Method for increasing surface hardness of 18Ni300 die steel for metal 3D printing

A 3D printing and surface hardness technology, applied in the field of 3D printing, can solve the problems of uneven surface hardness, easy cracking, poor corrosion resistance, etc., to achieve uniform surface hardness, reduce maintenance costs, and uniform internal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

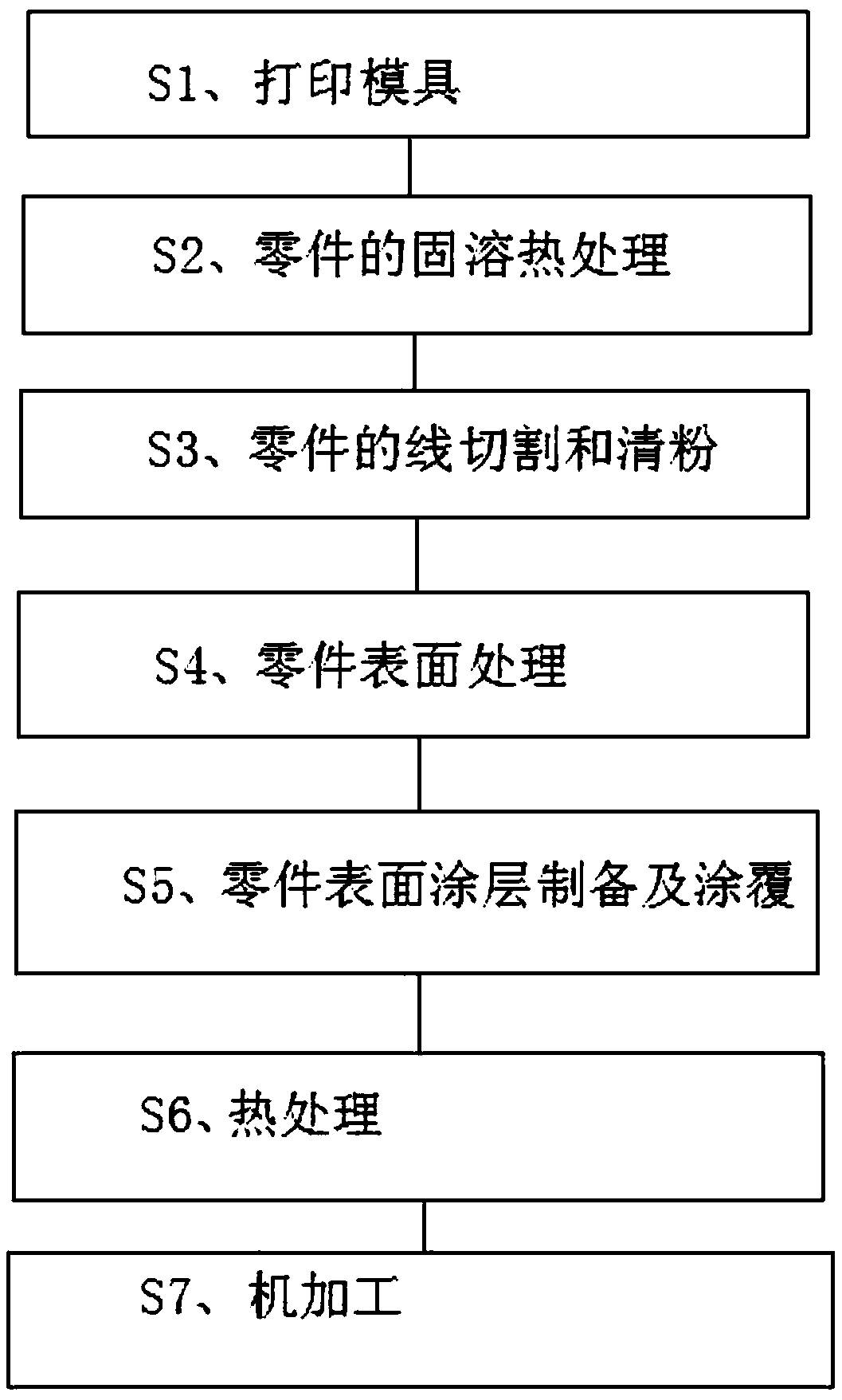

Method used

Image

Examples

specific example

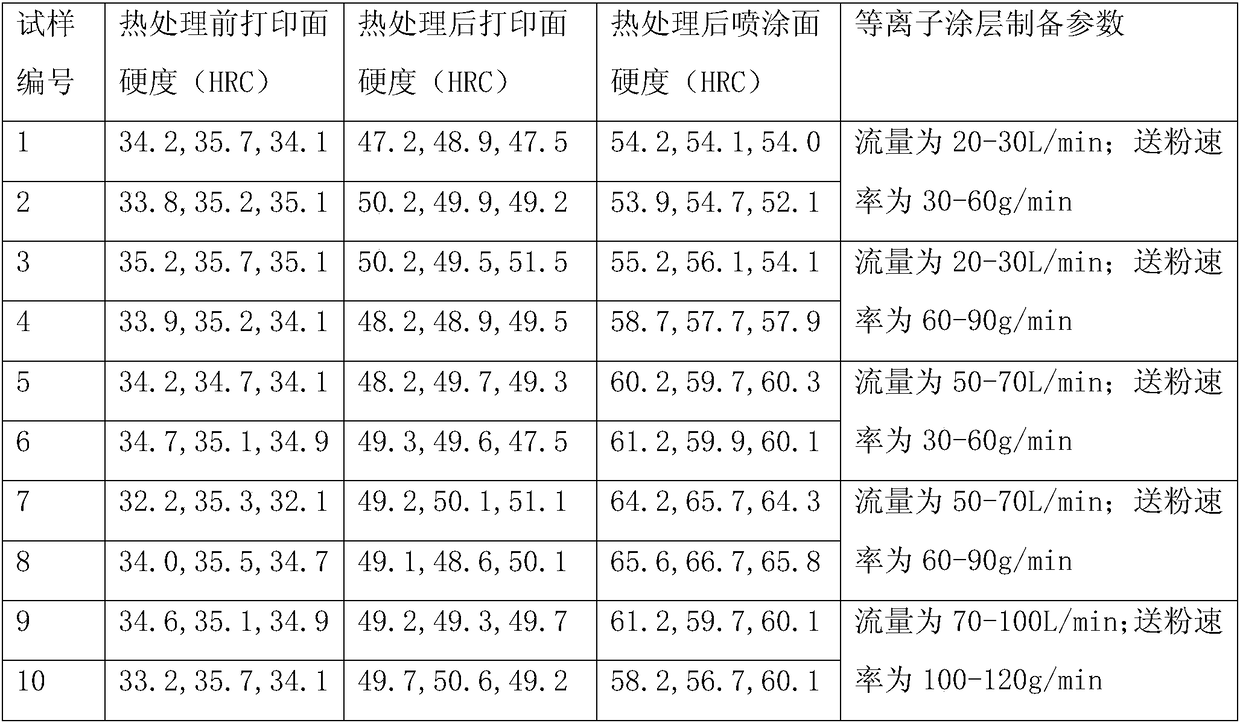

[0051] Print 10 pieces of 30×30×10mm in the same batch 3 The 18Ni300 mold steel sample blocks were used for coating preparation experiments with different plasma spraying process parameters. After heat treatment, hardness tests were carried out. Each group of 2 samples was used for coating preparation experiments with the same plasma spraying process parameters. In the actual experiment, two groups were taken The average value of is taken as the experimental result under this parameter. Experiments have proved that the pressure of argon gas is 0.3-0.6MPa, the flow rate is 50-70L / min, which can prevent ablation and oxidation of the coating material; when the powder feeding rate is 60-90g / min, and the coating thickness is 0.5-0.9mm, it can significantly Improve the surface hardness of the mold.

[0052] The test results are shown in Table 1 below.

[0053] Table 1

[0054]

specific Embodiment

[0055] The powder is dried at 80°C for 3 hours; the preheating temperature of the parts is 120-150°C;

[0056]During the preparation process, argon protection is used, the argon pressure is 0.3-0.6MPa, and the flow rate is 50-70L / min; to prevent ablation and oxidation of the coating material; the powder feeding rate is 60-90g / min, and the distance between the spray gun and the workpiece is 150- 180mm; coating thickness is 0.5~0.9mm.

[0057] Heat treatment: Put the parts in a muffle furnace for stress relief heat treatment. The system is: 300°C / h with the furnace heating up to 500°C, holding for 1h, cooling with the furnace to 300°C and then taking it out for air cooling.

[0058] Machining: Remove 0.3-0.5mm of the coating on the surface of the part as machining allowance.

[0059] Compared with the prior art, the present invention has the following beneficial effects:

[0060] ① The present invention can make the surface hardness of the mold reach 56-65HRC, and the NiCrBSi ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com