High ferrochrome roller

A high-chromium ferro-rolling technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of high-chromium-iron-rolling rolls that have not been reported, poor wear resistance of high-nickel-chromium materials, poor roll shape retention, etc. Achieve the effects of improving surface quality and service life, high matrix strength, and increasing millimetric rolling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

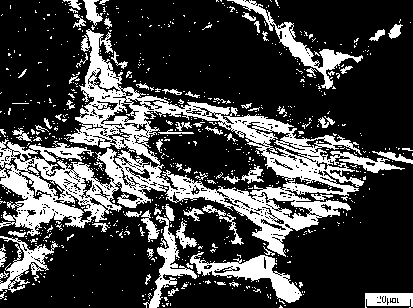

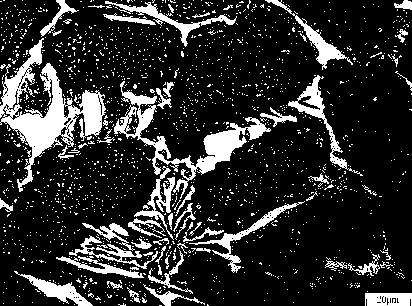

Image

Examples

Embodiment 1

[0041] In this embodiment, the composition design target of the working layer of the roll body is 2.40-2.60% of C, 0.60-0.70% of Si, 1.10-1.20% of Mn, 15.00-16.00% of Cr, 1.50-1.70% of Ni, 1.20-1.40% of Mo, V 0.30~0.50%, S≤0.05%, P≤0.05%, the rest is Fe and unavoidable impurities. The manufacturing method is as follows:

[0042] A. Smelting: Dosing ingredients according to the chemical composition of the working layer of the roll body, and then smelting in an induction furnace with a smelting temperature of 1450°C;

[0043]The core of the roll is made of pig iron, which is smelted in a blast furnace at a temperature of 1450°C. Before the furnace is released, an inoculant and a nodularizer are added to the molten iron. The inoculant is ferrosilicon and silicon-barium alloy. 0.4%, the nodulizer is a rare earth magnesium alloy, and the weight of the nodulizer accounts for 1.1% of the weight of the molten iron;

[0044] B. Centrifugal casting: Centrifugal pouring of the working ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com