Carbon nanotube antistatic material, slurry, film and preparation method of film

A carbon nanotube and antistatic technology, which is applied in the field of antistatic film, can solve the problems of poor conductivity and poor dispersion effect, and achieve the advantages of avoiding the influence of adhesion and surface resistivity, excellent heat dissipation performance and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The embodiment of the present invention provides a method for preparing a carbon nanotube antistatic film, comprising the following steps:

[0046] S10. Obtain carbon nanotubes with a tube length of 100-500 microns, a resin, and a solvent, and uniformly mix the carbon nanotubes, the resin, and the solvent to obtain a carbon nanotube resin mixture;

[0047] S20. Grinding the carbon nanotube resin mixture to obtain a grinding product;

[0048] S30. Obtain a curing agent, add the curing agent to the grinding product, and prepare a carbon nanotube antistatic slurry with a solid content of 70-85%;

[0049] S40. Making the carbon nanotube antistatic slurry into a carbon nanotube antistatic film.

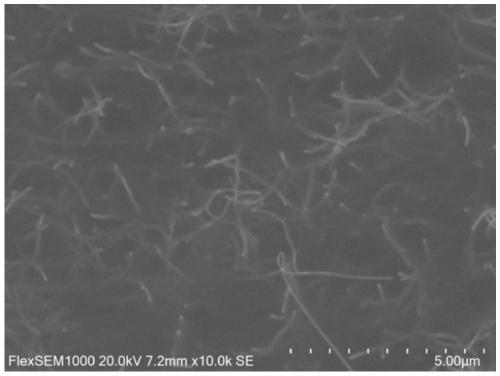

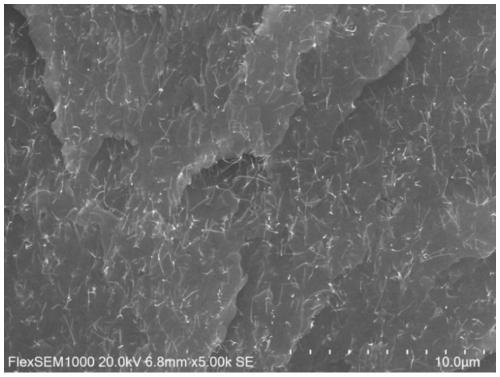

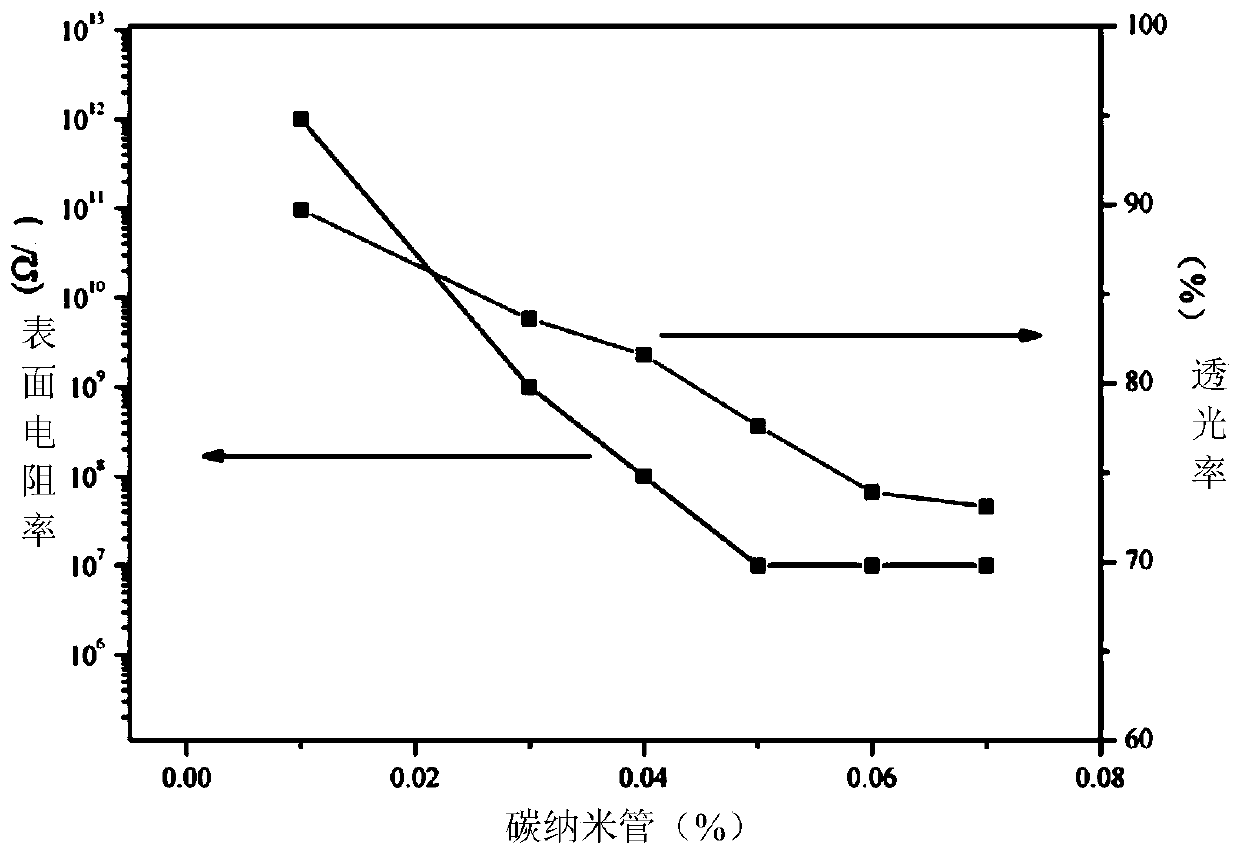

[0050] The preparation method of the carbon nanotube antistatic film provided by the embodiment of the present invention uses carbon nanotubes with a tube length of 100-500 microns, resin, curing agent and solution as raw materials, wherein the long-chain carbon nanotubes with a tu...

Embodiment 1

[0085] The embodiment of the present invention provides an antistatic film with a carbon nanotube content of 0.01%, which is prepared by the following steps:

[0086] S10. Take 0.015g (0.01%) of 200 μm long multi-walled carbon nanotubes by weighing, join in the epoxy resin of 100g, add 12.5g of acetone solvent, put into the beaker, adopt magnetic stirring evenly, the stirring time here is 30min Left and right, the naked eye looks uniform, and the carbon nanotube resin mixture is obtained.

[0087] S20. Put the uniformly mixed carbon nanotube resin mixture into a three-roll mill, first adjust the gap between the three rolls to 30 μm and run for 5 minutes; then, adjust the gap to 0 μm and run 30 times; finally, adjust the gap to 5 μm and run for 10 minutes, A ground product is obtained.

[0088] S30. Add 10 g of triethylenetetramine curing agent and 27.5 g of acetone solvent to the ground product. Prepare a carbon nanotube / resin mixture with a solid content of 80%, and defoam ...

Embodiment 2

[0091] The embodiment of the present invention provides an antistatic film with a carbon nanotube content of 0.03%, which is prepared by the following steps:

[0092] S10. Take 0.045g (0.03%) of 200 μm long multi-walled carbon nanotubes by weighing, join in the epoxy resin of 100g, add 12.5g of acetone solvent, put into the beaker, adopt magnetic stirring evenly, the stirring time here is 30min Left and right, the naked eye looks uniform, and the carbon nanotube resin mixture is obtained.

[0093] S20. Put the uniformly mixed carbon nanotube resin mixture into a three-roll mill, first adjust the gap between the three rolls to 30 μm and run for 5 minutes; then, adjust the gap to 0 μm and run 30 times; finally, adjust the gap to 5 μm and run for 10 minutes, A ground product is obtained.

[0094] S30. Add 10 g of triethylenetetramine curing agent and 27.5 g of acetone solvent to the ground product. Prepare a carbon nanotube / resin mixture with a solid content of 80%, and defoam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com