Hydraulic engineering composite plate and preparation method for same

A technology for water conservancy projects and composite boards, which is applied in metal processing equipment, chemical instruments and methods, manufacturing tools, etc., can solve the problems of high temperature, decreased mechanical properties of substrates, surface oxidation, etc., and achieves high mechanical properties and uniform surface hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

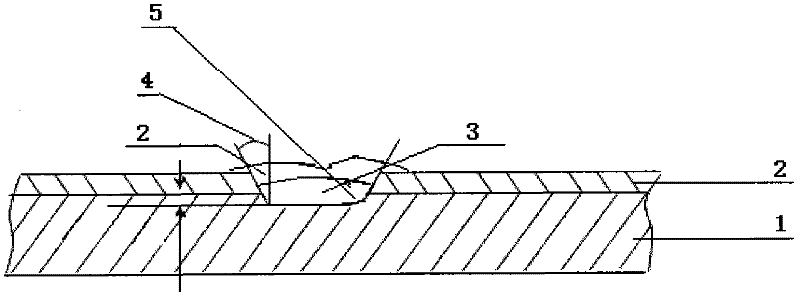

[0051] The present invention also provides a kind of preparation method of composite board, comprises the following steps:

[0052] (1) Treat the surface of the substrate and the double board;

[0053] (2) Explosive welding is carried out to the processed base plate and double plate;

[0054] (3) Carry out repair welding to the clad plate after explosive welding; and

[0055] (4) Heat-treating the composite plate in step (3).

[0056] Wherein the treatment described in the step (1) is grinding, preferably, the surface roughness of the ground substrate and doubler plate is greater than 25 μm. Preferably, the step (1) also includes matching the length and width of the base plate and the doubler plate, preferably the length and width of the doubler plate are respectively 90 mm ± 10 mm larger than the length and width of the base plate. The explosive used in the explosive welding described in step (2) is ammonium oil explosive , explosives are placed on the doubler plate, prefe...

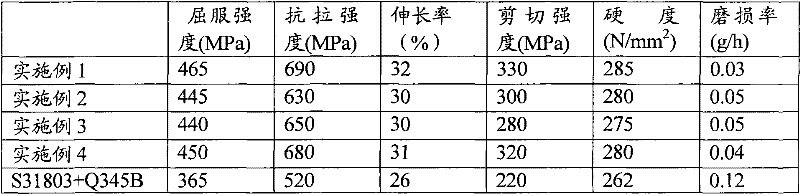

Embodiment 1

[0090] 1. Match

[0091] The substrate that meets the national standard GB / T1591-2008 is used as the substrate, and the following components are contained in terms of mass percentage: C: 0.17%; Si: 0.45%; Mn: 1.50%; Nb: 0.02%; V: 0.13%; Ti: 0.18%; Cr: 0.26%; N: 0.009%; Mo: 0.09%; Ni: 0.45%; P≤0.030%; S≤0.030%; the balance is iron and unavoidable impurities;

[0092] The composite board that meets the GB3280-2007 standard contains the following components in terms of mass percentage: C: 0.09%; Si: 1.20%; Mn: 2.60%; Nb: 0.18%; Cr: 19.3%; N: 0.24% ; Ni: 8.50%; P≤0.035%; S≤0.035%, the balance is iron and unavoidable impurities

[0093] Comparing the length and width of the two, the base plate is 10050mm long, 1500mm wide, and 26mm thick, the double plate is 10150mm long, 1580mm wide, and 4mm thick, and the length of the double plate is 100mm longer than that of the base plate; Width 80mm;

[0094] 2. Grinding the surface

[0095] Remove the oxides and sundries on the explosive...

Embodiment 2

[0106] 1. Match

[0107] The substrate that meets the national standard GB / T1591-2008 is used as the substrate, and contains the following components in terms of mass percentage: C: 0.14%; Si: 0.35%; Mn: 1.00%; Nb: 0.01%; V: 0.11%; Ti: 0.13%; Cr: 0.18%; N: 0.006%; Mo: 0.04%; Ni: 0.35%; P≤0.025%; S≤0.025%; the balance is iron and unavoidable impurities;

[0108] The compound board that meets the GB3280-2007 standard contains the following components in terms of mass percentage: C: 0.12%; Si: 1.50%; Mn: 3.00%; Nb: 0.20%; Cr: 20.0%; N: 0.30% ; Ni: 10.50%; P≤0.055%; S≤0.040%, the balance is iron and unavoidable impurities

[0109] Comparing the length and width of the two, the base plate is 10050mm long, 1500mm wide, and 26mm thick, and the double plate is 10140mm long, 1590mm wide, and 4mm thick, and the length of the double plate is 90mm longer than that of the base plate; Width 90mm;

[0110] 2. Grinding the surface

[0111] Remove the oxides and sundries on the explosive j...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com