Application of continuously prepared rubber masterbatch in tread rubber of truck tire

A technology for rubber masterbatch and truck tires, which is applied in the field of tire rubber compound production. It can solve the problems of adding silica and mixing, which is difficult to disperse, reduce tire rolling resistance, and reduce mixing steps, etc., to achieve low heat generation, superior, Reduced rolling resistance, effect of fewer kneading steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Add 50 parts of carbon black JW160 into 100 parts of 8% natural rubber in n-hexane solution, mix, inject continuously into the coagulator for coagulation, then spray off the solvent and dry to obtain masterbatch A.

[0056] Add masterbatch A to the internal mixer evenly, add 3.5 parts of zinc oxide, 2 parts of stearic acid, 2 parts of anti-aging agent 4020, 1.5 parts of anti-aging agent RD, and 2 parts of protective wax. Add 1.3 parts of accelerator NS and 1.3 parts of sulfur to the internal mixer after 1 hour. After mixing, pass the roller and release the sheet. After the mixed rubber is parked for 8 hours, use a flat vulcanizer to vulcanize at 150°C until it is fully vulcanized. Finally, the continuous preparation of vulcanizate is obtained. A tire with a specification of 11R22.5 was prepared by continuously preparing the tread compound.

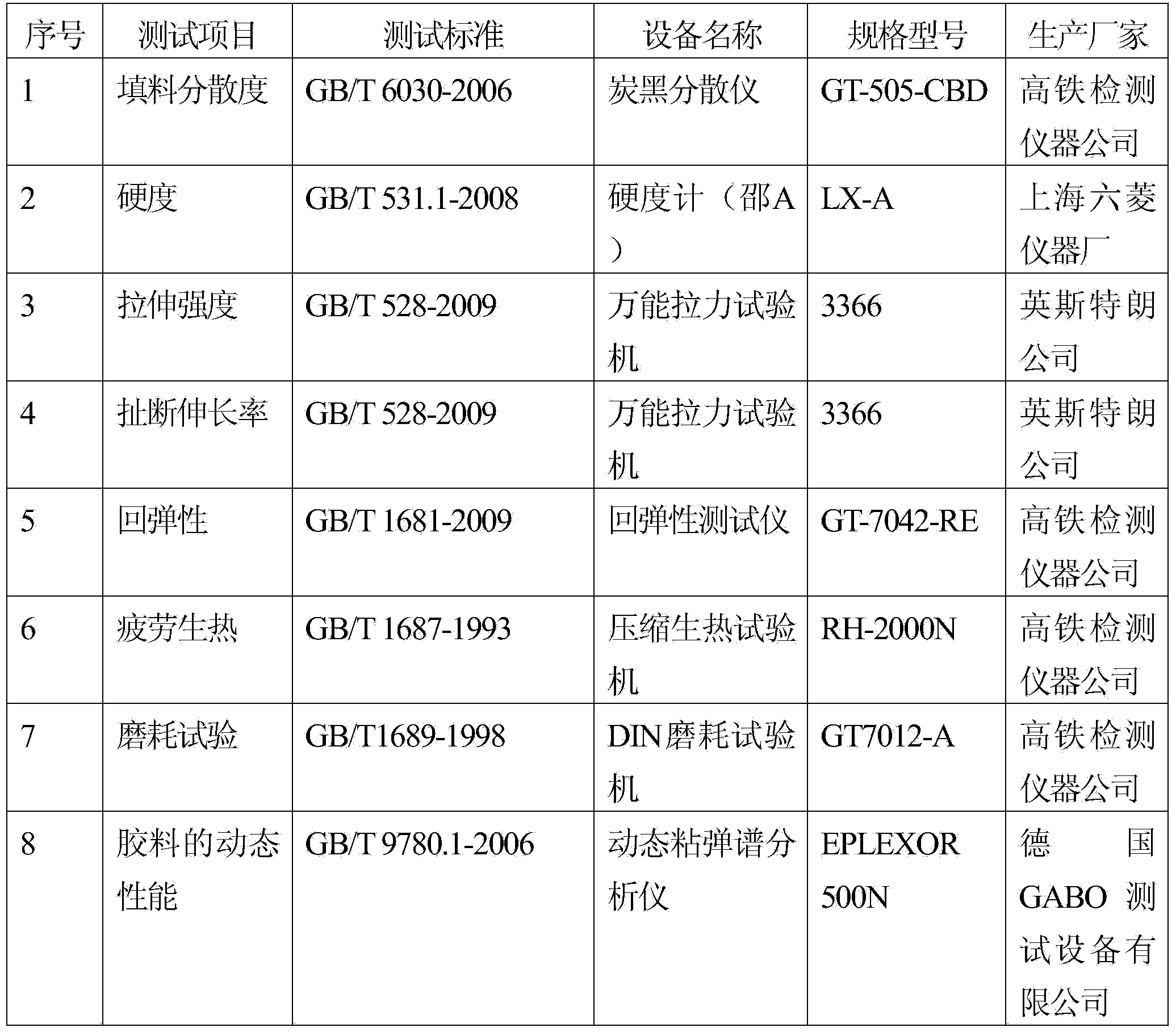

[0057] Table 4 embodiment 1 and comparative example 1 test performance

[0058]

[0059]

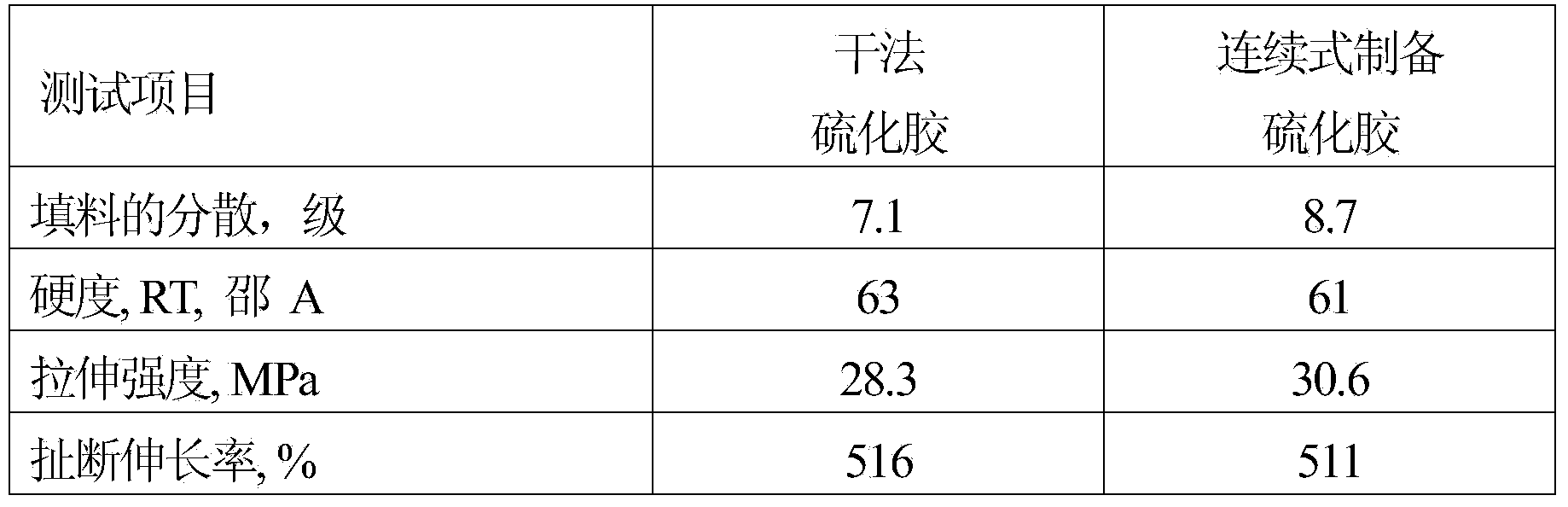

[0060] Table 5 Dry method and c...

Embodiment 2

[0066] Add 53 parts of carbon black N234 to 100 parts of 8% natural rubber n-hexane solution, then add 1.5 parts of anti-aging agent RD and 2 parts of anti-aging agent 4020, after mixing, continuously inject into the coagulator for coagulation, and then spray off the solvent And dry to obtain masterbatch A.

[0067] After adding masterbatch A to the internal mixer evenly, add 3.5 parts of zinc oxide, 2 parts of stearic acid, and 2 parts of protective wax. 1 part of accelerator NS, 1.3 parts of sulfur. After mixing, roll off the sheet. After the mixed rubber is parked for 8 hours, it is vulcanized to positive vulcanization with a flat vulcanizer at 150 ° C to obtain a continuous vulcanized rubber.

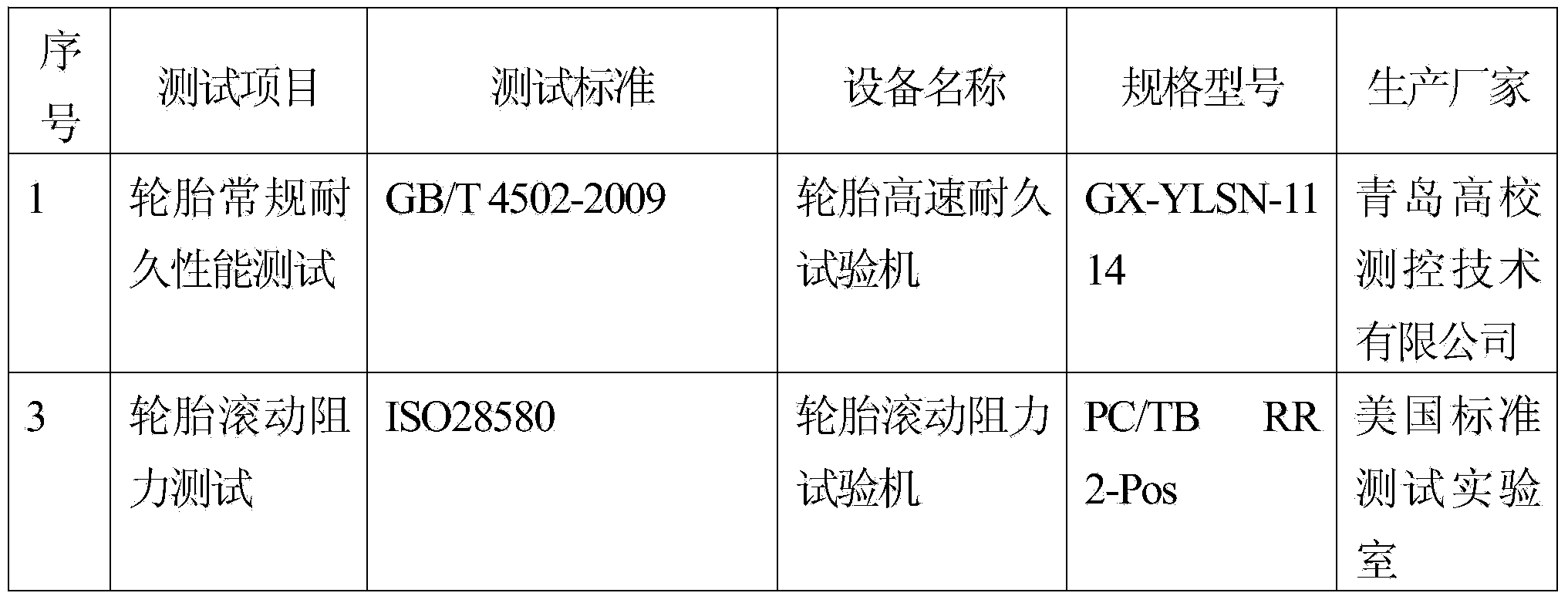

[0068] Table 6 embodiment 2 and comparative example 2 test performance

[0069]

[0070] It can be seen from Table 6 that the tensile strength, heat generation, abrasion and TanDelta60°C of vulcanizates prepared by continuous method are better than those prepared by dry mixing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com