Technology and device for mixing raw material of perlite acoustic board

A technology of mixing equipment and sound-absorbing panels, applied in mixers, chemical instruments and methods, dissolution, etc., can solve the problem of inability to achieve quantitative framing of perlite powder, inability to ensure the quality of adhesives, and inability to control adhesives. flow and other issues, to achieve the effect of facilitating continuous operation, reducing manual participation and accurate mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

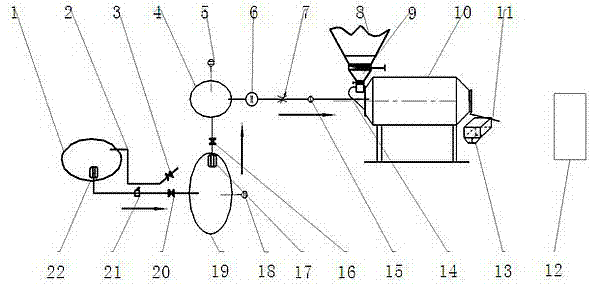

[0018] Perlite sound-absorbing board mixing process designed by the present invention (referred to as mixing process, see figure 1 ), the mixing process includes the following steps:

[0019] (1), preparation of water glass solution

[0020] Put the sodium silicate solid directly into the water glass tank 1, so that the sodium silicate and water fully react and liquefy into a water glass solution with a mass concentration of 1.3×10 3 kg / m 3 , use after the mixing temperature drops below 40C°;

[0021] (2), transport water glass solution

[0022] Use the liquefied screw pump 22 to transport the water glass solution from the pipeline to the batching tank 19, and the delivery pipeline is equipped with a batching electric valve 20 that is convenient for automatic control;

[0023] (3), preparation of adhesive

[0024] Add other materials required by the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com