Low-cost self-protection flux-cored wire containing multi-granularity deoxidizing agent and preparation method of low-cost self-protection flux-cored wire containing multi-granularity deoxidizing agent

A technology of flux-cored welding wire and deoxidizer, which is applied in welding equipment, welding medium, manufacturing tools, etc., can solve problems such as easy porosity, inability to guarantee deoxidation reaction, poor weld shape, etc., and achieve good weld metal surface shape, good Self-protection effect, effect of good welding process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

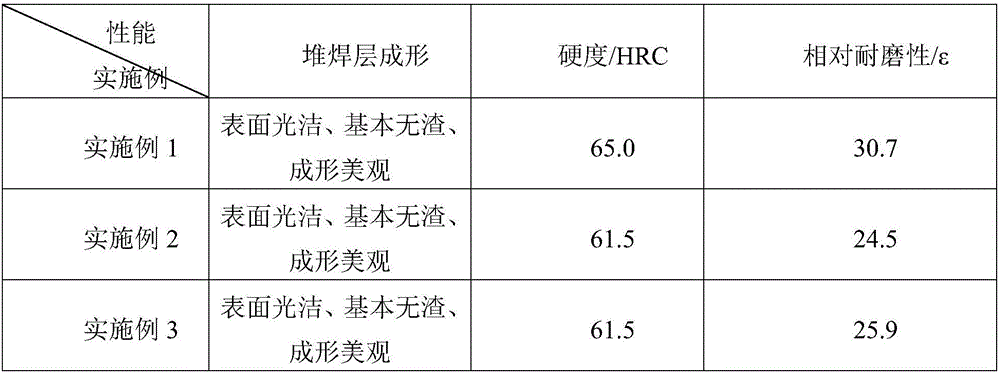

Embodiment 1

[0031] A low-cost self-shielding flux-cored welding wire containing deoxidizers of different particle sizes, including low-carbon steel strip and flux core, the flux core is filled in the steel strip, and the flux core components are prepared according to the following quality: including low-carbon steel strip and flux core , the drug core is filled in the steel belt, and the drug core components are prepared according to the following quality: 75g of 80 mesh high-carbon ferrochromium, 10g of different particle size deoxidizers, and 15g of 80 mesh iron powder. Among them, the deoxidizer is a mechanical mixture composed of graphite with different particle sizes, cellulose powder, aluminum-magnesium alloy and silicon-manganese alloy, specifically: 1g of 60-mesh graphite, 1.5g of 200-mesh graphite, 1g of 60-mesh cellulose powder , 0.5g of 200-mesh cellulose powder, 1g of 60-mesh aluminum-magnesium alloy, 1g of 200-mesh aluminum-magnesium alloy, 2g of 60-mesh silicon-manganese allo...

Embodiment 2

[0033]A low-cost self-shielding flux-cored welding wire containing deoxidizers of different particle sizes, including low-carbon steel strip and flux core, the flux core is filled in the steel strip, and the flux core components are prepared according to the following quality: including low-carbon steel strip and flux core , The drug core is filled in the steel belt, and the drug core components are prepared according to the following quality: 62g of 80 mesh high-carbon ferrochromium, 25g of different particle size deoxidizers, and 13g of 80 mesh iron powder. Among them, the deoxidizer is a mechanical mixture composed of graphite with different particle sizes, cellulose powder, aluminum-magnesium alloy and silicon-manganese alloy, specifically: 3g of 60-mesh graphite, 2.5g of 200-mesh graphite, 2.5g of 60-mesh cellulose Powder, 1g of 200-mesh cellulose powder, 3g of 60-mesh aluminum-magnesium alloy, 3g of 200-mesh aluminum-magnesium alloy, 5g of 60-mesh silicon-manganese alloy,...

Embodiment 3

[0035] A low-cost self-shielding flux-cored welding wire containing deoxidizers of different particle sizes, including low-carbon steel strip and flux core, the flux core is filled in the steel strip, and the flux core components are prepared according to the following quality: including low-carbon steel strip and flux core , the drug core is filled in the steel belt, and the drug core components are prepared according to the following quality: 68g of 80-mesh high-carbon ferrochromium, 17.8g of different particle size deoxidizers, and 14.2g of 80-mesh iron powder. Among them, the deoxidizer is a mechanical mixture composed of graphite with different particle sizes, cellulose powder, aluminum-magnesium alloy and silicon-manganese alloy, specifically: 2g of 60-mesh graphite, 2g of 200-mesh graphite, 2g of 60-mesh cellulose powder, 0.8g of 200-mesh cellulose powder, 2g of 60-mesh aluminum-magnesium alloy, 2g of 200-mesh aluminum-magnesium alloy, 4g of 60-mesh silicon-manganese all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com