Ball surface spray welding device for ball valve

A ball and ball valve technology, applied in the direction of fusion spraying, metal material coating process, coating, etc., can solve the problems of low processing efficiency, poor operating environment, high working intensity, etc., and achieve small joint surface stress and reasonable structure , high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

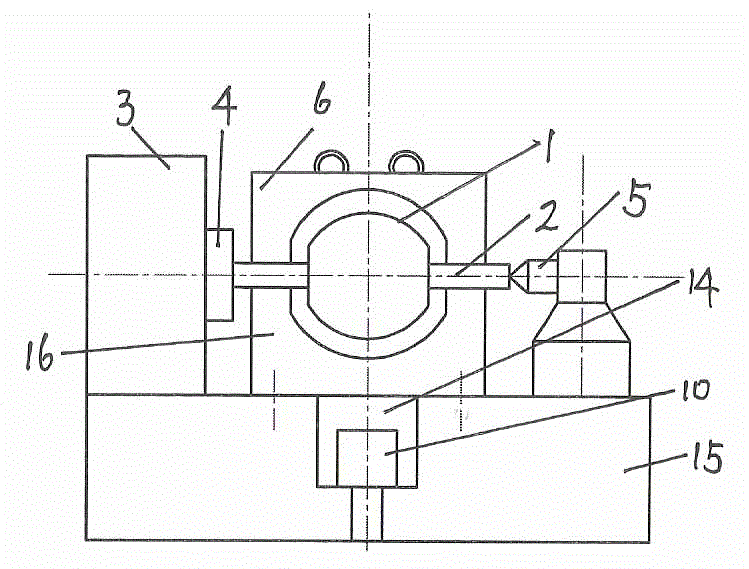

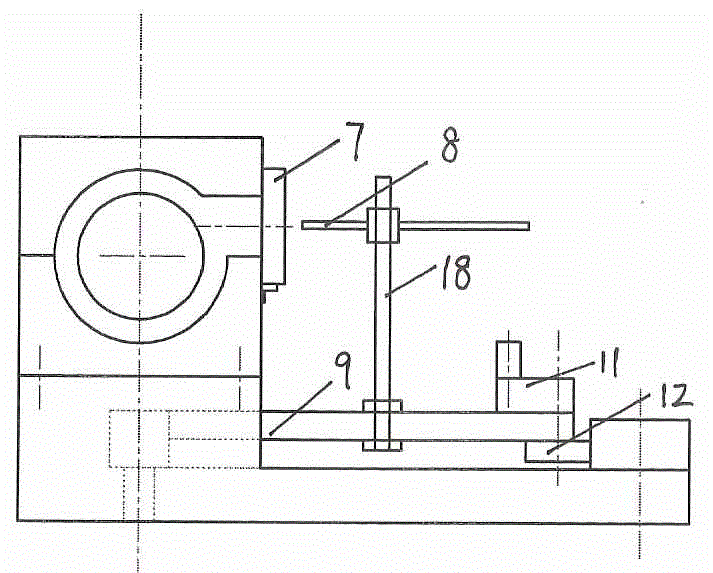

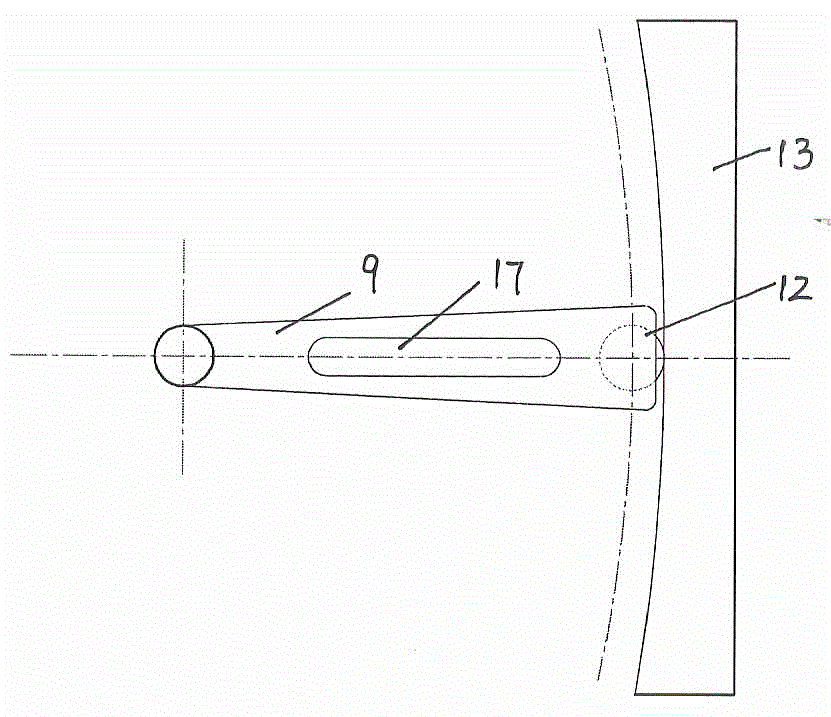

[0016] A ball valve surface spray welding device, including a temperature control box, a reduction box, a tailstock, a spray gun, and a spray gun swing mechanism. The temperature control box includes an upper box body 6 and a lower box body 16. There is a spray gun door, the upper box is covered on the lower box, the temperature control box is provided with a cavity for placing the sphere, the elastic mandrel passes through the hole of the sphere and fits tightly with the sphere; the two ends of the mandrel pass through the reduction box respectively. The front end chuck and the tailstock are pressed tightly; a spray gun is arranged on the outside of the spray gun door 7, and the spray gun is connected with the spray gun swing mechanism; 10, the other end of the support plate is fixedly connected with the gear 12 driven by the reduction box 11, the gear meshes with the arc surface of the arc-shaped rack 13, and the rotation of the gear on the arc-shaped rack surface drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com