Molybdenum-lanthanum alloy sintered blank preparation method and product thereof

A molybdenum-lanthanum alloy and billet technology, which is applied in the field of preparation of molybdenum-lanthanum alloy sintered blanks, can solve problems such as yield strength and tensile strength, etc., which are not very ideal, and achieve improved tensile strength, simple mixing process, and reduced pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

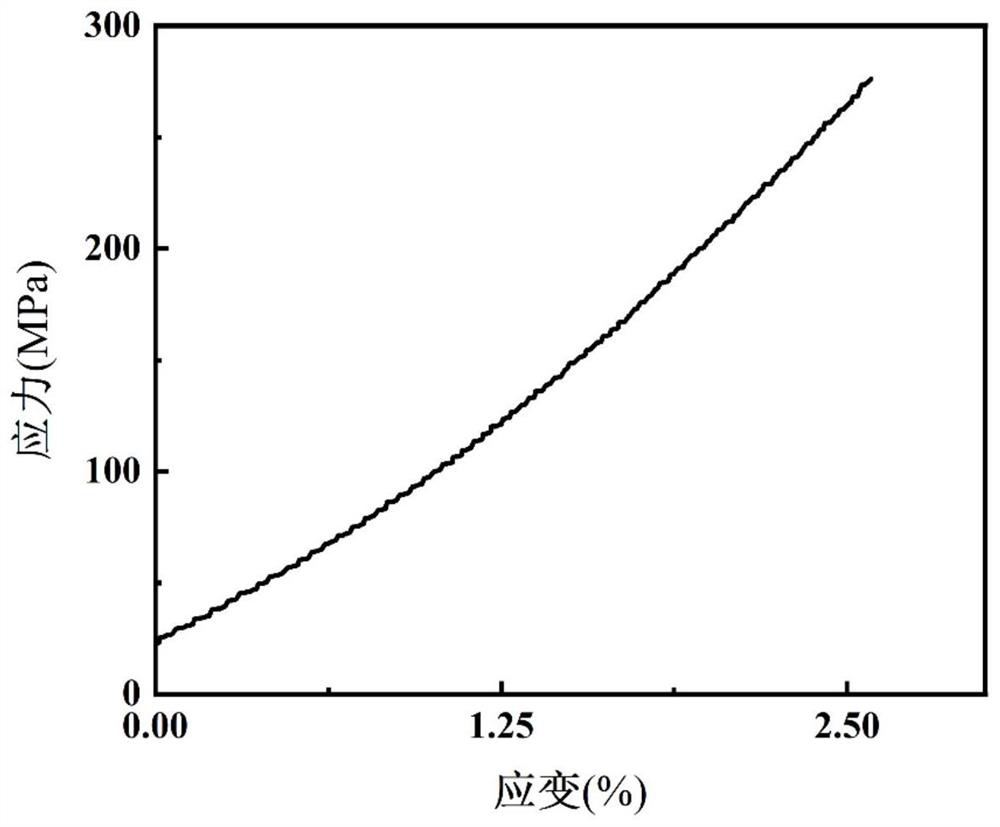

Embodiment 1

[0025] Weigh 59.4g of two-stage reduced molybdenum powder, weigh LaB 6 Put 0.6g of powder into the mixing bottle together, the speed of the mixer is 120r / min; the ratio of ball to material is 4:1; the total time of mixing is 12h, there is no protective gas, and the grinding balls are zirconia balls.

[0026] Take out the molybdenum powder powder after mixing the materials, put it into the prepared mold, and carry out cold isostatic pressing with a pressing pressure of 150MPa, and the holding time is 120s to obtain a compact;

[0027] Put the compact into the hydrogen sintering furnace, close the hydrogen sintering furnace before sintering and evacuate to a vacuum degree of less than 1.0×10 -2 Pa, wash the gas repeatedly before sintering to ensure the hydrogen sintering atmosphere, check the purity and ignite, then set the sintering program, heating and cooling speed: 0~1000℃, 10℃ / min; 1000~1500℃, 5℃ / min; 1500~ 1600°C, 2°C / min, when cooling down, when the temperature drops to ...

Embodiment 2

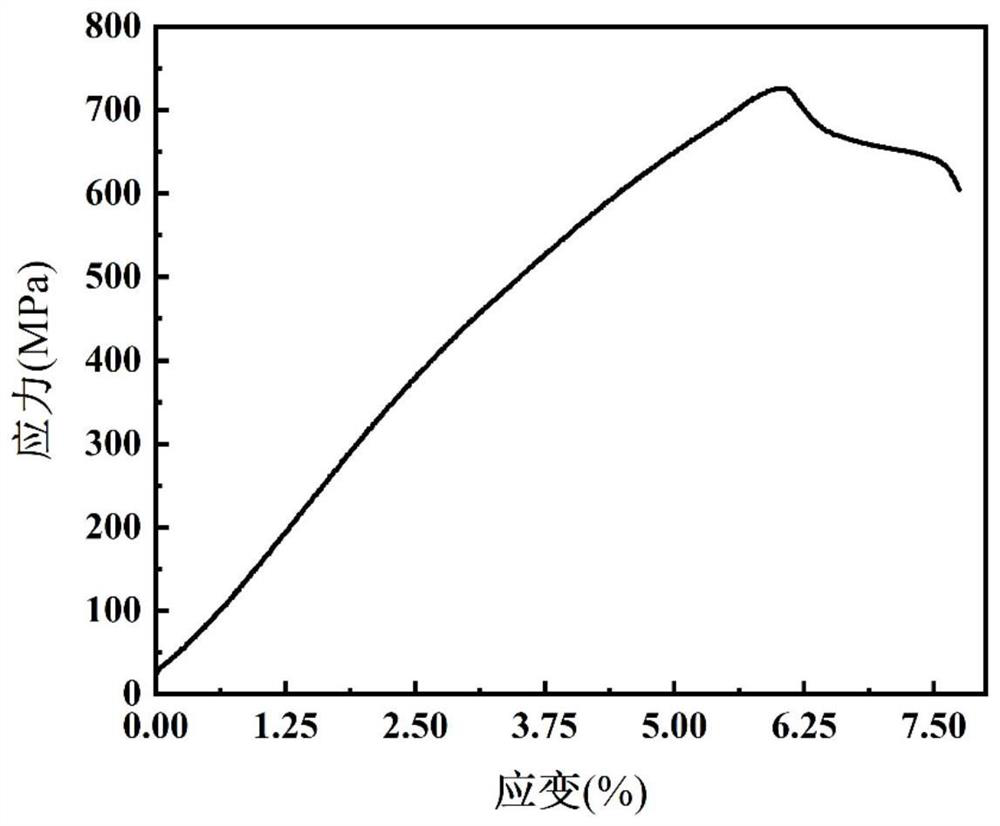

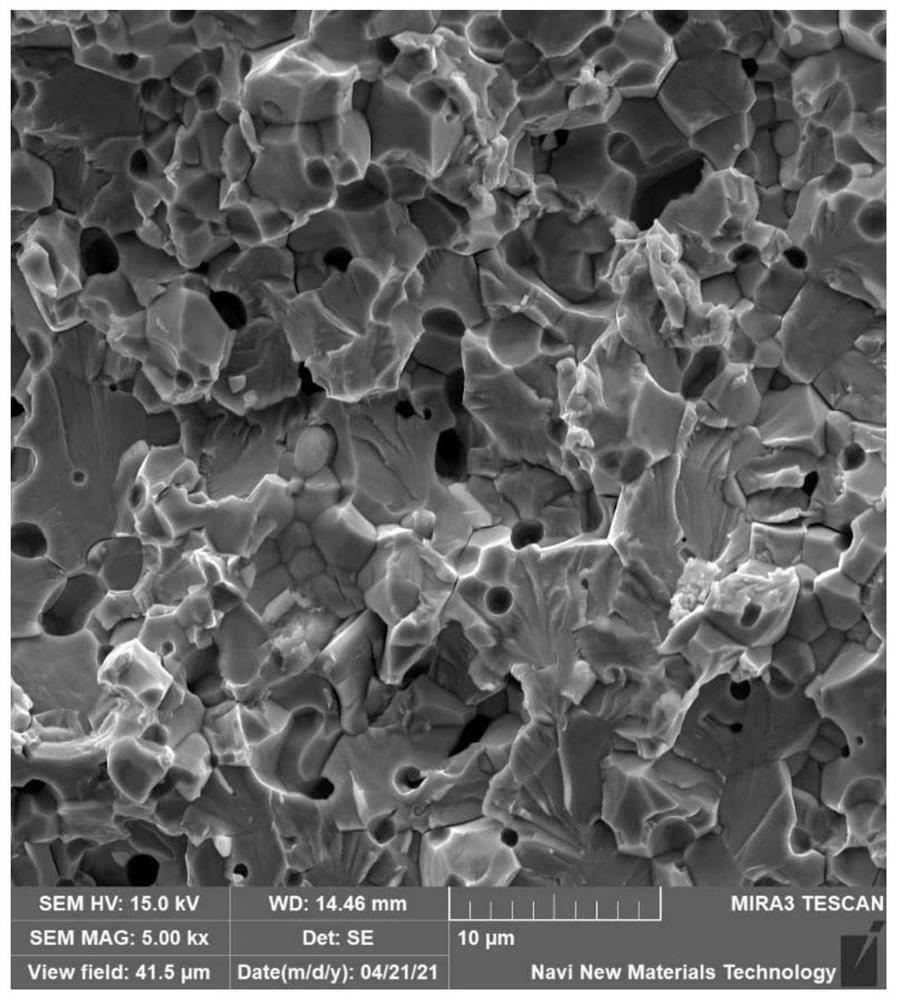

[0029] Process parameter is basically consistent with embodiment 1 in all preparation processes, only the LaB that mixes 6 The content becomes 1.5%. It can be seen from the data in Table 1 that at this sintering temperature, the density of the sample reaches 93.1%, the hardness is 224HV, and the tensile strength is 716Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com