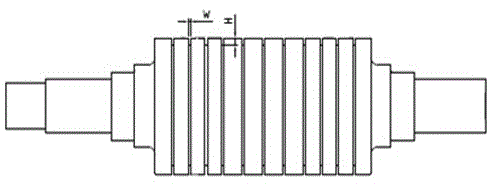

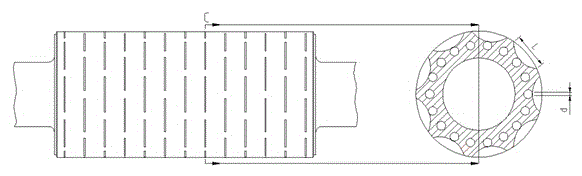

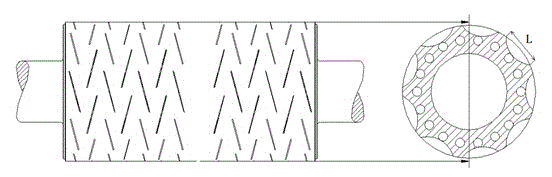

Machining method and manufacturing method of air suction grooves of corrugated roller

A processing method and suction groove technology, applied in the direction of machining/deformation, can solve the problems of notch wear, uneven heating, pitting, etc., and achieve the effect of increased wear life and uniform hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0021] A method for processing a corrugated roll suction groove, comprising the following steps:

[0022] (1) Pre-treatment, which specifically includes sequentially performing corrugating rolls: a. matrix modulation, b. preliminary processing, c. teeth opening, d. composite heat treatment;

[0023] (2) Grinding suction slot: such as Figure 4 As shown, the corrugated roll that has undergone compound heat treatment is installed on the special groove cutting machine. Measure the beating of the reference gear with the dial indicator, adjust the position of the four-turn chuck to ensure that the beating of the reference gear is less than 0.03mm, and then fix the four-jaw chuck; adjust the grooving machine installed on the special machine tool, acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com