Oil-resistant liquid sealant and preparation method thereof

A sealant, liquid technology, used in chemical instruments and methods, adhesives, adhesive types, etc., can solve the problem of poor mechanical properties of chlorosulfonated polyethylene rubber, poor adhesion and aging resistance, fluorine rubber. Low solubility and other problems, to achieve the effects of superior medium resistance and mechanical properties, moderate adhesion, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

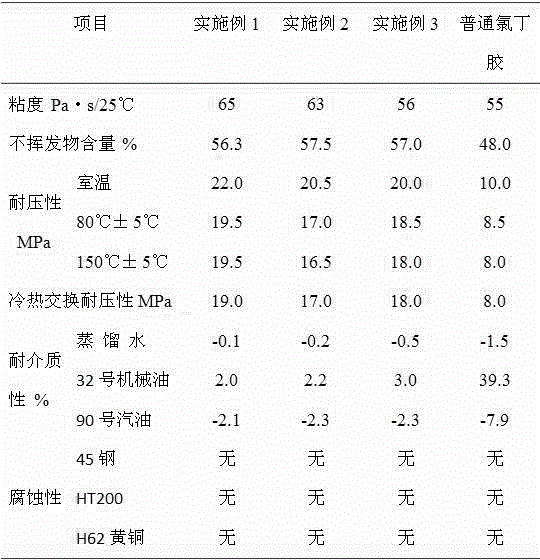

Examples

Embodiment 1

[0034] Oil-resistant liquid sealant, which includes the following components: nitrile rubber (42% acrylonitrile content), tackifying resin, reinforcing filler, titanium dioxide, anti-aging agent, solvent. Its weight percentage content is as follows: 18%, 3%, 32%, 2%, 0.5%, 44.5%.

[0035] The tackifying resin contains super tackifying resin and tert-butyl phenolic resin, and its weight ratio is: 1:2.

[0036] The reinforcing filler contains talcum powder, magnesium oxide, zinc oxide and fumed white carbon black, and its weight ratio is: 20:3:7:2.

[0037] The anti-aging agent contains anti-aging agent BLE and anti-aging agent KY-405, and their weight ratio is: 0.2:0.3.

[0038] The solvents are acetone, xylene, and N,N-dimethylformamide, and their weight ratios are: 3:7:1.

[0039] The preparation method of the above-mentioned oil-resistant liquid sealant comprises the following steps in turn:

[0040] a. First put the nitrile rubber into the rubber mixer to plasticize it i...

Embodiment 2

[0048] Oil-resistant liquid sealant, which includes the following components: nitrile rubber (acrylonitrile content 40%), tert-butyl phenolic resin, reinforcing filler, titanium dioxide, anti-aging agent BLE, solvent. Its weight percentage content is: 20%, 2.5%, 30%, 4%, 0.2%, 43.3%.

[0049] The reinforcing filler contains talc powder, activated magnesia and fumed white carbon black, the weight ratio of which is 25:2:3.

[0050] The solvent contains xylene and 1,4-dioxane in a weight ratio of 7:3.

[0051] The preparation method is the same as in Example 1. This method is used to prepare peelable oil-resistant liquid sealant.

Embodiment 3

[0053] Oil-resistant liquid sealant, which includes the following components: nitrile rubber (35% acrylonitrile content), tert-butyl phenolic resin, reinforcing filler, titanium dioxide, anti-aging agent BLE, solvent. Its weight percentage content is as follows: 22%, 2%, 30%, 2%, 0.2%, 43.8%.

[0054] The reinforcing filler contains talcum powder, magnesium oxide, zinc oxide and fumed white carbon black, and its weight ratio is: 18:3:7:2.

[0055] The solvent contains xylene and tetrahydrofuran, and its weight ratio is: 8:2.

[0056] The preparation method is the same as in Example 1. This method is used to prepare peelable oil-resistant liquid sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com