Positive plate, preparation method thereof and lithium ion battery

A technology for lithium-ion batteries and positive plates, applied in the direction of positive electrodes, electrode manufacturing, secondary batteries, etc., can solve the problems of high stirring requirements, high production costs, and low production efficiency, and achieve simplified stirring processes, reduced dosage, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

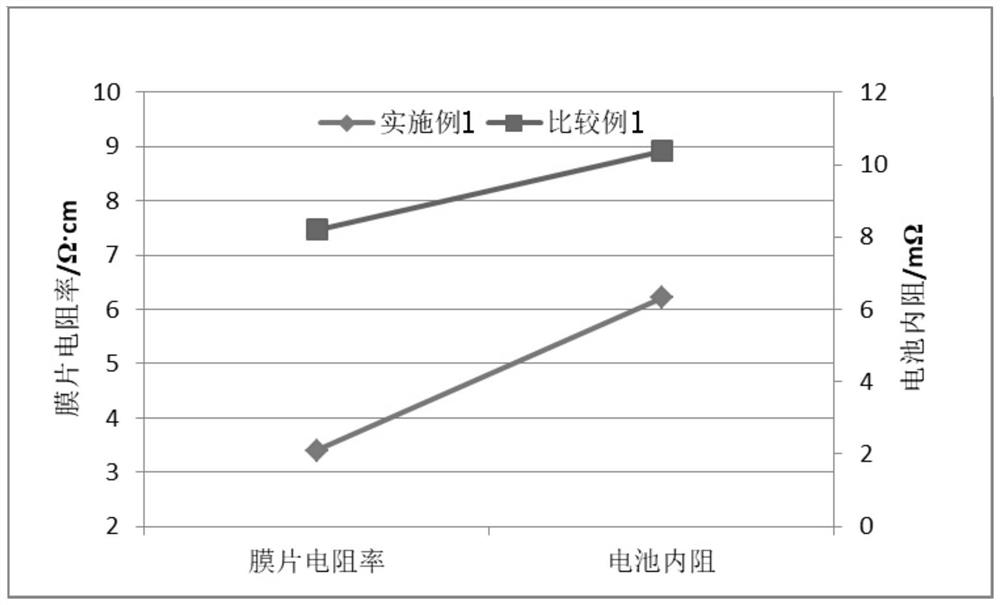

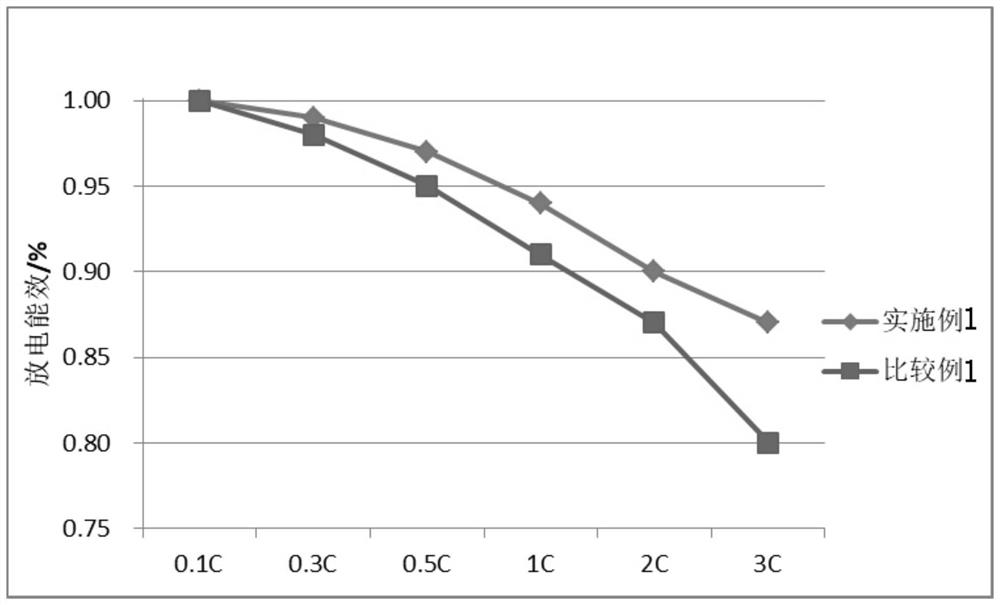

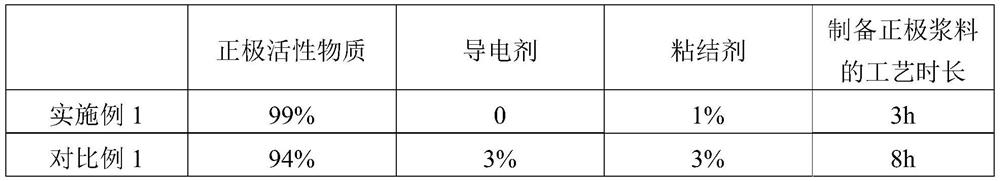

Embodiment 1

[0064] In this embodiment, the positive electrode sheet is prepared according to the following method:

[0065] (1) Conducting agent composite positive electrode material, binder PVDF and solvent NMP (without adding conductive agent, taking the total mass of conductive agent composite positive electrode material and binder as 100%, the mass fraction of binder is 1% , the mass fraction of the conductive agent composite positive electrode material is 99%) and stirred and mixed at 45°C for 3h to obtain a positive electrode slurry with a solid content of 60% and a viscosity of 15000mPa·s;

[0066] (2) Coating the positive electrode slurry described in step (1) on the surface of the current collector aluminum foil, after drying, cold pressing at a temperature of 25°C and a pressure of 30t to obtain the positive electrode sheet;

[0067] The pressing method of the cold pressing treatment is rolling, and the size of the roll gap is 120 μm.

[0068] In this embodiment, the conductive...

Embodiment 2

[0075] In this embodiment, the positive electrode sheet is prepared according to the following method:

[0076] (1) Composite positive electrode material with conductive agent, binder PVDF and solvent NMP (do not add conductive agent, take the total mass of conductive agent composite positive electrode material and binder as 100%, and the mass fraction of binder is 0.5% , the mass fraction of the conductive agent composite positive electrode material is 99.5%) and stirred and mixed for 5 hours at 25°C to obtain a positive electrode slurry with a solid content of 50% and a viscosity of 8000mPa·s;

[0077] (2) coating the positive electrode slurry described in step (1) on the surface of the current collector aluminum foil, after drying, cold pressing at a temperature of 15° C. and a pressure of 10 tons to obtain the positive electrode sheet;

[0078] The pressing method of the cold pressing treatment is rolling, and the size of the roll gap is 50 μm.

[0079] The conductive age...

Embodiment 3

[0081] In this embodiment, the positive electrode sheet is prepared according to the following method:

[0082] (1) Composite positive electrode material with conductive agent, binder PVDF and solvent NMP (do not add conductive agent, take the total mass of conductive agent composite positive electrode material and binder as 100%, and the mass fraction of binder is 5% , the mass fraction of the conductive agent composite positive electrode material is 95%) and stirred and mixed at 60°C for 2h to obtain a positive electrode slurry with a solid content of 70% and a viscosity of 25000mPa·s;

[0083] (2) Coating the positive electrode slurry described in step (1) on the surface of the current collector aluminum foil, after drying, cold pressing at a temperature of 35° C. and a pressure of 50 tons to obtain the positive electrode sheet;

[0084] The pressing method of the cold pressing treatment is rolling, and the size of the roll gap is 200 μm.

[0085] The conductive agent comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com