High-strength rubber composite material with excellent processability and preparation method thereof

A technology of rubber materials and composite materials, applied in the field of composite materials, can solve the problems of reduced mechanical properties, reduced dynamic properties and fatigue properties, limited application fields and consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

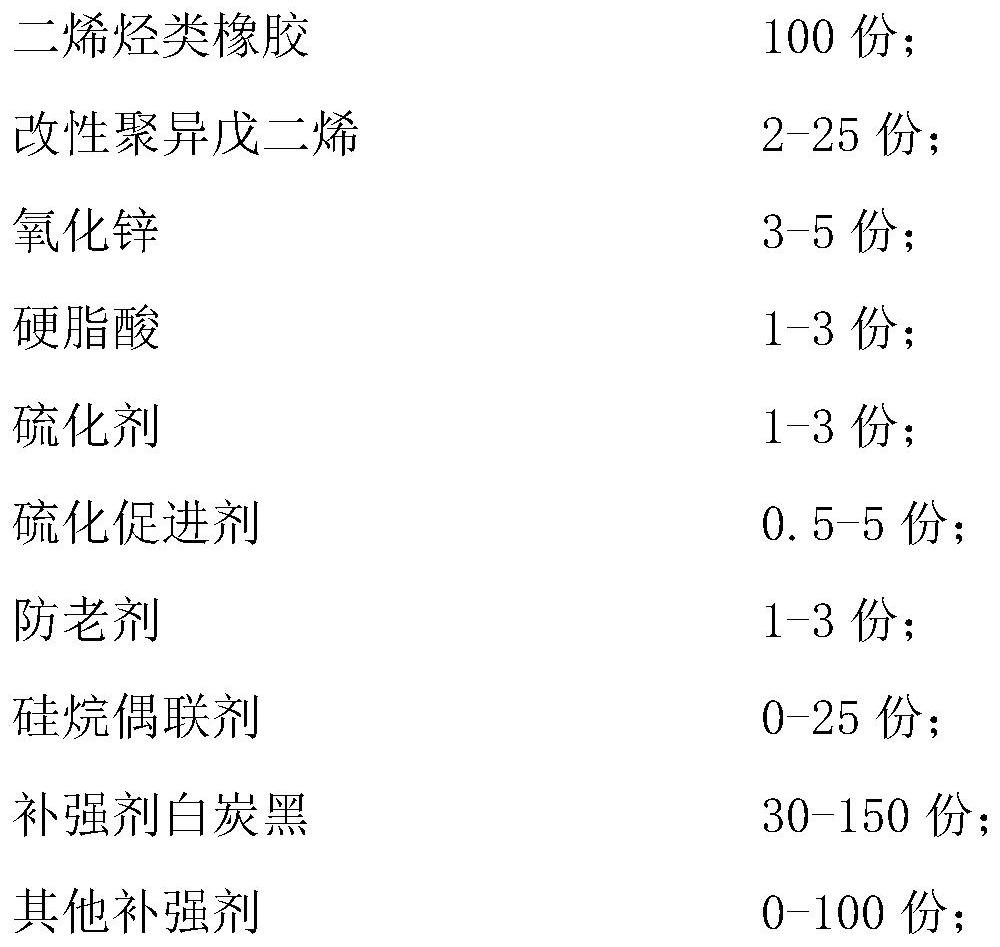

[0040] Example 1 and Comparative Example 1-3 were mixed by method 1, and Example 2-3 was mixed by method 2 to prepare the mixed rubber.

[0041] The formula system of each embodiment and comparative example, by weight, is as shown in the following table:

[0042]

[0043]

[0044] S1: Replace the air in the clean polymerization bottle with high-purity nitrogen under the condition of high-temperature baking, and replace it at least three times. After it cools down, introduce 148g of refined anhydrous and oxygen-free hexane under the protection of nitrogen, and then Add 41 g of polymer grade isoprene monomer and mix well.

[0045] S2: Add a total of 4.2ml of n-BuLi for polymerization and mistericide into the polymerization bottle with a syringe, and polymerize at 50°C for 4 hours while stirring.

[0046] S3: transfer out 95.32 g of the polymerization liquid after S2 polymerization, stop coagulation with methanol, and dry to constant weight to obtain low molecular weight p...

Embodiment 2

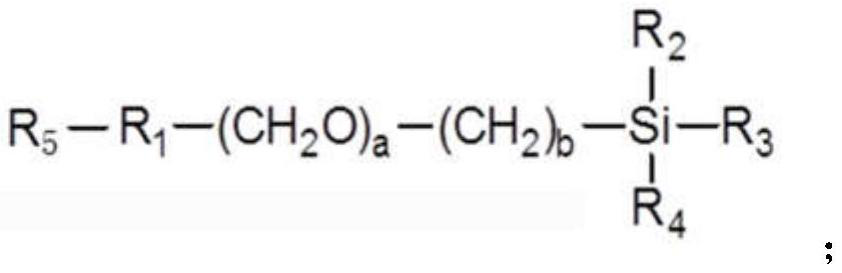

[0050] In Example 2 and Example 3, the modified polyisoprene is prepared by anionic polymerization, and the structure regulator tetrahydrofuran is added to the polymerization solvent, and the preparation process is the same as that of Example 1. The specific input amount of materials is: 22.4g of polymerization-grade isoprene monomer, 67.2g of hexane, 5.8g of tetrahydrofuran, 2.6ml of 0.99mol / L n-BuLi initiator, and 0.86ml of silane coupling agent KH561 was added in the later stage of polymerization. The molecular weight of the obtained modified polyisoprene is 1.36×10 4 g / mol, molecular weight distribution index is 1.52, microstructure content: 3,4-structure content accounts for 68.65%, 1,2-structure content accounts for 12.10%, 1,4-structure content accounts for 19.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com