Roller production method and roller produced by using method

A production method and roll technology, applied in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problem of segregation of carbides in composite joints, shrinkage and porosity of bushings, and uneven structure and composition. and other problems, to achieve the effect of tight bonding, reduced hardness, and no segregation of the organization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a roll production method, comprising:

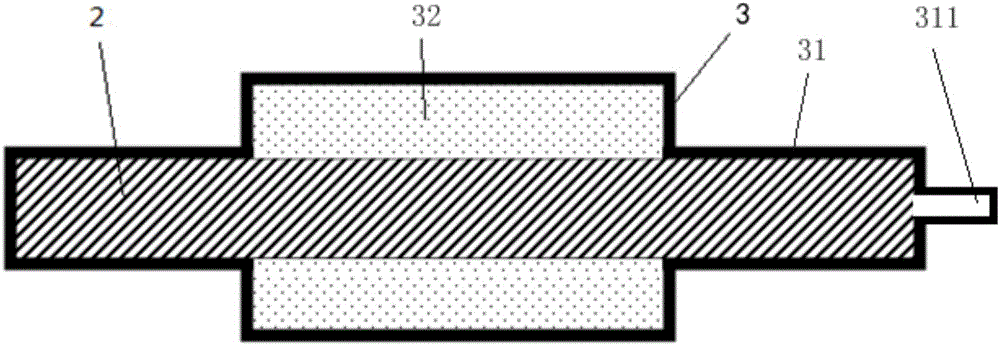

[0037] S1: Set a sheath 3 with an air port 311 outside the mandrel 2, and put alloy powder into the sheath 3 when setting, the sheath 3, such as figure 1 As shown, there are end portions 31 matching the diameter of the mandrel 2 at both ends in the axial direction, and an intermediate portion 32 for accommodating alloy powder is provided between the two end portions 31, and the intermediate portion 32 is connected to the An accommodating space for alloy powder is formed between the mandrels 2, and an air port 311 is formed on one of the ends 31. The alloy powder is prepared by an argon atomization method. The composition of the alloy powder is shown in Table 1. After the alloy powder is added to the sheath 3, it is filled in the sheath by vibration. The material of the sheath 3 is stainless steel, and the material of the mandrel 2 is low-cost ductile iron;

[0038] S2: Degas the alloy powder in the sheath...

Embodiment 2

[0043] This embodiment provides a roll production method. The difference from Embodiment 1 is that the composition of the alloy powder is different. The composition of the alloy powder is shown in Table 1, and the heat treatment process in the S5 step is different. In the S5 step, the annealing treatment is, The annealing temperature is 880°C, and the annealing holding time is 3 hours. When the temperature is lowered, the temperature is higher than 700°C, and the cooling rate is 10°C / h. After the temperature is lower than 700°C, it is cooled with the furnace. Quenching and tempering treatment is as follows: preheating temperature is 880°C, quenching temperature is 1100°C, high temperature tempering is carried out twice after quenching, and tempering temperature is 540°C.

Embodiment 3

[0045] This embodiment provides a roll production method. The difference from Embodiment 1 is that the composition of the alloy powder is different. The composition of the alloy powder is shown in Table 1, and the heat treatment process in the S5 step is different. In the S5 step, the annealing treatment is, The annealing temperature is 900°C, and the annealing holding time is 4 hours. When the temperature is lowered, the temperature is higher than 700°C, and the cooling rate is 11°C / h. After the temperature is lower than 700°C, it is cooled with the furnace. Quenching and tempering treatment is as follows: preheating temperature 900°C, quenching temperature 1200°C, high temperature tempering three times after quenching, tempering temperature 500°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com