Forged steel cold rolling roller cryogenic treatment method and novel nozzle adopted by same

A technology of cryogenic treatment and cold rolling, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of high cooling intensity, poor hardness uniformity of finished products, low temperature of forged steel cold rolling rolls, etc., to achieve reduced nozzle clogging, and finished products Increased hardness uniformity and uniform hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

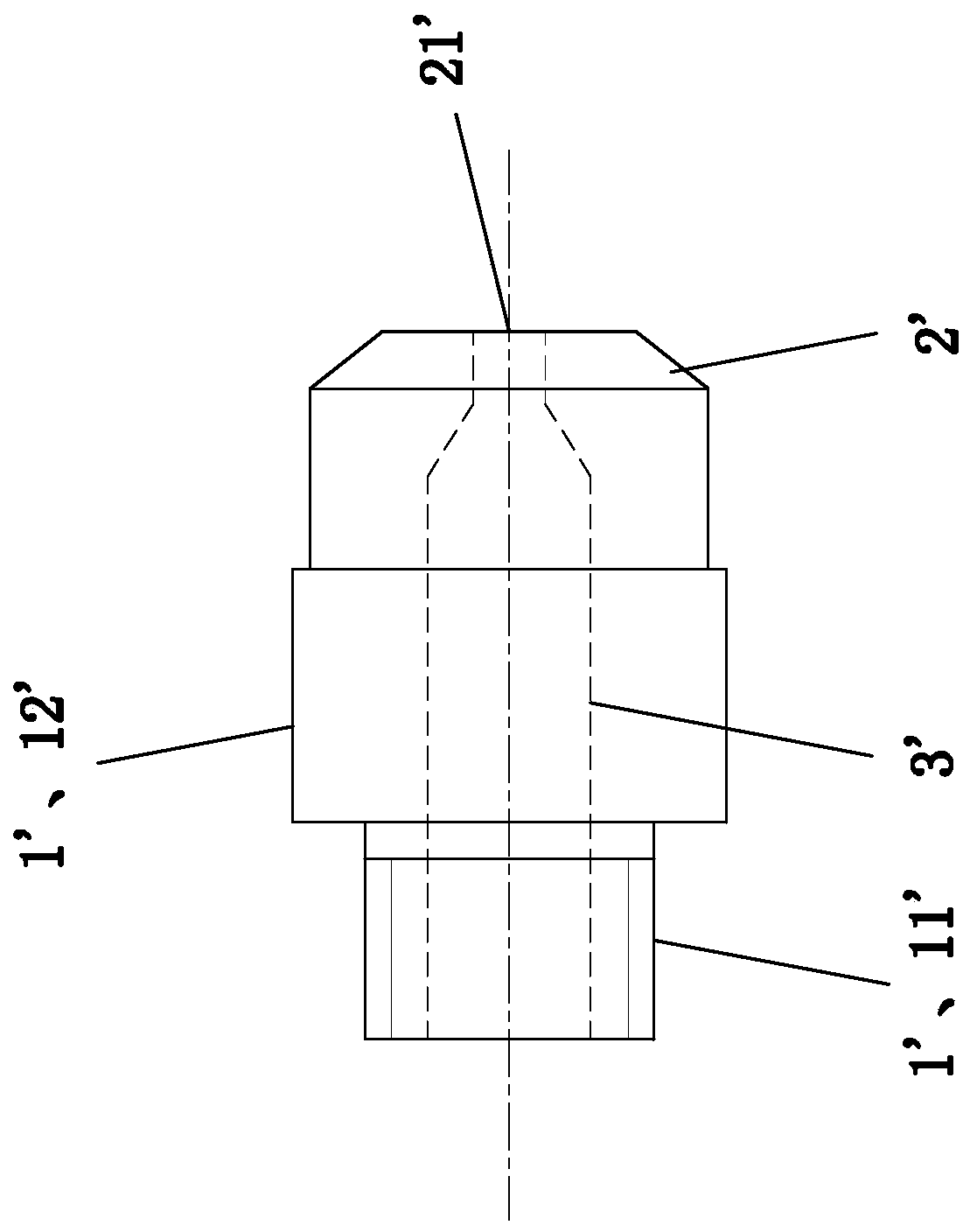

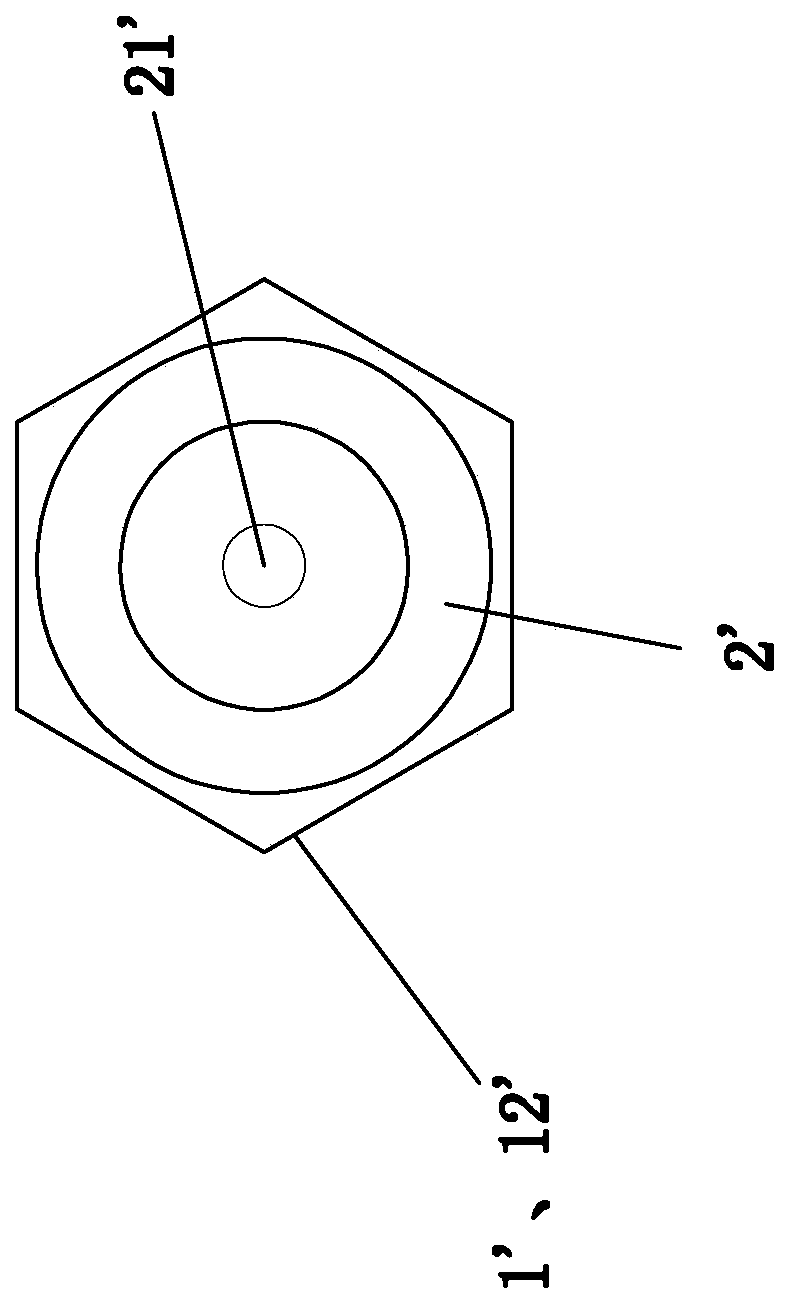

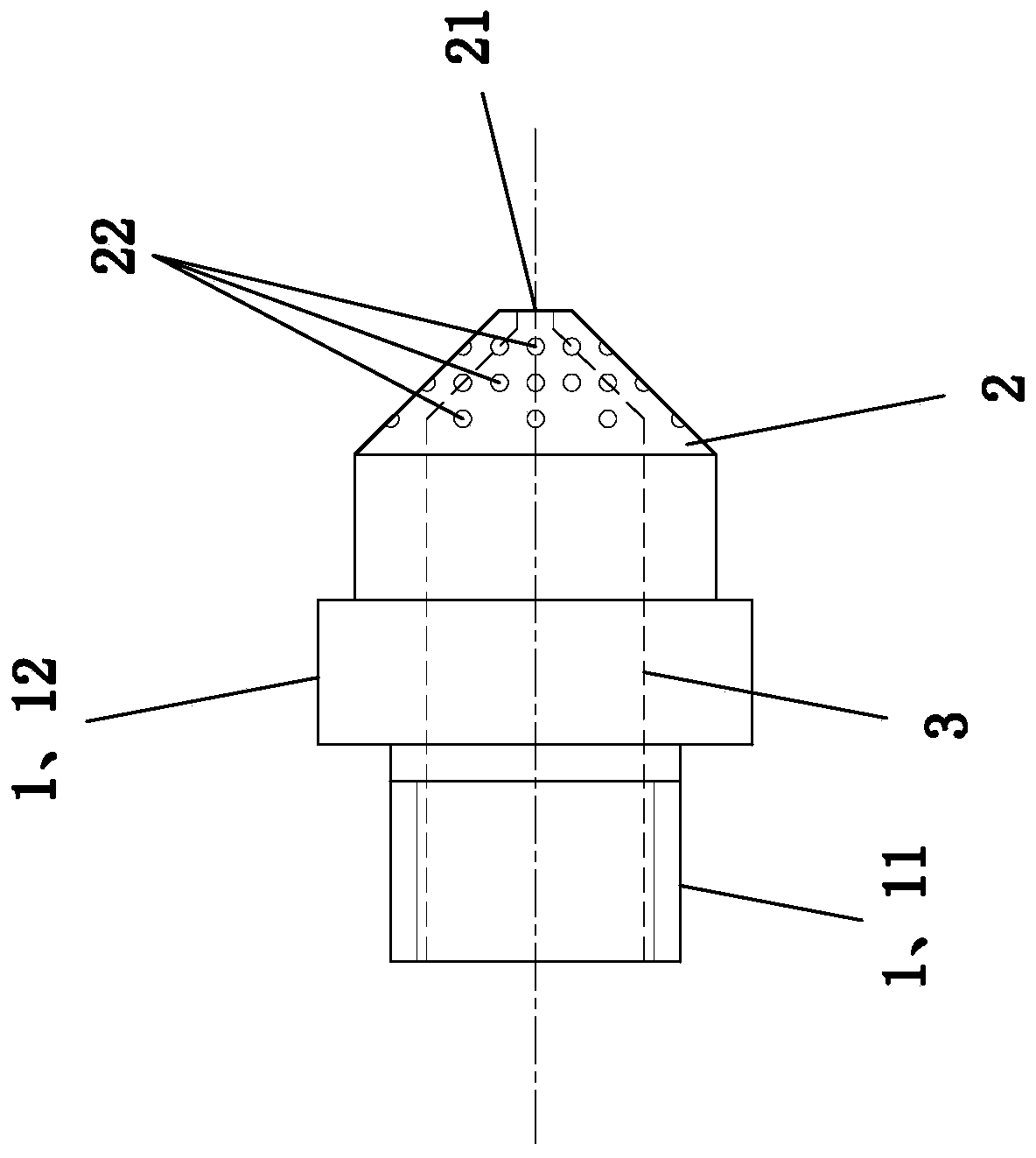

[0019] see image 3 and Figure 4 , the new nozzle of this embodiment has a mounting part 1 and a nozzle head 2, the mounting part 1 includes a threaded connection part 11 and a hexagonal screw rotating part 12, the cavity 3 inside the nozzle can reach 6mm, and the nozzle head 2 is provided with a diameter A large spout 21 of about 1 mm and several small spouts 22 with a diameter of about 0.5 mm arranged around the large spout 21.

[0020] The cryogenic treatment method of the present embodiment is as follows:

[0021] ①Put the forged steel cold roll in the cryogenic box first, and close the cryogenic box.

[0022] ②Through the control system to control the ultra-low temperature solenoid valve, spray liquid nitrogen from the liquid nitrogen storage tank into the cryogenic box through the liquid nitrogen nozzle and nozzle, and reduce the temperature in the cryogenic box to -140±1°C within 1.5 hours ;

[0023] ③Insulate at a temperature of -140±1°C for 3.5 hours. During the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com