Application of continuously prepared rubber masterbatch in steel cord adhesive

A technology of rubber masterbatch and steel cord, which is applied in the field of tire rubber compound production, can solve the problems of reducing mixing steps and not easy to disperse, and achieve the effects of reducing mixing steps, improving dispersion, and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 55 parts of N326 carbon black were added to 100 parts of 8% natural rubber in n-hexane solution, mixed, continuously injected into the coagulator for coagulation, and then desolventized and dried to obtain masterbatch A1.

[0054] Add masterbatch A1 to the internal mixer and mix evenly, add 8 parts of zinc oxide, 2 parts of anti-aging agent 4020, 0.2 parts of cobalt neodecanoate, 1.5 parts of resorcinol, remove the tablet after mixing, and park for 8 hours Then add the internal mixer and mix evenly, add 1.3 parts of accelerator DZ, 4.5 parts of adhesive glue RA, 4.5 parts of insoluble sulfur HD OT20, after mixing, pass the roller and release the film, and the mixed rubber is parked for 8 hours and then vulcanized with a flat plate After being vulcanized to positive vulcanization at 150°C, the vulcanizate 1 was prepared in a continuous manner.

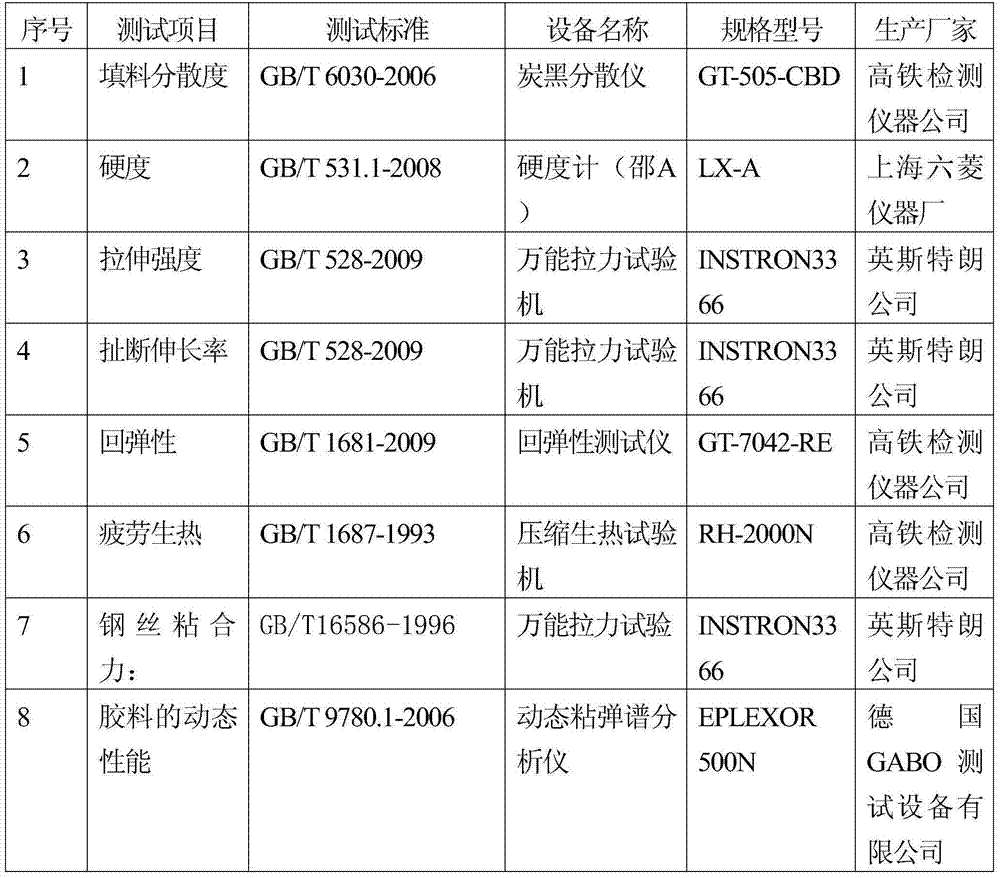

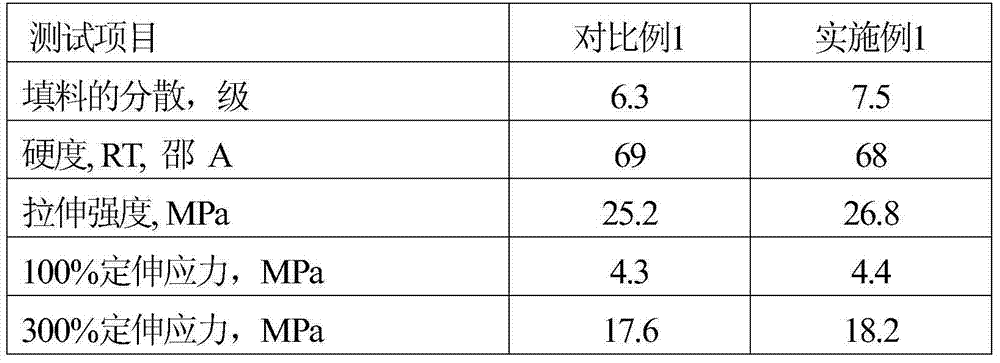

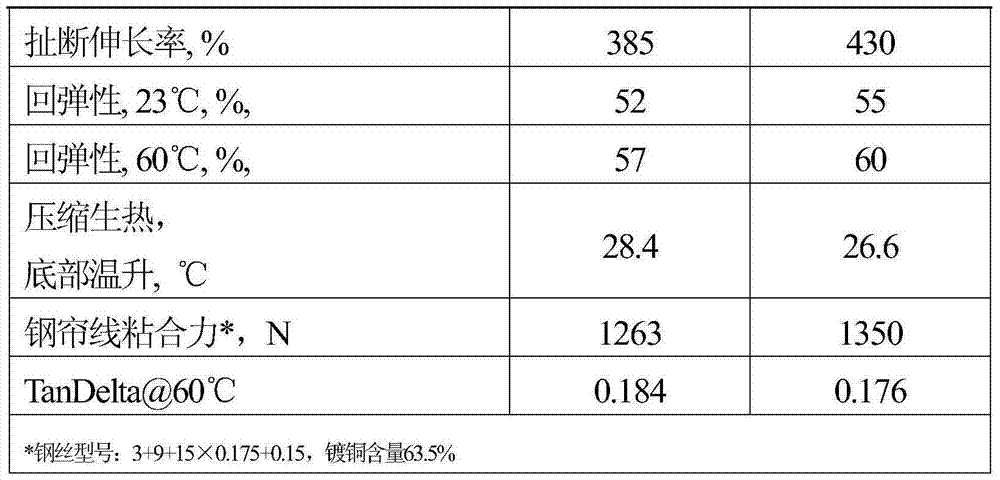

[0055] Table 1 Comparative example 1 and embodiment 1 performance

[0056]

[0057]

[0058] As can be seen from Table 1...

Embodiment 2

[0062] Add 45 parts of N375 carbon black, 15 parts of white carbon black, and 1.5 parts of organosilane coupling agent to 100 parts of 8% natural rubber in n-hexane solution, after mixing, continuously inject into the coagulator for coagulation, and then desolventize and dry to obtain Masterbatch A2.

[0063] Add masterbatch A2 to the internal mixer and mix evenly, add 10 parts of zinc oxide, 2 parts of anti-aging agent 4020, 1.2 parts of cobalt neodecanoate, 1.5 parts of resorcinol, and then release the tablet after mixing, and park for 8 hours Then add the internal mixer and mix evenly, add 1.2 parts of accelerator NS, 5 parts of adhesive glue RA, and 5 parts of insoluble sulfur HD OT20. After mixing, pass the roller and lower the sheet. The mixed rubber is parked for 8 hours and vulcanized by a flat plate After being vulcanized to positive vulcanization at 150°C, the vulcanizate 2 was prepared in a continuous manner.

Embodiment 3

[0071] Add 46 parts of N347 carbon black, 10 parts of white carbon black, and 1 part of organosilane coupling agent to 100 parts of 8% natural rubber n-hexane solution, after mixing, continuously inject into the coagulator for coagulation, and then desolventize and dry to obtain Masterbatch A3.

[0072] Add masterbatch A3 to the internal mixer evenly, add 10 parts of zinc oxide, 2 parts of anti-aging agent 4020, 0.8 parts of cobalt neodecanoate, 1.5 parts of resorcinol. Add 1.1 parts of accelerator DZ, 5 parts of adhesive glue RA, 5 parts of insoluble sulfur HD OT20 after mixing evenly in the internal mixer. After vulcanization to normal vulcanization at 150°C, the vulcanizate is prepared continuously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com