Application of continuously prepared rubber masterbatch in sedan tire tread rubber

A technology for rubber masterbatch and car tires, applied in special tires, vehicle parts, tire parts and other directions, can solve the problems of difficult dispersion, reduce tire rolling resistance, reduce mixing steps, etc., to solve difficult dispersion, reduce rolling resistance, reducing the effect of the mixing step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Add 75 parts of white carbon black, 6 parts of silane coupling agent Si69, 28 parts of aromatic oil and 2 parts of anti-aging agent 264 into the n-hexane solution of 70 parts of solution-polymerized styrene-butadiene rubber and 30 parts of butadiene rubber and mix them continuously. It was injected into the coagulator for coagulation, and then the solvent was removed and dried to obtain the masterbatch 1.

[0053] Add masterbatch 1 to the internal mixer evenly, add 3.5 parts of zinc oxide, 2 parts of stearic acid, 2 parts of anti-aging agent 4020, and 2 parts of protective wax. After the machine is uniform, add 2 parts of accelerator CZ, 2.1 parts of accelerator DPG, and 1.4 parts of sulfur, and after mixing, roll off the sheet, and the mixed rubber is parked for 8 hours. After vulcanization, the continuously prepared vulcanizate 1 was prepared. Tire 195 / 60R14 was prepared using continuous preparation of tread mix 1.

Embodiment 2

[0055] Add 75 parts of white carbon black, 6 parts of silane coupling agent Si69, 28 parts of aromatic oil, 3.5 parts of zinc oxide, 2 parts of stearic acid, 2 parts of anti-aging agent 264, 2 parts of anti-aging agent 4020, and 2 parts of protective wax into After mixing 70 parts of solution polystyrene-butadiene rubber and 30 parts of cis-butadiene rubber in n-hexane solution, they were continuously poured into the coagulator for coagulation, and then the solvent was removed and dried to obtain masterbatch 2.

[0056] After adding the masterbatch 2 into the internal mixer evenly, add 2 parts of accelerator CZ, 2.1 parts of accelerator DPG, and 1.4 parts of sulfur. After mixing, roll off the sheet and leave the mixed rubber for 8 hours. After being vulcanized to normal vulcanization at 165°C, the continuous vulcanizate 2 was prepared. Tire 195 / 60R14 was produced with continuous preparation of tread mix 2.

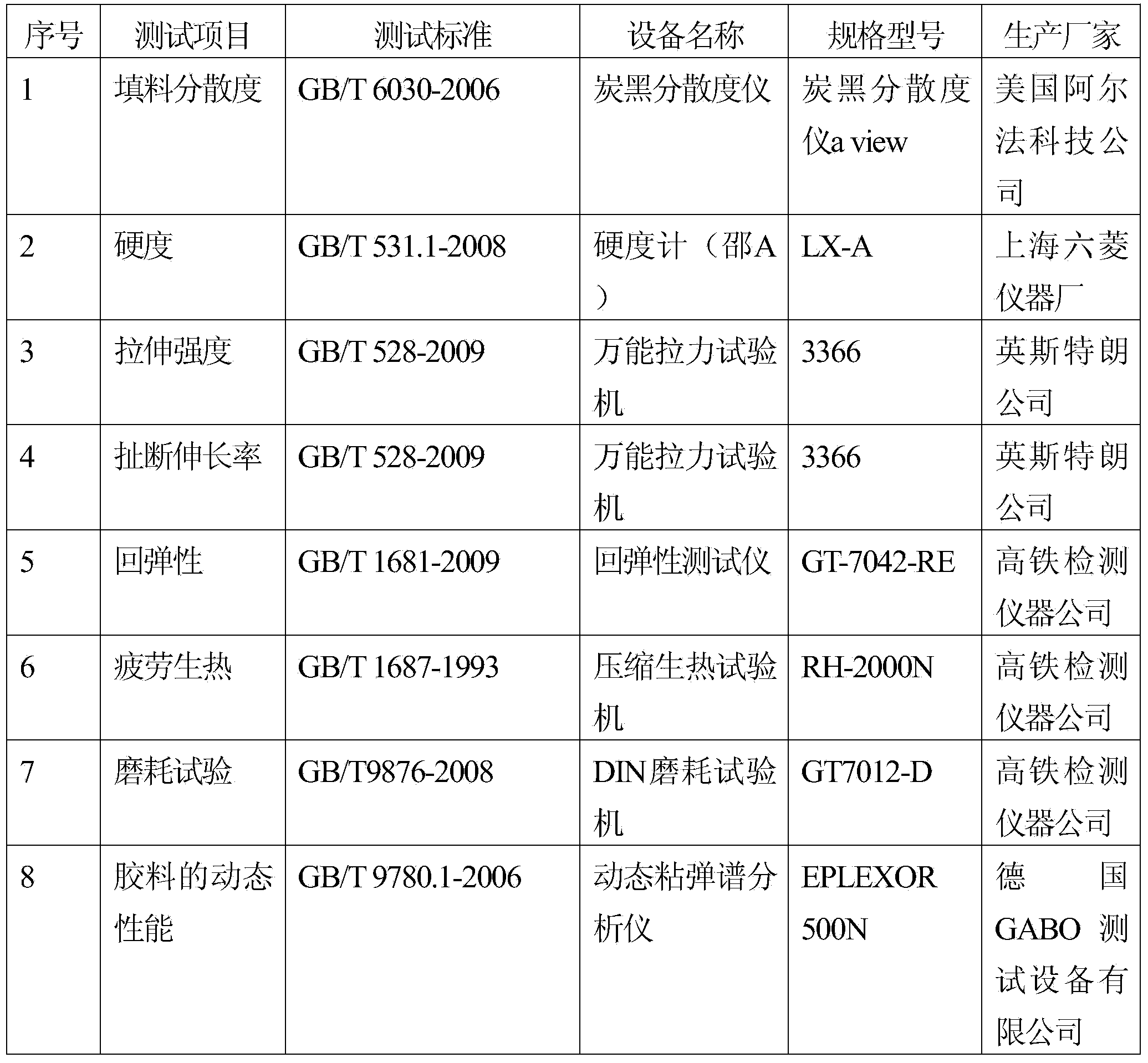

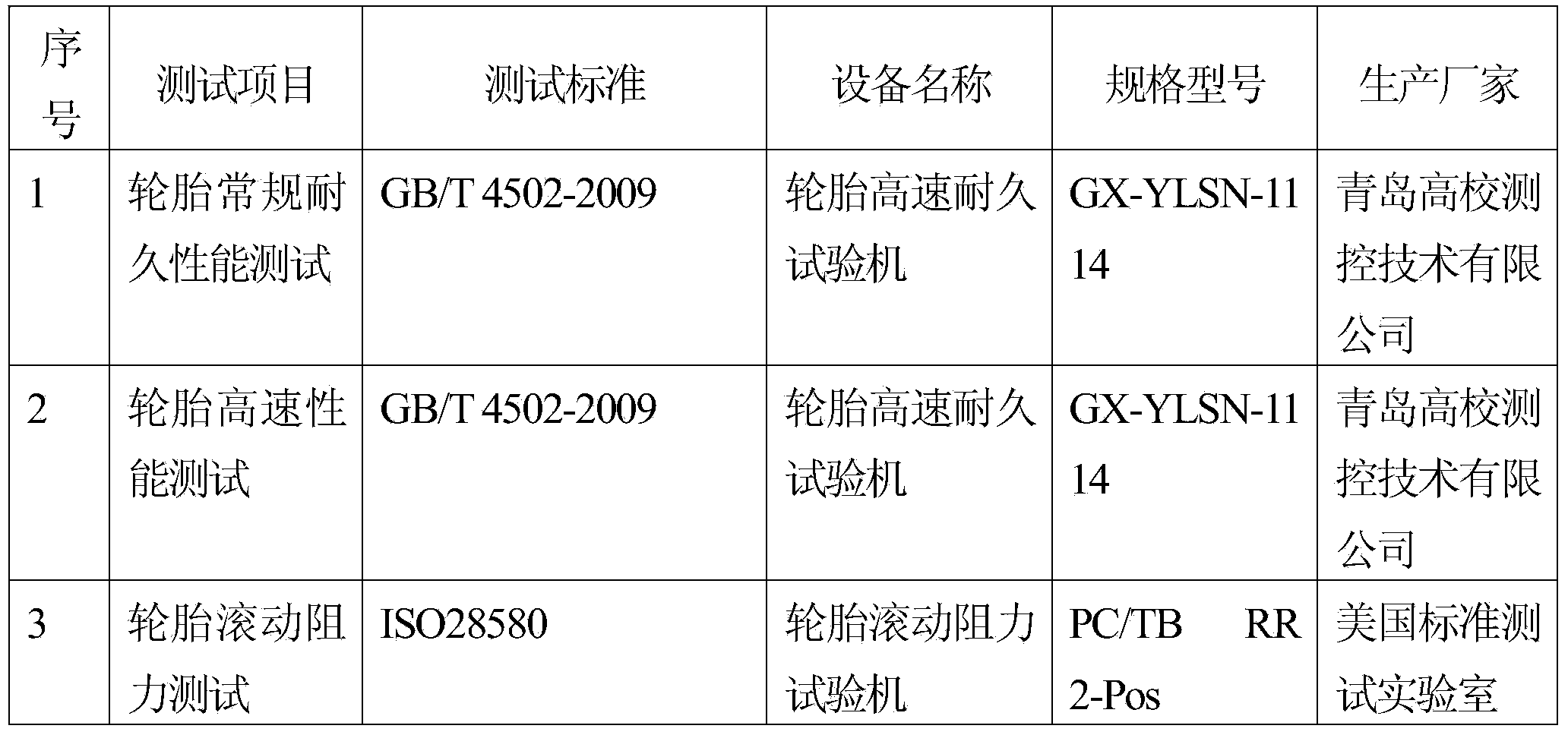

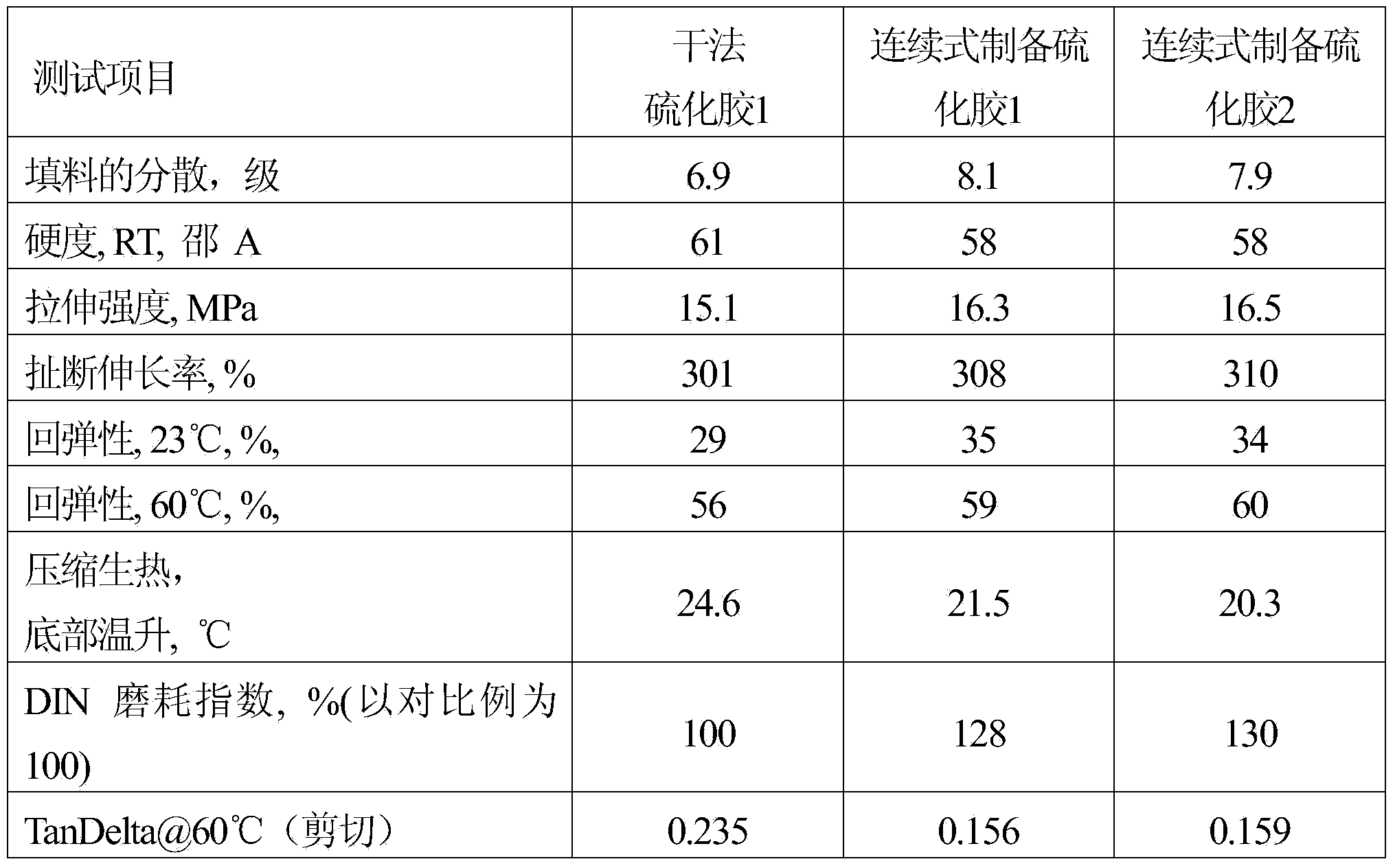

[0057] Table 4 Test performance of dry and continuous preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com