Hot roller supersonic spraying surface repair pretreatment method

A technology of supersonic spraying and surface repair, applied in coating, fusion spraying, metal material coating technology and other directions, can solve the problems of insufficient bonding strength and wear resistance of the sprayed layer surface, bruising, unqualified products, etc. To achieve the effect of enhanced bonding strength, uniform hardness and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

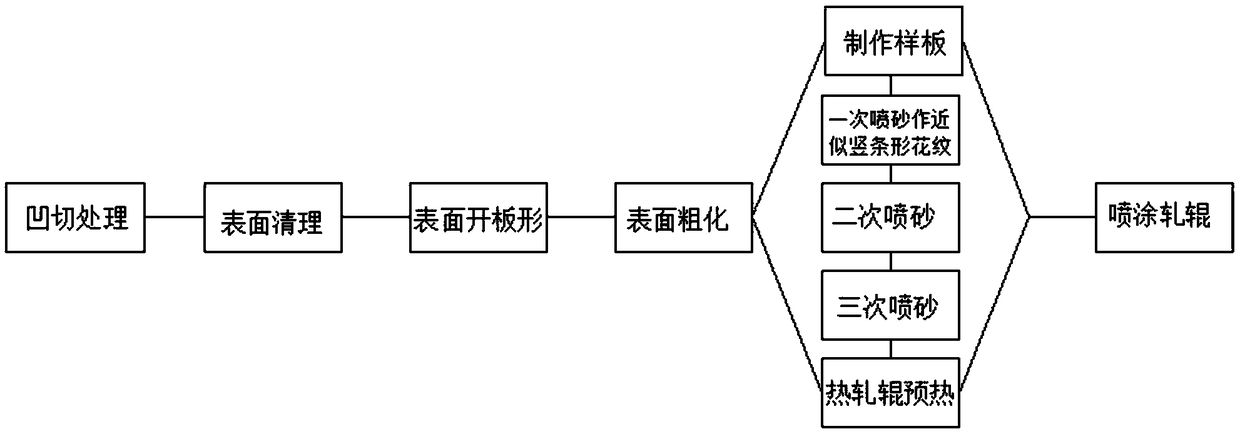

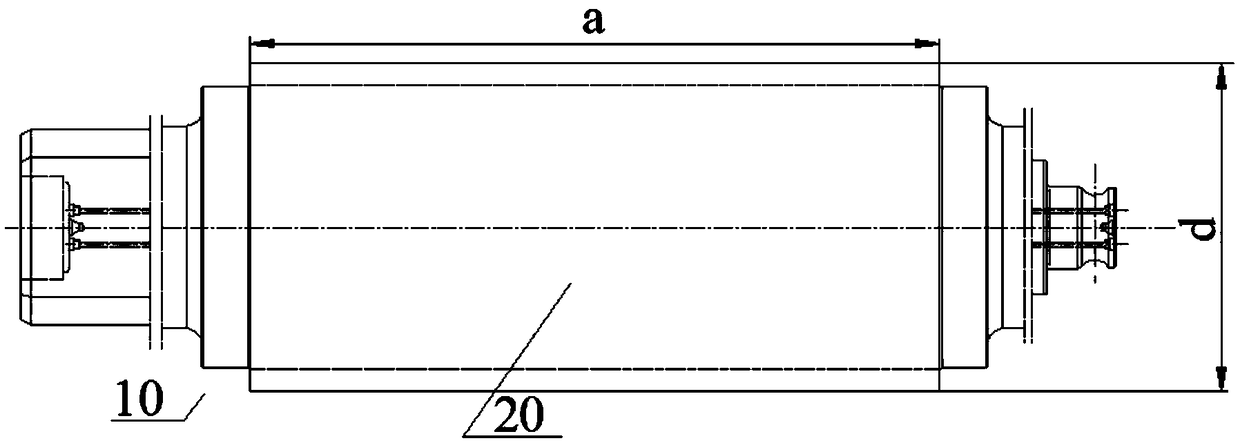

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the hot roll supersonic spraying surface repair pretreatment method of the present invention, the specific steps are: 1) concave cutting treatment: when there are groove marks of fatigue layer and local severe strain on the surface, turning treatment can be carried out under the premise that the strength allows , to provide space for thermal spraying; 2) Surface cleaning: remove oil, rust, paint, etc. on the surface of the workpiece to make the surface of the workpiece clean. The oily paint can be removed with a solvent cleaner. If the oil has penetrated into the base material, it can be heated with a flame To remove, the rust layer can be removed by acid leaching, mechanical grinding or sand blasting; 3) the surface is opened; 4) surface roughening, wherein the surface roughening specifically includes the following steps:

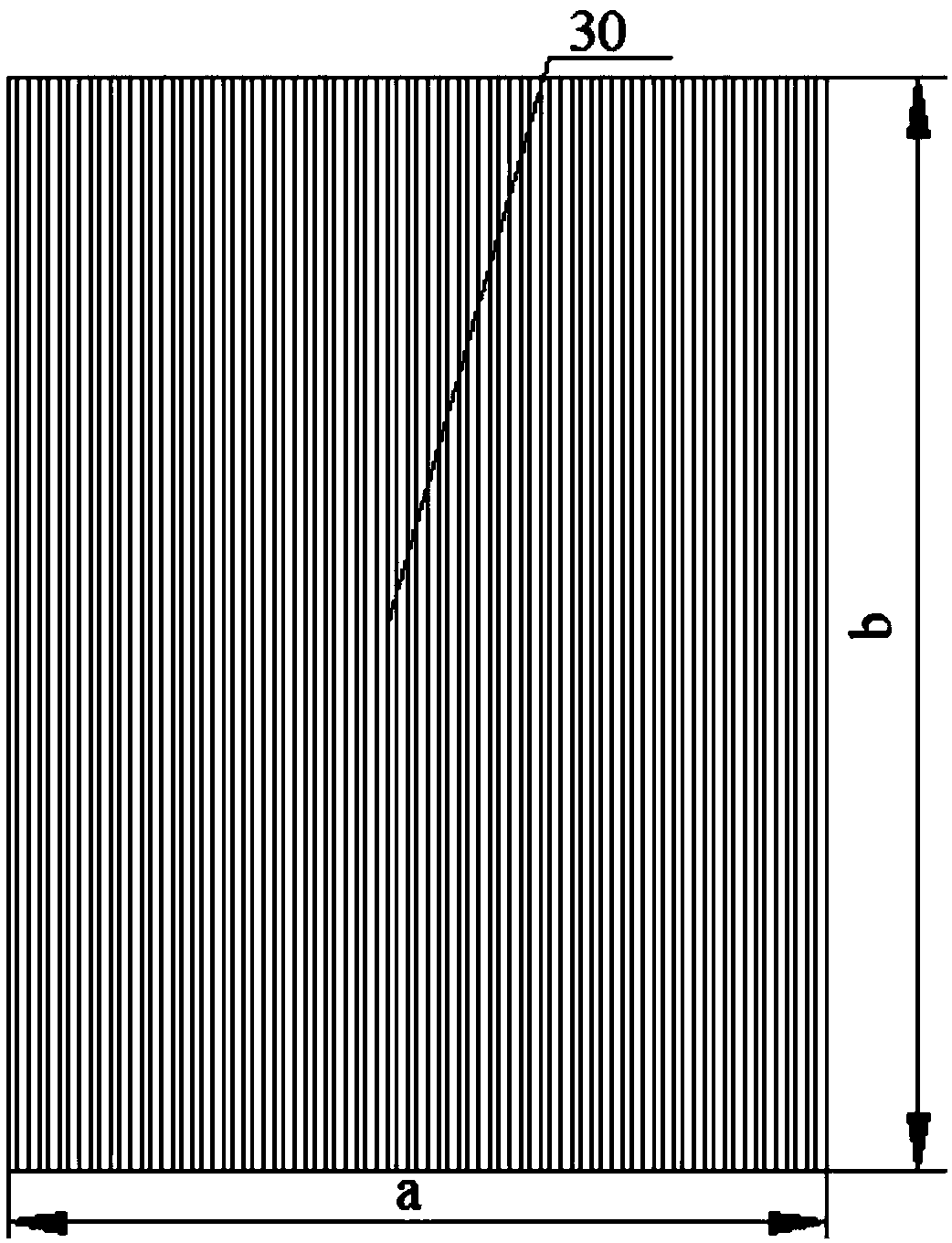

[0033] (1) A sandblasting to make a similar vertical stripe pattern

[0034] Inst...

Embodiment 2

[0043] In step (1), the preferred speed is: the roll rotates at a speed of 25-30r.p.m, and the sandblasting gun walks from one end of the surface to be sprayed to the other end left and right along the axial direction at a speed of 100mm.p.m.

[0044] The speed in step (1) can be adjusted to obtain an approximate vertical stripe pattern.

Embodiment 3

[0046] The sample is made of soft material, its shape is made according to relevant methods, and the sample is fixed on the surface of the roll.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com