MQ silicon resin coated phase change micro-capsule as well as preparation method and application thereof

A technology of MQ silicone resin and phase-change microcapsules, which is applied in the preparation of microcapsule preparations and microspheres, can solve the problems of easy leakage of phase-change materials, and achieve the effects of improving anti-leakage performance, alleviating leakage, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

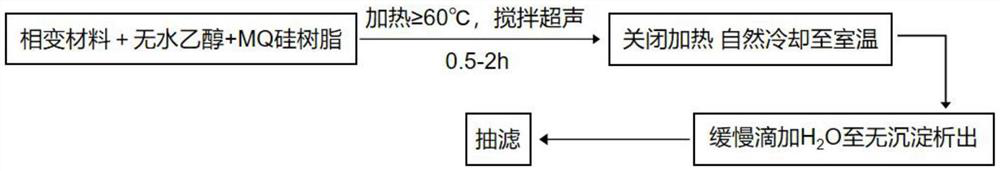

[0032] This embodiment 1 provides the first preparation method of MQ silicone resin-coated phase-change microcapsules, including the following steps.

[0033] Step 1, preparing a solution of MQ silicone resin-coated phase-change microcapsules.

[0034] Step 101, first weigh 200g of absolute ethanol, 100g of paraffin and 100g of methyl MQ silicone resin and place them in a 1000ml three-necked flask, then install a reflux condenser, a stirring device and a glass stopper on the three flasks, and finally put the 1000ml The three-necked flask is placed in a water bath or an oil bath;

[0035] Step 102, control the heating temperature of the water bath or oil bath to be above 60° C., and control the stirring device to heat and stir at a stirring speed of 500 r / min and condense and reflux for 2 hours to obtain the MQ silicone resin-coated phase-change microcapsule solution.

[0036] Step 2, preparing MQ silicone resin-coated phase-change microcapsule suspension.

[0037] Step 201, ...

Embodiment 2

[0043] This embodiment 2 provides the first preparation method of MQ silicone resin-coated phase-change microcapsules, including the following steps.

[0044] Step 1, the method for preparing the MQ silicone resin-coated phase-change microcapsule solution.

[0045] Step 101, first weigh 200g of absolute ethanol, 100g of organic silicon wax and 100g of methyl MQ silicone resin and place them in a 1000ml three-necked flask, then respectively install a reflux condenser, a stirring device and a glass stopper at the mouths of the three flasks, and finally Place the 1000ml three-neck flask in a water bath or oil bath;

[0046] Step 102, control the heating temperature of the water bath or oil bath to be above 60° C., and control the stirring device to heat and stir at a stirring speed of 500 r / min and condense and reflux for 2 hours to obtain the MQ silicone resin-coated phase-change microcapsule solution.

[0047] Step 2, preparing MQ silicone resin-coated phase-change microcapsul...

Embodiment 3

[0053] This embodiment 3 provides the first preparation method of MQ silicone resin-coated phase-change microcapsules, including the following steps.

[0054] Step 1, the method for preparing the MQ silicone resin-coated phase-change microcapsule solution.

[0055] Step 101, first weigh 200g of absolute ethanol, 100g of paraffin and 100g of vinyl MQ silicone resin and place them in a 1000ml three-necked flask, then respectively install a reflux condenser, a stirring device and a glass stopper at the mouths of the three flasks, and finally place the 1000ml The three-necked flask is placed in a water bath or an oil bath;

[0056] Step 102, control the heating temperature of the water bath or oil bath to be above 60° C., and control the stirring device to heat and stir at a stirring speed of 500 / min, and condense and reflux for 2 hours to obtain the MQ silicone resin-coated phase-change microcapsule solution.

[0057] Step 2, preparing MQ silicone resin-coated phase-change micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com