Hot rolling alloy steel for train brake disc

A technology of alloy steel and brake discs, applied in the field of hot-rolled alloys, can solve problems such as long-term service fatigue, local wear, and cracks, and achieve the effects of reducing subsequent processing, reducing production costs, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments and the drawings of the specification.

[0016] The material of the present invention adopts smelting + refining outside the vacuum furnace, and the compression ratio of the hot-rolled material is ≥3. By adjusting the distribution ratio of each component in the raw material, the obtained product composition is within the scope of the present invention. The following examples are obtained by specific testing.

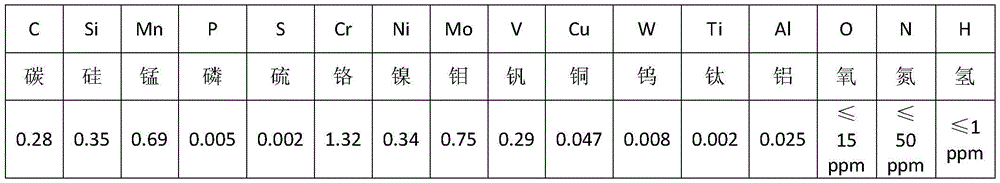

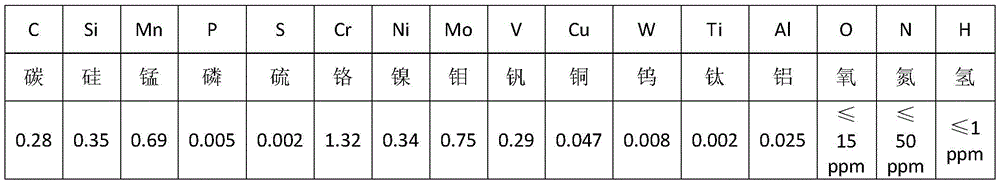

[0017] The mass percentage content of each component is

[0018]

[0019] The rest is Fe element.

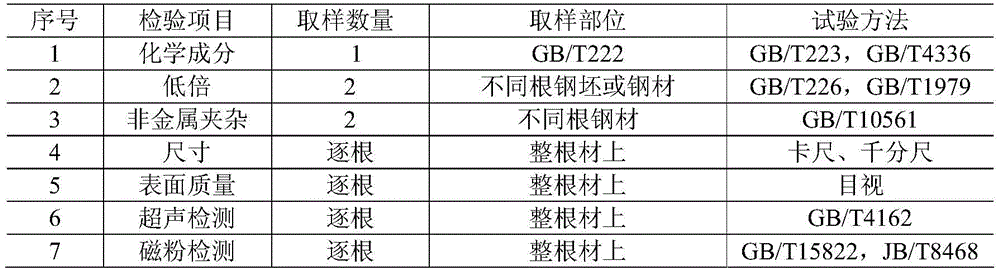

[0020] The products of the above-mentioned embodiments were inspected, and there were no visible shrinkage cavities, bubbles, cracks, inclusions, peeling, white spots, delamination, intergranular cracks, etc. on the acid immersion macrostructure test piece of the steel cross section. The test method of each batch of steel should be implemented in accordance with Table 1.

[0021] Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com