Method for eliminating color differences of machined surface of electroslag martensite circle forging machine

A martensite and machining technology, which is applied in the field of eliminating the surface color difference of electroslag martensitic round forging machining, can solve the problems of affecting product image, affecting contract fulfillment on time, uneven surface hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

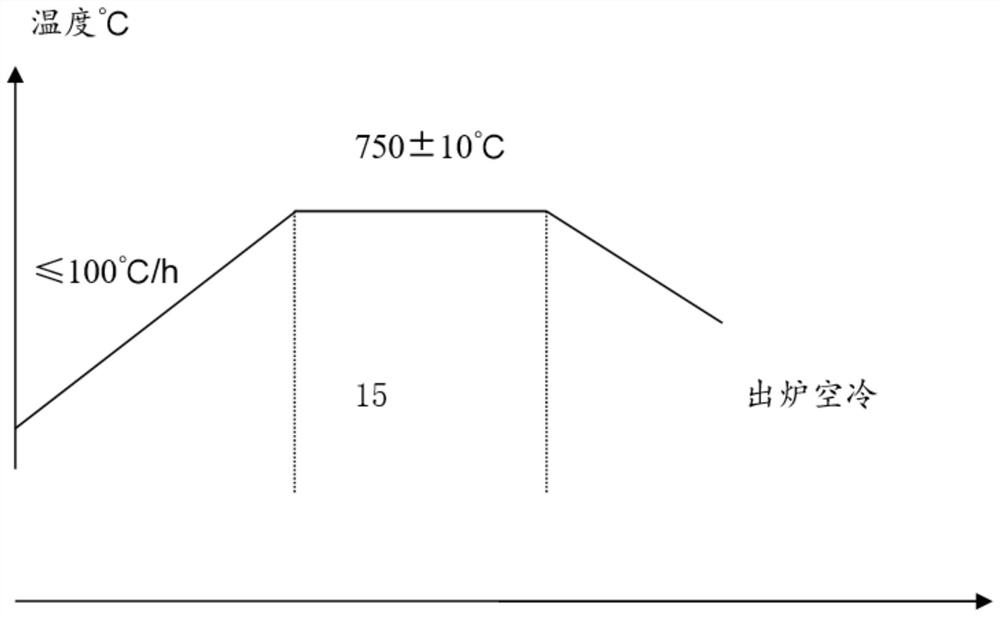

[0039] This method is implemented in the profile factory diameter forging machine forging electroslag 2Cr13 forging circle. The raw material of the electrode blank is ¢550mm, the electroslag ingot shape is ¢710mm, the finished product specification is ¢330, and the forging circle is optimized and improved by two annealing processes after forging;

[0040] The two-time annealing process specifically includes:

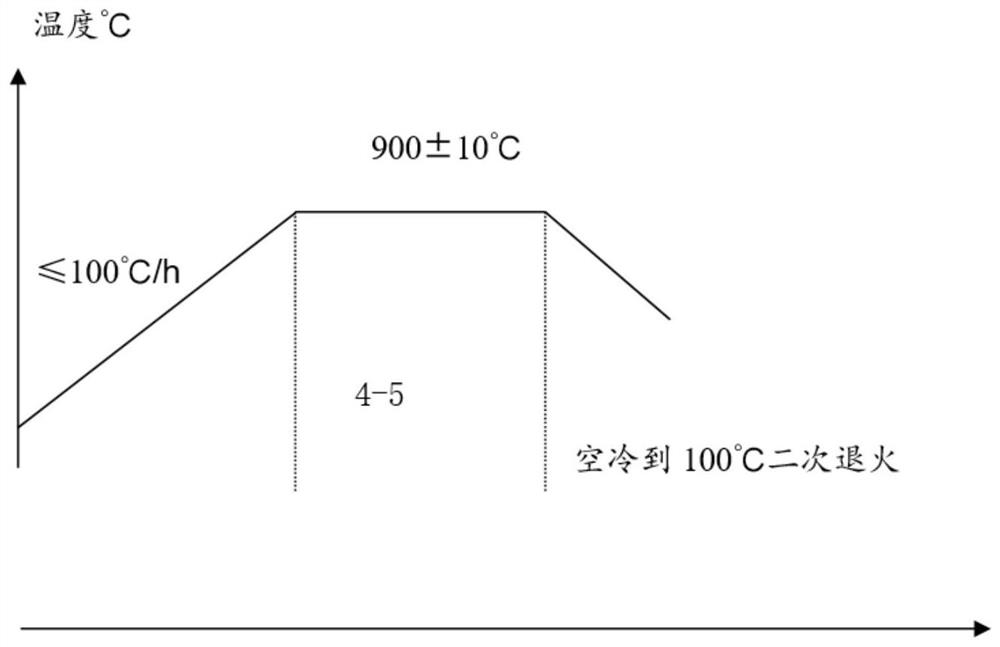

[0041] 1) First annealing:

[0042] Annealing at 880-920°C for 4-5 hours, and air cooling to below 100°C after taking out the furnace, can transform the residual austenite in the forged 2Cr13 forged circle into martensite;

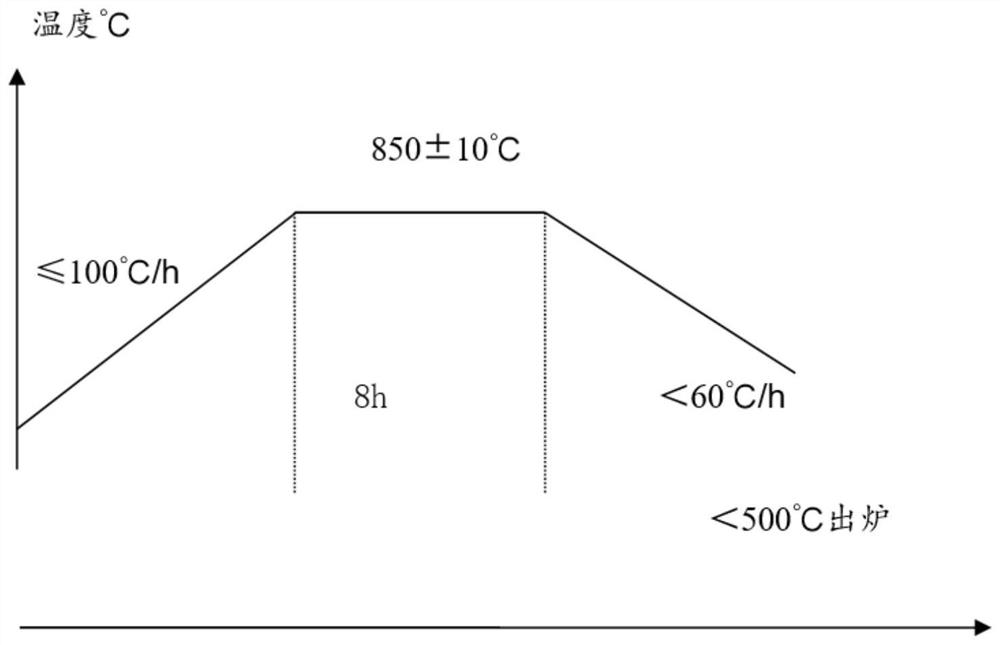

[0043] 2) Second annealing:

[0044] After the first annealing, the 2Cr13 forged circle is annealed at 750±10°C for 15 hours, and then air-cooled after the first annealing, the martensite obtained by the first annealing can be transformed into tempered martensite.

[0045] The surface and structure comparison of the forging machine before and after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com