Portable welding pen

A portable, soldering pen technology, applied in welding equipment, thermite welding equipment, manufacturing tools, etc., can solve the problems of short length of flame-retardant head, high cost, low safety factor, etc., to achieve increased safety, simple composition, and easy operation quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

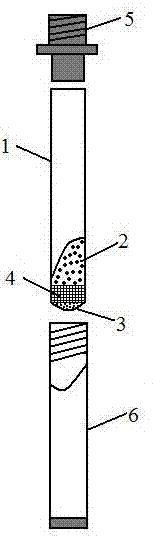

Embodiment 1

[0027] A portable soldering pen, thermite is composed of exothermic agent, slagging agent and alloying agent. The components and proportions of the exothermic agent are: CuO powder: 60wt%, Al powder: 20 wt%; the proportions of the components of the slagging agent are: CaF 2 Powder: 8wt%, CaSO 4 Powder: 5wt%; the components and proportions of the alloying agent are: ferromanganese 3wt%, ferronickel 4wt%. The particle size of each powder is between 150 mesh and 200 mesh, among which CuO powder is industrial copper shavings, the surface layer of the particle is oxidized, the core is still metallic copper, and the oxidation rate is 70%. Firstly, each component was weighed according to the above percentage ratio, and dried in an electric heating constant temperature blast drying oven (T=80°C) for 6 hours. Then mix in a high-speed mixer for 1 minute to obtain thermite 2; fill the thermite 2 into a paper tube 1 with a diameter of 11 mm and a length of 150 mm, and install an ignitio...

Embodiment 2

[0030] A portable soldering pen, thermite is composed of exothermic agent, slagging agent and alloying agent. The components and proportions of the exothermic agent are: CuO powder: 68wt%, Al powder: 17 wt%; the proportions of the components of the slagging agent are: CaF 2 Powder: 5wt%, CaSO 4 Powder: 7wt%; the components and proportions of the alloying agent are: ferromanganese 1wt%, ferronickel 2wt%. The particle size of each powder is between 150 mesh and 200 mesh, among which CuO powder is industrial copper shavings, the surface layer of the particle is oxidized, the core is still metallic copper, and the oxidation rate is 75%. Firstly, each component was weighed according to the above percentage ratio, and dried in an electric heating constant temperature blast drying oven (T=80°C) for 7 hours. Then mix in a high-speed mixer for 1 minute to obtain thermite 2; fill the thermite 2 into a paper tube 1 with a diameter of 13 mm and a length of 170 mm, and install an ignitio...

Embodiment 3

[0033] A portable soldering pen, thermite is composed of exothermic agent, slagging agent and alloying agent. The components and proportions of the exothermic agent are: CuO powder: 70wt%, Al powder: 15wt%; the proportions of the components of the slagging agent are: CaF 2 Powder: 4wt%, CaSO 4 Powder: 6wt%; the components and proportions of the alloying agent are: ferromanganese 2wt%, ferronickel 3wt%. The particle size of each powder is between 150 mesh and 200 mesh, among which CuO powder is industrial copper scrap, the surface layer of the particle is oxidized, and the core is still metallic copper, and the oxidation rate is 80%. First, weigh each component according to the above percentage ratio, and dry it in an electric constant temperature blast drying oven (T=80°C) for 8 hours. Then mix in a high-speed mixer for 1 minute to obtain thermite 2; fill the thermite 2 into a paper tube 1 with a diameter of 14 mm and a length of 200 mm, and install an ignition section 4 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com