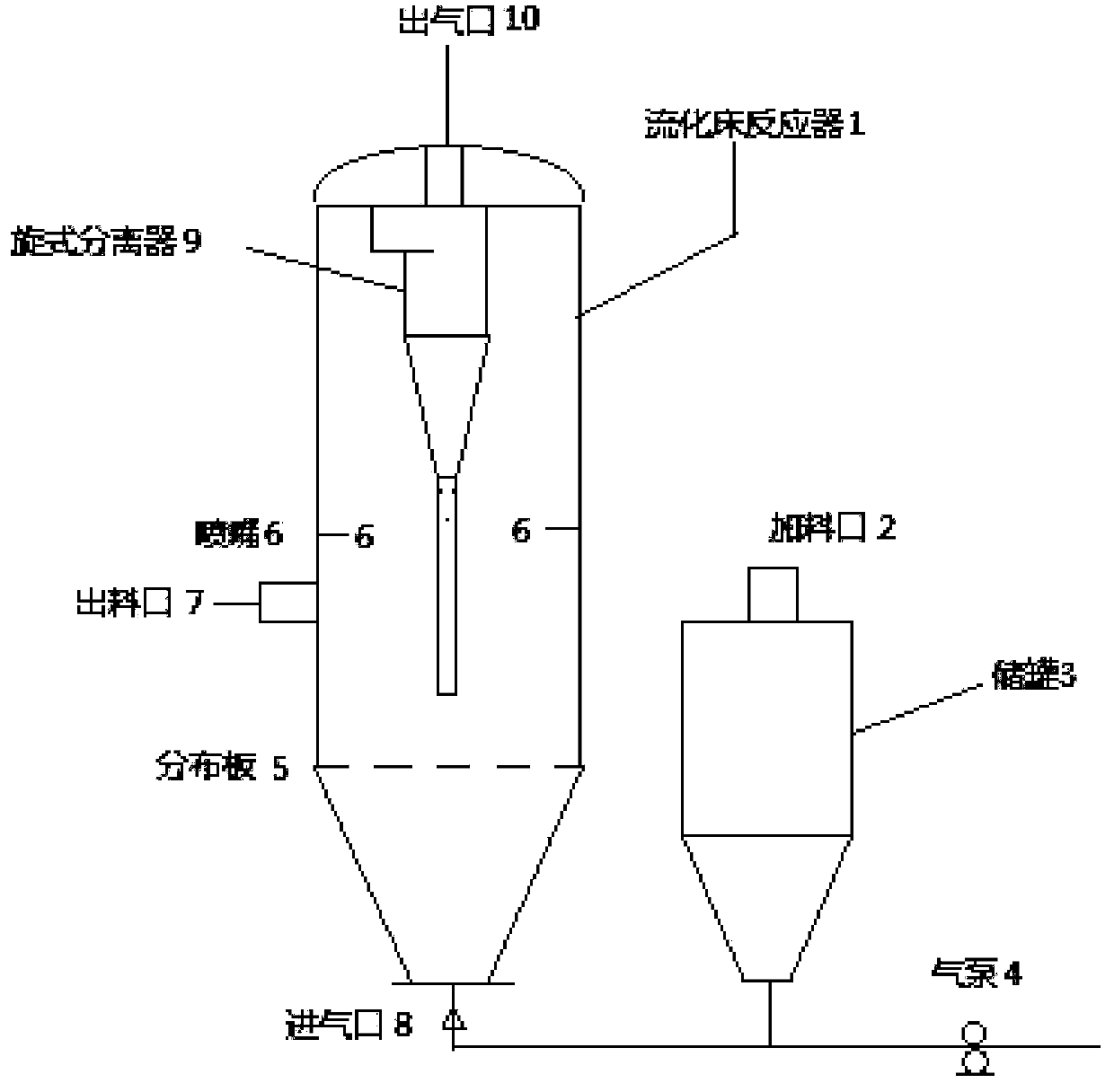

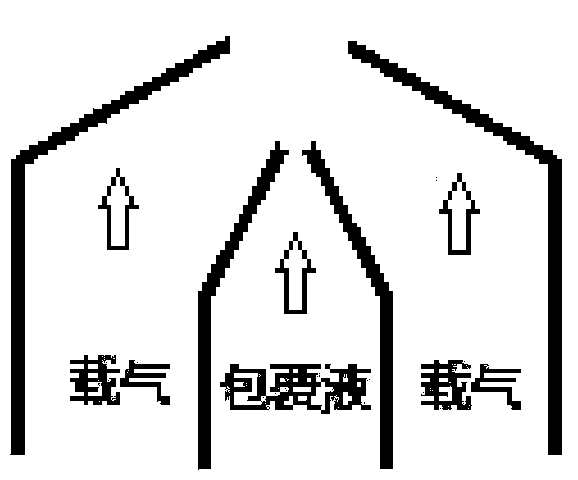

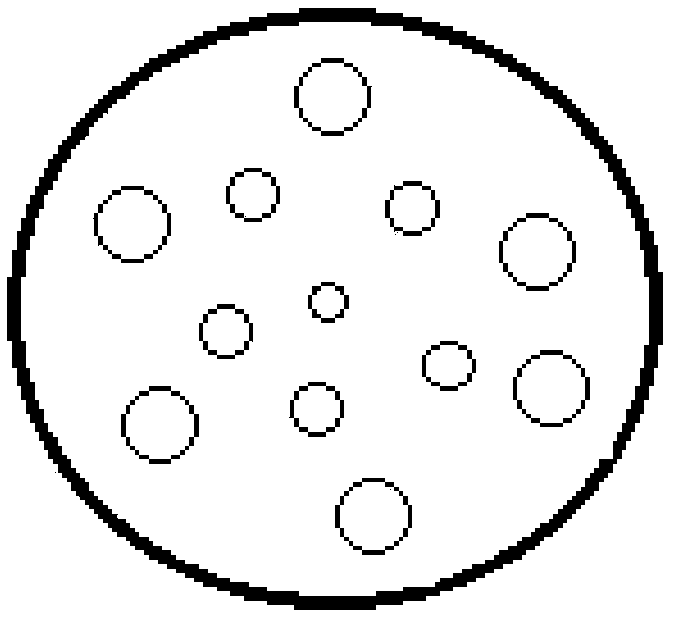

Coated modified electrode material and preparation method thereof

ActiveCN109585797AAchieve hybridMaintain coating uniformityCell electrodesSecondary cellsMaterials scienceElectrode material

The invention discloses a coated modified electrode material and a preparation method thereof. The method comprises the following steps of spraying a coating liquid into a fluidized bed reactor through a nozzle of a fluidized bed to be mixed with an electrode material which is in a fluidized state, so that coating of the electrode material by a coating material precursor is realized; and then carrying out sintering to obtain the coated modified electrode material which consists of the electrode material and a coating material which coats the surface of the electrode material. By further optimizing the component connection relation of the fluidized bed and the structural design of a gas distribution plate and the nozzles, the coating uniformity can be improved, the coating process can be simplified, the coating process cost is lowered, and the cycling performance of the electrode material is improved, and meanwhile, the problems of influence caused by an abnormal fluidization phenomenonand blocking of the nozzles during working are solved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Emulsion nano composite acrylic acid copolymerization slurry and preparation method thereof

The present invention relates to fabric sizing material, and is especially one kind of environment friendly nanometer composite fabric sizing agent of acrylate copolymer emulsion and its preparation process. The fabric sizing agent comprises acrylate copolymer size and inorganic material, and has solid content of 10-50 wt%. The preparation process includes the following steps: adding clay into water and regulating pH value to form homogeneous clay dispersing liquid; compounding oil soluble monomer solution; compounding water soluble monomer solution with alkali regulated pH value; mixing clay dispersing liquid, oil soluble monomer solution, water soluble monomer solution, emulsifier and initiator via stirring; heating for copolymerization; regulating pH value and filtering to obtain product. The fabric sizing agent has simple preparation process and high performance.

Owner:QINGDAO UNIV

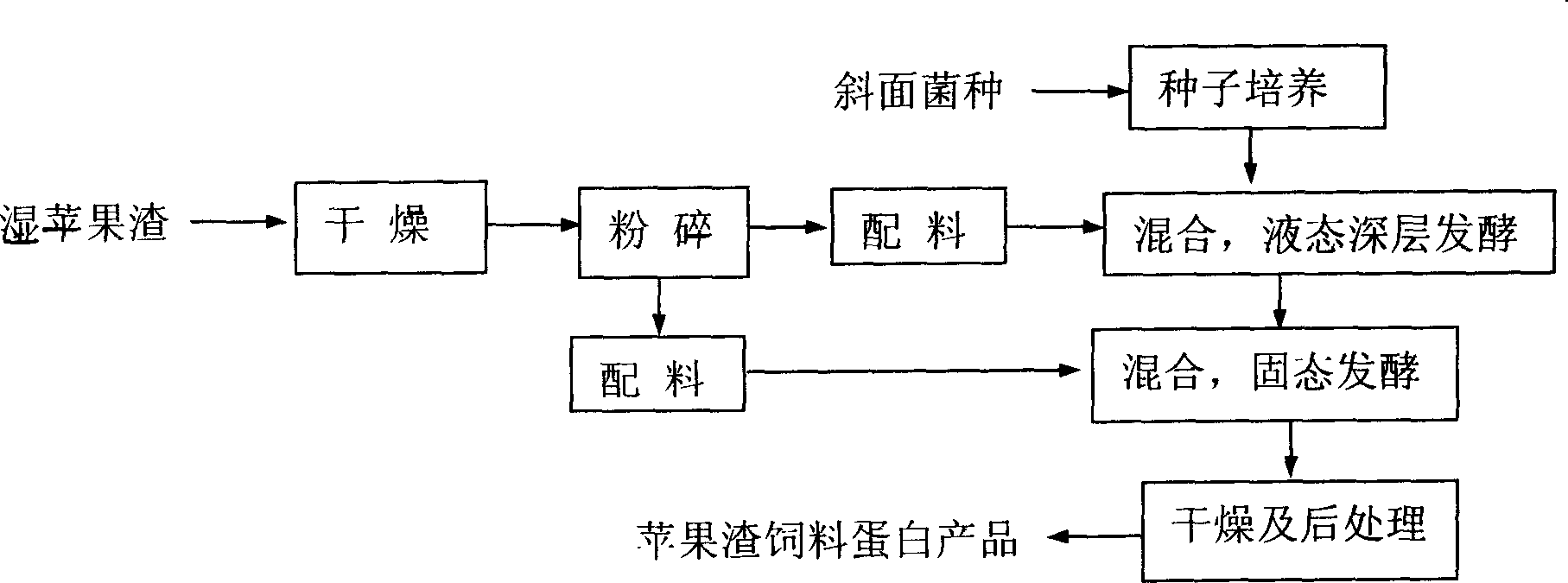

Method for manufacturing feedstuff protein by solid state fermentation of apple dregs liquid

InactiveCN1663421AReduce dosageReduce manufacturing costFood processingAnimal feeding stuffChemistrySubmerged fermentation

The invention discloses a method of producing feed albumen by solid state fermentation from pomace liquid, whose productive technique is that firstly batching crushed pomance into liquid state fermentation cultivated base, then accessing mixed bacterial with germ all grown to process liquid deep fermentation, finally accessing bacterial liquid after deep fermentation into solid state fermentation cultivated base of pomace to continue fermentation. Compared with single solid state fermentation, the technique mentioned above needs less germ cultivated base, bacterial pure cultivated and reduces the cost. Meantime breed albumen product contains more albumen, nutrition with low cost, and is more fit to product in scale and spreading application for the industry of producing feed albumen by pomace fermentation.

Owner:NORTHWEST UNIV

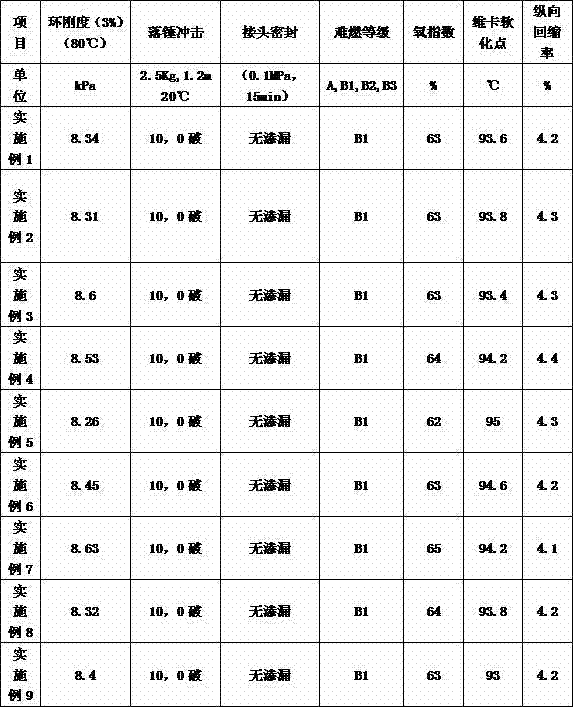

CPVC for power cable sleeve and preparation method thereof

ActiveCN103897297ASimplify the mixing processEasy to processPlastic/resin/waxes insulatorsProcedure AgentsPower cable

The invention discloses CPVC for a power cable sleeve and a preparation method thereof. The CPVC consists of the following raw materials in parts by weight: 50-70 parts of CPVC resin, 30-50 parts of PVC resin, 2.5-5 parts of a stabilizer, 2-3 parts of a lubricating anti-impact modifying agent, 2-4 parts of a lubricating processing aid, 10-30 parts of a filling material and 0.02-0.2 part of a pigment. The prepared compound material disclosed by the invention is simple in mixing process and easy to process; pipes prepared are 93-95 DEG C in Vicat temperature, and various physical indexes achieve standard of the power cable sleeve; moreover, the CPVC is low in cost, good in weather fastness and good in flame retardance.

Owner:山东高信化学股份有限公司

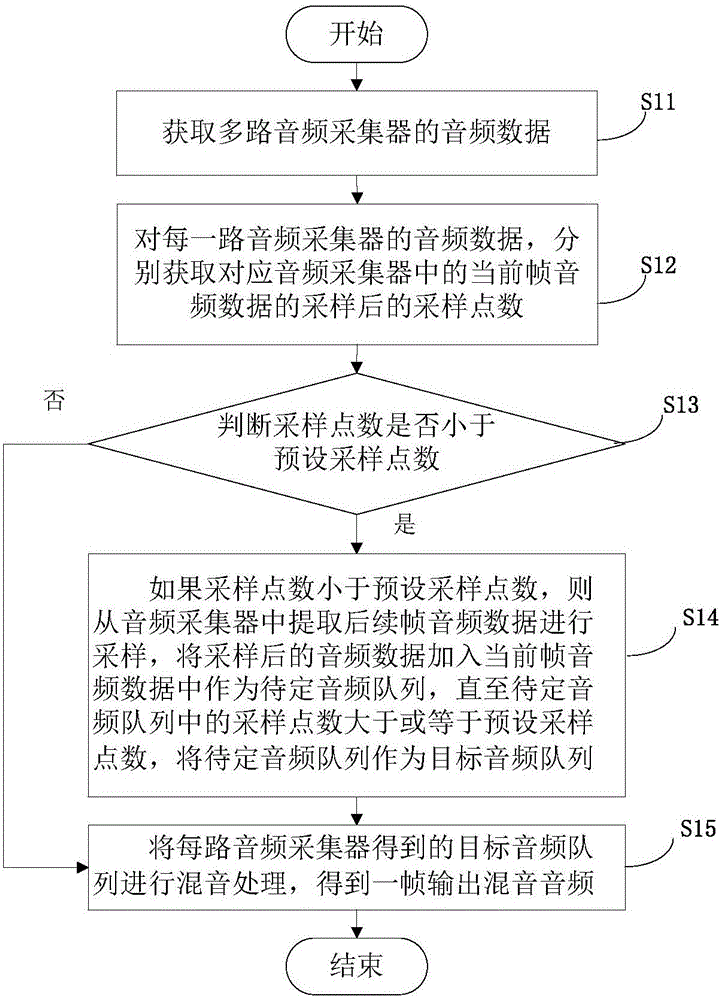

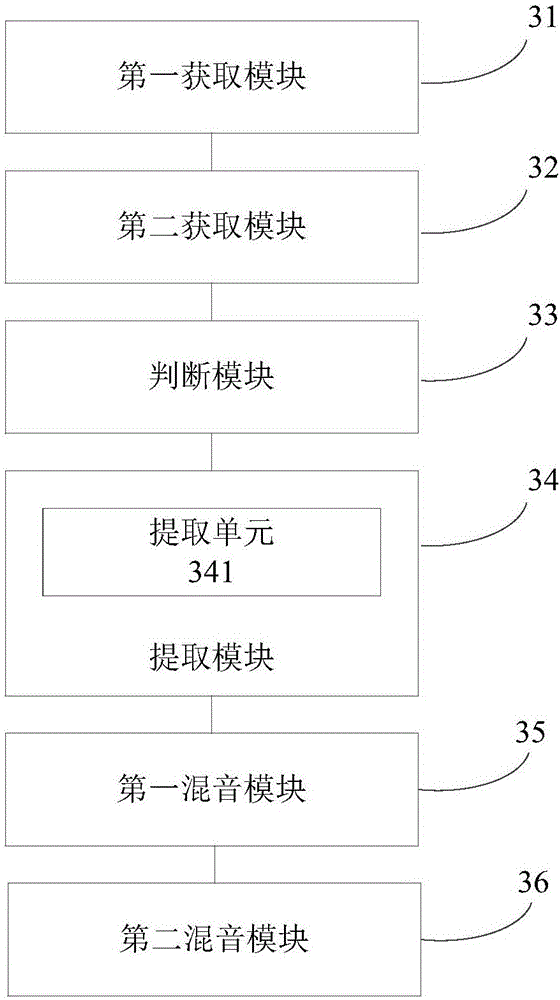

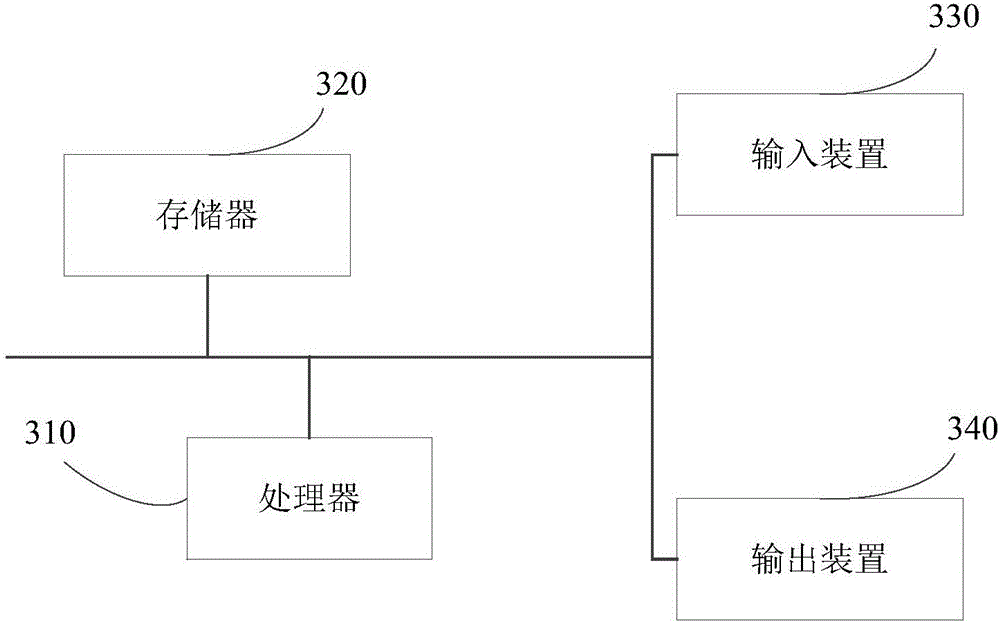

Audio mixing method and apparatus, and electronic device

InactiveCN106816152AImprove processing efficiencySolve the problem of not being able to output normallySpeech analysisElectric equipmentMulti path

The invention discloses an audio mixing method and apparatus, and an electronic device. The audio mixing method comprises: audio data of multi-path audio collectors are obtained; for the audio data of each path of audio collector, the sampling point number of current-frame audio data after sampling in the corresponding audio collector are obtained; if the sampling point number is determined to be smaller than a preset sampling point number, follow-up-frame audio data are extracted from the audio collector to carry out sampling, the sampled audio data are added into the current-frame audio data to form a to-be-determined audio queue until the sampling point number in the to-be-determined audio queue is larger than or equal to the preset sampling point number, and the to-be-determined audio queue is used as a target audio queue; and mixing processing is carried out on the target audio queue obtained by all paths of audio collectors to obtain one frame of outputted mixed audio unit. Therefore, a processing step of searching for a datum sampling point number can be avoided; the mixing process can be simplified; and a problem that whole mixed audio unit can not be outputted normally because one path of audio data have a problem can be solved.

Owner:LETV HLDG BEIJING CO LTD +1

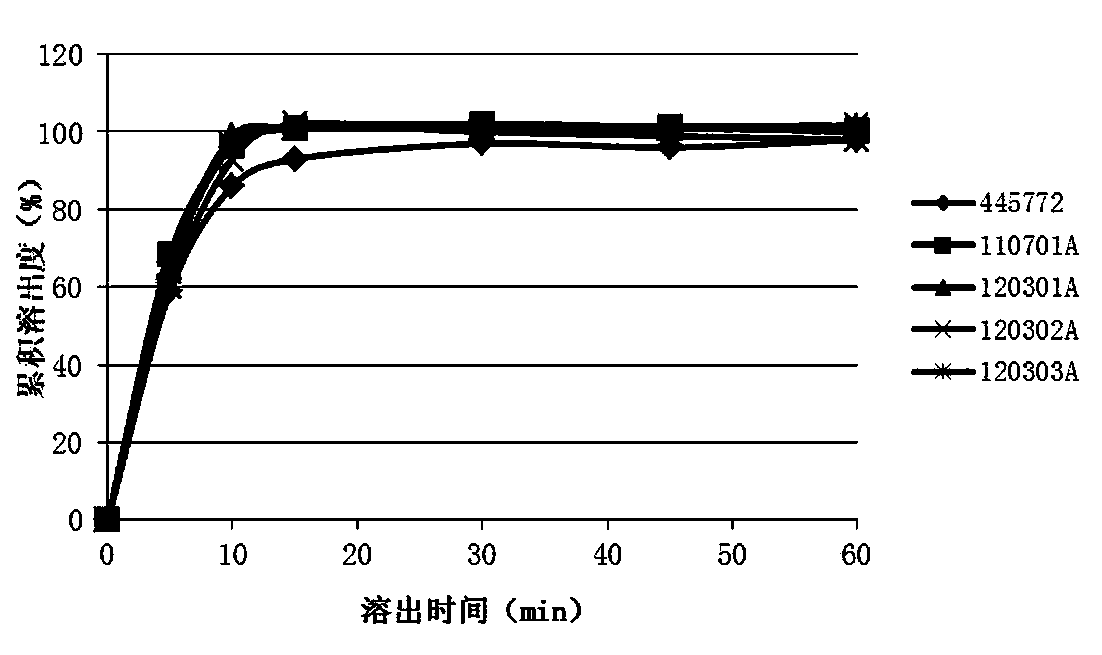

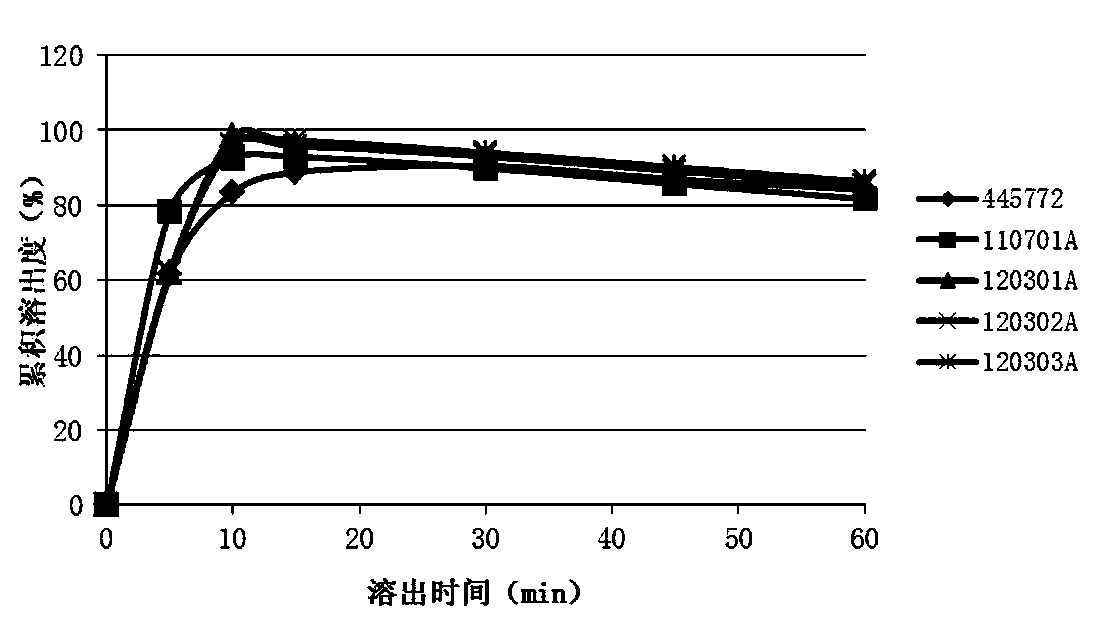

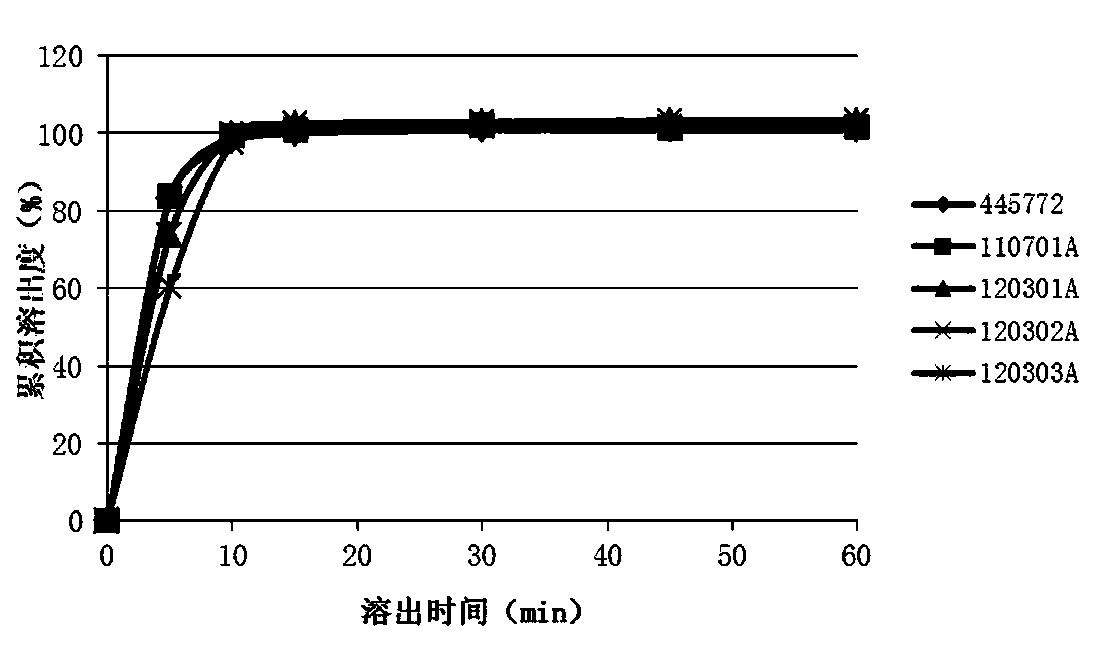

Method for producing omeprazole sodium bicarbonate capsule

ActiveCN103860584AReduce unit usageGood treatment effectOrganic active ingredientsInorganic active ingredientsOMEPRAZOLE/SODIUM BICARBONATECellulose

The invention provides a method for producing an omeprazole sodium bicarbonate capsule. 40 mg omeprazole comprises the following raw and auxiliary materials in unit: 40 mg of omeprazole, 1100 mg of sodium bicarbonate, 20-30 mg of cross-linked carboxymethyl cellulose sodium, and 1-5 mg of magnesium stearate; the particle size distribution of omeprazole is as follows: D10 is more than or equal to 1 mum, D50 is less than or equal to 10 mum, and D90 is less than or equal to 20 mum; the particle size of sodium bicarbonate is more than 100 meshes. 20 mg omeprazole comprises the following raw and auxiliary materials in unit: 20 mg of omeprazole, 1100 mg of sodium bicarbonate, 20-30 mg of cross-linked carboxymethyl cellulose sodium, and 1-5 mg of magnesium stearate; the particle size distribution of omeprazole is as follows: D10 is more than or equal to 1 mum, D50 is less than or equal to 10 mum, and D90 is less than or equal to 20 mum; the particle size of sodium bicarbonate is more than 100 meshes. The method provided by the invention has the beneficial effects hat the particle size of omeprazole is controlled in a smaller range, the unit amount of magnesium stearate is reduced, and the therapeutic effect of drugs is improved; a raw material mixing process in the production process is simplified.

Owner:XIAMEN ENCHENG PHARMA CO LTD

Hare growth fattening premix without antibiotics and feed

The invention relates to a hare growth fattening premix without antibiotics and a feed. The hare growth fattening premix without the antibiotics and the feed, disclosed by the invention, have the benefits that probiotic, an enzyme preparation, cretian origanum oil and garlicin are in combined action, so that healthy complete digestion microenvironment is formed in gastroenteric internal environment; several substances in appropriate proportion are scientifically added and are collocated with other raw materials, so that the optimal feed digestibility is further achieved, the health of gastrointestinal tracts of hares is further improved, and the growth rate of the hares is increased. The technical method is simple, safe and reliable, and can completely replace the antibiotics.

Owner:何贵明

Antibiotics-free premixed material and antibiotics-free feed for growth and fattening of mutton sheep

InactiveCN105124177ANon-mutagenic, teratogenic, carcinogenicLow mutagenic teratogenic carcinogenicAnimal feeding stuffAntibiotic YDigestion

The invention relates to an antibiotics-free premixed material and an antibiotics-free feed for growth and fattening of mutton sheep. The premix material and the feed are advantaged in that by means of cooperative effects among probiotics, enzyme preparations, oregano oil and allicin, a healthy and complete digestion micro-environment is formed in the stomach and intestine, wherein the feed achieves the best digestion rate due to scientifically addition of several substances in proper ratio with other raw materials, thereby further improving health in the stomach and intestine of mutton sheep and increasing growth speed of the mutton sheep. The premix material and the feed are simple in technical method, are safe and reliable and can be used for replacing antibiotics completely.

Owner:何贵明

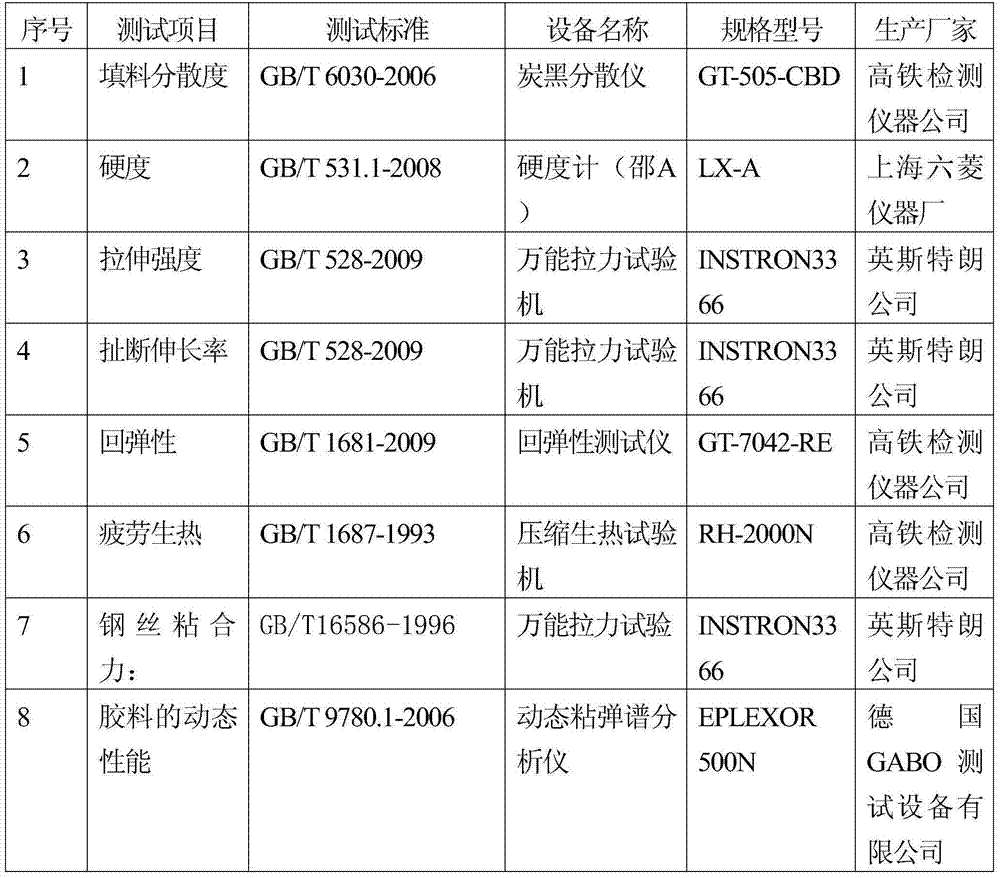

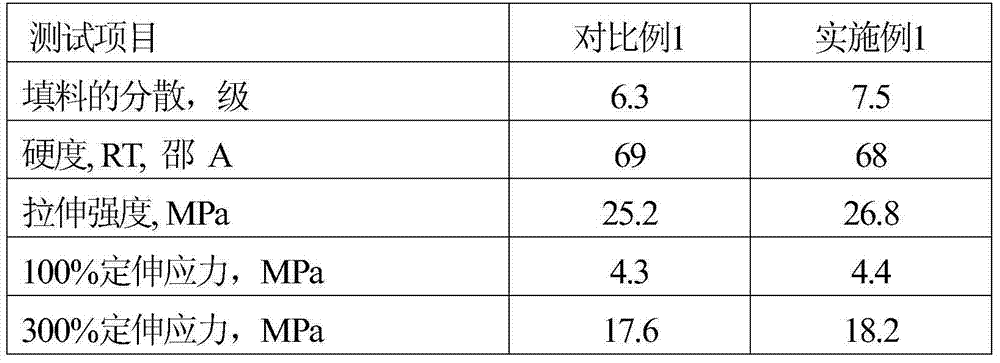

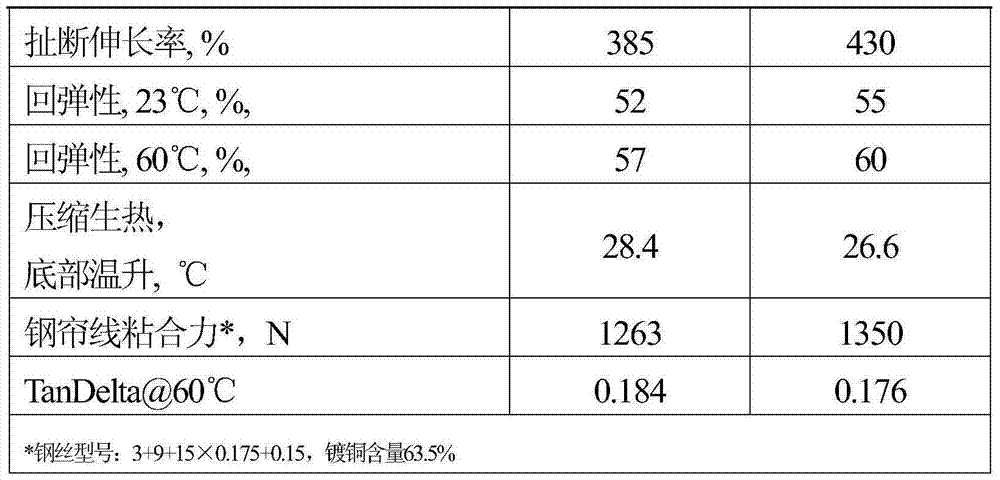

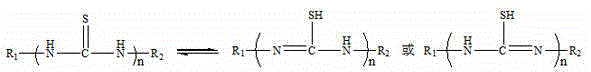

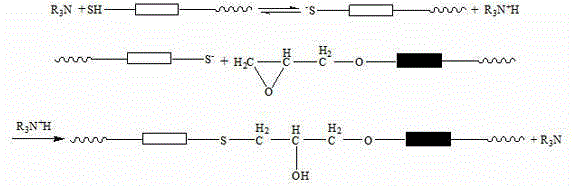

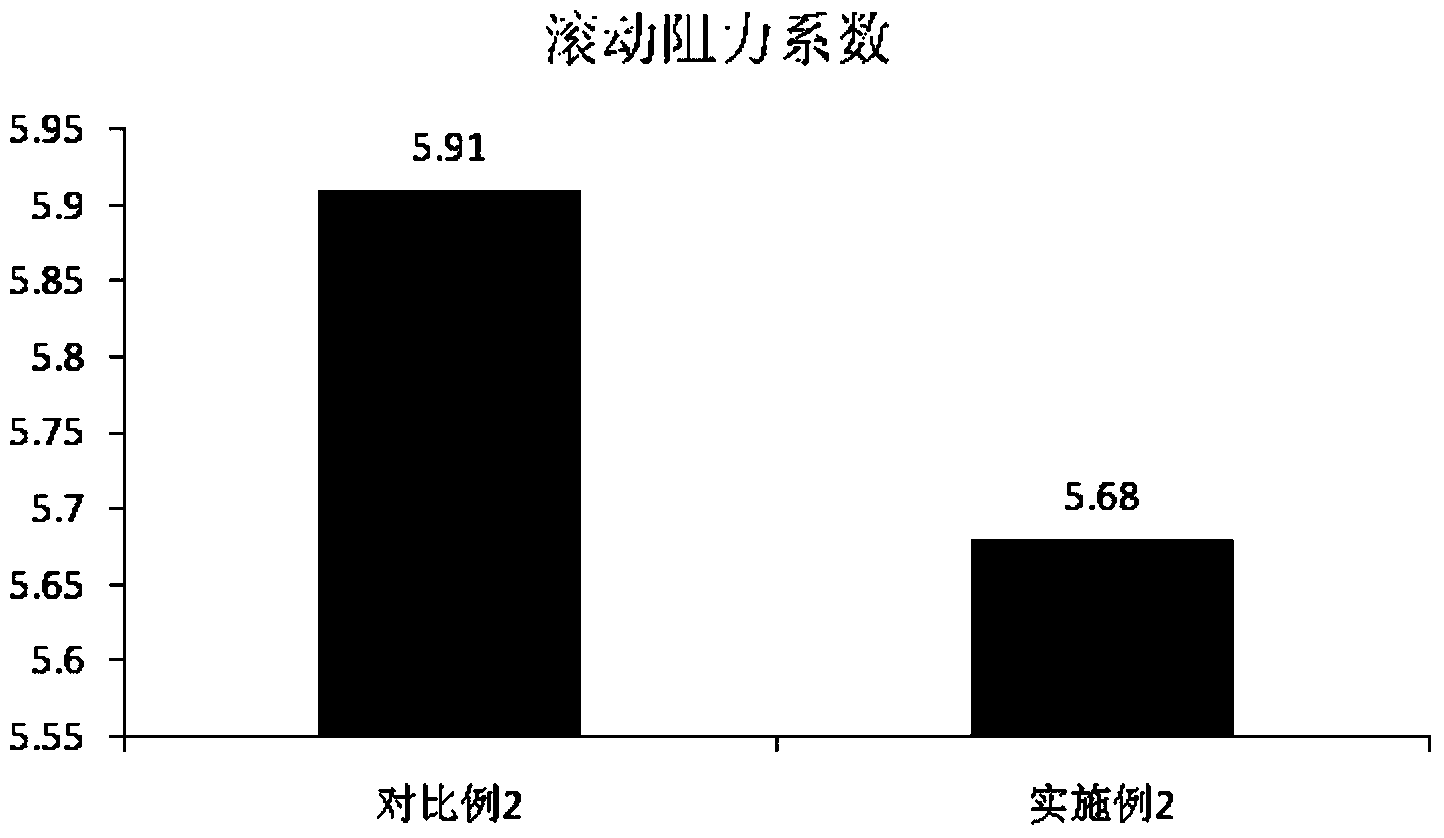

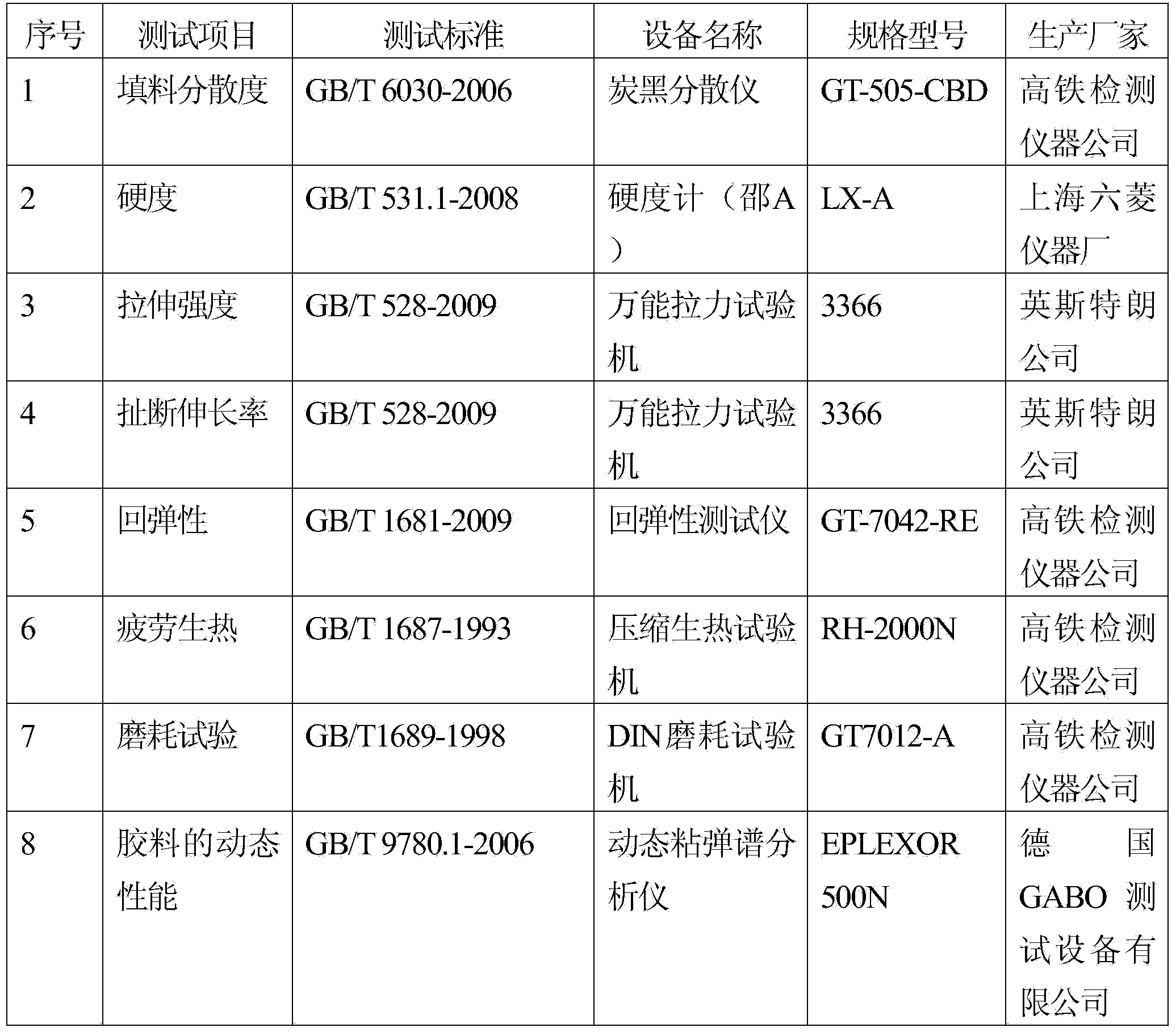

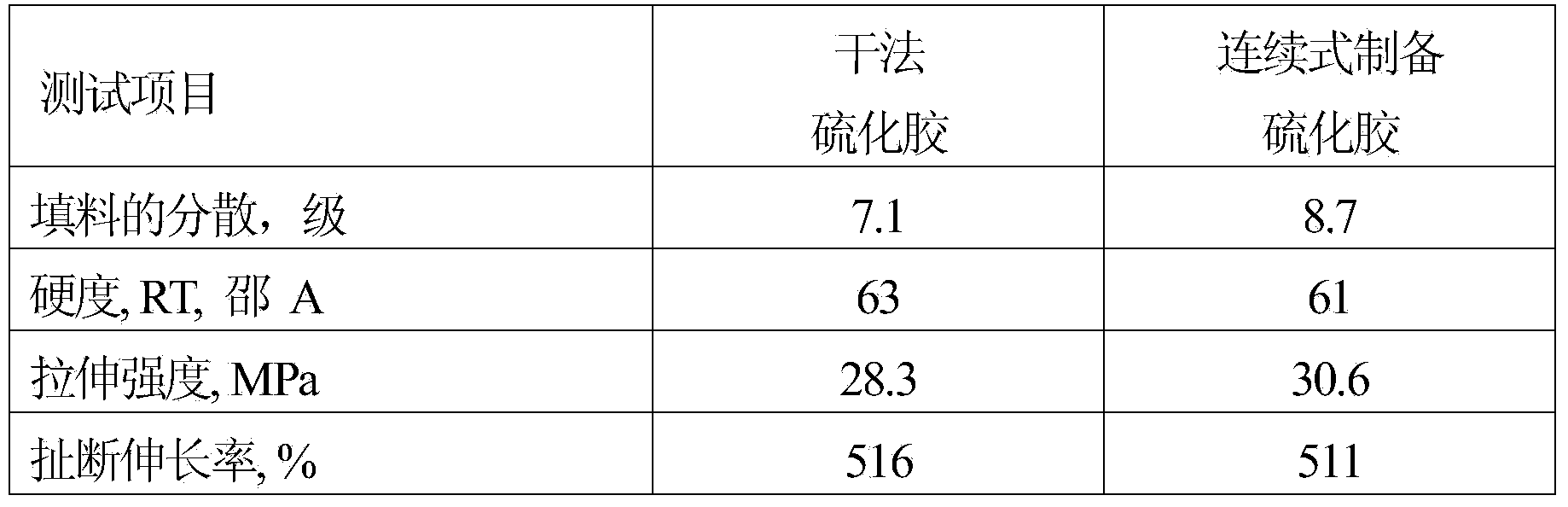

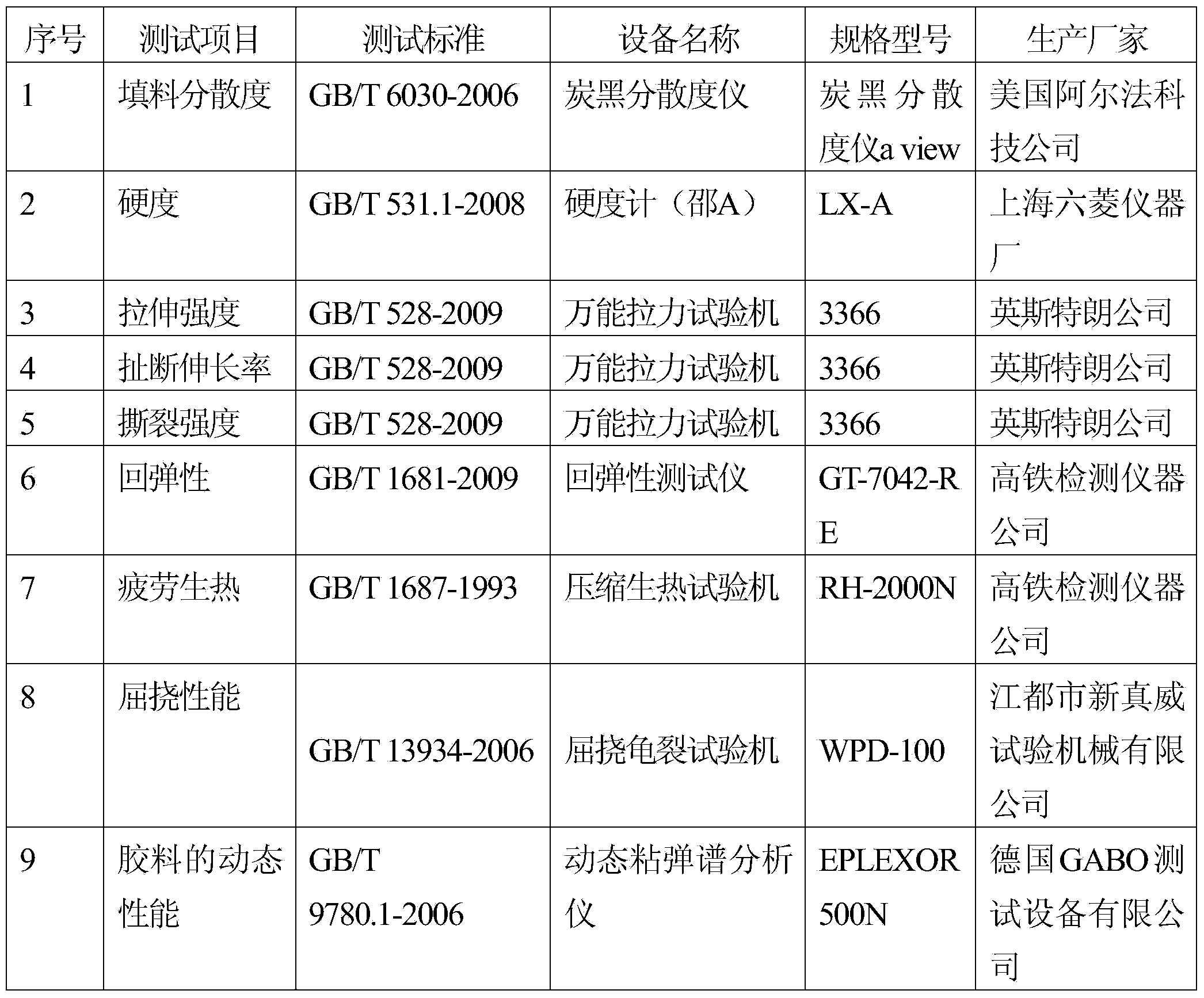

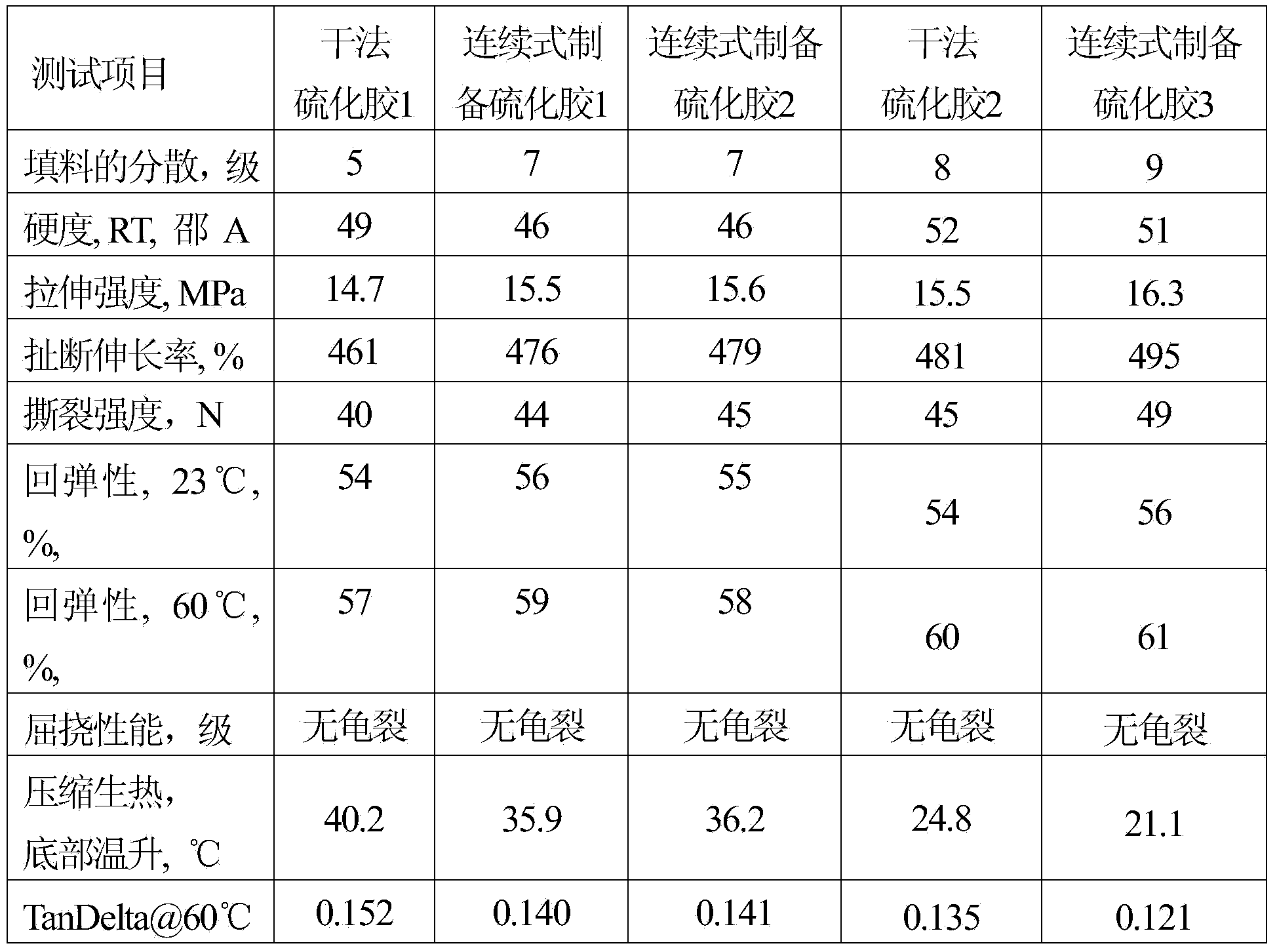

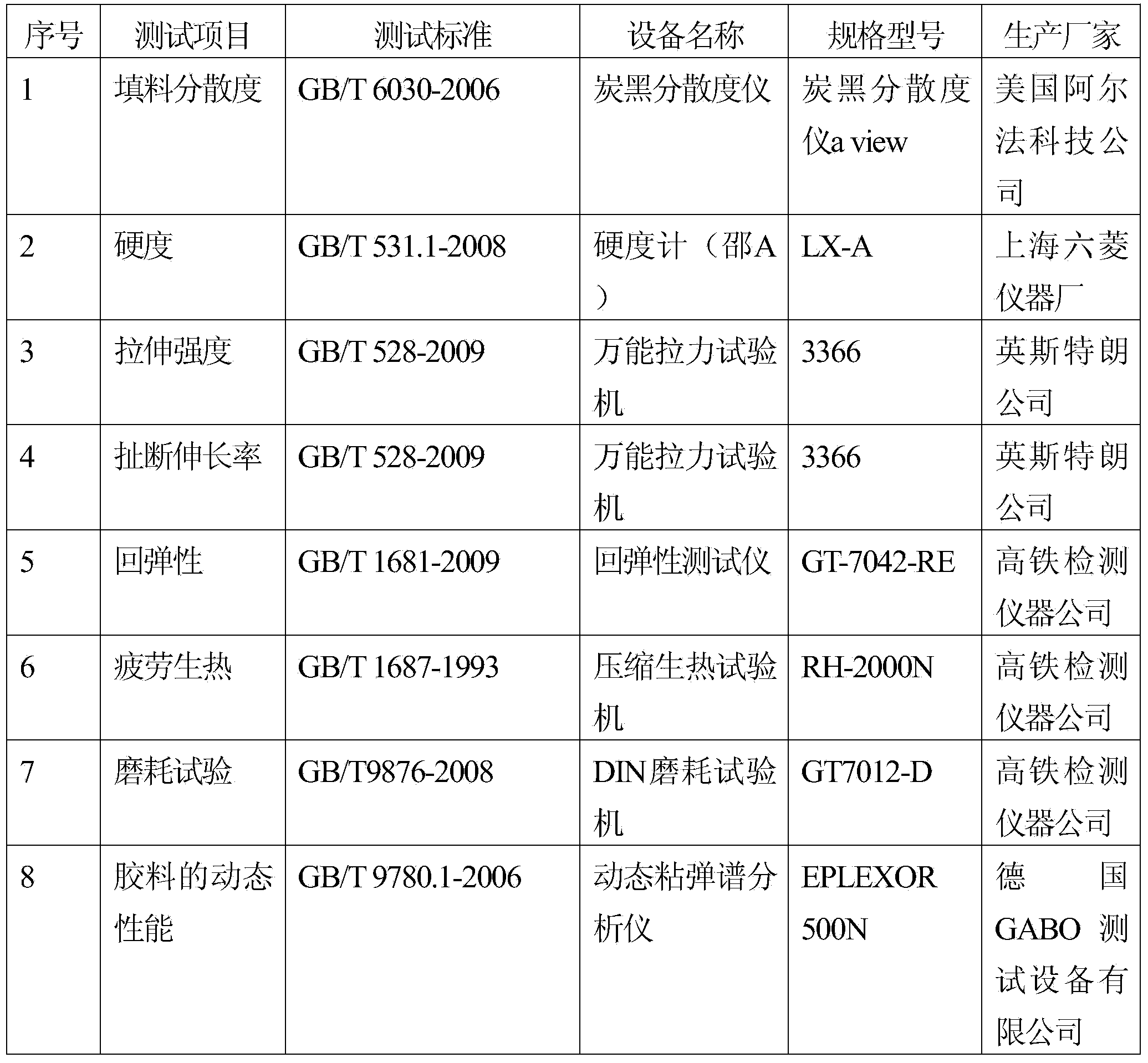

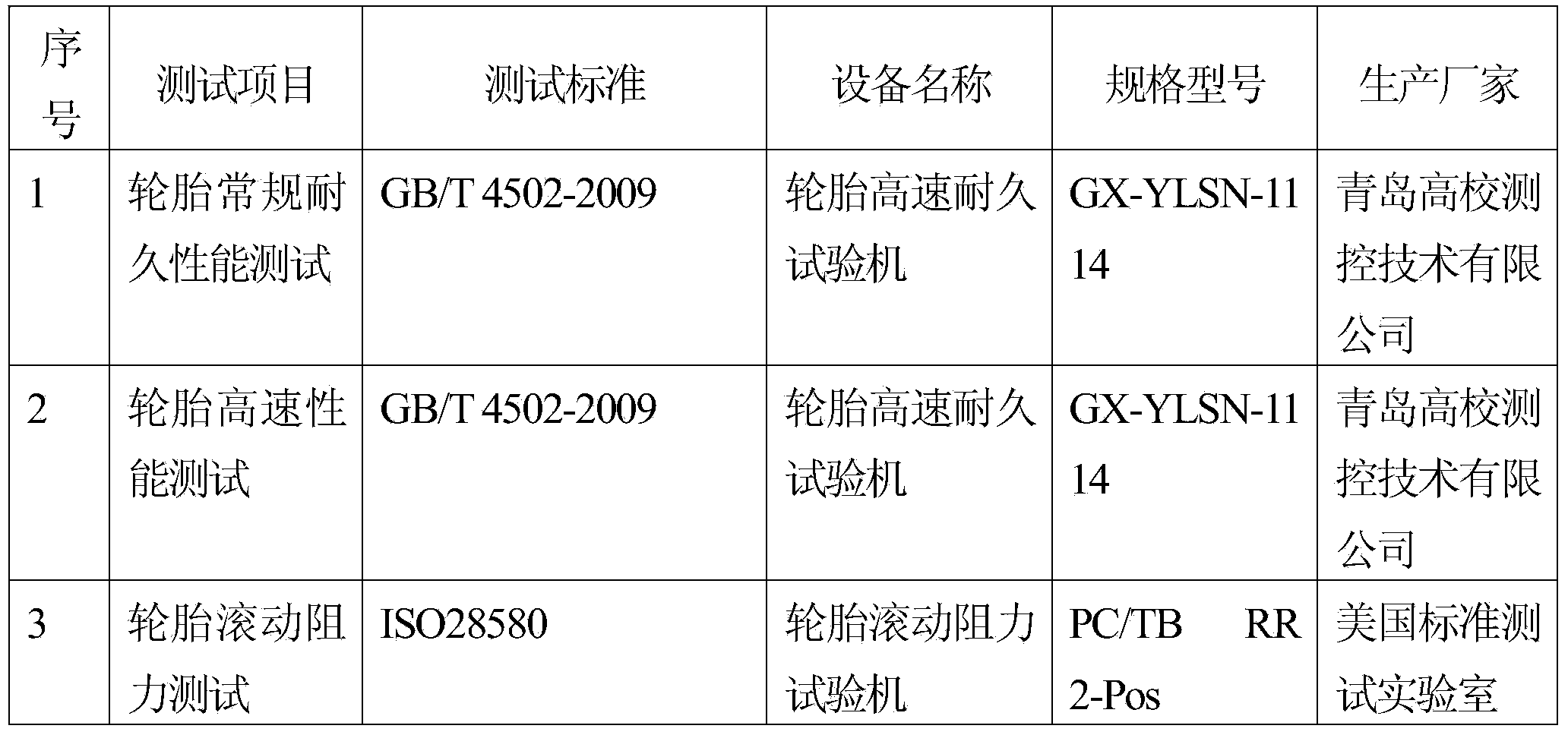

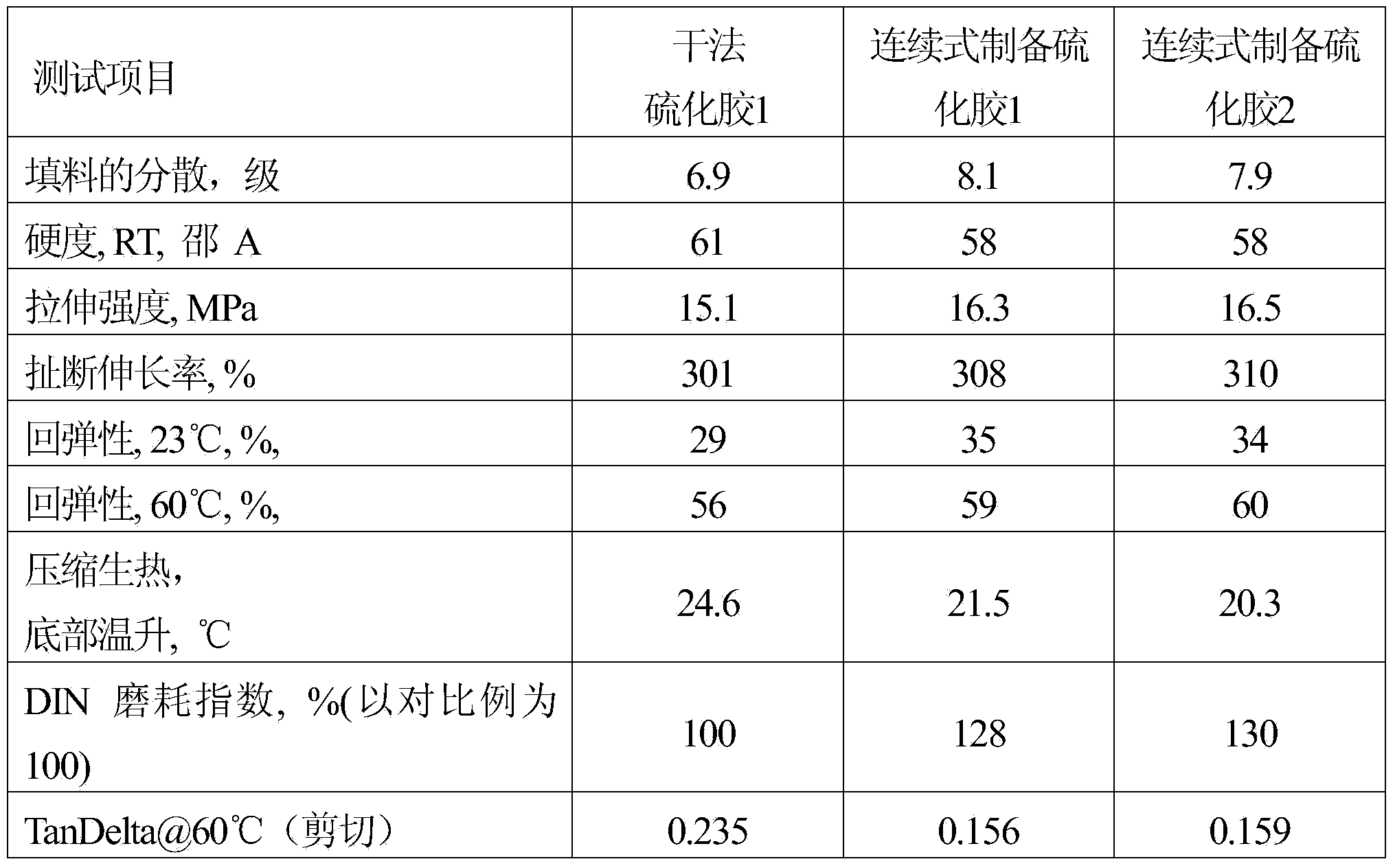

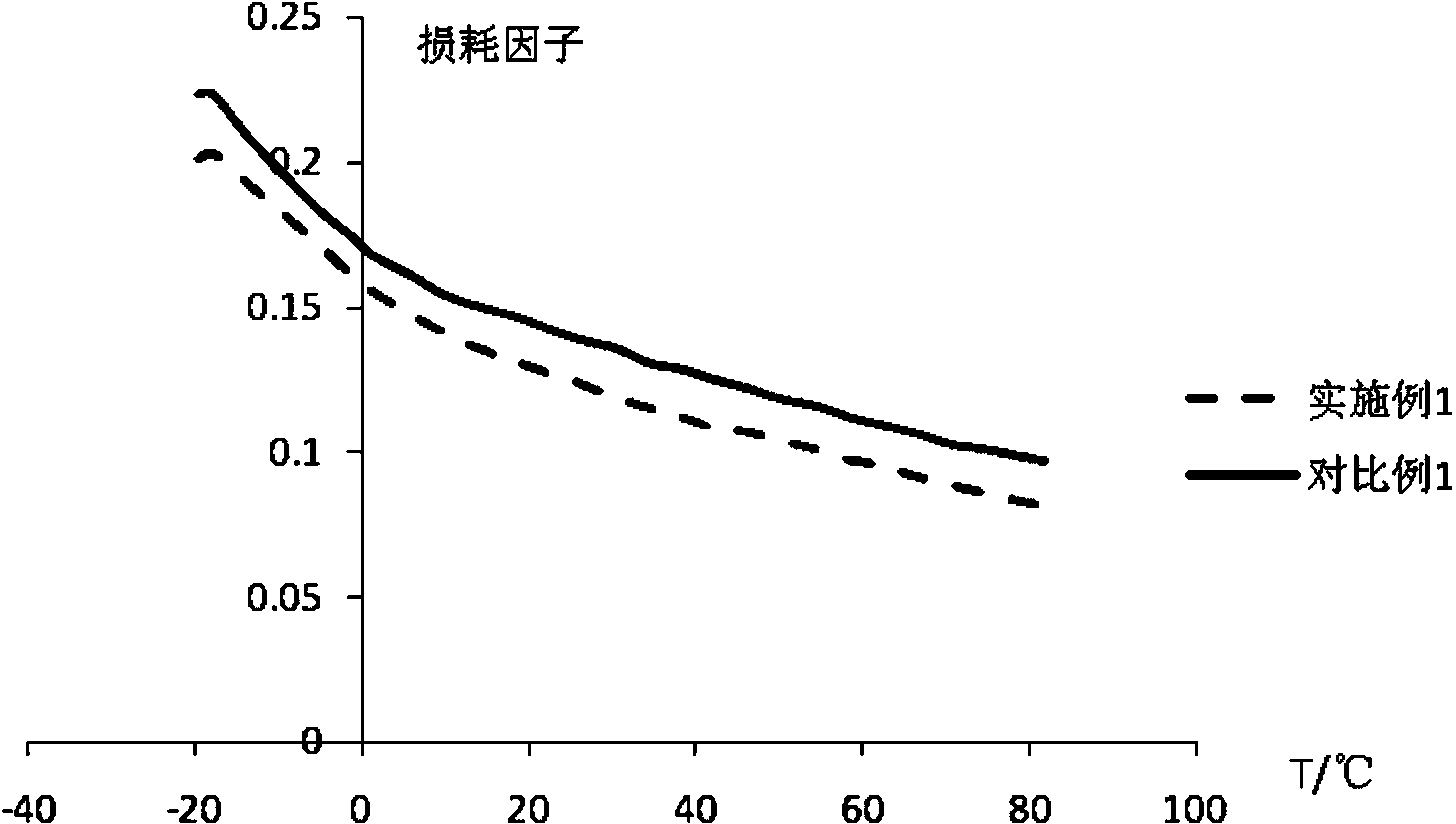

Application of continuously prepared rubber masterbatch in steel cord adhesive

The invention relates to application of a continuously prepared rubber masterbatch in a steel cord adhesive. The application of the continuously prepared rubber masterbatch in the steel cord adhesive is completed by following steps: a, adding filler to a rubber solution, and optionally adding a coupling reagent, an anti-aging agent, a metal binder, an active agent and / or oil, mixing and dispersing uniformly, injecting into coagulator for coagulating, desolventizing and drying to obtain a rubber masterbatch; b, adding the rubber masterbatch in an internal mixer, then adding the anti-aging agent, the metal binder, the active agent and / or oil, mixing, adding a vulcanizing agent and an accelerant and uniformly mixing to obtain a steel cord adhesive-rubber compound; and c, vulcanizing the steel cord adhesive-rubber compound to obtain steel cord adhesive vulcanizate.

Owner:EVE RUBBER RES INST

Epoxy adhesive used under low temperature

InactiveCN101265399AImprove craftsmanshipSimplify the mixing processEpoxy resin adhesivesPolyesterPliability

The invention relates to an epoxy resin adhesive used under low temperature, which comprises epoxy resin, a liquid aromatic amine curing agent, a modifying agent and a coupling agent; the weight proportion of the epoxy resin, the liquid aromatic amine curing agent, the modifying agent and the coupling agent is 100:(10-50):(0-40):(0-3); the epoxy resin can adopt aromatic glycidyl ether epoxy resin, aromatic glycidyl amine epoxy resin or alicyclic ethylene oxidic ester epoxy resin; the liquid aromatic amine curing agent adopts a liquid aromatic diamine curing agent; the modifying agent adopts a flexible flexibilizer including polyester, polyurethane or / and polyether segment; the coupling agent adopts gamma-aminopropyltriethoxylsilane or gamma-glycidyl ether propyl trimethoxy silane. The adhesive is liquid at the room temperature and low temperature, thereby having good flow property, tenacity and cold-proof and heat-proof impact property; the performance of the adhesive is stable; the preparation method is simple; in addition, the used raw materials all come from the market, and the raw materials are low in price and are easy to be acquired.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

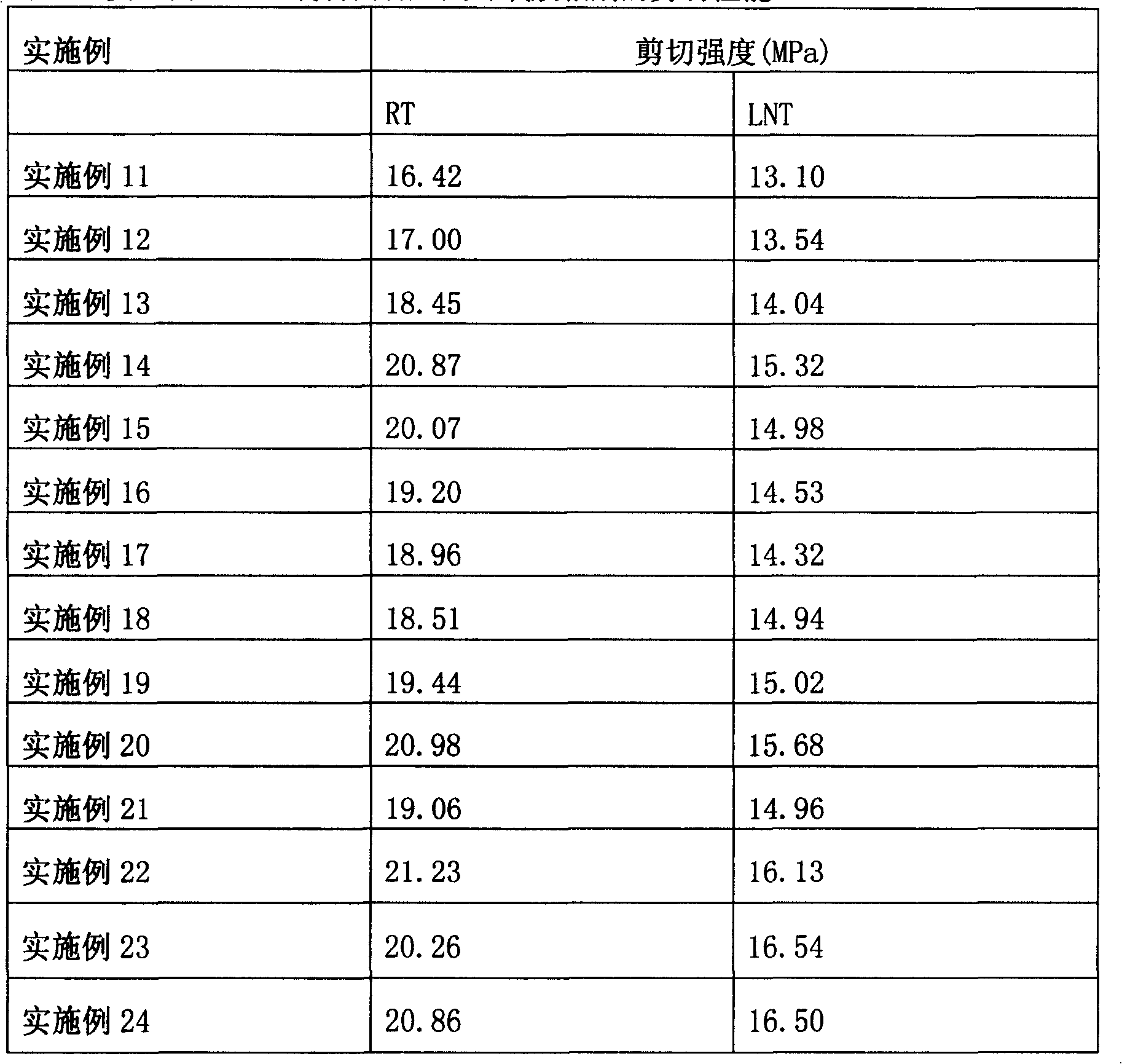

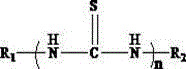

Curing agent for epoxy resin and epoxy adhesive used at ultralow temperature

ActiveCN105199081ALess irritatingLow toxicityNon-macromolecular adhesive additivesEpoxy resin adhesivesFirming agentDiethylene glycol

The invention relates to a curing agent for epoxy resin and an epoxy adhesive used at ultralow temperature and prepared from the curing agent. The curing agent is an oligomer prepared by decyclization and deamination of a molecular structure as shown in the description and condensation of FZ-201 compound alicyclic amine and thiourea under the action of diethylene glycol, wherein FZ-201 compound alicyclic amine is dimethylcyolohexlemine, dimethylcyclopentylamine and N-aminoethylpiperazine; the weight part ratio of FZ-201 compound alicyclic amine to thiourea to diethylene glycol is 100:25:20; the epoxy adhesive used at ultralow temperature comprises epoxy resin and the curing agent which are in the weight part ratio of 95:(15-35); and the epoxy resin is bisphenol A glycidyl ether epoxy resin E-51 with bifunctionality. The open-loop alicyclic amine with a molecular structure as shown in the description is used as the curing agent, the molecular structure not only contains amino groups, but also contains the molecular structure as shown in the description, and the crosslinking density of the epoxy adhesive is lower than that of an epoxy resin adhesive of an alicyclic fatty amine curing agent only containing amino groups, so that the defect of high brittleness of a cured product is overcome, and the epoxy adhesive is high in toughness, suitable for use in an ultralow-temperature environment, simple in preparation process as well as cheap and available in raw materials.

Owner:HUBEI GREENHOME MATERIALS TECH INC

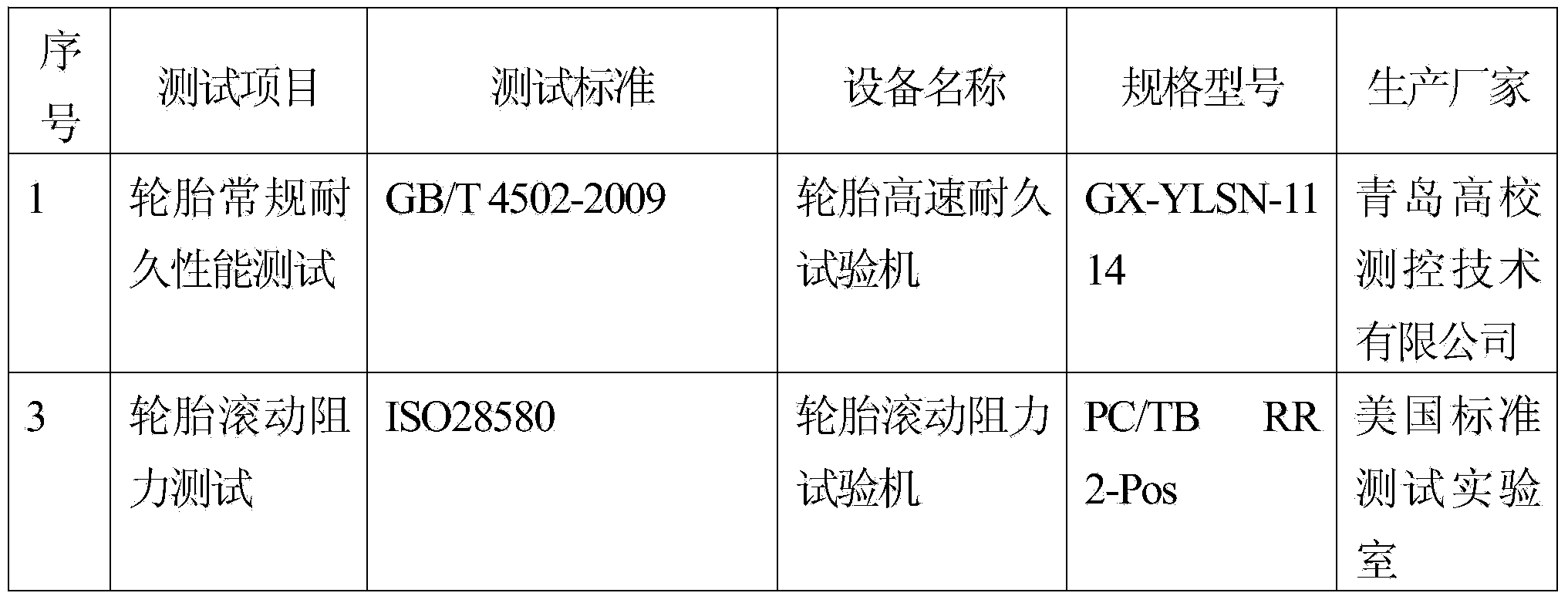

Application of continuously prepared rubber master batch in truck tire base

The invention relates to application of a continuously prepared rubber master batch in a truck tire base, which comprises the following steps: a) adding carbon black into a rubber-solvent rubber solution, mixing, continuously injecting into a condenser for condensation, removing the solvent, and drying to obtain a carbon black master batch; b) adding silica white and a coupling agent into the rubber-solvent rubber solution, mixing, continuously injecting into a condenser for condensation, removing the solvent, and drying to obtain a silica white master batch; c) adding the carbon black master batch and a silica white master batch into a Banbury mixer, uniformly mixing, adding an anti-aging agent, an activator and / or oil, compounding uniformly, and standing; d) adding a vulcanizing agent and an accelerator, and continuing compounding uniformly to obtain truck tire base compounded rubber; and e) vulcanizing the truck tire base compounded rubber to obtain the truck tire base vulcanized rubber.

Owner:EVE RUBBER RES INST

Low thermal conductivity wall thermal insulation coating and its preparation method

InactiveCN107163831ASolve insulation problemsAddress impact resistanceFireproof paintsAnti-corrosive paintsEpoxyThermal insulation

The invention discloses a low thermal conductivity wall thermal insulation coating and its preparation method and relates to the technical field of building materials. The low thermal conductivity wall thermal insulation coating is prepared from 75 to 85 parts of polyamide resin, 55 to 65 parts of epoxy resin, 45 to 55 parts of modified hollow ceramic beads, 35 to 40 parts of silica airgel, 30 to 33 parts of talc powder, 25 to 27 parts of glass wool, 20 to 23 parts of an inorganic additive, 15 to 20 parts of an infrared reflective pigment, 15 to 18 parts of aids and 85 to 95 parts of deionized water. The low thermal conductivity wall thermal insulation coating can form a low thermal conductivity protection layer on the wall after curing and has good corrosion resistance, cohesiveness and compressive strength.

Owner:合肥市淑芹美装饰工程有限公司

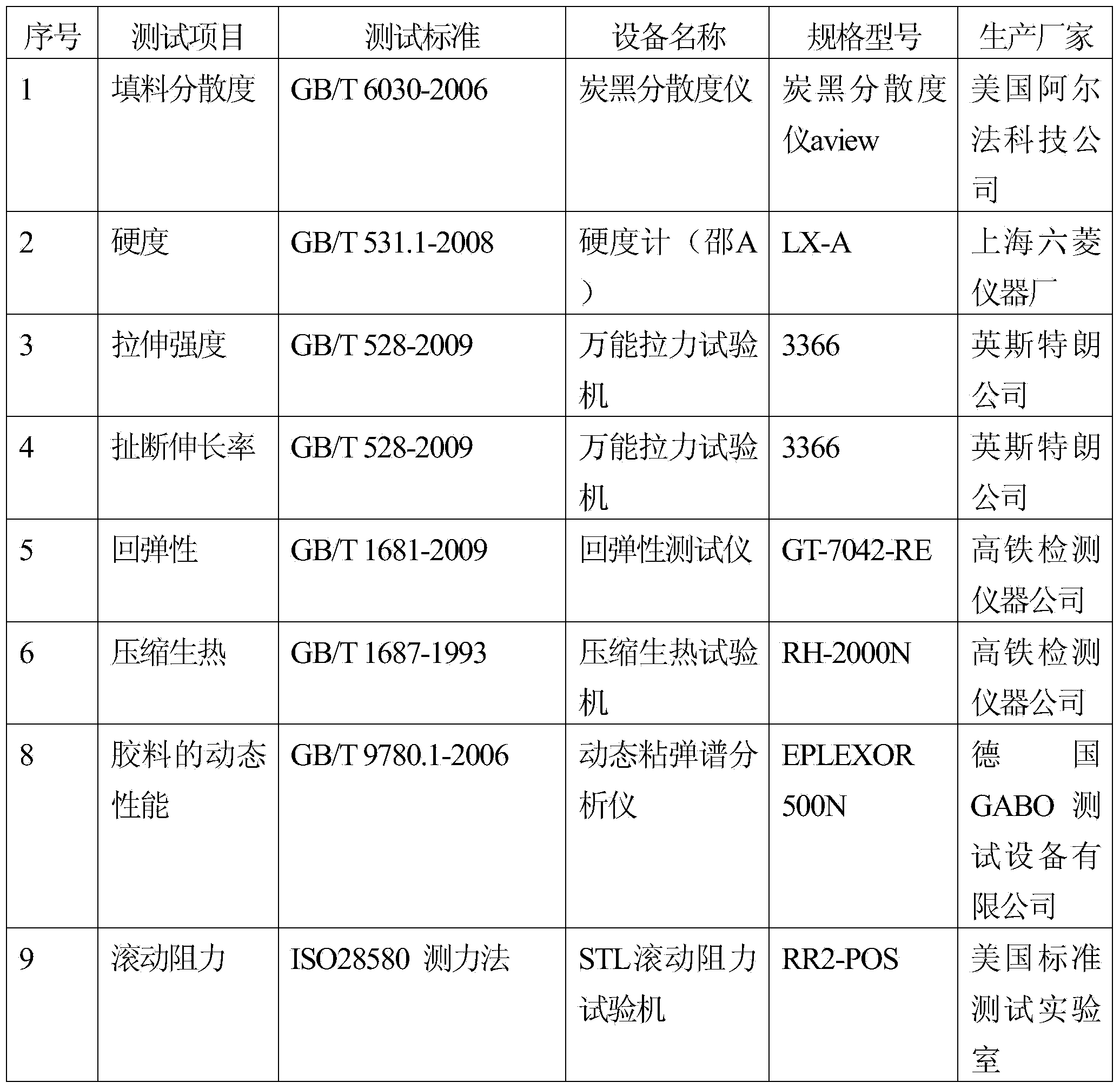

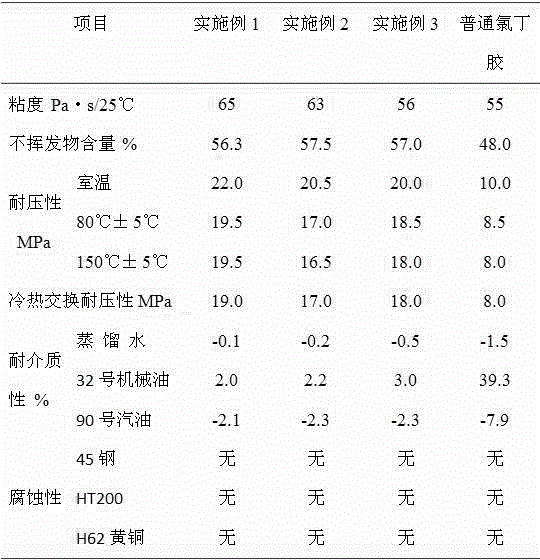

Oil-resistant liquid sealant and preparation method thereof

ActiveCN103602285AGood oil resistanceExcellent medium resistanceNon-macromolecular adhesive additivesOther chemical processesPolymer scienceNitrile rubber

The invention belongs to a sealant, and particularly relates to a solvent type oil-resistant liquid sealant and a preparation method thereof. The solvent type oil-resistant liquid sealant comprises the following components: 15-30% of nitrile rubber, 2-5% of tackifying resin, 20-45% of reinforcing filler, 0-5% of pigment, 0.5-2% of antiager and 0-60% of solvent. The preparation method comprises the following steps: firstly putting the nitrile rubber into a rubber refining machine, plasticizing so as to form a thin film and cutting the thin film into pieces for standby application; putting the weighed solvent, filler and pigment into a reaction kettle in proportions, stirring for about 1 hour at a high speed, then putting the tackifying resin and the antiager into the reaction kettle, stirring, putting the treated nitrile rubber into the reaction kettle, stirring for about 4-5 hours at a high speed, after dissolving materials into a bright white uniform viscous glue solution, cooling and carrying out vacuum defoaming so as to obtain the oil-resistant liquid sealant. The oil-resistant liquid sealant is convenient to use and has excellent pressure-resistant property, medium-resistant property and endurance property.

Owner:GLEIHOW NEW MATERIALS CO LTD

Novel storage battery production method

ActiveCN108461831AReduce sheddingReduce softeningMaterial nanotechnologyFinal product manufactureGlass fiberPorous carbon

The invention discloses a novel storage battery production method. The novel storage battery production method comprises the following steps: preparing raw material powder for preparing a porous carbon material, mixing the raw material powder for preparing the porous carbon material and raw materials for preparing a positive and negative active substances, stirring and preparing a paste-like substance, and smearing the paste-like substance on a graphite grid; carbonizing the paste-coated graphite grid, activating, perforating, cooling, thus obtaining a positive polar electrode and a negative polar electrode; laminating the positive polar plate, a glass fiber partition plate and the negative polar plate to form a multilayer polar plate, assembling the laminated multilayer polar plate into abattery box, and injecting electrolyte into the battery box; after the battery box is filled with the electrolyte, standing for 30 minutes, charging and discharging a battery, and activating the positive and negative active substances; and after the battery is domesticated, adjusting the concentration of the electrolyte in the battery, and sealing a liquid injection hole of the battery. By adopting the novel storage battery production method, not only can the problem of the complicated traditional production process be solved, but also the problem that the environment is severely polluted inthe production process can be solved, the service life of the battery can be prolonged, and the high-magnification charging-discharging performance can be improved.

Owner:山东鑫时利新能源科技有限公司

Application of continuously prepared rubber masterbatch in tread rubber of truck tire

The invention relates to application of continuously prepared rubber masterbatch in tread rubber of a truck tire. The application comprises the following steps: a) adding carbon black into a rubber solution, uniformly mixing, dispersing and injecting into a coagulator for coagulating, spraying a solvent remover and drying to obtain the rubber masterbatch; b) adding the rubber masterbatch into an internal mixer, adding a vulcanizing agent and an accelerator and uniformly mixing to obtain a rubber compound for the truck tire tread; and c) vulcanizing the rubber compound for the truck tire tread under vulcanizing conditions to obtain vulcanized rubber for the truck tire tread, wherein a step of adding an additive is performed in the step a) and / or step b), and the additive comprises one or more of a coupling agent, an anti-aging agent, an active agent, oil and other processing aids and the rubber is one or more of natural rubber, polybutadiene rubber, polyisoprene rubber and polystyrene-butadiene rubber.

Owner:EVE RUBBER RES INST

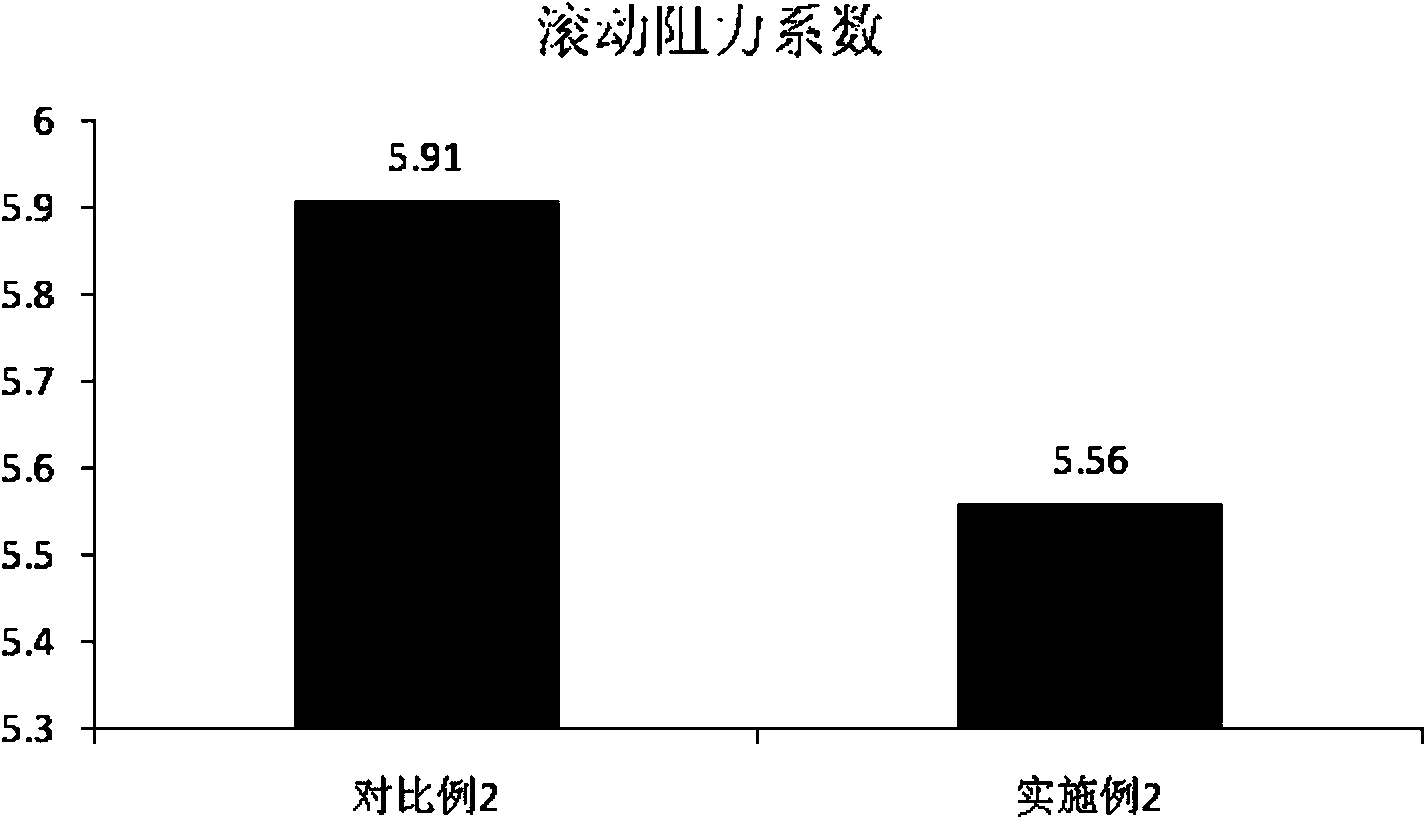

Application of continuously prepared rubber masterbatch to sidewall rubber of car tire

ActiveCN104387599AReduce rolling resistanceGood mechanical propertiesSpecial tyresMasterbatchPolymer science

The invention relates to an application of continuously prepared rubber masterbatch to the sidewall rubber of a car tire. The application comprises the following steps of: (a) adding a filler into a rubber solution, mixing, dispersing uniformly, injecting the dispersed mixture into a coagulator for coagulation, desolventizing and drying to obtain the rubber masterbatch; (b) adding the rubber masterbatch into a mixer, adding a vulcanizing agent and an accelerating agent and mixing uniformly to obtain a sidewall rubber compound for the car tire; and (c) vulcanizing the sidewall rubber compound for the car tire under a vulcanizing condition to obtain the vulcanized sidewall rubber compound for the car tire. The application further comprises the step of adding additives in the step (a) and / or the step (b), wherein the additives comprises one or more of a coupling agent, an anti-aging agent, an activating agent, oil and a thickening agent. The rubber in the rubber solution is one or one of natural rubber, polybutadiene rubber, polyisoprene rubber and polystyrene-butadiene rubber.

Owner:EVE RUBBER RES INST

Application of continuously prepared rubber masterbatch in sedan tire tread rubber

InactiveCN104311929AImprove wear performanceReduce rolling resistanceSpecial tyresRolling resistance optimizationMasterbatchPolymer science

The invention relates to application of a continuously prepared rubber masterbatch in sedan tire tread rubber. The application comprises the following steps: a, adding white carbon black, a coupling agent, an anti-aging agent and oil into rubber solution, uniformly mixing and dispersing the raw materials, injecting the mixture into a coagulator to carry out coagulation, then desolvating and drying to obtain the rubber masterbatch; b, adding the rubber masterbatch into an internal mixer, adding a vulcanizing agent and an accelerant and uniformly mixing to obtain a sedan tire tread rubber masterbatch; and c, carrying out vulcanizing on the sedan tire tread rubber masterbatch to obtain the sedan tire tread rubber. The application also comprises the step of adding additives; the additives are added in the step a and / or the step b; and the additives are one or more of the coupling agent, the anti-aging agent, an active agent, the oil and other processing assistants, wherein the rubber is one or more of polybutadiene rubber, polyisoprene rubber and polystyrene-butadiene rubber.

Owner:EVE RUBBER RES INST

Colloidal nano sulfur and sulfur colloidal nano encapsulation modification method

ActiveCN103709464AGood dispersionFlexible feeding methodMicroballoon preparationMicrocapsule preparationCross-linkElastomer

The invention discloses a colloidal nano sulfur and a sulfur colloidal nano encapsulation modification method. The colloidal nano sulfur comprises the following components: 70 to 80 parts by weight of sulfur, 8 to 10 parts by weight of liquid nitrile rubber, 5 to 7 parts by weight of triglycerin fatty acid ester, 4 to 8 parts by weight of fatty acid monoglyceride and 3 to 5 parts by weight of zinc stearate. The sulfur colloid nano encapsulation modification method comprises steps of mixing, reaction, grinding and cooling. The powder sulfur modified capsule nano colloid provided by the invention can comprehensively improve the dispersion of mixing rubber material and ensure product molding sulfuration to form a homogeneous three-dimensional cross-linked structure elastomer. The feeding mode is flexible and suitable for production processes of different product rubber compounds; and the colloidal nano sulfur is an indispensable crosslinking auxiliary agent for modern rubber formula and efficient production process.

Owner:WUXI NO 2 RUBBER

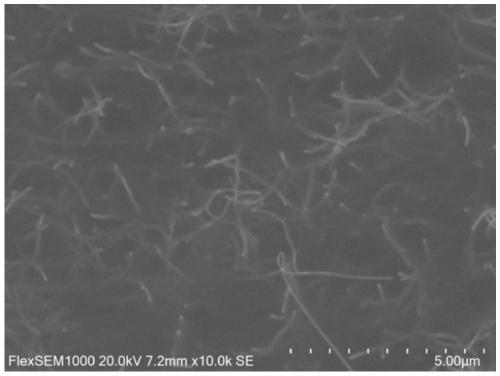

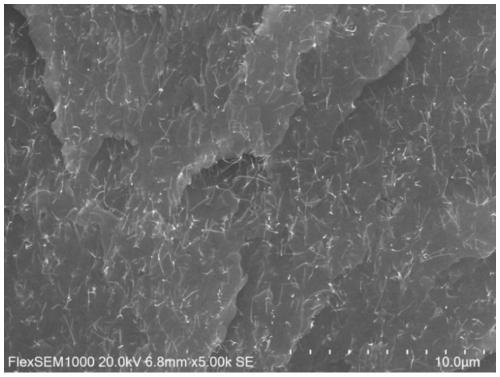

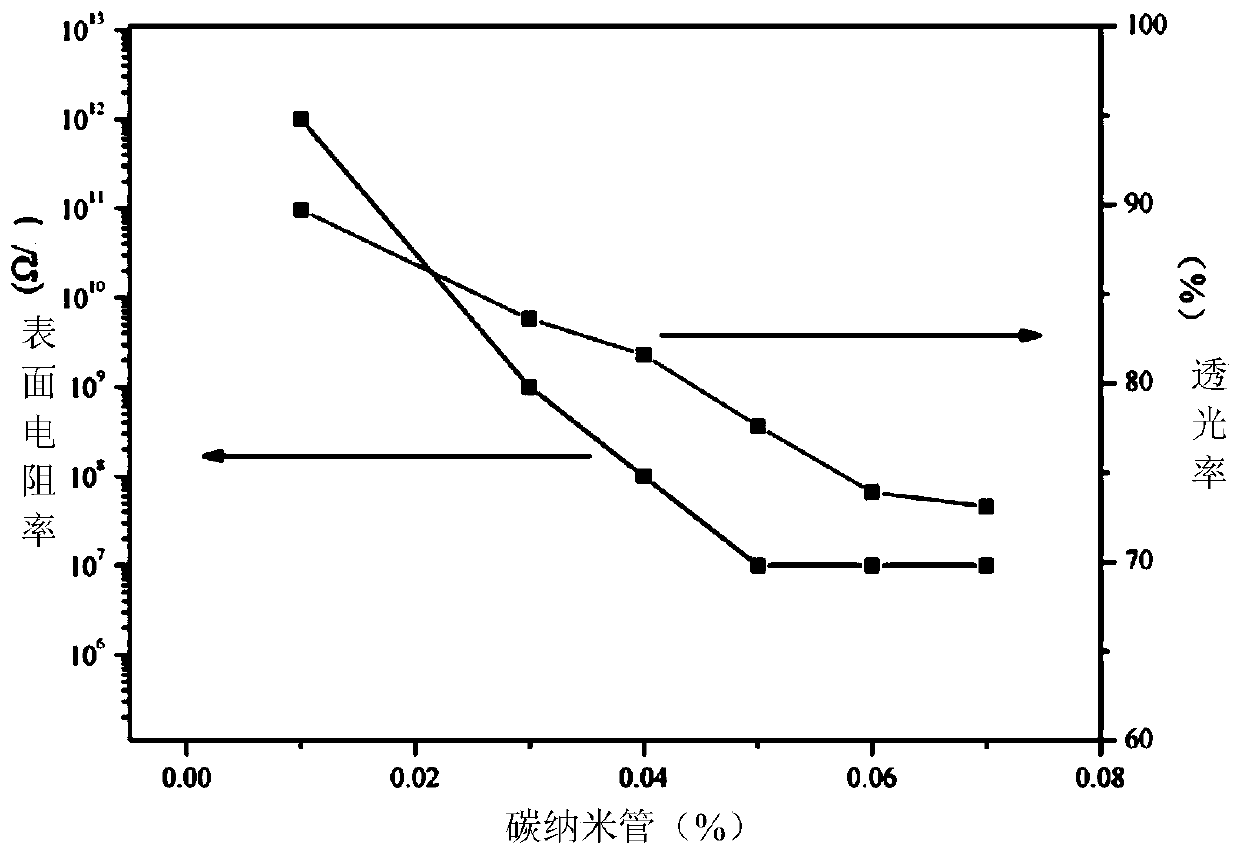

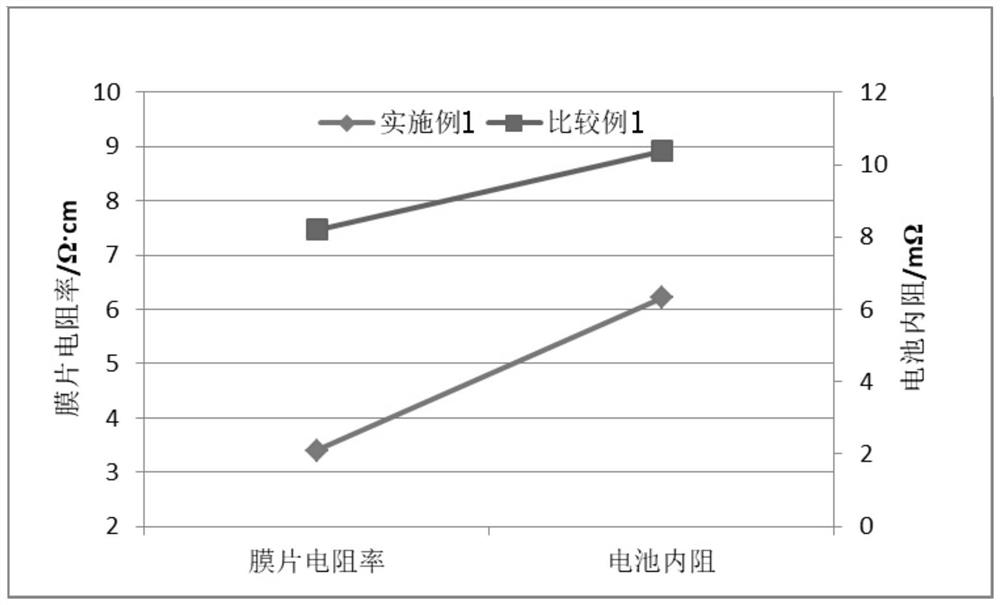

Carbon nanotube antistatic material, slurry, film and preparation method of film

Belonging to the technical field of antistatic films, the invention in particular relates to a carbon nanotube antistatic film and a preparation method thereof. The method includes: acquiring carbon nanotubes with a tube length of 100-500 microns, resin and a solvent, mixing the carbon nanotubes, the resin and the solvent evenly to obtain a carbon nanotube resin mixture; performing roller type grinding treatment on the carbon nanotube resin mixture to obtain a grinding product; acquiring a curing agent and the solvent, adding the curing agent and the solvent into the grinding product to prepare a carbon nanotube antistatic slurry with a solid content of 70-85%; and making the carbon nanotube antistatic slurry into a carbon nanotube antistatic film. The preparation process adopted by the invention can enable uniform dispersion of long chain carbon nanotubes in the slurry without additional dispersant, thus avoiding the influence of dispersant on film adhesion and surface resistivity. Also, the preparation method has a simple process, and is suitable for industrial production.

Owner:SHENZHEN XIWAN TECH CO LTD

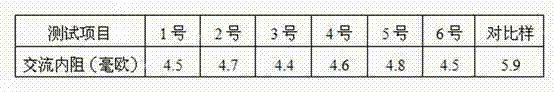

Conductive agent used for lithium iron phosphate battery and preparation method thereof

ActiveCN102136576BSlow down the sinking speedGood dispersionCell electrodesLithium vanadium phosphate batteryLithium iron phosphate

The invention discloses a conductive agent used for a lithium iron phosphate battery, and also discloses a preparation method for the conductive agent. The conductive agent consists of a carbon nanotube / carbon black composite material, graphene and a bonding agent in the weight ratio of 1:(0.001-0.1):(0.01-1). The preparation method comprises the following steps of: first, preprocessing the carbon nanotube / carbon black composite material; then, performing ultrasonic dispersion on the carbon nanotube / carbon black composite material and the bonding agent in secondary distilled water; next, adding the graphene into the secondary distilled water under the condition of ultrasonic waves; and finally, performing the ultrasonic dispersion to prepare the conductive agent. The preparation method for the conductive agent is simple; and the prepared conductive agent has uniform dispersion and high stability. The conductive agent has high electronic conductivity and uniform heat conduction; and the lithium iron phosphate battery prepared by adopting the conductive agent has remarkably improved electrochemical performance and obviously reduced alternating-current internal resistance.

Owner:中创新航科技(江苏)有限公司

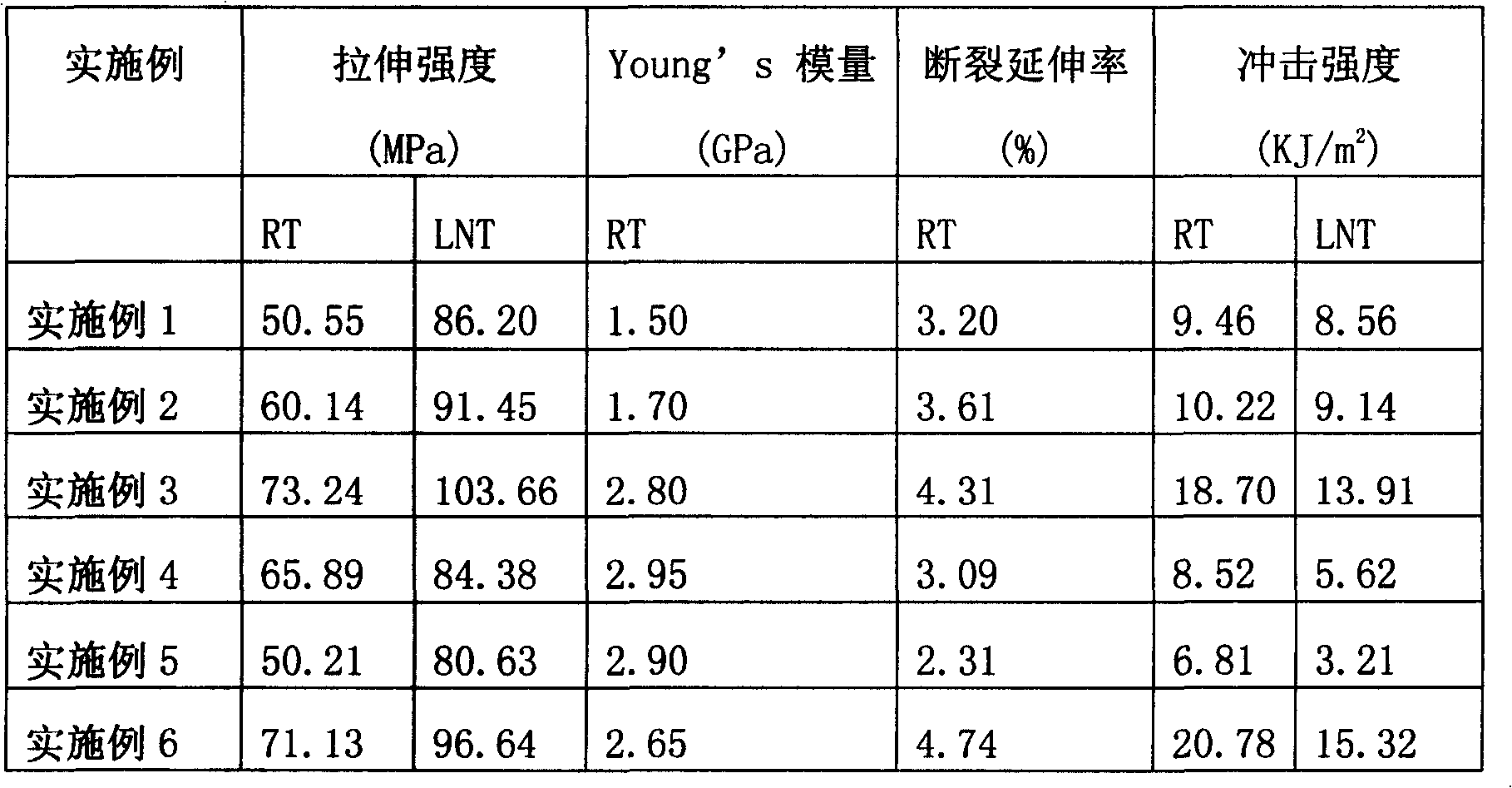

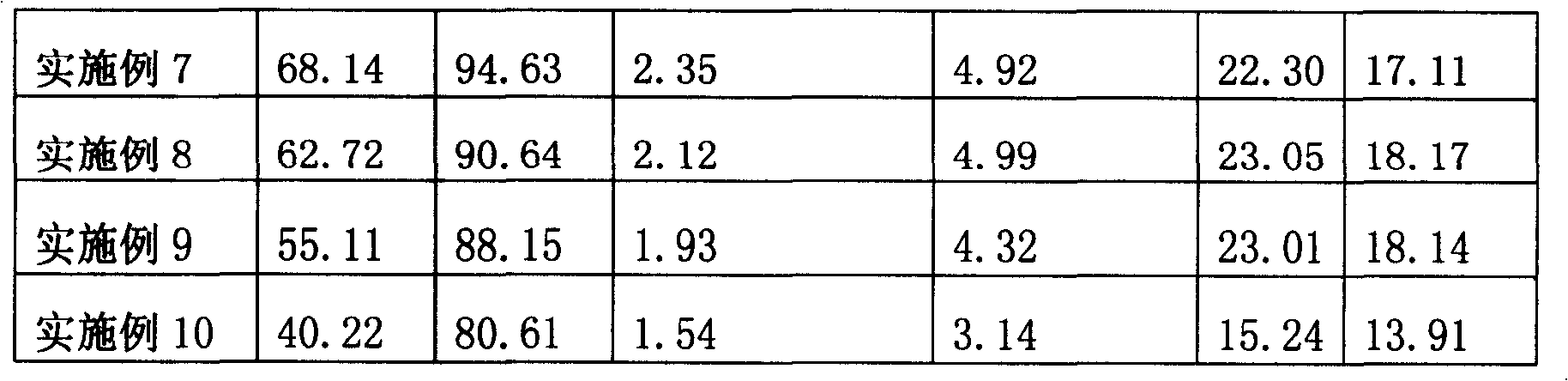

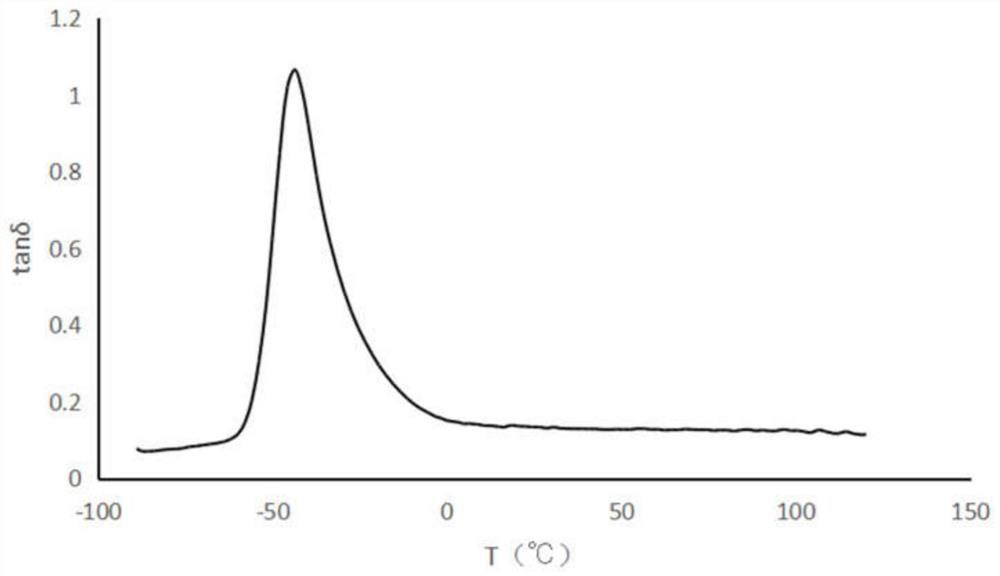

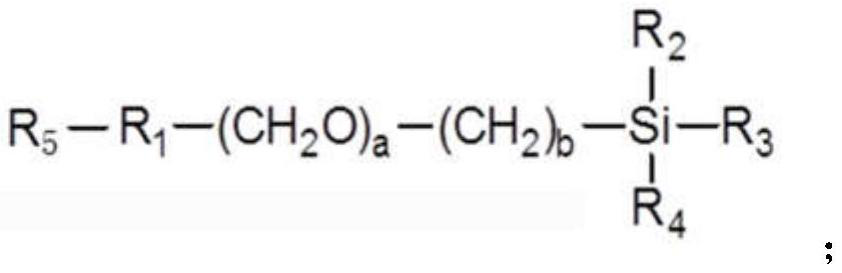

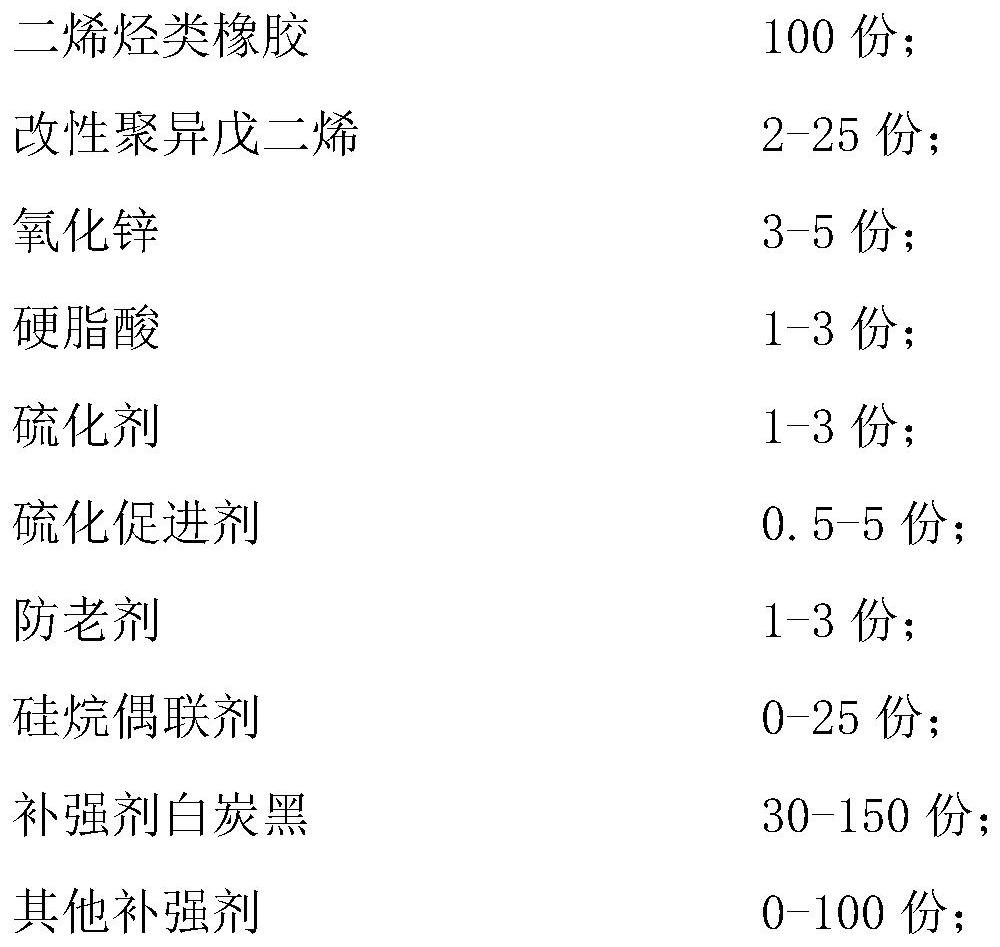

High-strength rubber composite material with excellent processability and preparation method thereof

The invention relates to the field of composite materials, and particularly provides a high-strength rubber composite material with excellent processability and a preparation method thereof. According to the rubber composition, siloxane-terminated and modified low-molecular-weight polyisoprene is mainly used to replace oils in a diene and white carbon black formula system, so that the processability of the rubber composite material is improved, the tensile strength and tear strength of the composite material vulcanized rubber are remarkably improved, and the anti-fatigue performance of the material is further improved.

Owner:QINGDAO UNIV OF SCI & TECH

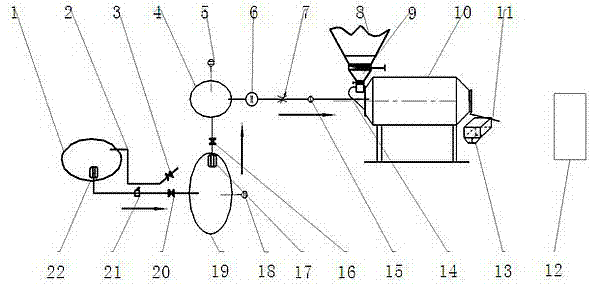

Technology and device for mixing raw material of perlite acoustic board

ActiveCN103831055AReduce manual involvementAvoid harmCovering/liningsMixer accessoriesPerliteSodium silicate

The invention discloses a technology and a device for mixing a raw material of a perlite acoustic board. The technology comprises the following steps of 1, sodium silicate solution preparation, 2, sodium silicate solution conveying, 3, binder preparation, 4, binder conveying: conveying the binder into a material supplying tank, 5, binder flow control, 6, accurate taking of materials, 7, accurate mixing and 8, vibration impurity-removal. According to the technology, the device mainly comprises 1, three liquid containers comprising a sodium silicate tank, a material blending tank and a material supplying tank, 2, three solution transfer pumps comprising a submerged pump, a blending screw pump and a liquefaction screw pump, 3, detection devices comprising a valve, a filter, a liquidometer and a flowmeter, 4, blending stirring and assist devices comprising a proportioner, a blending stirring station, a vibrating screen, a diversion groove and a diversion hopper, and 5, a control system comprising a programmable logic controller, an industrial touch screen, a transformer and a relay.

Owner:HEBEI UNIV OF TECH

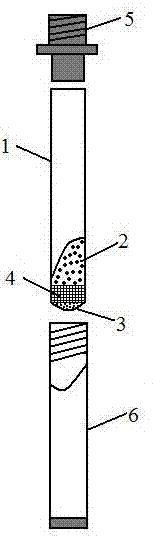

Portable welding pen

ActiveCN102151982BSimple ingredientsEnsure consistencyAlumino-thermic welding apparatusAl powderEngineering

Owner:常熟紫金知识产权服务有限公司

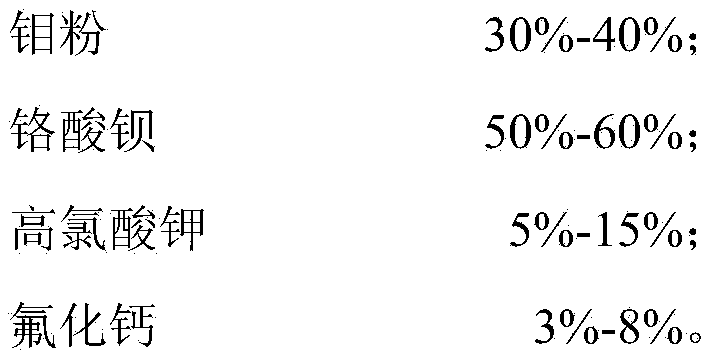

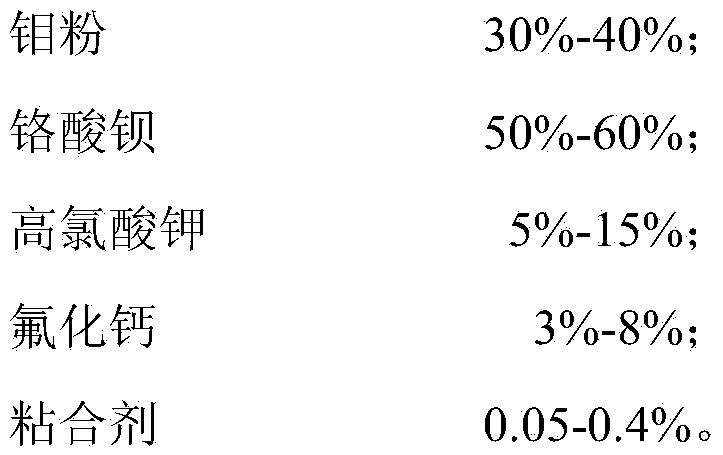

Delay composition with long-term healing per second and production method of delay composition

The invention discloses a delay composition with long-term healing per second and a production method of the delay composition, and aims at solving the problems that the existing delay composition with long-term healing per second is generally poor in precision and complex in preparation process. The delay composition comprises the following components in percentage by weight: 30%-40% of molybdenum powder, 50%-60% of barium chromate, 5%-15% of potassium perchlorate and 3%-8% of calcium fluoride. The production method of the delay composition has the advantages of a simple production process, a high yield, energy conservation and environmental friendliness, less wastewater produced in the process, and the like. Meanwhile, the delay composition with long-term healing per second disclosed by the invention has the characteristics of a wide delay time range, precise delay, good storage performance and the like, and has a wide application and development prospect in the military and civilian fields at home and abroad.

Owner:YAHUA GROUP MIANYANG INDAL

Molybdenum-lanthanum alloy sintered blank preparation method and product thereof

The invention discloses a preparation method of a molybdenum-lanthanum alloy sintered blank and a product thereof, and the preparation method comprises the following steps: 1) preparation of a mixture: weighing molybdenum powder and LaB6 according to a certain proportion, and then mixing to obtain the uniformly mixed mixture; (2) preparing a blank: pressing the mixed powder in the step (1) according to requirements to obtain the blank; (3) preparing a pure molybdenum sintered product: putting the blank in the step (2) into a sintering furnace; and carrying out sintering molding in a hydrogen atmosphere according to set process parameters to obtain a molybdenum-lanthanum alloy sintered blank. According to the invention, a small amount of LaB6 is added into Mo powder, so that the material mixing process is relatively simple, and large-scale application can be realized. According to the method, hydrogen atmosphere sintering is adopted, the requirement for sintering equipment is not high, meanwhile, the highest sintering temperature is 1600 DEG C, compared with a traditional sintering method with the temperature higher than 1900 DEG C, energy can be effectively saved, pollution can be reduced, and it can be guaranteed that the grain size of molybdenum metal products is not too large through relatively low-temperature sintering.

Owner:CENT SOUTH UNIV

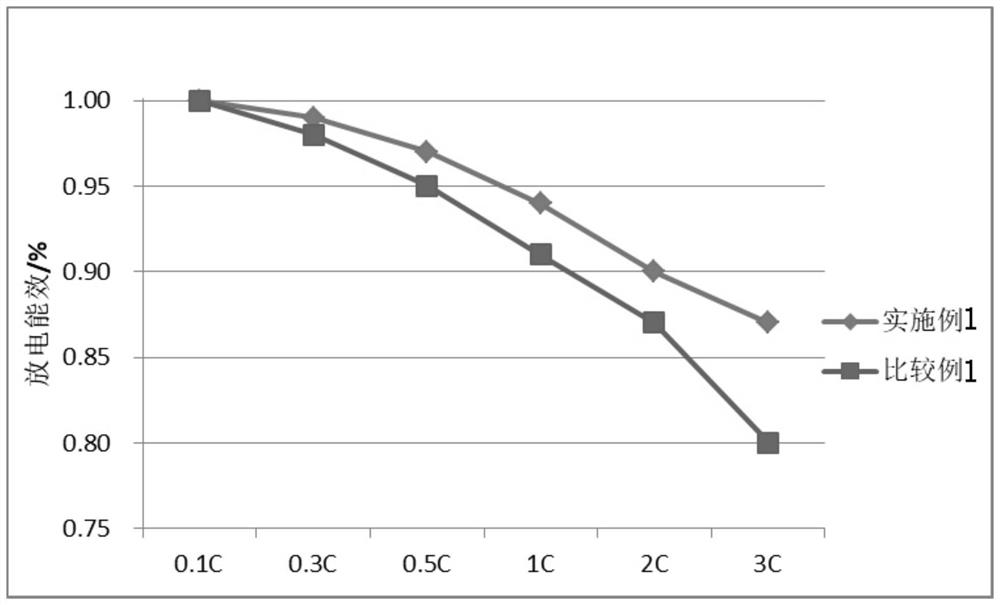

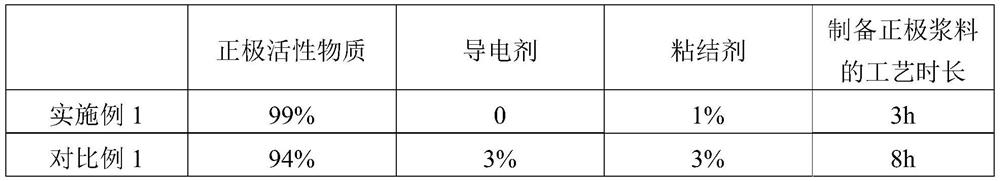

Positive plate, preparation method thereof and lithium ion battery

InactiveCN112331818ASimplify the mixing processShorten mixing timeSecondary cellsPositive electrodesElectrically conductiveElectrical battery

The invention provides a positive plate, a preparation method thereof and a lithium ion battery. The method comprises the following steps: 1) mixing a conductive agent composite positive electrode material, a binder and a solvent to obtain positive electrode slurry; and 2) coating the surface of a current collector with the positive electrode slurry, and carrying out cold pressing treatment to obtain the positive plate. According to the preparation method of the positive plate provided by the invention, the conductive agent is compounded with the positive electrode material, the positive electrode material and the conductive agent are combined, no additional conductive agent needs to be added in the process of mixing to form slurry, the stirring process can be greatly simplified, only one-step charging and stirring process is needed, the stirring time is shortened, the positive plate production efficiency is improved, and the production cost is reduced. Meanwhile, the conductive agentis used for compounding the positive electrode material instead of being added in the process of mixing the slurry, so that local agglomeration caused by non-uniform dispersion of the conductive agentin the stirring process can be prevented, the consistency of slurry dispersion is ensured, the coating effect of the positive electrode piece is improved, and the consistency of the battery is further improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD +1

Production method and application of additive for increasing content of unsaturated fatty acid in egg

ActiveCN103859167AIncrease egg productionPromote absorptionAnimal feeding stuffGrape seedFeed additive

The invention discloses a production method and application of a feed additive for increasing the content of unsaturated fatty acids in an egg and belongs to the technical field of applications of feed additives. The production method is mainly characterized by comprising the following steps: superfine-grinding, optimizing a mixture ratio and mixing the main raw materials including perila seeds, grape seeds, vitamin and branched chain amino acid to produce the feed additive for increasing the content of the unsaturated fatty acids in the egg. The additive is used in an egg laying period of a hen and the addition ratio of the additive is 0.2%-0.5% or 2-5 kg per ton of daily ration. When the additive is used in the egg laying period of the hen, the egg laying rate of the hen can be enhanced, the immunity of the organism of the hen can be improved and the content of the omega-3 and omega-6 unsaturated fatty acids can be increased.

Owner:播恩集团股份有限公司

Application of continuously-prepared rubber masterbatch to rubber compound for shoulder pad of truck tire

The invention relates to an application of continuously-prepared rubber masterbatch to the rubber compound for the shoulder pad of a truck tire, comprising the following steps of: (a) adding a filler, optionally adding an additive into a rubber solution, wherein the additive can be a coupling agent, an anti-aging agent, an activating agent or / and oil, mixing and dispersing uniformly, injecting the dispersed mixture into a coagulator for coagulation, desolventizing, and drying to obtain the rubber masterbatch; (b) adding the rubber masterbatch into a mixer, optionally adding an anti-aging agent, an activating agent or / and oil, mixing, directly adding a coupling agent and an accelerating agent, and mixing uniformly to obtain a rubber compound for the shoulder pad of the tire of the truck; and (c) vulcanizing the rubber compound to obtain the vulcanized rubber compound for the shoulder pad of the truck tire.

Owner:EVE RUBBER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com