Vertical boat and vertical heat processing apparatus for semiconductor process

A semiconductor, vertical technology, applied in semiconductor/solid-state device manufacturing, lighting and heating equipment, furnace types, etc., can solve problems such as cracks and wafer scars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

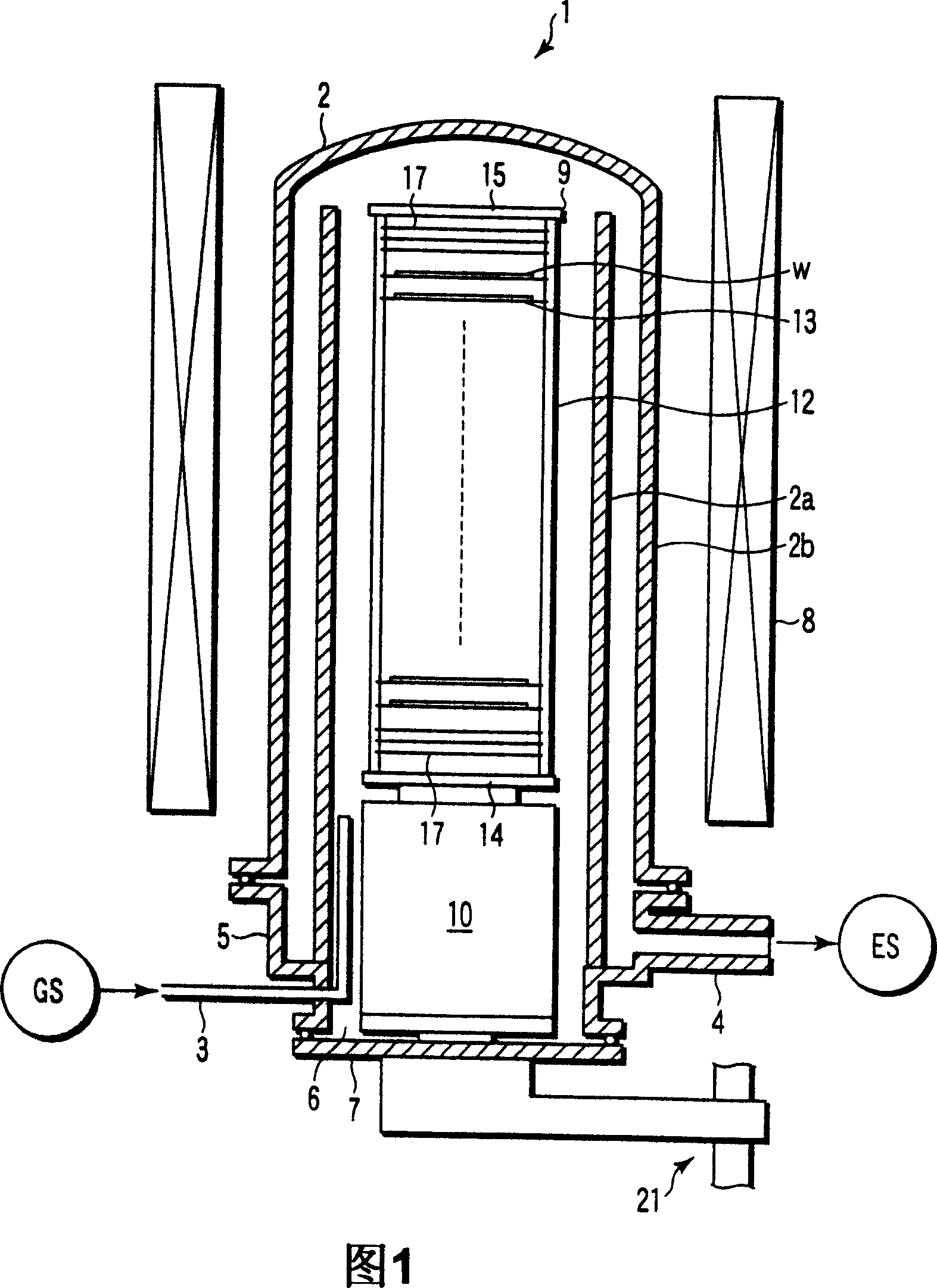

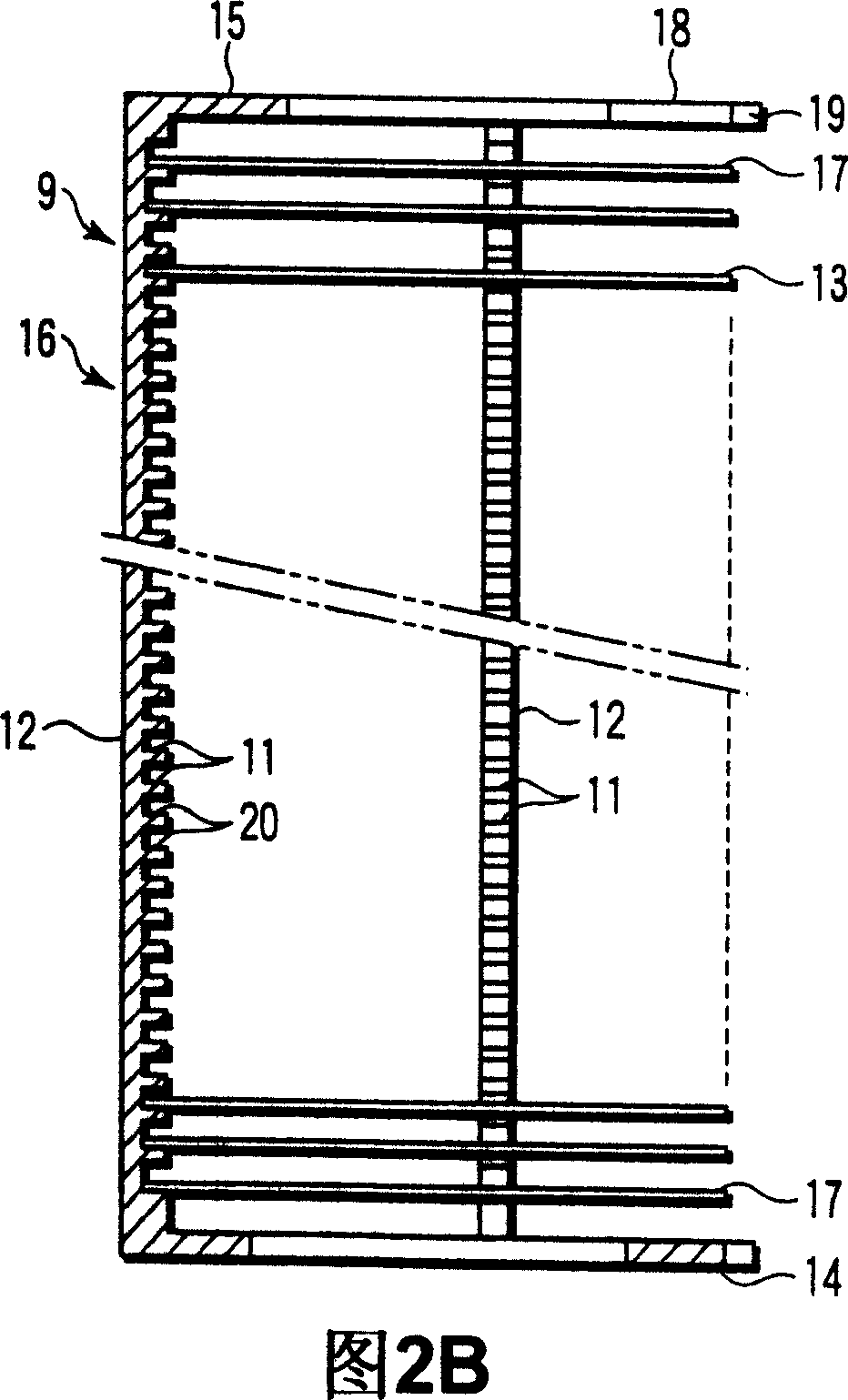

[0042] The inventors of the present invention have studied problems related to vertical boats for wafer heat treatment that occur in vertical heat treatment apparatuses during the development of the present invention. As a result, the present inventors have made the findings described below.

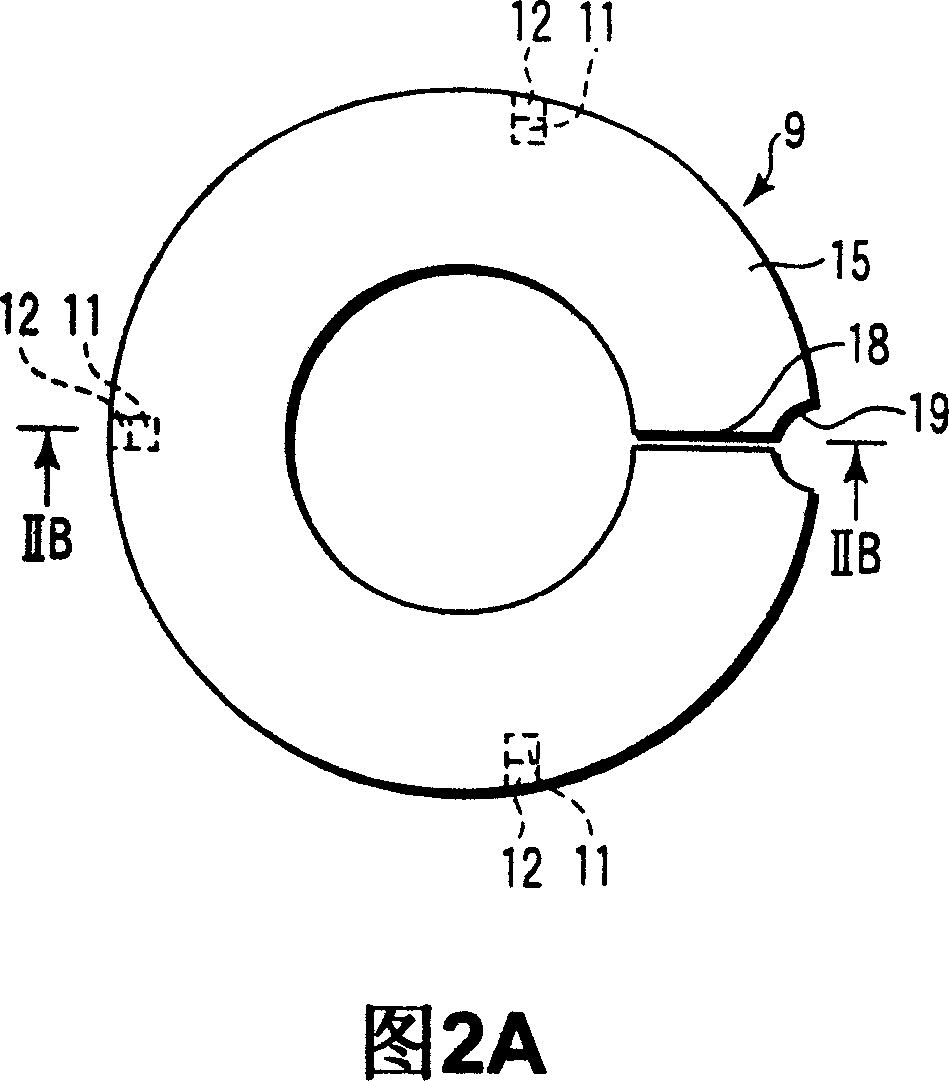

[0043] FIG. 8A is a cross-sectional view explaining a problem caused by self-weight stress of a wafer when a vertical wafer boat is used. FIG. 8B is a cross-sectional view explaining a problem caused by thermal expansion of a wafer when a vertical wafer boat is used. In this vertical boat, the upper surface 13 a of the support plate 13 is formed in a horizontal state. If the wafer W is placed on the support plate 13, as shown in FIG. 8A, the central part of the wafer W will be bent downward due to the stress of its own weight. As a result, stress concentration occurs at the portion of the wafer W corresponding to the inner peripheral portion of the support plate 13 (indicated by a x ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com