Automatic feeding riveter

A technology of automatic feeding and riveting machines, applied in the field of automatic feeding riveting machines, can solve the problems of low production efficiency, accidental injuries to operators, expensive diss hydraulic presses, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

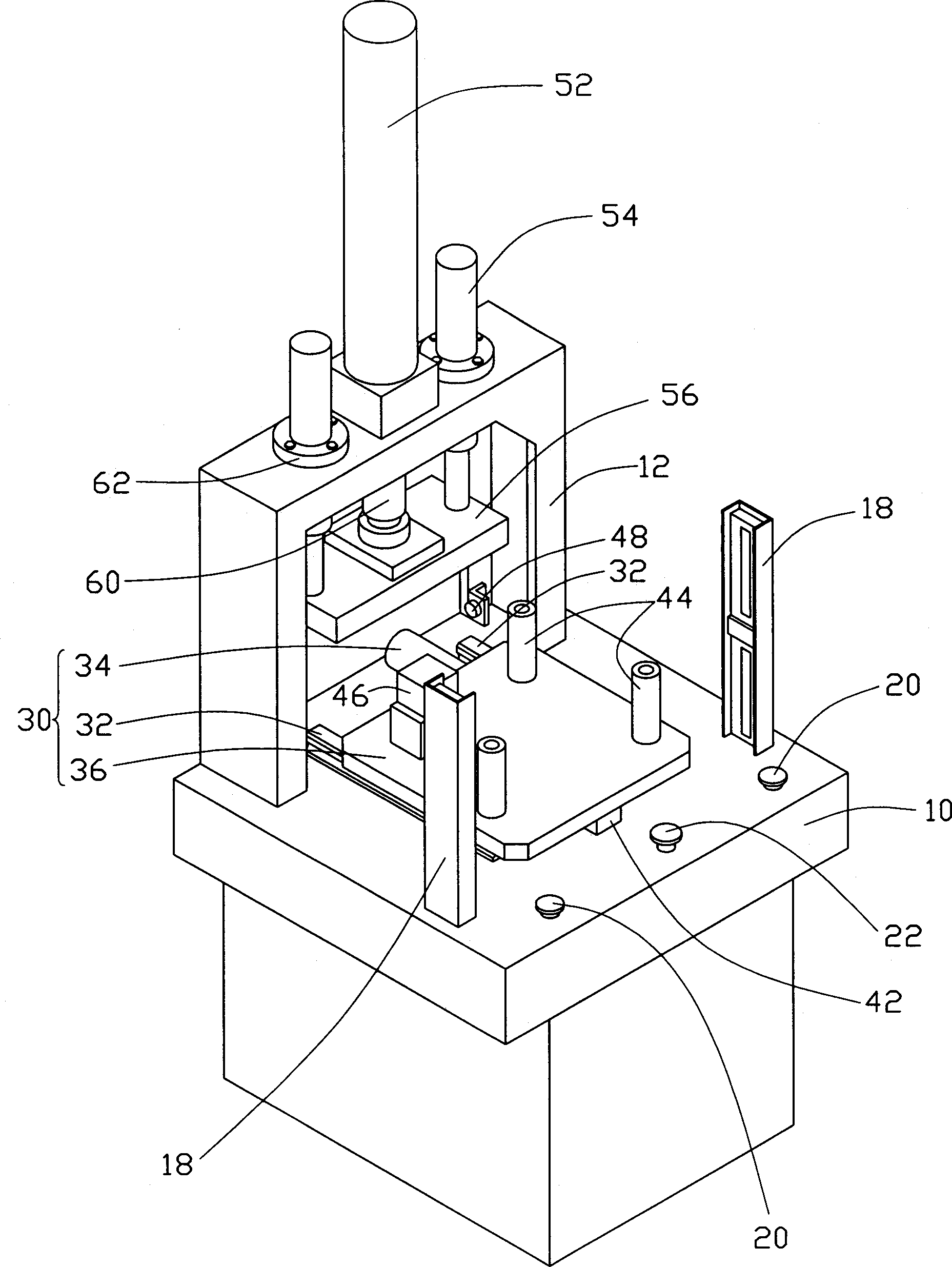

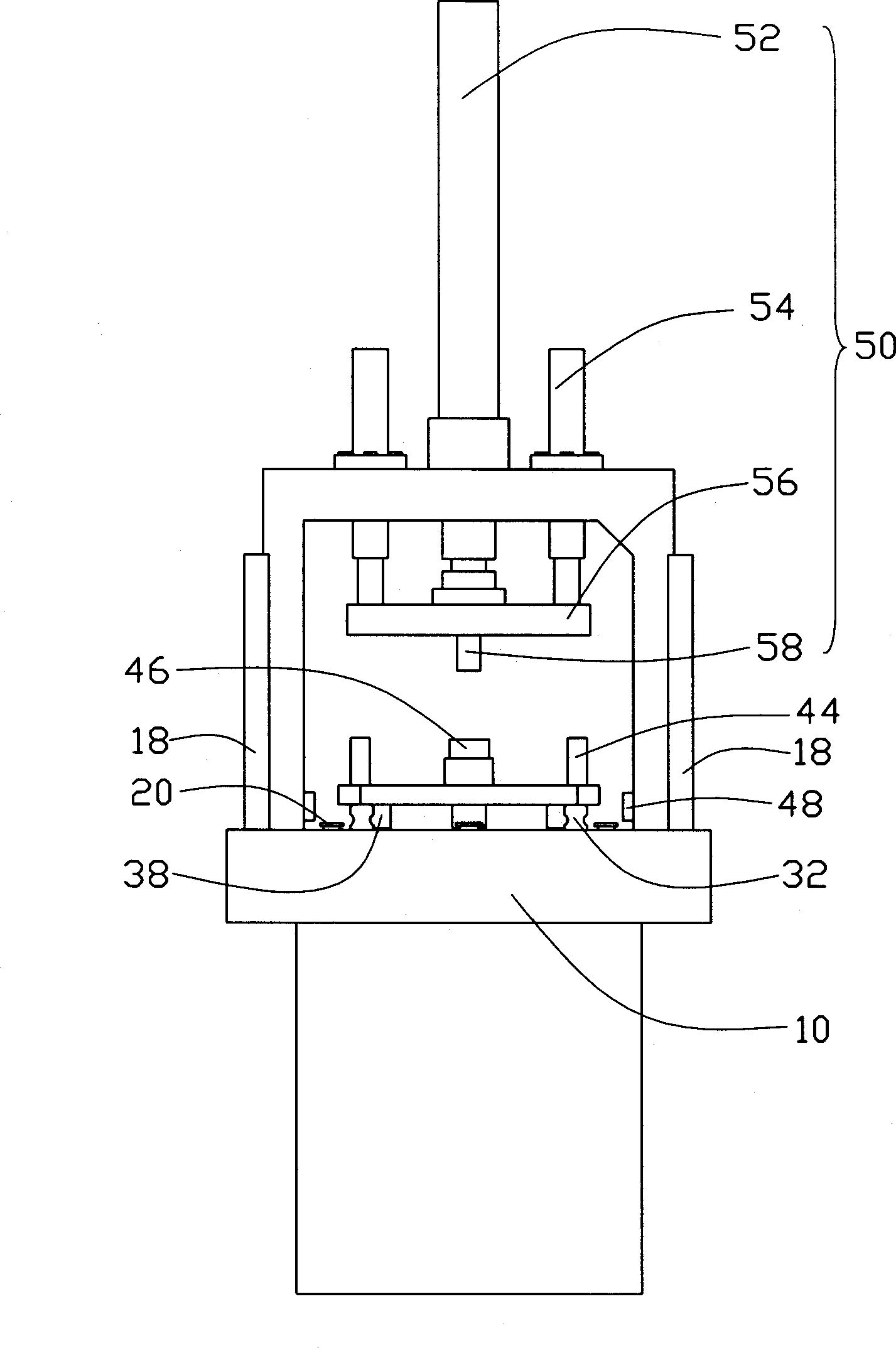

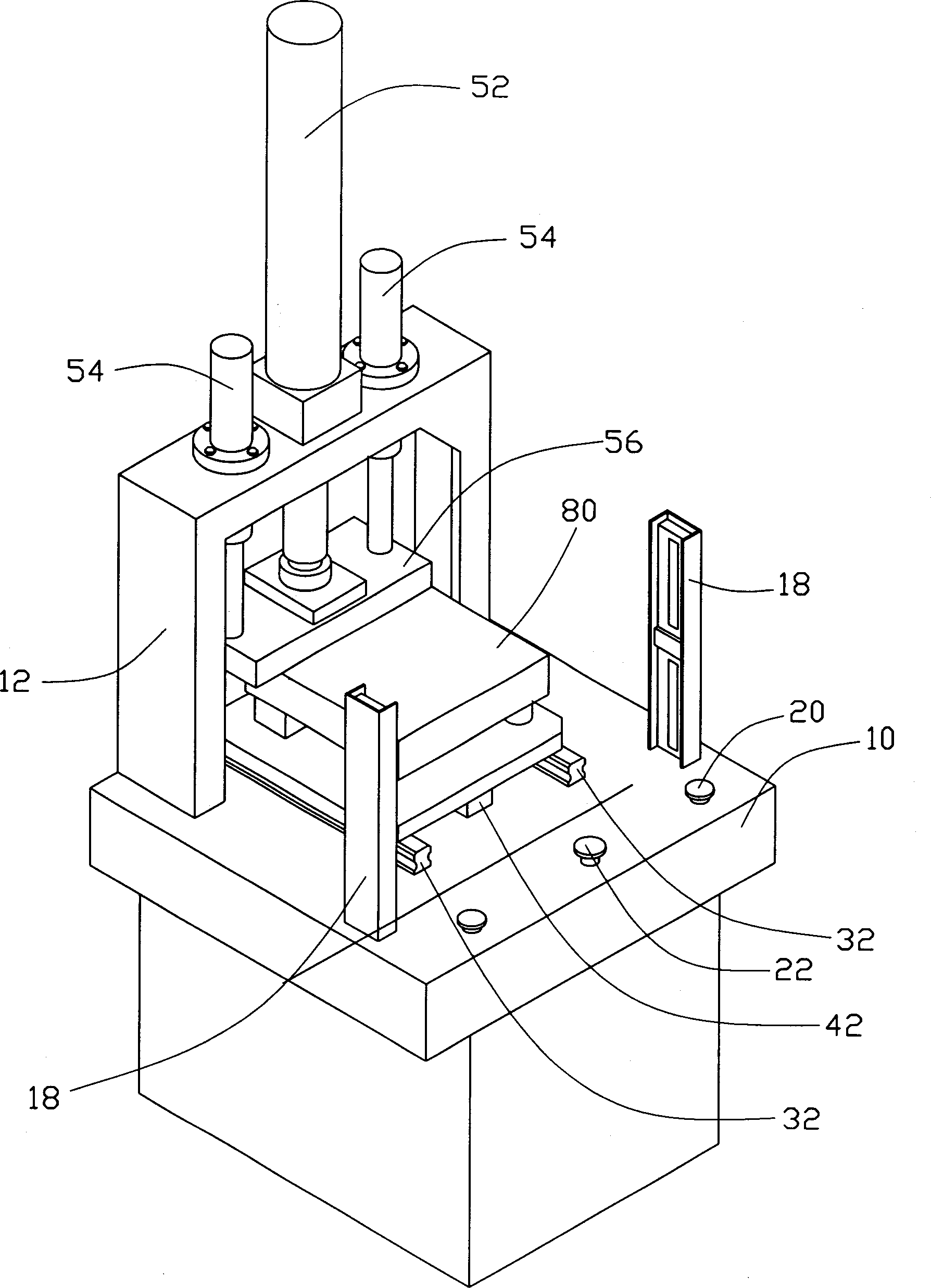

[0011] see figure 1 and figure 2 , The automatic feeding riveting machine of the present invention includes a base 10 , a feeding mechanism 30 and a riveting device 50 .

[0012] A ㄇ-shaped support frame 12 is vertically installed on the rear end of the upper surface of the base 10, and a photoelectric relay 18 is respectively installed on both sides of the front end of the base 10. When an object is blocked between the two photoelectric relays 18, the riveting Closed machine will not start to ensure the safety of the operator. The front edge of the base 10 is provided with a start button 20 on both sides and an emergency stop button 22 in the middle.

[0013] The feeding mechanism 30 includes two slide rails 32 arranged in parallel, a small air cylinder 34 and a lower template 36 . The two slide rails 32 are arranged on the middle part of the upper surface of the base 10, and they extend to the bottom of the support frame 12. The small cylinder 34 is installed between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com